Roller Chain - Tsubaki

Roller Chain - Tsubaki Roller Chain - Tsubaki

Roller ChainInstallation & Maintenance3.4 Lubrication Systems and Methods Table 2LubricationSystemMethodQuantity of OilDrive ChainAIDrip LubricationOil is applied with an oilcan or brush in the gapbetween the pin link andinner link clearances onthe slack side of thechain.0Make sure chainoperation is suspendedwhile lubricating.A simple case can beused. Oil from the oilcup is supplied by dripfeeding.Oil should be applied at fixed intervals, usuallyabout every eight hours, or as often as necessaryto prevent the bearing areas from becoming dry.* An automatic lubricator is also available for yourconvenience. Please consult Tsubaki for moredetails.Apply about 5 - 20 drops of oil per minute forevery strand of chain. Actual quantity depends onthe chain speed.IIOil Bath LubricationThe chain is installed ina leak-free casing.Chain should be submerged in oil 1/4” to 1/2”. Ifthe oil depth “h” is too large, the composition ofthe oil may change due to heat generated (morethan +80°C/+176°F) and lose some of itseffectiveness.BLubrication by Slinger DiscInstall the slinger disc in aleak-free oil casing. Oil issplashed on the chain.The circumference speedshould be at least 656ft./min If the width of thechain is greater than 4.9”,attach slinger discs toboth sides.The bottom of the slinger disc should be loweredto a position 1” from the surface of the oil. Thechain should not pass through the oil.CLubrication using a PumpUse a leak-free casing.A pump is used tocirculate the oil, which isthen cooled. Thenumber of supply holesshould equal Z+1, whereZ is the umber ofstrands of chain.Oil quantity guide for each supply hole (Litres/min)ChainTypeChain Number RS60Chain Speed and(ft./min) underRS 1,640 ~ 2,620SUPER 980 or lessRS 2,620 ~ 3,660SUPER 980 ~ 1,6401.02.0RS80RS1001.52.5RS120RS1402.53.5RS160andover4.05.0RS 3,660 ~ 4,600SUPER 1,640 or more3.03.54.56.0Examine the pins and bushings after removing the chain to confirm the effectiveness of the lubrication. Any scratches or reddish-brown color appearing on theirsurfaces indicates that the system is not being adequately lubricated.A-110

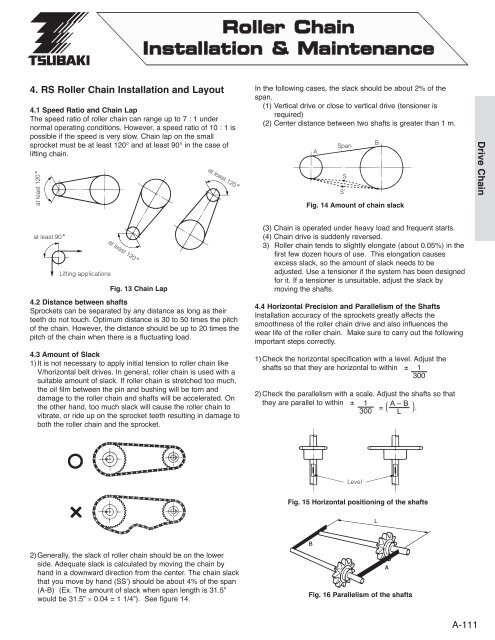

Roller ChainInstallation & Maintenance4. RS Roller Chain Installation and Layout4.1 Speed Ratio and Chain LapThe speed ratio of roller chain can range up to 7 : 1 undernormal operating conditions. However, a speed ratio of 10 : 1 ispossible if the speed is very slow. Chain lap on the smallsprocket must be at least 120° and at least 90° in the case oflifting chain.˚˚In the following cases, the slack should be about 2% of thespan.(1) Vertical drive or close to vertical drive (tensioner isrequired)(2) Center distance between two shafts is greater than 1 m.Drive ChainFig. 14 Amount of chain slack˚4.2 Distance between shaftsSprockets can be separated by any distance as long as theirteeth do not touch. Optimum distance is 30 to 50 times the pitchof the chain. However, the distance should be up to 20 times thepitch of the chain when there is a fluctuating load.4.3 Amount of Slack1) It is not necessary to apply initial tension to roller chain likeV/horizontal belt drives. In general, roller chain is used with asuitable amount of slack. If roller chain is stretched too much,the oil film between the pin and bushing will be torn anddamage to the roller chain and shafts will be accelerated. Onthe other hand, too much slack will cause the roller chain tovibrate, or ride up on the sprocket teeth resulting in damage toboth the roller chain and the sprocket.˚Fig. 13 Chain Lap(3) Chain is operated under heavy load and frequent starts.(4) Chain drive is suddenly reversed.3) Roller chain tends to slightly elongate (about 0.05%) in thefirst few dozen hours of use. This elongation causesexcess slack, so the amount of slack needs to beadjusted. Use a tensioner if the system has been designedfor it. If a tensioner is unsuitable, adjust the slack bymoving the shafts.4.4 Horizontal Precision and Parallelism of the ShaftsInstallation accuracy of the sprockets greatly affects thesmoothness of the roller chain drive and also influences thewear life of the roller chain. Make sure to carry out the followingimportant steps correctly.1) Check the horizontal specification with a level. Adjust theshafts so that they are horizontal to within ± 13002) Check the parallelism with a scale. Adjust the shafts so thatthey are parallel to within ± 1 A– B300= ( ).LFig. 15 Horizontal positioning of the shafts2) Generally, the slack of roller chain should be on the lowerside. Adequate slack is calculated by moving the chain byhand in a downward direction from the center. The chain slackthat you move by hand (SS’) should be about 4% of the span(A-B) (Ex. The amount of slack when span length is 31.5”would be 31.5” × 0.04 = 1 1/4”). See figure 14.Fig. 16 Parallelism of the shaftsA-111

