MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

MAINTENANCE MANUAL - Meritor

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

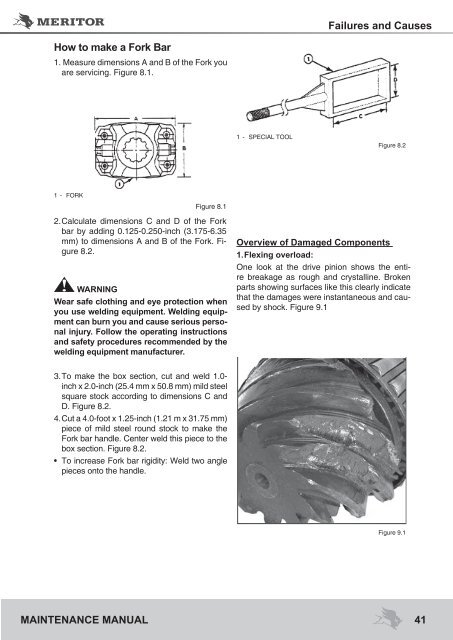

Failures and CausesHow to make a Fork Bar1. Measure dimensions A and B of the Fork youare servicing. Figure 8.1.1 - Special ToolFigure 8.21 - ForkFigure 8.12. Calculate dimensions C and D of the Forkbar by adding 0.125-0.250-inch (3.175-6.35mm) to dimensions A and B of the Fork. Figure8.2.WARNINGWear safe clothing and eye protection whenyou use welding equipment. Welding equipmentcan burn you and cause serious personalinjury. Follow the operating instructionsand safety procedures recommended by thewelding equipment manufacturer.Overview of Damaged Components1. Flexing overload:One look at the drive pinion shows the entirebreakage as rough and crystalline. Brokenparts showing surfaces like this clearly indicatethat the damages were instantaneous and causedby shock. Figure 9.13. To make the box section, cut and weld 1.0-inch x 2.0-inch (25.4 mm x 50.8 mm) mild steelsquare stock according to dimensions C andD. Figure 8.2.4. Cut a 4.0-foot x 1.25-inch (1.21 m x 31.75 mm)piece of mild steel round stock to make theFork bar handle. Center weld this piece to thebox section. Figure 8.2.• To increase Fork bar rigidity: Weld two anglepieces onto the handle.Figure 9.1<strong>MAINTENANCE</strong> <strong>MANUAL</strong>41