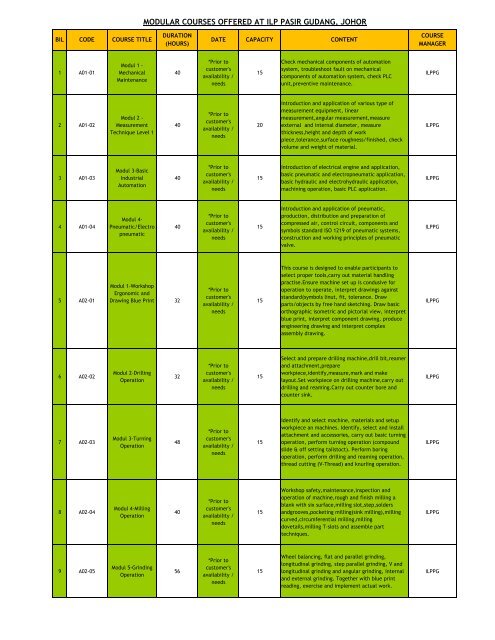

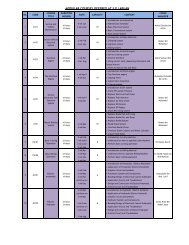

MODULAR COURSES OFFERED AT ILP PASIR GUDANG, JOHOR

MODULAR COURSES OFFERED AT ILP PASIR GUDANG, JOHOR

MODULAR COURSES OFFERED AT ILP PASIR GUDANG, JOHOR

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

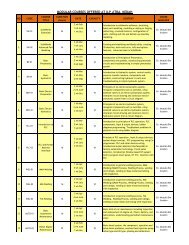

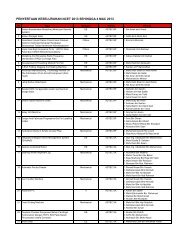

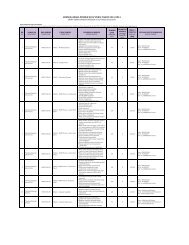

BIL CODE COURSE TITLEDUR<strong>AT</strong>ION(HOURS)D<strong>AT</strong>E CAPACITY CONTENTCOURSEMANAGER10 A02-06Modul 1-Materialsand Benchwork32*Prior tocustomer'savailability /needs20Carry out knocking and hammering on workpiece,grind cutting tool(drill bit,punch,chisel).Cutmetal work piece (filling),chiselling,sawing,chaindrilling.Carry out tool cutting on external andinternal threads(taps and discs). Carry out handreaming.Carry out hand scrapping on metal workpiece,check linear and angular measurement onwork piece.<strong>ILP</strong>PG11 A02-07Modul 2-EDMMachining40*Prior tocustomer'savailability /needs10General introduction to EDM,introduction to DieSinking Machines,generators?Technology of DieSinking Machine, machining language for Die-Sinking, practical exercises on Die-Sinking,introduction to wire cut machines andpractical exercises on Wire Cut.<strong>ILP</strong>PG12 A02-08Modul 3-AdvanceTurning Operation48*Prior tocustomer'savailability /needs10Identify & select machine, material and set-up workpiece on machine. Install attachments & accessoriescarry out basic turning operation. Perform boring,drilling, reaming, V thread cutting & Knurlingoperation.<strong>ILP</strong>PG13 A02-09Modul 4-AdvanceMilling andGrinding Operation64*Prior tocustomer'savailability /needs10Milling machine attachment (indexing head & rotarytable)<strong>ILP</strong>PG14 A03-01Modul 1-CNC LatheOperation60*Prior tocustomer'savailability /needs10Identify and select machine, materials and set upwork piece on machine. Identify, select and installattachment and accessories. Identify, select andmaintain cutters. Performboring,lapping,reaming,threading(inner andouter)operation.<strong>ILP</strong>PG15 A03-02Modul 2-CNCMilling Operation60*Prior tocustomer'savailability /needs10This course is designed to enable participants toacquire knowledge and skill in operation of verticalMilling Machine. Participants will be thaught theoryand practical skill of various milling techniques.CONTENT; Workshop safety. Operation of machine.Rough and finish milling a blank with six surface.Milling slot, step, shoulder and grove. Pocketmilling. Inspection and maintenance. Assemble parttechniques.<strong>ILP</strong>PG16 A03-03Modul 3-CNC EDMWire Cut Operation60*Prior tocustomer'savailability /needs10This course is designed to enable participants toacquire knowledge and skill in operation of CNCEDM Wire-Cut machine.Participants will be taughttheory and practical of CNC EDM Wire-Cutprogramming and actual machining.1. Introduction to Computerized Numerical Control(CNC) EDM Wire-Cut machine and their advantages.2. Basic machine coordinate for CNC EDM Wire-Cutmachine.3. Prepare program for CNC EDM Wire-Cut operation(dry run).4. Set up work piece on CNC EDM Wire-Cutmachine.5. Set up wire for CNC EDM Wire-Cut operation.6. Carry out CNC EDM Wire-Cut operation.7. Inspect product after machining operation.<strong>ILP</strong>PG

