HAYNES ® 230 ® alloy For Power Plant Applications

HAYNES ® 230 ® alloy For Power Plant Applications

HAYNES ® 230 ® alloy For Power Plant Applications

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

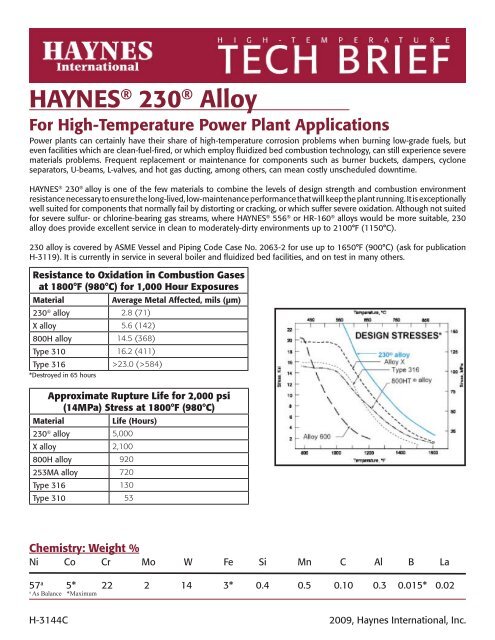

<strong>HAYNES</strong> <strong>®</strong> <strong>230</strong> <strong>®</strong> Alloy<strong>For</strong> High-Temperature <strong>Power</strong> <strong>Plant</strong> <strong>Applications</strong><strong>Power</strong> plants can certainly have their share of high-temperature corrosion problems when burning low-grade fuels, buteven facilities which are clean-fuel-fired, or which employ fluidized bed combustion technology, can still experience severematerials problems. Frequent replacement or maintenance for components such as burner buckets, dampers, cycloneseparators, U-beams, L-valves, and hot gas ducting, among others, can mean costly unscheduled downtime.<strong>HAYNES</strong> <strong>®</strong> <strong>230</strong> <strong>®</strong> <strong>alloy</strong> is one of the few materials to combine the levels of design strength and combustion environmentresistance necessary to ensure the long-lived, low-maintenance performance that will keep the plant running. It is exceptionallywell suited for components that normally fail by distorting or cracking, or which suffer severe oxidation. Although not suitedfor severe sulfur- or chlorine-bearing gas streams, where <strong>HAYNES</strong> <strong>®</strong> 556 <strong>®</strong> or HR-160 <strong>®</strong> <strong>alloy</strong>s would be more suitable, <strong>230</strong><strong>alloy</strong> does provide excellent service in clean to moderately-dirty environments up to 2100°F (1150°C).<strong>230</strong> <strong>alloy</strong> is covered by ASME Vessel and Piping Code Case No. 2063-2 for use up to 1650°F (900°C) (ask for publicationH-3119). It is currently in service in several boiler and fluidized bed facilities, and on test in many others.Resistance to Oxidation in Combustion Gasesat 1800°F (980°C) for 1,000 Hour ExposuresMaterialAverage Metal Affected, mils (µm)<strong>230</strong> <strong>®</strong> <strong>alloy</strong> 2.8 (71)X <strong>alloy</strong> 5.6 (142)800H <strong>alloy</strong> 14.5 (368)Type 310 16.2 (411)Type 316 >23.0 (>584)*Destroyed in 65 hoursApproximate Rupture Life for 2,000 psi(14MPa) Stress at 1800°F (980°C)MaterialLife (Hours)<strong>230</strong> <strong>®</strong> <strong>alloy</strong> 5,000X <strong>alloy</strong> 2,100800H <strong>alloy</strong> 920253MA <strong>alloy</strong> 720Type 316 130Type 310 53Chemistry: Weight %Ni Co Cr Mo W Fe Si Mn C Al B La57 a 5* 22 2 14 3* 0.4 0.5 0.10 0.3 0.015* 0.02aAs Balance *MaximumH-3144C 2009, Haynes International, Inc.

<strong>HAYNES</strong> <strong>®</strong> <strong>230</strong> <strong>®</strong> AlloyTypical Tensile Properties Solution Annealed (Plate):TestTemperatureUltimateTensile Strength0.2% YieldStrengthElongation in2 in (51mm)°F (°C) Ksi (MPa) Ksi (MPa) %Room (Room) 125 (860) 57 (395) 501000 (540) 103 (705) 40 (275) 531200 (650) 98 (675) 40 (275) 551400 (760) 88 (605) 42 (275) 531600 (870) 63 (435) 37 (255) 651800 (980) 35 (240) 21 (145) 832000 (1095) 20 (140) 11 (76) 832100 (1150) 13 (91) 7 (47) 1062200 (1205) 9 (65) 4 (30) 109Typical Rupture Properties (Plate):TemperatureTypical Rupture Properties: Stress Required toProduce Rupture in Hours Shown, Ksi (MPa)°F (°C) 100 1,000 10,0001200 (650) 56.0 (385) 42.5 (295) 29.0 (200)1400 (760) 27.0 (185) 20.0 (140) 14.2 (98)1600 (870) 13.7 (95) 9.5 (66) 6.2 (43)1800 (980) 6.0 (41) 3.0 (21) 1.6 (11)1900 (1040) 3.5 (24) 1.8 (12) -2000 (1095) 2.1 (14) 1.0 (7) -2100 (1150) 1.2 (8) 0.6 (4) -Typical Room Temperature Physical Properties:British UnitsMetric UnitsDensity 0.324 lb/in 3 8.97 g/cm 3Electrical Resistivity 49.2 µohm-in 125 µohm-cmDynamic Modulus of Elasticity 30.6 x 10 6 psi 211 GpaThermal Conductivity 62 Btu-in/ft 2 -hr-°F 8.9 W/m-KSpecific Heat 0.095 Btu/lb.-°F 397 J/Kg-KEnvironmental Resistance:Oxidation in Air - Excellent at 2100°F (1150°C)Hydrogen Embrittlement - ExcellentNitriding - Best Commercial AlloyCarburization - Equal to Alloy XSulfidation - Equal to Alloy XChlorination - Equal to Alloy 625The data and information in this publication are based on work conducted principally by Haynes International, Inc. and are believed tobe reliable. However, we do not make any warranty or assume any legal liability or responsibility for its accuracy, completedness, orusefulness. Nor do we represent that Its use would not Infringe upon private rights. Any suggestions as to uses and applications forspecific <strong>alloy</strong>s are opinions only and Haynes International, Inc. makes no warranty of results to be obtained in any particular situation.1020 W. Park Ave P.O. Box 9013 Kokomo, Indiana USA 46904-9013Telephone: 765-456-6012 800-354-0806 FAX: 765-456-6905 haynesintl.com