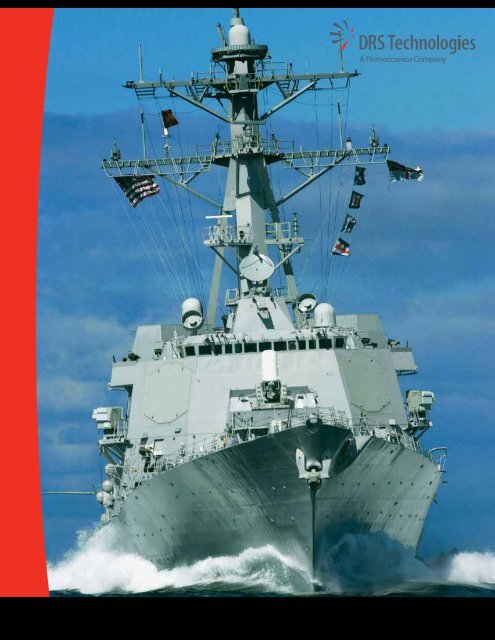

Integrated Marine Systems Catalog DRS TECHNOLOGIES

Integrated Marine Systems Catalog DRS TECHNOLOGIES

Integrated Marine Systems Catalog DRS TECHNOLOGIES

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Some images herein are U.S. Navy Photos. No endorsement expressed or implied.

Thank you for choosing <strong>DRS</strong> to meet your system needs. <strong>DRS</strong>’offerings are vast and range from core hardware and softwareproducts to complete system integration and installationservices. This <strong>Integrated</strong> <strong>Marine</strong> <strong>Systems</strong> catalog provides anoverview of readily available products and services, amongthem: Propulsion System Integration, Power Distribution,Power Conversion, Heating Ventilation Air Conditioning andRefrigeration, Machinery Plant Controls, Power Conditioning,Electric Motors and Turbo Machinery.The offerings in this catalog touch on <strong>DRS</strong>’ product and designcapabilities. Our full service approach includes a team ofproduct and system experts who are skilled at guiding youthrough the process of defining, designing and meeting yourcomponent or system needs.This catalog combines the former Ship <strong>Systems</strong> catalog of<strong>DRS</strong> Power & Control Technologies with the products andcapabilities of <strong>DRS</strong> Marlo Coil, <strong>DRS</strong> Pivotal Power and <strong>DRS</strong>Power Technology. In addition to expanding the offerings foundin this catalog, you will find full color photos of our products,and site specific contact information to connect you directlywith the product specialist.For those familiar with the former Ship Controls <strong>Systems</strong> <strong>Catalog</strong>you will find the Motor Controllers & Accessories section to belargely reflective of that catalog, with part numbering and pagedesigns that reflect the history of product presentation for easeof use.<strong>DRS</strong> is ready to serve with a long history of successfully fieldedproduct and a talented and creative design team.Contact information by product area is found to the right on this page. Toinquire further or place an order, simply contact the facility by phone orvia email. To expedite response to your request please provide us with thefollowing upon inquiry:• Your name• Your contact telephone number and email address• The name of your organization• The country in which your organization resides• The product description and, if applicable, the catalogpage number upon which it appearsA product specialist will contact you directly within 24 hours of your receiptof your inquiry.NEW PRODUCTS<strong>DRS</strong> Power & Control Technologies, Inc.4265 N. 30th Street, Milwaukee, WI 53216Phone: 414.875.2900 Fax: 414.875.4319Email: IMS-BD@drs.comMotor Control AND OPERATOR INTERFACESpecification AND DOCUMENTS<strong>DRS</strong> Power & Control Technologies, Inc.4265 N. 30th Street, Milwaukee, WI 53216Phone: 800.552.2829 Fax: 414.875.4764Email: IMS-BD@drs.comMOTOR Control and Operator Interface<strong>DRS</strong> Power & Control Technologies, Inc.4265 N. 30th Street, Milwaukee, WI 53216Phone: 800.552.2829 Fax: 414.875.4764Email: IMS-BD@drs.comPower Solutions<strong>DRS</strong> Pivotal Power, Inc.150 Bluewater Rd., Bedford, NS B4B 1G9Phone: 902.835.7268 Fax: 902.835.6026Email: info@pivotalpower.comHeating, Ventilating,Air Conditioning & REFRIGERATION<strong>DRS</strong> Marlo Coil6060 Highway PP, High Ridge, MO 63049-0171Phone: 636.677.6600 Fax: 636.677.1203Email: marlo.navysales@drs.comPermanent Magnet MotorsTURBO MACHINERY<strong>DRS</strong> Power Technology, Inc.166 Boulder Drive, Suite 201E, Fitchburg, MA 01420Phone: 978.353.5500 Fax: 978.353.5107Email: powertechnology.info@drs.comUpdated list prices and PDF version of this catalog are available at <strong>DRS</strong>.com. 3