BIL CODE COURSE TITLEDUR<strong>AT</strong>ION(HOURS)D<strong>AT</strong>E CAPACITY CONTENTCOURSEMANAGER17 A03-04Modul 4-CNC EDMDie SinkingOperation60*Prior tocustomer'savailability /needs10This course is designed to enable participants toacquire knowledge and skill in operation of CNCEDM Die Sinking machine.Participants will be taughttheory and practical of CNC EDM Die Sinkingprogramming and actual machining.1. Introduction to Computerized Numerical Control(CNC) EDM Die Sinking machine and theiradvantages.2. Basicmachine coordinate for CNC EDM Die Sinkingmachine.3. Prepare program for CNC EDM Die Sinkingoperation (dry run).4. Set up work piece on CNC EDM Die Sinkingmachine.5. Set up wire for CNCEDM Die Sinking operation.6. Carry out CNC EDM Die Sinking operation.7. Inspect product after machining operation.<strong>ILP</strong>PG18 A04-01Modul 1-Metallurgyand Metrology45*Prior tocustomer'savailability /needs10This course is designed to provide participants withopportunities to acquire knowledge and skills inusing metrology instruments for inspection, layoutand measuring.1. Introduction to metrology.2. System of measurement.3. Measurement with graduated scales.4. Scale instruments.5. The vernier instruments.6. Micrometer instruments.7. Use of gauge block.8. Gauges.9. Measurement by compariser (using severalmeasuring equipment)10. Calibration.11. Angle measurements.12. Component visual instrument.<strong>ILP</strong>PG19 A04-02Modul 2-Basic CNCTurning and Milling67*Prior tocustomer'savailability /needs10Introduction on preparing absolute and incrementalprogram.Control system in CNC turning andmilling,G and M codes. Method of Programming insequence,cutting speed and feed. CNC turning andmilling main features(function of various controlsand controller panel), safety precautions.Introduction on EDM Programming, types ofelectrode materials and characteristics, type ofwork holding devices,cutting parameters, surfacefinish, safety and precautions.Introduction on wire cut programming, types ofwire sizes, materials and characteristics, machiningcondition and parameters, safety and precautions.<strong>ILP</strong>PG20 A04-03Modul 3-DieDesign,Manufacturing andMaintenance(CandidatesRequirement: BasicAutocad)60*Prior tocustomer'savailability /needs10Material science, Machining, AutoCad, Die Design -Press machine(machine spec), feed system.Stamping press design - Land angular clearance,guide plate tool, cutting force, strip layout,punches, dies, strippers, pilots, side cutters,fasteners and dowel pin, compound tools, blankingand piercing tool<strong>ILP</strong>PG21 A08-01Modul 1-TechnicalDrawing andIdentifying CuttingTools48*Prior tocustomer'savailability /needs10Interpret basic engineering drawing, interpretdrawing standards and symbols, verify partsdimension against drawing, interpret conversioncharts, construct geometrical drawing, drawnisometric and orthographic projections.<strong>ILP</strong>PG

