MSDS - Insulation Supplies

MSDS - Insulation Supplies

MSDS - Insulation Supplies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

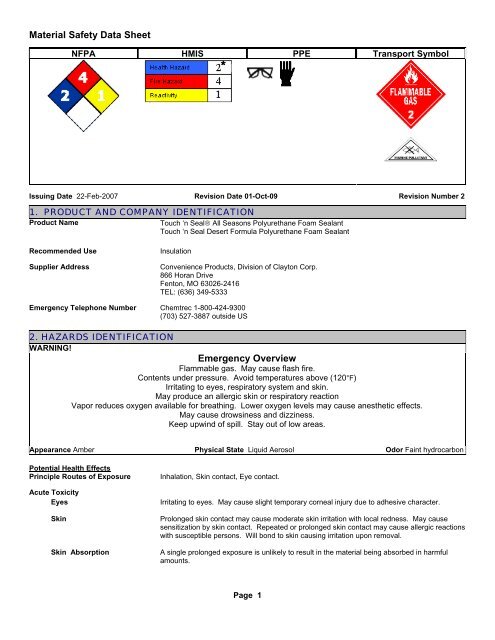

Touch ‘n Seal® All Seasons Polyurethane Foam SealantTouch ‘n Seal Desert Formula Polyurethane Foam SealantRevision Date 01 Oct 2009Methods for ContainmentMethods for Cleaning UpOther InformationIf possible, turn leaking containers so that gas escapes rather than liquid. Allow substance toevaporate. Contain spilled materials if possible without risk. Absorb with materials such assawdust, dirt or vermiculite. Collect in suitable and properly labeled open containers. Do notplace in sealed containers. Curing foam gives off CO 2 . Wash what is left of the spill site withlarge quantities water.Attempt to neutralize the spilled material by adding suitable decontaminate solution:Formulation 1: Sodium carbonate 5-10%; liquid detergent 0.2 – 2%; water to make up to100%, OR Formulation 2: concentrated ammonia solution 3 – 8%; liquid detergent 0.2 – 2%;water to make up to 100%. If ammonia formulation is used, use good ventilation to preventvapor exposure. Sweep up and shovel into suitable containers for disposal.Ventilate the area. Curing foam gives off CO 2 . Do not put curing foam in a sealed drum.7. HANDLING AND STORAGEHandlingAvoid contact with skin, eyes and clothing. Wash thoroughly after handling. Ensure adequateventilation. Take necessary action to avoid static electricity discharge (which might causeignition of organic propellant vapors). Keep away from open flames, hot surfaces and sourcesof ignition. Do not Smoke. Avoid breathing vapors or mists. Contents under pressure. Do notpuncture or incinerate cans. Container, even those that have been emptied, can containvapors. Do not cut, drill, grind, weld or perform similar operations on or near empty containers.Do not stick pin or any other sharp object into opening on top of can.StorageKeep containers tightly closed in a cool, well-ventilated place. Keep in properly labeledcontainers. Keep in an area equipped with sprinklers. Keep out of the reach of children. Idealstorage temperature is 16-32 °C / 60 – 90 °F. Storage above 32 °C / 90 °F will reduce itsshelf-life. Never keep at temperatures above 48.8°C / 120°F.8. EXPOSURE CONTROLS / PERSONAL PROTECTIONExposure GuidelinesChemical Name ACGIH TLV OSHA PEL NIOSH IDLHMethylene bisphenyl isocyanateTWA: 0.005 ppmCeiling: 0.02 ppm75 mg/m 3(MDI)Ceiling: 0.2 mg/m 3Isobutane TWA: 1000 ppm N/A N/APropaneTWA: 2,500 ppmSTEL 1,000 ppm,3,500 mg/m 3 8Hr TWA: 1000 ppm1,800.0 mg/m 3 2100 ppmNIOSH IDLH: Immediately Dangerous to Life or HealthEngineering MeasuresPersonal Protective EquipmentEye/Face ProtectionSkin and Body protectionRespiratory ProtectionHygiene MeasuresShowersEyewash stationsVentilation systemsSafety glasses with side-shields.Impervious gloves. Lightweight protective clothing.Atmospheric levels of PMDI should be maintained below the exposure guidelines. If exposurelimits are exceeded or irritation is experienced, use a NIOSH/MSHA approved air-purifyingrespirator equipped with an organic vapor absorbent and a particle filter. For situations wherethe atmospheric levels exceed the level for which an air-purifying respirator is effective, use apositive-pressure air-supplied respirator. Respiratory protection must be provided inaccordance with current local regulations.When using, do not eat, drink or smoke. Maintain regular cleaning of equipment, work areaand clothing.Page 4

