Refrigeration Manual - HVAC and Refrigeration Information Links

Refrigeration Manual - HVAC and Refrigeration Information Links

Refrigeration Manual - HVAC and Refrigeration Information Links

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

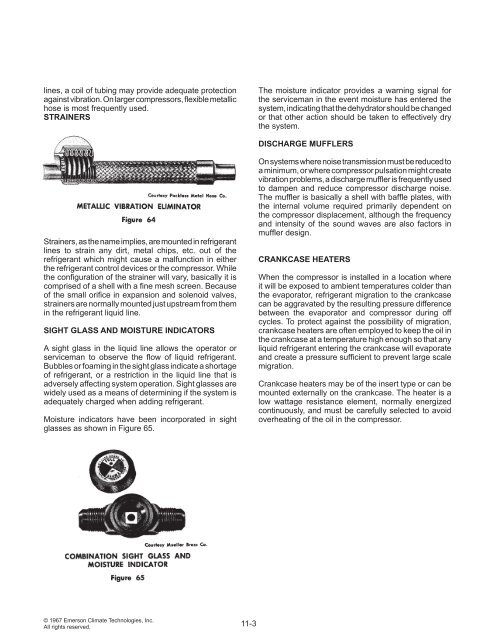

lines, a coil of tubing may provide adequate protectionagainst vibration. On larger compressors, flexible metallichose is most frequently used.STRAINERSThe moisture indicator provides a warning signal forthe serviceman in the event moisture has entered thesystem, indicating that the dehydrator should be changedor that other action should be taken to effectively drythe system.DISCHARGE MUFFLERSStrainers, as the name implies, are mounted in refrigerantlines to strain any dirt, metal chips, etc. out of therefrigerant which might cause a malfunction in eitherthe refrigerant control devices or the compressor. Whilethe configuration of the strainer will vary, basically it iscomprised of a shell with a fine mesh screen. Becauseof the small orifice in expansion <strong>and</strong> solenoid valves,strainers are normally mounted just upstream from themin the refrigerant liquid line.SIGHT GLASS AND MOISTURE INDICATORSA sight glass in the liquid line allows the operator orserviceman to observe the flow of liquid refrigerant.Bubbles or foaming in the sight glass indicate a shortageof refrigerant, or a restriction in the liquid line that isadversely affecting system operation. Sight glasses arewidely used as a means of determining if the system isadequately charged when adding refrigerant.Moisture indicators have been incorporated in sightglasses as shown in Figure 65.On systems where noise transmission must be reduced toa minimum, or where compressor pulsation might createvibration problems, a discharge muffler is frequently usedto dampen <strong>and</strong> reduce compressor discharge noise.The muffler is basically a shell with baffle plates, withthe internal volume required primarily dependent onthe compressor displacement, although the frequency<strong>and</strong> intensity of the sound waves are also factors inmuffler design.CRANKCASE HEATERSWhen the compressor is installed in a location whereit will be exposed to ambient temperatures colder thanthe evaporator, refrigerant migration to the crankcasecan be aggravated by the resulting pressure differencebetween the evaporator <strong>and</strong> compressor during offcycles. To protect against the possibility of migration,crankcase heaters are often employed to keep the oil inthe crankcase at a temperature high enough so that anyliquid refrigerant entering the crankcase will evaporate<strong>and</strong> create a pressure sufficient to prevent large scalemigration.Crankcase heaters may be of the insert type or can bemounted externally on the crankcase. The heater is alow wattage resistance element, normally energizedcontinuously, <strong>and</strong> must be carefully selected to avoidoverheating of the oil in the compressor.© 1967 Emerson Climate Technologies, Inc.All rights reserved.11-3