Trucking Executive Thought Leaders - Inbound Logistics

Trucking Executive Thought Leaders - Inbound Logistics

Trucking Executive Thought Leaders - Inbound Logistics

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

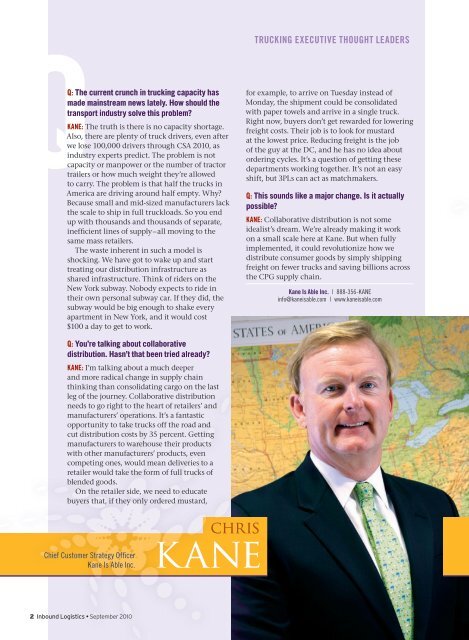

QQ: The current crunch in trucking capacity hasmade mainstream news lately. How should thetransport industry solve this problem?Kane: The truth is there is no capacity shortage.Also, there are plenty of truck drivers, even afterwe lose 100,000 drivers through CSA 2010, asindustry experts predict. The problem is notcapacity or manpower or the number of tractortrailers or how much weight they’re allowedto carry. The problem is that half the trucks inAmerica are driving around half empty. Why?Because small and mid-sized manufacturers lackthe scale to ship in full truckloads. So you endup with thousands and thousands of separate,inefficient lines of supply – all moving to thesame mass retailers.The waste inherent in such a model isshocking. We have got to wake up and starttreating our distribution infrastructure asshared infrastructure. Think of riders on theNew York subway. Nobody expects to ride intheir own personal subway car. If they did, thesubway would be big enough to shake everyapartment in New York, and it would cost$100 a day to get to work.trucking executive THOUGHT LEADERSfor example, to arrive on Tuesday instead ofMonday, the shipment could be consolidatedwith paper towels and arrive in a single truck.Right now, buyers don’t get rewarded for loweringfreight costs. Their job is to look for mustardat the lowest price. Reducing freight is the jobof the guy at the DC, and he has no idea aboutordering cycles. It’s a question of getting thesedepartments working together. It’s not an easyshift, but 3PLs can act as matchmakers.Q: This sounds like a major change. Is it actuallypossible?Kane: Collaborative distribution is not someidealist’s dream. We’re already making it workon a small scale here at Kane. But when fullyimplemented, it could revolutionize how wedistribute consumer goods by simply shippingfreight on fewer trucks and saving billions acrossthe CPG supply chain.Kane Is Able Inc. | 888-356-KANEinfo@kaneisable.com | www.kaneisable.comQ: You’re talking about collaborativedistribution. Hasn’t that been tried already?Kane: I’m talking about a much deeperand more radical change in supply chainthinking than consolidating cargo on the lastleg of the journey. Collaborative distributionneeds to go right to the heart of retailers’ andmanufacturers’ operations. It’s a fantasticopportunity to take trucks off the road andcut distribution costs by 35 percent. Gettingmanufacturers to warehouse their productswith other manufacturers’ products, evencompeting ones, would mean deliveries to aretailer would take the form of full trucks ofblended goods.On the retailer side, we need to educatebuyers that, if they only ordered mustard,Chief Customer Strategy OfficerKane Is Able Inc.ChrisKane2 <strong>Inbound</strong> <strong>Logistics</strong> • September 2010