Terluran HH-112 - Promaplast

Terluran HH-112 - Promaplast

Terluran HH-112 - Promaplast

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

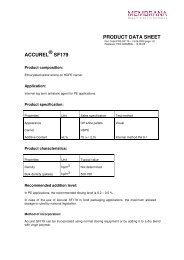

Preliminary Data Sheet09/99 TL <strong>HH</strong>-<strong>112</strong> ABS<strong>Terluran</strong> ® <strong>HH</strong>-<strong>112</strong>Acrylonitrile/Butadiene/Styrene<strong>Terluran</strong> ® <strong>HH</strong>-<strong>112</strong> acrylonitrile/butadiene/styrene copolymer (ABS) is an injection molding grade with very high resistanceto heat deformation. It has high rigidity and medium impact resistance for a broad range of applications.Property Description Method Units <strong>Terluran</strong> <strong>HH</strong>-<strong>112</strong> ABSDensity ASTM D1505 g/cm 3 1.06Melt Volume Rate (Melt Flow Index)220°C/10kgASTM D1238 ml/10 min. 6.00Tensile Strength at Yield, v=50 mm/min ASTM D638 psi (MPa) 8,400 (58)Elongation at Yield ASTM D638 % 3.0Tensile Strength at Break, v=50 mm/min ASTM D638 psi (MPa) 5,700 (39)Tensile Modulus ASTM D638 psi (MPa) 406,000 (2,800)Flexural Strength ASTM D790 psi (MPa) 12,800 (88)Flexural Modulus ASTM D790 psi (MPa) 392,000 (2,700)Notched Izod Impact Strength, 0.125”73°F (23°C)-22°F (-30°C) ASTM D256 ft.lbs./in. (J/m)1.9 (100)1.0 (55)Heat Deflection Temperature at 1.8 MPa (HDT A)4hrs. at 80°C ISO 75-2 °F (°C) 228 (109)Heat Deflection Temperature at 0.45 MPa (HDT B)4hrs. at 80°C ISO 75-2 °F (°C) 237 (114)Vicat Softening Temperature, Rate A, Loading 2 ASTM D1525 °F (°C) 234 (<strong>112</strong>)Values shown are based on limited testing of unmodified, uncolored material (unless otherwise noted) and are not intended to beused in establishing maximum or minimum ranges for specification purposes.Plastics and Fibers

<strong>Terluran</strong> ®Processing<strong>HH</strong>-<strong>112</strong> ABSBASF Performance PlasticsProductsDrying<strong>Terluran</strong> ® <strong>HH</strong>-<strong>112</strong> ABS will attract moisture from theatmosphere, with the rate depending on temperature andhumidity. It is recommended that the material be dried ina dehumidifying dryer at 170°F to 175°F (75°C - 80°C) for2 - 4 hours.RecyclingA maximum of 20% reprocessed material can be addedto the virgin product provided that it has not beencontaminated or previously degraded. The reprocessedmaterial must be dried to prevent any addition of moistureto the virgin material before processing.Not all applications permit the use of regrind. The use ofregrind should be tested for the appropriate mechanicalproperties per the specific molded part and application.Processing TemperaturesInjection temperatures for <strong>Terluran</strong> ® <strong>HH</strong>-<strong>112</strong> ABS liebetween 430°F and 520°F (220°C - 270°C). Moldtemperatures for <strong>Terluran</strong> ® <strong>HH</strong>-<strong>112</strong> ABS lie between105°F and 140°F (40°C - 60°C).Processing PrecautionsAvoid excessive melt temperatures and long residencetimes as this could lead to thermal degradation.For Technical Assistance please call:1-800-527-TECH (1-800-527-8324) or1-734-324-5150 if calling from outside the U.S.© 1999 BASF CorporationBASF Plastic Materials offers a broad range of performance plastics fromwhich users can select an optimum material to meet their requirements.These materials include several types of Ultramid ® polyamides (6, 66, 6/66,6/6T), Ultraform ® acetal copolymer, Ultradur ® polybutylene terephthalates,Luran ® styrene/acrylonitrile, Luran ® S acrylonitrile/styrene/acrylate (ASA)and ASA/polycarbonate blends, <strong>Terluran</strong> ® acrylonitrile/butadiene/styrene,Terlux ® methylmethacrylate/ acrylonitrile/butadiene/styrene, Ultrason ® Epolyethersulfone, and Ultrason ® S polysulfone.Important: While the descriptions, designs, data and informationcontained herein are presented in good faith and believed to be accurate, itis provided for your guidance only. Because many factors may affectprocessing or application/use, we recommend that you make tests todetermine the suitability of a product for your particular purpose prior to use.NO WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED,INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FORA PARTICULAR PURPOSE, ARE MADE REGARDING PRODUCTSDESCRIBED OR DESIGNS, DATA OR INFORMATION SET FORTH,OR THAT THE PRODUCTS, DESIGNS, DATA OR INFORMATION MAYBE USED WITHOUT INFRINGING THE INTELLECTUAL PROPERTYRIGHTS OF OTHERS. IN NO CASE SHALL THE DESCRIPTIONS,INFORMATION, DATA OR DESIGNS PROVIDED BE CONSIDERED APART OF OUR TERMS AND CONDITIONS OF SALE. Further, youexpressly understand and agree that the descriptions, designs, data andinformation furnished by BASF hereunder are provided gratis and BASFassumes no obligation or liability for the description, designs, data andinformation given or results obtained, all such being given and accepted atyour risk.Luran, <strong>Terluran</strong>, Ultradur, Ultraform, Ultramid, and Ultrason are registeredtrademarks of BASF AG.Terlux is a registered trademark of BASF Corporation.BASF CorporationBASF CorporationPlastic MaterialsPlastics Applications Center3000 Continental Drive - North 1609 Biddle AvenueMount Olive, New Jersey 07828-1234 Wyandotte, Michigan 48192Tel: 800-BC-RESIN Tel: 734-324-5105Fax: 973-426-3912 Fax: 734-324-6858BASF CanadaBASF Mexicana S.A. de C.V.345 Carlingview Drive Insurgentes Sur 975Toronto, Ontario M9W 6N9Col. Ciudad de los DeportesCanadaDelegación Benito JuarezTel: 416- 675-361103710 México, D.F.Fax: 416-674-2588MéxicoTel: 011-52-5-325-2624Fax: 011-52-5-611-6751World Wide Web: http://www.basf.com/plasticsBASF SMART FAXAutomated telephone request system to deliver datasheets to you via fax.Dial the phone number below and follow the voice commands.Request document no. 1 for complete listing.800-TOP-FAX1 (734-283-8373 outside the U.S.)Plastics and Fibers