- Page 59 and 60: 3/16”PitchMiniatureChainRS15Tsuba

- Page 61 and 62: British Standard/DINRoller ChainDri

- Page 63 and 64: British Standard/DINRoller ChainLam

- Page 65 and 66: British Standard/DINRoller ChainNic

- Page 67 and 68: British Standard/DIN ChainDrive Sel

- Page 69 and 70: Anti-CorrosiveRoller ChainAn Introd

- Page 71 and 72: Anti-CorrosiveRoller ChainNeptuneAn

- Page 73 and 74: Anti-CorrosiveRoller ChainStainless

- Page 75 and 76: Anti-CorrosiveRoller ChainNickel Pl

- Page 77 and 78: Anti-CorrosiveRoller ChainStainless

- Page 79 and 80: Leaf ChainLEAF CHAIN SELECTION GUID

- Page 81 and 82: Leaf ChainAL TypeLeaf ChainL1Chain

- Page 83 and 84: Leaf ChainBL TypeLeaf ChainConnecti

- Page 85 and 86: Specialty ChainLow Noise (SN)Specia

- Page 87 and 88: ASpecialty ChainLaminated Block Cha

- Page 89 and 90: Roller Chain ToolsChain Cutting Too

- Page 91 and 92: Drive Chain SelectionData required

- Page 93 and 94: Drive Chain Selection4. Selection F

- Page 95 and 96: Drive Chain SelectionAll of the cha

- Page 97 and 98: Drive Chain SelectionExample based

- Page 99 and 100: Drive Chain SelectionExample based

- Page 101 and 102: Drive Chain Selection8. Selection M

- Page 103 and 104: Drive Chain SelectionProcedure 3: (

- Page 105 and 106: Drive Chain Selection9. Selection b

- Page 107 and 108: Roller ChainInstallation & Maintena

- Page 109: Roller ChainInstallation & Maintena

- Page 113 and 114: Roller ChainInstallation & Maintena

- Page 115 and 116: Roller ChainInstallation & Maintena

- Page 117 and 118: Roller ChainInstallation & Maintena

- Page 119 and 120: Roller ChainInstallation & Maintena

- Page 121 and 122: Roller ChainInstallation & Maintena

- Page 123 and 124: How to OrderRoller Chain1. Example

- Page 125 and 126: A-125Drive ChainNo.ofPitchesRS251/4

- Page 127: Warning!WARNINGUSE CARE TO PREVENT

<strong>Roller</strong> <strong>Chain</strong>Installation & Maintenance4. RS <strong>Roller</strong> <strong>Chain</strong> Installation and Layout4.1 Speed Ratio and <strong>Chain</strong> LapThe speed ratio of roller chain can range up to 7 : 1 undernormal operating conditions. However, a speed ratio of 10 : 1 ispossible if the speed is very slow. <strong>Chain</strong> lap on the smallsprocket must be at least 120° and at least 90° in the case oflifting chain.˚˚In the following cases, the slack should be about 2% of thespan.(1) Vertical drive or close to vertical drive (tensioner isrequired)(2) Center distance between two shafts is greater than 1 m.Drive <strong>Chain</strong>Fig. 14 Amount of chain slack˚4.2 Distance between shaftsSprockets can be separated by any distance as long as theirteeth do not touch. Optimum distance is 30 to 50 times the pitchof the chain. However, the distance should be up to 20 times thepitch of the chain when there is a fluctuating load.4.3 Amount of Slack1) It is not necessary to apply initial tension to roller chain likeV/horizontal belt drives. In general, roller chain is used with asuitable amount of slack. If roller chain is stretched too much,the oil film between the pin and bushing will be torn anddamage to the roller chain and shafts will be accelerated. Onthe other hand, too much slack will cause the roller chain tovibrate, or ride up on the sprocket teeth resulting in damage toboth the roller chain and the sprocket.˚Fig. 13 <strong>Chain</strong> Lap(3) <strong>Chain</strong> is operated under heavy load and frequent starts.(4) <strong>Chain</strong> drive is suddenly reversed.3) <strong>Roller</strong> chain tends to slightly elongate (about 0.05%) in thefirst few dozen hours of use. This elongation causesexcess slack, so the amount of slack needs to beadjusted. Use a tensioner if the system has been designedfor it. If a tensioner is unsuitable, adjust the slack bymoving the shafts.4.4 Horizontal Precision and Parallelism of the ShaftsInstallation accuracy of the sprockets greatly affects thesmoothness of the roller chain drive and also influences thewear life of the roller chain. Make sure to carry out the followingimportant steps correctly.1) Check the horizontal specification with a level. Adjust theshafts so that they are horizontal to within ± 13002) Check the parallelism with a scale. Adjust the shafts so thatthey are parallel to within ± 1 A– B300= ( ).LFig. 15 Horizontal positioning of the shafts2) Generally, the slack of roller chain should be on the lowerside. Adequate slack is calculated by moving the chain byhand in a downward direction from the center. The chain slackthat you move by hand (SS’) should be about 4% of the span(A-B) (Ex. The amount of slack when span length is 31.5”would be 31.5” × 0.04 = 1 1/4”). See figure 14.Fig. 16 Parallelism of the shaftsA-111