Description Type Pages Description Type PagesPilot Devices and Other ItemsSeparate Flush Mounting Pushbuttonsand Indicating Lights 6981ED165 66-686981ED166 66-68Replacement Indicating Light Transformers 69Separate Flush MountingSelector Switches 6981ED200 70-71Watertight Remote Control Stations 6981 72-76Explosion-Proof RemoteControl Stations 6981 77-78Cast Brass Watertight RemoteControl Stations 6981 79-80“Emergency Stop” PushbuttonStations 6981 81Flush Mounting Drum Type Transferor Selector Switch 6982-T5 82Drum Type Transfer or Selector Switch 6982-T5 83-84Cam Type Master Switch 6982-T8 85Pedestal Mounted Cam TypeMaster Switch 6982-T9 86Snap Action Limit Switches 6984NL 87-89Silicon Bronze Explosion Proof /Watertight Limit Switches 6984NLX-W 90Snap Action Limit Switch 6984-T11/T1291-94Geared Type Limit Switch 6984 95Overtemperature Monitor 6991 96Overspeed Trip Drive 6999 97Navy Control Circuit Wiring 98Navy Power Terminal Blocks,100, 150 and 300 Amperes 993 KVA AC UPS 1056 KVA AC UPS 106Helicopter Starter 107<strong>DRS</strong> Trusted Series 108-109Forklift Battery Charger 110Heating, Ventilating, Air Conditioning& REFRIGERATIONVentilation Heaters S21X-T38X 113Unit Coolers UW51-55 114Cooling Coils (50 Series) DW51-58 115Cooling Coils (60 Series) DW61-68 116Fan Coil Assemblies FCA 117Fan Coil Units FCU H/V 118Spruance Class Fan Coil Units FCU 1-9 119Unit Heaters 11-16 120Gravity Cooling Coils GW/GF 1,3 & 5 121Permanent Magnet MOTORSElectric Ship Propulsion Motors 123Hybrid Electric Ship Propulsion Motors/Generators 124Permanent-Magnet Axial Air Core (PAAC)Motors and Generators 125Permanent-Magnet Axial (PA) Series PMMotors and Generators 126Permanent-Magnet Radial FieldEmbedded Magnet (PRE) Series Motors 127Rotating Machinery Packaging — SteamTurbine Design, Assembly and Repair 128Power Solutions0.8 KW DC UPS 1012.4 KW DC UPS 1021.0 KW DC Rectifier 1032 KVA AC UPS 104Updated list prices and PDF version of this catalog are available at <strong>DRS</strong>.com. 5