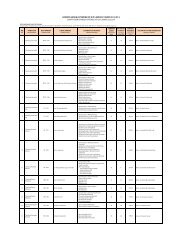

BIL CODE COURSE TITLEDUR<strong>AT</strong>ION(HOURS)D<strong>AT</strong>E CAPACITY CONTENTCOURSEMANAGER22 A08-02Modul 2-SMAWWelding96*Prior tocustomer'savailability /needs10Prepare, maintain and Perform weldingoperation.Welding skills with multipass fillet andsingle V-Groove in all positionWelding to AWS andISO requirements<strong>ILP</strong>PG23 A09-01Modul 1-BasicFabrication36*Prior tocustomer'savailability /needs10Introduction to metal fabrication practices andsafety precautions. Layout procedures, selectionand use of shop tools and fabrication machineryincluding shears, hand, grinders, etc. Set upoperations of oxy-acetylene welding/cuttingequipments. Set up and operations of arc-weldingmachine. Welding and flame cutting, developmentdrawings. Fabrication of workpieces by usingtemplates, such as cone hopper, square and roundelbow and T-joint.<strong>ILP</strong>PG24 A09-02Modul 2-Fabrication MetalWork92*Prior tocustomer'savailability /needs10Set up and operation of oxy-acetylenewelding/cutting equipment's and arc weldingmachine, development drawing. Preparation oftemplates, fabrication work: Fabrication of squareto round shape workpiece, joining pipes in 90degrees three pitch turn and y-branch, fabricatingthree-piece rectangular to round elbow.<strong>ILP</strong>PG25 A09-03Modul 3 - Basic MIGWelding32*Prior tocustomer'savailability /needs101. Set up GMAW equipment and ACC2. Socket Electrode3. Join workpiece by GMAW welding 1 F and 2 F.<strong>ILP</strong>PG26 A09-04Modul 4 - BasicGTAW Welding32*Prior tocustomer'savailability /needs101. Setup GTAW equipment and ACC2. Socket tungsten electrode3. Socket welding electrode4. Join workpiece by GTAW process 1F and 2 F.<strong>ILP</strong>PG27 A11-01Modul 1-OverhaulPetrol Engine60*Prior tocustomer'savailability /needs161. Introduction to Petrol engine2. Service Cooling system3. General Overhaul4. Using correct tools, Measuring Instrument andTorque Wrench Check for Bent,Twist and Wear<strong>ILP</strong>PG28 A11-02Modul 2-Basic CarService andMaintenance60*Prior tocustomer'savailability /needs16Servicing Points Of Service- Lubricating System- Engine Servicing.- Battery Servicing.- Braking System- Steering System.- Clutch & Transmission System.- Lighting System.- Air Cond System.<strong>ILP</strong>PG29 A11-03Modul 3-ServiceCar AirConditioningSystem R13 &R134a40*Prior tocustomer'savailability /needs16Introduction to air-conditioning principle andsystem, Air-Conditioning basic components,wiringsystem and device,purging system,charging system,technique pump dawn, installation andcommissioning, Troubleshoot.<strong>ILP</strong>PG30 A11-04Modul 4-ServiceDiesel Engine FuelSystem30*Prior tocustomer'savailability /needs16Basic diesel system, the component, operation andsolve diesel problems<strong>ILP</strong>PG31 A11-05Modul 5-Check andService ElectronicFuel InjectionSystem30*Prior tocustomer'savailability /needs161. Introduction to EFI system2. Check EFI system Pressure3. Replace Electrical Fuel Pump Replace FuelInjectors4. Replace Air Flow meter5. Replace EFI Sensors6. Replace EFI Relays7. Check EFI wiring system<strong>ILP</strong>PG

