Roller Chain - Tsubaki

Roller Chain - Tsubaki Roller Chain - Tsubaki

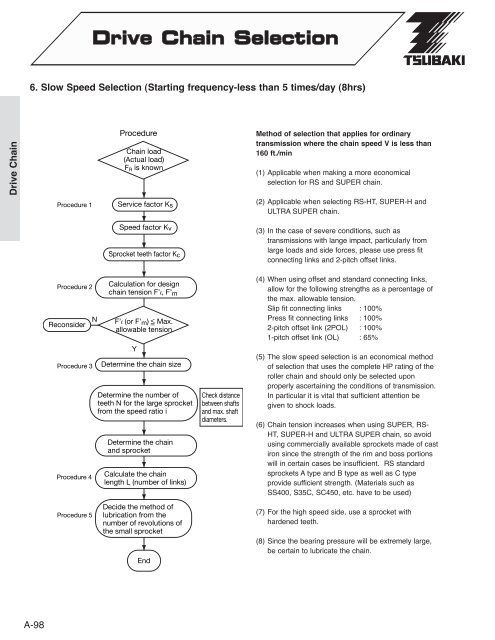

Drive Chain Selection6. Slow Speed Selection (Starting frequency-less than 5 times/day (8hrs)Drive ChainProcedure 1ProcedureChain load(Actual load)F R is knownService factor KsMethod of selection that applies for ordinarytransmission where the chain speed V is less than160 ft./min(1) Applicable when making a more economicalselection for RS and SUPER chain.(2) Applicable when selecting RS-HT, SUPER-H andULTRA SUPER chain.Speed factor KvSprocket teeth factor Kc(3) In the case of severe conditions, such astransmissions with lange impact, particularly fromlarge loads and side forces, please use press fitconnecting links and 2-pitch offset links.Procedure 2ReconsiderProcedure 3Procedure 4NCalculation for designchain tension F’l, F’ mF’l (or F’ m )

Drive Chain SelectionExample based on the slow speed selectionMachine: Conveyor driveChain load: 3754 lbs.Motor: 15 HPReducer ratio : 30High speed shaft : 50 r/min, shaft diameter 2 1/2”Low speed shaft : 20 r/min, shaft diameter 3 7/8”Distance b/w shafts : 60”Starting frequency : 4 times/dayType of shock: Some shock involvedSprocket 15T(PCD: 7.2”)60"(center distance)2.6"Sprocket 38T(PCD: 18.1”)Drive ChainReducer ratio(i = 30)3.7"Drive Roller Chain(RS120)Calculate the Roller Chain speed V.PN’nV = = 10001.5 × 15 × 5012= 93.75 ft/min < 160 ft/minThe calculated speed (93.75ft./min) is less than 160ft/min, so slow speed selection can be used.Imperial UnitsMetric UnitsF l = 3754 lbs.F l = 1700 (kgf)Procedure 1 :Service factor K s = 1.3 ……………… some shock (Table 2)Speed factor K v = 1.06 ……………… V = 28.6 m/min (90 ft./min) (Table 3)Sprocket teeth factor K c = 1.27 ……… N’ = 15T (Table 3)Procedure 2 : Calculate design chain tension F’ lF’ l = F l × K s × K v × K c= 3751 x 1.3 x 1.06 x 1.27= 6569 lbs.Procedure 2 : Calculate design chain tension F’ lF’ l = F l × K s × K v × K c= 1700 × 1.3 × 1.06 × 1.27= 2975 (kgf)Procedure 3 : Slow speed selection for RS Roller ChainRS120 can be used since the maximum allowable tension of 6830 lbs. (3100 kgf) is larger than the design chain tension 6569lbs. (2975 kgf). The driver sprocket is RS120-15T B-type (Max. shaft diameter 3 1/4” > Driver shaft diameter 2 1/2”, thereforeacceptable) provided it has hardened teeth. The driven sprocket is RS120-38T B-type, provided the bore diameter ismanufactured to meet the diameter of the driven shaft (3.7”).Procedure 4 : Number of chain links( ) 2N – N'38 – 15N + N' 6.28 38 + 15 6.28L = + 2C + = + 2 × 40+2C240= 106.8 links → 107 links Distance between shafts = 60”Procedure 5 : Lubrication method is by drip or brush( ) 260C = 1.5= 40A-99

