Brechtelsbauer - Workspace - Imperial College London

Brechtelsbauer - Workspace - Imperial College London

Brechtelsbauer - Workspace - Imperial College London

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Stirred Tank Scale-Up<br />

An (ex-) Practitioner’s View<br />

MemTide Process Development Course<br />

<strong>London</strong>, 23-24 February 2012<br />

Dr. Clemens <strong>Brechtelsbauer</strong><br />

Principal Teaching Fellow<br />

Department of Chemical Engineering<br />

<strong>Imperial</strong> <strong>College</strong> <strong>London</strong><br />

c.brechtelsbauer@imperial.ac.uk

Contents<br />

� Further Reading<br />

� The Design Environment<br />

� Manufacturing steps<br />

� Unit operations<br />

� The design base<br />

� Mixing<br />

� Vessels, impellers and baffles<br />

� Flow regimes<br />

� Power draw<br />

� Scale-Up<br />

� Similarity concept<br />

� Scale-up rules<br />

� Multiphase systems<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 2 Stirred Tank Scale-Up

Further Reading<br />

� Edward L. Paul, Victor A. Atiemo-Obeng, Suzanne M. Kresta (Eds.)<br />

Handbook of Industrial Mixing<br />

John Wiley & Sons, 2004<br />

� Ekato Ruehr- und Mischtechnik GmbH<br />

Ekato Handbook of Mixing Technology<br />

Ekato GmbH, 2000<br />

� John H. Atherton, Keith J. Carpenter<br />

Process Development: Physicochemical Concepts<br />

Oxford University Press, 1999<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 3 Stirred Tank Scale-Up

Steps in API/Fine Chem Manufacture<br />

Risk<br />

Scale<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 4 Stirred Tank Scale-Up

Reactions<br />

• Kinetics<br />

• Multi-<br />

phase<br />

Reaction<br />

Extraction<br />

Unit Operations<br />

Chemistry: Reactions and Separations Particle Forming Unit Operations<br />

Separations<br />

• Distillation<br />

• Extraction<br />

Environmental<br />

• Mass Balance<br />

• Recovery<br />

Distillation<br />

Crystallisation<br />

• Scale-up<br />

Crystallisation<br />

Isolation<br />

• Filtration<br />

• Centri-<br />

fuges<br />

Filtration<br />

Drying<br />

• Filter-<br />

Dryers<br />

Drying<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 5 Stirred Tank Scale-Up

The Nature of the Beast<br />

Process = Chemistry + Equipment Physics<br />

Or<br />

“chemical rate constants are scale independent,<br />

whereas physical parameters are not”<br />

John H. Atherton<br />

Author of<br />

“Process Development: Physicochemical Concepts”<br />

Simply put:<br />

“Ye cannae change the<br />

laws of physics, Jim!”<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 6 Stirred Tank Scale-Up

H=T<br />

Standard Vessel Geometry<br />

D<br />

T<br />

B<br />

=<br />

T/10<br />

C=T/3<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 7 Stirred Tank Scale-Up

Ship’s Wheel vs. Cartwheel<br />

� Low shear<br />

� Good for solid suspension<br />

� High shear<br />

� Good for dispersions<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 8 Stirred Tank Scale-Up

D<br />

D<br />

V static � 1 % V nominal<br />

V stir, min � 5 % V nominal<br />

V dish � 7 % V nominal<br />

V mix, min � 30-40 % V nominal<br />

Beware of the Dork Side<br />

V(stir, min) / V(mix, min) [L]<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

Minimum Stir and Mixing Volumes<br />

0 500 1000 1500 2000 2500 3000<br />

Nominal vessel volume [L]<br />

“Minimum stirred volume”<br />

d o e s n o t m e a n<br />

“Minimum mixed volume”<br />

V stir min [L]<br />

V mix min [L]<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 9 Stirred Tank Scale-Up

Impeller Types<br />

� Radial flow impeller<br />

� Discharges liquid radially outwards<br />

towards vessel walls<br />

• Transitional & turbulent regime<br />

• Good for dispersing<br />

� Axial flow impeller<br />

� Discharges liquid axially towards base<br />

or liquid surface depending on<br />

rotation direction<br />

• Transitional & turbulent regime<br />

• Good for blending & suspending<br />

� Mixed flow impeller<br />

� Flow predominantly in axial direction<br />

with also a radial component<br />

• Transitional & turbulent regime<br />

• Good for blending, suspending &<br />

dispersing<br />

� Close clearance impeller<br />

� Ensures good motion near vessel walls<br />

• Laminar regime<br />

• Good for blending<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 10 Stirred Tank Scale-Up