BIL CODE COURSE TITLEDUR<strong>AT</strong>ION(HOURS)D<strong>AT</strong>E CAPACITY CONTENTCOURSEMANAGER32 A11-06Modul 6-ServiceAuto ElectricalSystem40*Prior tocustomer'savailability /needs16Basic vehicle electrical system, the component,operation and troubleshooting.<strong>ILP</strong>PG33 A12-01Modul 1-AutocadFundamentals64*Prior tocustomer'savailability /needs20Introduction to CAD, setting-up drawing, drawingdisplay, coordinate system, inquiry, draw, editingcommand slayers & object properties, hatching etc.<strong>ILP</strong>PG34 A12-02Modul 2-PrepareProduct Drawing32*Prior tocustomer'savailability /needs20Preparation of drawing, common elements indrafting, industrial practices relating to drawing<strong>ILP</strong>PG35 A12-03Modul 3-PerformComputer AidedDesign 2D48*Prior tocustomer'savailability /needs161. Basic rules for the program operation2. Drawing begin,load and store3. Basic draw commands.4. Editing the drawing.5. Trimming operations.6. Working with polylines.7. Constructing Spline Curves.8. Applying text,fonts and styles.9. Constructing sectional and patterned drawings.10. Introduction to dimensioning.11. Plotting the work.<strong>ILP</strong>PG36 A12-04Modul 4-PerformDrawingManagement32*Prior tocustomer'savailability /needs20 <strong>ILP</strong>PG37 A12-05Modul 5-Auto DeskInventor 3D64*Prior tocustomer'savailability /needs15Using 3D Design command,basic surface commands,advanced surface command and finally understandthe assembly and practise.<strong>ILP</strong>PG38 B01-1Pendawai ElektrikSatu Fasa –Peperiksaan ST(Wireman 1 Phase )320 Jan / Jul 10This course PW 2 covers theory and practice onsurface and concealed wiring. It also covers IEE/IECRegulation, and Electricity Supply Act 1990, onelectrical wiring<strong>ILP</strong>PG39 B01-2Pendawai ElektrikTiga Fasa –Peperiksaan ST(Wireman 3 Phase )360 Jan / Jul 10Preparation to sit for PW4 examination. Syllabusincluding – Electricity Supply Act, IEE WiringRegulation, first-aid, basic electricity, cable,wiring, testing, electrical measuring tools, circuit,earthing, electrical devices, etc.<strong>ILP</strong>PG40 B03-1Penjaga JenteraElektrik ‘AO’ –Peperiksaan ST(Chargeman AO )360 Jan / Jul 20Motor control system Low Voltage SwitchMaintenance of air circuit breaker Commissioning oflow volt-age switchboard.Electrical ServiceAct,electrical rules & regulation.Cable,Fire fightingsystem, Air Conditioning system,Underground cable,Motor & control devices.Three Phase Motor.<strong>ILP</strong>PG41 B03-2Penjaga JenteraElektrik ‘A4’ –Peperiksaan ST(Chargeman A4 )360 Jan / Jul 10Electrical Chargeman(A0) syllabus,Low VoltageOverhead line system.Low voltage generation &synchronising system.<strong>ILP</strong>PG

BIL CODE COURSE TITLEDUR<strong>AT</strong>ION(HOURS)D<strong>AT</strong>E CAPACITY CONTENTCOURSEMANAGER42 B04-01Modul 1-ProcessMeasurement andMaintenance24*Prior tocustomer'savailability /needs20Calibrate temperature switch using temperatureprobe, calibrator and multimeter so that the setpoint of the switch meets process specification.Calibrate level switch using level stand pipeindicator and multimeter so that the set point ofthe switch meets process specification. Functionalcheck on flow switch using simulated flow andmultimeter so that the flow switch is functioning asper specification. Functional check on solenoidvalve using air/power supply source and pressuregauge so that the solenoid valve is functioning tospecification.<strong>ILP</strong>PG43 B04-02 Modul 2-Calibration 40*Prior tocustomer'savailability /needs20Install pneumatic transmition lines and componentsusing hook-up diagram, tubing bender, cutter andleak detection solution so that it provides air supplyto the transmitter for signal transmition. Installelectrical signal transmition lines and componentsusing wiring diagram, hand tools and multimeter sothat it provides electrical power and signaltransmition to the instruments. Calibrate pressuregauge using pressure calibrator and hand tools sothet the acuracy of the reading meetsmanufacturer's specification. Functional check onlimit switch appropriate triggering devices andmultimeter so that function as per plantrequirement. Service process regulator usingpressure gauge and hand tools so thet the processregulator is in working condition dan meetsmanufacturer's specification.<strong>ILP</strong>PG43 B04-03Modul 3-ControlValve and AuxiliaryInstrument24*Prior tocustomer'savailability /needs20Install pneumatic transmition lines and componentsusing hook-up diagram, tubing bender, cutter andleak detection solution so that it provides air supplyto the transmitter for signal transmition. Installelectrical signal transmition lines and componentsusing wiring diagram, hand tools and multimeter sothat it provides electrical power and signaltransmition to the instruments. Calibrate pressuregauge using pressure calibrator and hand tools sothet the acuracy of the reading meetsmanufacturer's specification. Functional check onlimit switch appropriate triggering devices andmultimeter so that function as per plantrequirement. Service process regulator usingpressure gauge and hand tools so thet the processregulator is in working condition dan meetsmanufacturer's specification.<strong>ILP</strong>PG44 B04-04Modul 4-InstrumentSafety and Security24*Prior tocustomer'savailability /needs20Apply Instrument safety and security by using smokedetector,heat detector,ultraviolet/infrareddetector/pressure calibrator,temperatureswitch,temperature probe,level switch,multimeterand flow switch,relay and limit switch so that relayand limit switch function maintained, periodiccheck on fire alarm system performed and plantsafety system performed in accordance with themanufacturers manual and standard operatingprocedure.<strong>ILP</strong>PG45 B05-01Modul 1-ElectronicFundamental66*Prior tocustomer'savailability /needs15Electrical concepts, Ohm's Law, PassiveComponents,Resistor,Capacitor,Inductor,TransformerActive Components,Diode,Transistor,OptoComponenets,Integrated Circuit.<strong>ILP</strong>PG

