Refrigeration Manual - HVAC and Refrigeration Information Links

Refrigeration Manual - HVAC and Refrigeration Information Links

Refrigeration Manual - HVAC and Refrigeration Information Links

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

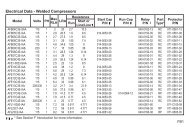

will be maintained. As soon as a stabilized condition isreached, <strong>and</strong> liquid refrigerant is no longer reaching thepump, the oil pressure will return to normal.DRY AIR HOLDING CHARGEAll Copel<strong>and</strong>® br<strong>and</strong> compressors are thoroughlydehydrated at the factory, <strong>and</strong> are shipped with a dry airholding charge. The pressure inside a factory processedcompressor is a guarantee that the compressor is leaktight, <strong>and</strong> the interior is absolutely dry. When installed,the compressor must be evacuated to remove the airfrom the system.compressors have been developed for increasedefficiency when evaporating temperatures are in the-30° F. to -80° F. range.Two stage compressors are divided internally into low(or first) <strong>and</strong> high (or second) stages. On Copelametic®two stage compressors now in production, the ratio oflow stage to high stage displacement is 2 to 1. The threecylinder models have two cylinders on the low stage <strong>and</strong>one on the high, while the six cylinder models have fourcylinders on the low <strong>and</strong> two on the high.COMPRESSOR COOLINGAir cooled compressors require an adequate flowof cooling air over the compressor body to preventthe compressor from overheating. The air flow fromthe fan must be discharged directly on the motorcompressor.Air drawn through a compartment in whichthe compressor is located usually will not cool thecompressor adequately.Water cooled compressors are provided with a waterjacket or wrapped with a copper water coil, <strong>and</strong> watermust be circulated through the cooling circuit when thecompressor is in operation.Refrigerant cooled motor-compressors are designedso that suction gas flows around <strong>and</strong> through themotor for cooling. At evaporating temperatures below0° F. additional motor cooling by means of air flow isnecessary since the decreasing density of the refrigerantgas reduces its cooling ability.COMPRESSOR CAPACITYCapacity data is available from the manufacturer oneach model of compressor for the refrigerants with whichthe compressor can be used. This data may be in theform of curves or in tabular form, <strong>and</strong> lists the BTU/hr.capacity at various saturated suction <strong>and</strong> dischargetemperatures.It is difficult to estimate compressor capacities accuratelyon the basis of displacement <strong>and</strong> compression ratiobecause of design differences between different models,but occasionally these factors can be valuable inestimating the comparative performance of compressorson the same application.TWO STAGE COMPRESSORSBecause of the high compression ratios encounteredin ultra-low temperature applications, two stageThe suction gas enters the low stage cylinders directlyfrom the suction line, <strong>and</strong> is discharged into the interstagemanifold at interstage pressure. Since the interstagedischarge vapor has a relatively high temperature,liquid refrigerant must be metered into the interstagemanifold by the desuperheating expansion valve toprovide adequate motor cooling <strong>and</strong> prevent excessivetemperatures during second stage compression. Thedischarge of the low stage enters the motor chamber<strong>and</strong> crankcase, so the crankcase is at interstagepressure.Desuperheated refrigerant vapor at interstage pressureenters the suction ports of the high stage cylinders, <strong>and</strong>is then discharged to the condenser at the condensingpressure.See Figures 6 <strong>and</strong> 7 on pages 3-6 <strong>and</strong> 3-7 of Part Ifor typical two stage systems.© 1967 Emerson Climate Technologies, Inc.All rights reserved.4-6