Understanding the Force<br />

In a stirred vessel, the presence of baffles is essential to convert the vortexing motion of<br />

the impeller into top to bottom mixing.<br />

No baffles is worst. Partial baffling is better. Full baffling is best.<br />

� Baffles are needed to promote the flow pattern<br />

characteristic of the impeller type<br />

� 4 Baffles, typical width T/12 (US) or T/10 (EU)<br />

with wall gap to prevent solids build-up<br />

� Beavertail and finger baffles are often used in<br />

glass-lined vessels<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 11 Stirred Tank Scale-Up

Power Draw<br />

� The power drawn by an<br />

impeller is expressed through a<br />

power number equation:<br />

P = Po ρ N 3 D 5<br />

� Power number<br />

� Po, or Newton number, Ne<br />

� Depends on<br />

• Impeller type<br />

• Impeller and vessel<br />

dimensions<br />

• Properties of the phases<br />

present<br />

� Must be measured!<br />

DE/V<br />

E 1/V<br />

E 2/V<br />

A 1, v 1, h 1, p 1<br />

A 2, v 2, h 2, p 2<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 12 Stirred Tank Scale-Up

Flow Regimes<br />

� Different parts of a vessel can<br />

experience different flow conditions<br />

� Assess by Reynolds number<br />

2<br />

� N D Inertial Force<br />

Re � �<br />

� Frictional Force<br />

� The “power curve” Po vs Re can be used<br />

to evaluate the flow regime for the<br />

whole process<br />

� Laminar: Re < 10<br />

• Po � Re -1<br />

� Transitional: 10 < Re < 10 3<br />

• Po = f(Re)<br />

� Turbulent: Re > 10 3<br />

• Po = constant<br />

Ekato Handbook of Mixing<br />

Technology, p. 15<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 13 Stirred Tank Scale-Up

Geometric Similarity<br />

� A single scale ratio, s, defines the relative magnitude of all<br />

linear dimensions between the large and small scale:<br />

H 1<br />

D 1<br />

T 1<br />

C 1<br />

D<br />

D<br />

2 2 2<br />

s � � � �<br />

1<br />

T<br />

T<br />

1<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 14 Stirred Tank Scale-Up<br />

H<br />

H<br />

1<br />

C<br />

C<br />

2<br />

1<br />

H 2<br />

D 2<br />

T 2<br />

C 2

Kinematic & Dynamic Similarity<br />

� Kinematic Similarity<br />

� Velocities at<br />

geometrically similar<br />

positions remain<br />

constant<br />

• Constant tip speed<br />

• Constant superficial<br />

gas velocity<br />

• Constant maximum<br />

liquid velocity in<br />

impeller discharge<br />

� Dynamic Similarity<br />

� Ratio of forces<br />

(dimensionless groups)<br />

remain constant at<br />

different scales<br />

• Beware:<br />

– The relationship<br />

between process<br />

performance and the<br />

dimensionless group<br />

may not be linear!<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 15 Stirred Tank Scale-Up

Process Requirements<br />

� A process may be controlled by one or more of:<br />

� Liquid blending<br />

• reaction<br />

• homogenisation<br />

� Solid-liquid mixing<br />

• solid catalysed reaction<br />

• dispersion<br />

� Gas-liquid mixing<br />

• fermentation<br />

• hydrogenation<br />

� Dispersing immiscible liquid<br />

• reaction<br />

• emulsions<br />

� Heat transfer<br />

� Defining controlling duty is key to successful scale-up!<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 16 Stirred Tank Scale-Up

Scale-Up Rules<br />

� Geometrically similar vessels<br />

� Turbulent regime<br />

Process Rule Constant Parameter<br />

Liquid blending Equal tip speed N � D<br />

Solid suspension Zwietering N js � D 0.85<br />

Solid distribution Equal energy input P / V<br />

Gas-liquid Equal mass transfer P / V (= k La)<br />

Heat transfer Equal Re N � D 2<br />

Fast reactions Equal mixing time N<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 17 Stirred Tank Scale-Up

Scale-Up Decisions<br />

Scale-up experiments and modelling essential!<br />

(1) Constant Mixing Time<br />

(2) Constant P/V<br />

(3) Just suspension<br />

(4) Tip speed<br />

(5) Reynolds number<br />

Note:<br />

• Criteria are mutually exclusive<br />

• On scale-up, impeller speed<br />

goes down<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 18 Stirred Tank Scale-Up