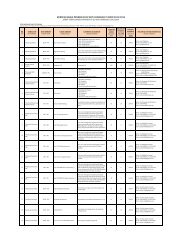

BIL CODE COURSE TITLEDUR<strong>AT</strong>ION(HOURS)D<strong>AT</strong>E CAPACITY CONTENTCOURSEMANAGER46 B05-02Modul 2-Pneumatic andElectropneumatic24*Prior tocustomer'savailability /needs15Principle,symbol and components of pneumatic.Direct and indirect manual controlRead pneumatic schematic componentPrinciple,symbol and components of electropneumatic.<strong>ILP</strong>PG47 G01-01Modul 1-MicrosoftWord 2000-Intermediate16*Prior tocustomer'savailability /needs351. Add bullets to a document using the drop downmenus2. Apply default bullet formatting to a list using thetoolbar3. Remove bullet formatting from a list4. Modify the bullets in the Format Bullets andNumbering dialog box5. Apply picture bullets6. Add numbers to a document7. Add numbering to a list using the toolbar8. Add Outline Numbering9. Set up different headers on different pages10. Add a border to an object11. Remove a border from an object12. Add a Page Border13. Add shadowing or shading to a border14. Apply white text on a black background15. Adjust line spacing in a document16. Set text flow for paragraph formatting17. Automatically hyphenate a word18. Set or change tabs using the Ruler19. Set or change tabs using the drop down menus20. Create columns from existing text21. Change the width of parallel columns22. Insert column breaks23. Remove column formatting<strong>ILP</strong>PG48 G01-02Modul 2-MicrosoftWord 2000-Advanced16*Prior tocustomer'savailability /needs351. Styles2. Templates3. Using AutoFormat4. Long Documents - Section Formatting and Master5. Documents6. Using Fields7. Customizing Word8. Advanced Use of Find and Replace9. Word Macros10. Miscellaneous Advanced Features10.1 Bookmarks10.2 File Conversion10.3 Equation Editor10.4 Footnote10.5 AutoSummarize10.6 Document Map10.7 What is Outlining?10.8 Highlight Changes10.9 Password Protection10.10 Word Count<strong>ILP</strong>PG49 G01-03Modul 3-MicrosoftExcel 2000-Intermediate16*Prior tocustomer'savailability /needs351. Working With Functions2. Sorting3. Editing Data4. Charting5. Filtering6. Linking Work Books7. Selecting Ranges<strong>ILP</strong>PG