Touch ‘n Seal® All Seasons Polyurethane Foam SealantTouch ‘n Seal Desert Formula Polyurethane Foam SealantRevision Date 01 Oct 20099. PHYSICAL AND CHEMICAL PROPERTIESAppearance Amber Odor Faint hydrocarbonOdor Threshold No information available Physical State Liquid AerosolpHNo information availableFlash Point-104°C / -155°F (based onpropellant.)Autoignition TemperatureNot applicableDecomposition temperature No data available Boiling Point/Range -42°C / -43.6°FMelting Point/RangeFlammability Limits in AirNot applicableNo data availableViscosityExplosion LimitsNo information availableNo data availableSpecific Gravity 1.01 Water Solubility Not CompatibleSolubility No data available Evaporation Rate No data availableVapor Pressure No data available Vapor Density No data availablePartition Coefficient (noctanol/water)Not applicable EPA VOC 1.29 (lb/gal) 155 (g/l)10. STABILITY AND REACTIVITYStabilityConditions to AvoidIncompatible ProductsHazardous Decomposition ProductsHazardous PolymerizationStable under recommended storage conditionsKeep away from open flames, hot surfaces and sources of ignition.Temperatures above 48.8°C / 120°F. Exposure to elevatedtemperatures can cause product to decompose.Water. Alcohols. Strong bases. Strong oxidizing agents. Finelypowdered metals.Carbon monoxide (CO), Carbon dioxide (CO 2 ), Nitrogen oxides(NOx), Hydrogen cyanide.Hazardous polymerization does not occur.11. TOXICOLOGICAL INFORMATIONAcute ToxicitySensitization - SkinSkin contact may cause an allergic skin reaction. Animal studies have shown that skin contactwith isocyanates may play a role in respiratory sensitization.Sensitization – RespiratoryMay cause allergic respiratory response. MDI concentrations below the exposure guidelinesmay cause allergic respiratory reactions in individuals already sensitized. Asthma-likesymptoms may include coughing, difficult breathing and a feeling of tightness in the chest.Occasionally, breathing difficulties may be life threatening.Product InformationChemical Name LD50 Oral LD50 Dermal LC50 InhalationFlame retardant 1,250 mg/kg ( Rat ) >5,000 mg/kg ( Rabbit ) * >4.6 mg/l ( Rat ) 4 hFlame retardant 26,100 g/kg ( Rat ) >10,000 ml/kg ( Rabbit )Page 5