- Page 47 and 48: Heavy Duty Roller ChainComparison o

- Page 49 and 50: Heavy Duty Roller ChainSuper Series

- Page 51 and 52: Heavy Duty Roller ChainSuper Series

- Page 53 and 54: Heavy Duty Roller ChainSuper Series

- Page 55 and 56: THeavy Duty Roller ChainSuper-H Ser

- Page 57 and 58: MiniatureRoller ChainDrive ChainAn

- Page 59 and 60: 3/16”PitchMiniatureChainRS15Tsuba

- Page 61 and 62: British Standard/DINRoller ChainDri

- Page 63 and 64: British Standard/DINRoller ChainLam

- Page 65 and 66: British Standard/DINRoller ChainNic

- Page 67 and 68: British Standard/DIN ChainDrive Sel

- Page 69 and 70: Anti-CorrosiveRoller ChainAn Introd

- Page 71 and 72: Anti-CorrosiveRoller ChainNeptuneAn

- Page 73 and 74: Anti-CorrosiveRoller ChainStainless

- Page 75 and 76: Anti-CorrosiveRoller ChainNickel Pl

- Page 77 and 78: Anti-CorrosiveRoller ChainStainless

- Page 79 and 80: Leaf ChainLEAF CHAIN SELECTION GUID

- Page 81 and 82: Leaf ChainAL TypeLeaf ChainL1Chain

- Page 83 and 84: Leaf ChainBL TypeLeaf ChainConnecti

- Page 85 and 86: Specialty ChainLow Noise (SN)Specia

- Page 87 and 88: ASpecialty ChainLaminated Block Cha

- Page 89 and 90: Roller Chain ToolsChain Cutting Too

- Page 91 and 92: Drive Chain SelectionData required

- Page 93 and 94: Drive Chain Selection4. Selection F

- Page 95 and 96: Drive Chain SelectionAll of the cha

- Page 97: Drive Chain SelectionExample based

- Page 101 and 102: Drive Chain Selection8. Selection M

- Page 103 and 104: Drive Chain SelectionProcedure 3: (

- Page 105 and 106: Drive Chain Selection9. Selection b

- Page 107 and 108: Roller ChainInstallation & Maintena

- Page 109 and 110: Roller ChainInstallation & Maintena

- Page 111 and 112: Roller ChainInstallation & Maintena

- Page 113 and 114: Roller ChainInstallation & Maintena

- Page 115 and 116: Roller ChainInstallation & Maintena

- Page 117 and 118: Roller ChainInstallation & Maintena

- Page 119 and 120: Roller ChainInstallation & Maintena

- Page 121 and 122: Roller ChainInstallation & Maintena

- Page 123 and 124: How to OrderRoller Chain1. Example

- Page 125 and 126: A-125Drive ChainNo.ofPitchesRS251/4

- Page 127: Warning!WARNINGUSE CARE TO PREVENT

Drive <strong>Chain</strong> Selection6. Slow Speed Selection (Starting frequency-less than 5 times/day (8hrs)Drive <strong>Chain</strong>Procedure 1Procedure<strong>Chain</strong> load(Actual load)F R is knownService factor KsMethod of selection that applies for ordinarytransmission where the chain speed V is less than160 ft./min(1) Applicable when making a more economicalselection for RS and SUPER chain.(2) Applicable when selecting RS-HT, SUPER-H andULTRA SUPER chain.Speed factor KvSprocket teeth factor Kc(3) In the case of severe conditions, such astransmissions with lange impact, particularly fromlarge loads and side forces, please use press fitconnecting links and 2-pitch offset links.Procedure 2ReconsiderProcedure 3Procedure 4NCalculation for designchain tension F’l, F’ mF’l (or F’ m )