� Mixing design by function<br />

� Principles<br />

Future Multi-Purpose Plants<br />

� Focused diversity by unit<br />

operation<br />

� Multi-flight agitation<br />

� Vessel types<br />

� A: Reactor with work-up<br />

� B: Reactor / crystalliser<br />

� C: Crystalliser<br />

� D: Reactor / hydrogenator<br />

� E: Hydrogenator<br />

� Physical properties determine<br />

process design envelope<br />

� Implemented at GSK<br />

A<br />

B C<br />

E<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 19 Stirred Tank Scale-Up<br />

D

Multiphase Systems Scale-Up<br />

Process Assessment<br />

Scale-down Study<br />

Continuous<br />

Improvement<br />

Plant Supplies Campaign<br />

Scale-up Projection<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 20 Stirred Tank Scale-Up

Process Assessment<br />

� Respiratory portfolio, final stage re-crystallisation<br />

� Important for process success:<br />

� Minimisation of variability on scale-up of “particle forming step”<br />

� Reproducible, narrow particle size distribution<br />

• Homogeneous growth conditions to promote particle uniformity<br />

• Low shear to prevent attrition<br />

� Initial hydro-dynamic simulation of flow profile by CFD for pilot and plant vessels<br />

1500 L Pilot Plant 4000 L Manufacturing<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 21 Stirred Tank Scale-Up

� To determine the effect of<br />

shear & suspension on<br />

particle size & distribution,<br />

which cannot be predicted<br />

through CFD<br />

� 2 L conical base lab reactor<br />

set up to scale-down<br />

manufacturing reactor<br />

Scale-Down Study<br />

� Effect of improved suspension:<br />

� No effect on particle size<br />

� Effect of shear:<br />

� No effect on particle size or<br />

distribution (PSD)<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 22 Stirred Tank Scale-Up

Scale-Up Projection<br />

� Just suspension speed determined experimentally for 2L lab reactor<br />

� CFD multi-phase<br />

simulation based on<br />

experimental stirrer<br />

speed:<br />

� Plant operating impeller speeds recommended to maintain<br />

homogeneous suspension<br />

� Stevenage pilot plant (1500 L): 60-70 RPM<br />

� prevent risk of settling<br />

� provide homogeneous growth conditions<br />

� verify negligible shear effect<br />

Lab, 2 L, 400 RPM Pilot Plant, 1500 L, 60-70 RPM<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 23 Stirred Tank Scale-Up

(P/V)large / (P/V)lab<br />

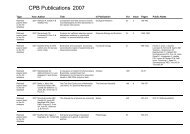

Plant Supplies Campaign<br />

� Analysis of lab and pilot plant<br />

results by different scale-up<br />

parameters<br />

� solid suspension<br />

� shear<br />

� overall energy input<br />

1000<br />

100<br />

10<br />

1<br />

0.1<br />

0.01<br />

Scale-up by constant<br />

mixing time<br />

energy input<br />

solid suspension<br />

shear<br />

heat transfer<br />

Penney Diagram<br />

1.00E+00 1.00E+01 1.00E+02 1.00E+03 1.00E+04<br />

Vplant / Vlab<br />

� Shear and energy input have<br />

� no effect on particle size<br />

� Increased suspension on scale-up:<br />

� no effect on particle size<br />

� slightly narrower PSD<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 24 Stirred Tank Scale-Up<br />

[microns]

� Extrapolation to Manufacturing:<br />

Process Assessment<br />

Jurong V460 (4000 L), 48 RPM<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 25 Stirred Tank Scale-Up

The Voice of Scale-Up Experience<br />

Do Don’t<br />

Collaborate Add solids to a reaction<br />

Log Evaporate to dryness<br />

Sample Use “all in & heat”<br />

Safety test & review Rely on critical timing<br />

Use test Do hot filtrations<br />

Keep it simple Risk all in one batch<br />

McConville, F. X., CEP 103 (2007) 18-19<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 26<br />

Stirred Tank Scale-Up

As Clear as Mud?<br />

"No one will believe you solved this problem in one day!<br />

We've been working on it for months.<br />

Now, go act busy for a few weeks and I'll let you know<br />

when it's time to tell them."<br />

(R&D supervisor, Minnesota Mining and Manufacturing/3M Corp.)<br />

Dr. Clemens <strong>Brechtelsbauer</strong> Slide 27 Stirred Tank Scale-Up