BIL CODE COURSE TITLEDUR<strong>AT</strong>ION(HOURS)D<strong>AT</strong>E CAPACITY CONTENTCOURSEMANAGER50 G01-04Modul 4-MicrosoftExcel 2000-Advanced16*Prior tocustomer'savailability /needs351. Templates and styles2. Importing data3. Macros and custom control4. Customizing excel5. Security and proofing within excel6. Excel auditing tools<strong>ILP</strong>PG51 G01-05Modul 5-MicrosoftPower Point 2000-Intermediate16*Prior tocustomer'savailability /needs35Describe the new PowerPoint 2007 Environment;Locate and use the Microsoft Office Button;Locate and Customize the Quick Access Toolbar(Q<strong>AT</strong>);Locate and use Tabs, Groups, and Commands in theRibbon U.I.;Experiment with Live Preview;Browse and Select a Design theme;Create a Title Slide and Content Slide;Duplicate a slideFormat text (style, size, color, effects, alignment);Save and Close a presentation;Change Document Properties;Open an existing presentation;Change the layout of a slide;Rearrange slides in a presentation;Display different views of a presentation;Publish a presentation as a handout in MicrosoftWord format;Preview, Print and Close a presentation.<strong>ILP</strong>PG52 G01-06Modul 6-MicrosoftPower Point 2000-Advanced16*Prior tocustomer'savailability /needs35Insert and use a Table;Create, insert, and enhance SmartArt graphics;Create and insert links to a file or website;Insert sound from a file;Preview slide transitions and animations;Apply commonly used animations to text orgraphics;Preview, apply, and use animated effects for slidetransitions;Start and customize a slide show;Create and insert comment side notes;Locate and modify Slide Master templates.<strong>ILP</strong>PG53 G01-07Modul 7-MicrosoftAccess 2000-Intermediate16*Prior tocustomer'savailability /needs351. Creating And Using Database2. Design Table3. Design Form4. Queries5. Reports6. Relationship7. Importing & Exporting Data8. Finishing Touches<strong>ILP</strong>PG54 G01-08Modul 8-MicrosoftProject 200016*Prior tocustomer'savailability /needs35Find your way around the Project 2000 screenUnderstand the different buttons on the toolbarand what they can doSee and understand the Calendar viewSee and understand the Gantt chart view<strong>ILP</strong>PG55 G01-09Modul 1-ComputerMaintenance16*Prior tocustomer'savailability /needs15Identity computer component and performcomputer assembly. Install operating system andcomputer application<strong>ILP</strong>PG56 G01-10Modul 2-BasicNetworking16*Prior tocustomer'savailability /needs15PC networking terms and consepts,transmissionmedia,network topologies andarchitectures,transport protocols and setup,installand configure PC network.<strong>ILP</strong>PG

BIL CODE COURSE TITLEDUR<strong>AT</strong>ION(HOURS)D<strong>AT</strong>E CAPACITY CONTENTCOURSEMANAGER57 G01-11Modul 1-MicrosoftFront Page 200016*Prior tocustomer'savailability /needs351. Create a New Web Site2. Create a Web Site with a Wizard3. Create a Web Site using a Template4. Use the Web Location Options area5. Choose Web Hosting Service Providers6. Choose ISP Service Providers7. Use a Personal Web Server8. Create a new Page using a Template9. Check Spelling10. Check Hyperlinks11. Set Tasks12. Set Permissions<strong>ILP</strong>PG58 G01-12Modul 2-WebsiteDesigning (HTML,PHP and MySQL)32*Prior tocustomer'savailability /needs35Introduction to HTML basic,creating a webpage,publishing HTML pages,font control andspecial characters,arranging text in list,makingpages display quickly,background and colourcontrol,creating HTML forms and embeddingmultimedia in web pages.<strong>ILP</strong>PG59 G01-13Modul 3-Internetand Email8*Prior tocustomer'savailability /needs35Introduction to the internet, getting connected,internet application and understanding the WorldWide Web.<strong>ILP</strong>PG60 G01-14Modul 4-InteractiveGraphic withAdobe/Ulead16*Prior tocustomer'savailability /needs351. Introduction to Adobe Photoshop2. Design Text3. Color modification on Photos4. Design photo frame5. Basic Technique modifying image6. Manipulate photo<strong>ILP</strong>PG