Touch ‘n Seal® All Seasons Polyurethane Foam SealantTouch ‘n Seal Desert Formula Polyurethane Foam SealantRevision Date 01 Oct 2009Chemical Name LD50 Oral LD50 Dermal LC50 InhalationPolymethylene polyphenylene49 g/kg ( Rat ) 9400 mg/kg ( Rabbit ) 490 mg/m 3 ( Rat ) 4 hisocyanateMethylene bisphenyl isocyanate9200 mg/kg ( Rat )(MDI)Polyol blend 64 ml/kg ( Rat ) 20 ml/kg ( Rabbit )Isobutane658 mg/l ( Rat ) 4 hMethylenediphenyl diisocyanate 6200 mg/kg ( Rabbit ) 0.369 mg/l ( Rat ) 4 hPropane 658 mg/kg ( Rat )Dimethyl ether308.5 mg/ l ( Rat ) 4 h* A single dermal application produced no mortality. The product is a mild irritant to rabbit skin following a 24-hour exposure.Chronic ToxicityChronic ToxicityCarcinogenicityMutagenicityReproductive ToxicityTarget Organ EffectsEndocrine Disruptor InformationRepeated or prolonged exposure may cause central nervous system damage. Tissue injury inthe upper respiratory tract and lungs has been observed in laboratory animals after repeatedexcessive exposures to MDI/polymeric MDI aerosols. Intentional misuse by deliberatelyconcentrating and inhaling contents may be harmful or fatal. Chronic hydrocarbon abuse hasbeen associated with irregular heart rhythms and potential cardiac arrest. Repeated orprolonged contact causes sensitization, asthma and eczemas.There are no known carcinogenic chemicals in this productContains no known mutagenetic chemicalsThis product does not contain any known or suspected reproductive hazardsContains component(s) that have been reported to cause effects on the following organs inanimals: Kidney, Liver, Bone marrow.This product does not contain any known or suspected endocrine disruptors12. ECOLOGICAL INFORMATIONThis product contains a chemical which is listed as a severe marine pollutant according to DOT.Movement & Partitioning:Persistence and Degradability:In the aquatic and terrestrial environment, PMDI movement is expected to be limited by itsreaction with water forming predominantly insoluble polyureas.In the aquatic and terrestrial environment, PMDI reacts with water forming predominantlyinsoluble polyureas that appear to be stable. In the atmospheric environment, material isexpected to have a short tropospheric half-life, based on calculations and by analogy withrelated diisocyanates.EcotoxicityEcotoxicity effects.Chemical Name Toxicity to Algae Toxicity to Fish Microtox Daphnia Magna (Water Flea)Flame retardantEC50 = 0.3 – 11.1 mg/L 24 hFlame retardant EC50/47 mg/L (96 h)Methylenediphenyl EC50 = 3230 mg/L 96 hEC50 > 1000 mg/L 24 hdiisocyanateDimethyl etherLC50 (goldfish) 3677 mg/L,96 hLC50 1852 mg/L, 96 hChemical NameLog PowFlame retardant 2.59Isobutane 2.88Propane 2.3Dimethyl ether -0.18Page 6

Touch ‘n Seal® All Seasons Polyurethane Foam SealantTouch ‘n Seal Desert Formula Polyurethane Foam SealantRevision Date 01 Oct 200913. DISPOSAL CONSIDERATIONSWaste Disposal MethodShould not be released into the environment. Dispose of in accordance with local regulations.Allow foam to cure before disposal.Contaminated PackagingUS EPA Waste NumberDispose of in accordance with local regulationsD00114. TRANSPORT INFORMATIONDOTProper Shipping Name Consumer commodityHazard ClassORM-DDescriptionConsumer commodity, ORM-DTDGUN-NoUN1950Proper Shipping Name AerosolsHazard Class 2.1Description UN1950, Aerosols, 2.1MEXUN-NoUN1950Proper Shipping Name AerosolsHazard Class 2.1Description UN1950, Aerosols, 2.1ICAOUN-NoUN1950Proper Shipping Name AerosolsHazard Class 2.1DescriptionUN1950, AerosolsIATAUN-NoUN1950Proper Shipping Name Aerosols, flammableHazard Class 2.1ERG Code10LDescription UN1950, Aerosols, flammable, 2.1IMDG/IMOUN-NoUN1950Proper Shipping Name AerosolsHazard Class 2.1EmS No.F-D, S-UDescriptionUN1950, Aerosols, 2.1, Marine Pollutant (chlorinated paraffin), LTD QTYRIDUN-NoUN1950Proper Shipping Name AerosolsHazard Class 2Classification Code5ADescriptionUN1950 Aerosols, 2, RIDADR/RID-Labels 2ADRADNUN-NoUN1950Proper Shipping Name AerosolsHazard Class 2Classification Code5AADR/RID-Labels 2UN-NoUN1950Proper Shipping Name AerosolsHazard Class 2Classification Code5APage 7

Touch ‘n Seal® All Seasons Polyurethane Foam SealantTouch ‘n Seal Desert Formula Polyurethane Foam SealantRevision Date 01 Oct 200914. TRANSPORT INFORMATIONSpecial Provisions 63, 190, 191, 277, 913Description UN1950, Aerosols, 2Hazard Labels 2Limited QuantitySee SP27715. REGULATORY INFORMATIONInternational InventoriesTSCADSLEINECS/ELINCSENCSCHINAKECLPICCSAICSCompliesCompliesCompliesCompliesCompliesCompliesCompliesCompliesU.S. Federal RegulationsOSHA Hazard CommunicationStandardThis product is a “Hazardous Chemical” as defined by the OSHA HazardCommunication Standard, 29CFR 1910.1200.SARA 313Section 313 of Title III of the Superfund Amendments and Reauthorization Act of 1986 (SARA). This product contains a chemical orchemicals that are subject to the reporting requirements of the Act and Title 40 of the Code of Federal Regulations, Part 372:Chemical Name CAS-No Weight % SARA 313 - ThresholdValuesPolymethylene polyphenylene isocyanate 9016-87-9 10-30 1.0Methylene bisphenyl isocyanate (MDI) 101-68-8 10-30 1.0Methylenediphenyl diisocyanate 26447-40-5 1-5 1.0SARA 311/312 Hazard CategoriesAcute Health HazardChronic Health HazardFire HazardSudden Release of Pressure HazardReactive HazardYesYesYesYesNoPage 8

Touch ‘n Seal® All Seasons Polyurethane Foam SealantTouch ‘n Seal Desert Formula Polyurethane Foam SealantRevision Date 01 Oct 2009Clean Water ActThis product does not contain any substances regulated as pollutants pursuant to the Clean Water Act (40 CFR 122.).CERCLAThis material, as supplied, contains one or more substances regulated as a hazardous substance under the ComprehensiveEnvironmental Response Compensation and Liability Act (CERCLA) (40 CFR 302).Chemical Name Hazardous Substances RQs Extremely Hazardous Substances RQsMethylene bisphenyl isocyanate (MDI)5000 lbU.S. State RegulationsCalifornia Proposition 65WARNING! This product contains a chemical(s) known to the State of California to cause cancer, or birth defects or other reproductive harm.(concentration < 0.1%)U.S. State Right-to-Know RegulationsChemical Name Massachusetts New Jersey Pennsylvania Illinois Rhode IslandDimethyl ether X X X XPropane X X X XIsobutane X X XMethylene bisphenylisocyanate (MDI)X X X X XInternational RegulationsMexico - GradeThe exposure limits values for 101-68-8 are listed under two synonyms:Diphenylmethane diisocyanate - 0.02 ppm TWA; 0.2 mg/m 3 TWAMethylene bisphenyl isocyanate - 0.005 ppm TWA; 0.051 mg/m 3 TWAChemical Name Carcinogen Status Exposure LimitsMethylene bisphenyl isocyanate (MDI)Mexico: TWA= 0.02 ppmMexico: TWA= 0.2 mg/m 3Diphenylmethane diisocyanateMexico: TWA= 0.005 ppmMexico: TWA= 0.051 mg/m 3CanadaThis product has been classified in accordance with the hazard criteria of the Controlled Products Regulations (CPR) and the<strong>MSDS</strong> contains all the information required by the CPR.WHMIS Hazard ClassA Compressed gasesB5 Flammable aerosolD2B Toxic materialsChemical NameMethylene bisphenyl isocyanate (MDI)NPRIXPage 9

Touch ‘n Seal® All Seasons Polyurethane Foam SealantTouch ‘n Seal Desert Formula Polyurethane Foam SealantRevision Date 01 Oct 2009LegendNPRI - National Pollutant Release InventoryWHMIS – Workplace Hazardous Materials Information SystemTSCA – Toxic Substance Control ActDSL – Domestic Substance ListEINECS – European Inventory of Existing Commercial Chemical SubstancesENCS – Japan, Existing and New Chemical SubstancesKECL- Korean Existing Chemical ListPICS – Philippine Inventory of Chemicals and Chemical SubstancesAICS – Australian Inventory of Chemical SubstancesTDG – Transportation of Dangerous Goods ActICAO – International Civil Aviation OrganizationIATA – International Maritime Dangerous Goods CodeIMDG – International Maritime Dangerous Goods Code16. OTHER INFORMATIONIssuing DateRevision DateRevision Note22-Feb-200701-Oct-09Revised by Clayton Corporation EHS DepartmentDisclaimerThe information provided on this <strong>MSDS</strong> is correct to the best of our knowledge, information and belief at the date of itspublication. The information given is designed only as a guide for safe handling, use, processing, storage, transportation,disposal and release and is not to be considered as a warranty or quality specification. The information relates only to thespecific material designated and may not be valid for such material used in combination with any other material or in anyprocess, unless specified in the text.End of <strong>MSDS</strong>Page 10