<strong>Integrated</strong> <strong>Marine</strong> <strong>Systems</strong>Propulsion <strong>Systems</strong> Integration and Power Distribution<strong>DRS</strong> has extensive marine systems experience showcasingcapabilities developed through a century of proudly servingthe U.S. Navy and our international allies. Whether it’s designand/or selection of a single component or full integration ofevery aspect of a marine propulsion system, our <strong>Integrated</strong><strong>Marine</strong> <strong>Systems</strong> (IMS) team is focused on developing anddeploying the most advanced power generation, conversion,distribution, and propulsion control technology in the world.Our product is designed and manufactured to meet stringentstandards for reliability, durability and maintainability. Amongthe standards used are: Military Specifications (MIL-SPEC),American Bureau of Shipping (ABS), Institute of Electrical andElectronics, Engineers(IEEE) standards, ISOCertified - 9001 and14001.As customer-centricpartners <strong>DRS</strong>listens and deliverssolutions through allproduct offerings.Our commitment toexecution excellence, technologyinnovation and broadly diversifiedvendor partnerships ensuresdeployment of superior marinesystems, transforming the navaland marine forces of today into highly equipped and versatilewar fighters of tomorrow.Our IMS product and services portfolio is broad andadaptable including:Propulsion System Integration<strong>DRS</strong>’ comprehensive approach to propulsion systemintegration encompasses design, assembly, test, installationand support. Leveraging our significant experience incomponent design and system deployment, our productsand systems can be found on a variety of ship classesranging in complexity from nuclear submarines to surfacecombatant support ships.Power Distribution<strong>DRS</strong> provides equipment and systems across the fullspectrum of shipboard power distribution need includingmedium and low voltage switchboards and load centers,hardened circuit breakers, and integrated powermanagement systems.Our new <strong>Integrated</strong> Fight-Through Power (IFTP) system isa redundant power conversion-based zonal power systemdesigned to support requirements for growing powerefficiency demands on future navy ships.Machinery Plant Control andMonitoring <strong>Systems</strong>Our innovative solutions for naval machinery control,automation and networking include ruggedized COTStechnology qualified for shock, vibration, acoustic andEMI requirements. Existing, fielded, and fully qualified <strong>DRS</strong>products include:• Server/Network Cabinets• Logic Processors• Data Acquisition Units• Displays/WorkstationsOpen Architecture Software: OpenSea Developed by <strong>DRS</strong> for naval and marine applications,OpenSea provides the ultimate in open architecture,platform-independent distributed control system (DCS)software. Simple, flexible integration enables improvedlogistical support, enhanced crew training and reducedmanning. Redundant communication assures completecommunication among all major systems.Design | Analyze | Select | Package

Motor Controls and DrivesProudly fielded on every U.S. Navalcombatant since WWII, <strong>DRS</strong>motor control products are provenperformers in harsh marineenvironments. Our rugged variablespeed drives (VSDs) can befound wherevervariable speed/frequency is a keyoperating parameter.We provide a widerange of reliablemotor control anddrive offerings to ourcustomers by leveragingour strong engineering capabilities, fullunderstanding of applicable MIL-SPECs andexperience gained from a history of successful products.Propulsion and Power GenerationPower-dense <strong>DRS</strong> Permanent Magnet (PM) machines offerinnovative solutions for direct drive ship propulsion, hybridelectric drive and power generation for auxiliary systems.Our unique set of core competencies enables us to develop awide range of PM machines in radial and axial-field topologiesthat meet tough standards for military and commercialapplications.PM motors and generatorshave significant advantagesin size, weight and power overconventional motors. They areideal for dimension and/orweight constrained applications wheresignificant torque, high efficiency andprecise control across load and speed variations are essential.Rotating Machinery PackagingAs a full-service equipment packager we have designed and/or assembled aero-derivative gas turbine packages using eachmajor engine manufacturers’ products. These units are inservice in naval and ground power applications around the world.Whether build-to-print production or more extensive systemspackaging is required <strong>DRS</strong> is readyto meet the needs of anymachinery packagingproject.Shipboard Power Conversion and Conditioning<strong>DRS</strong> power conversion and conditioning systems meetstringent specifications and have been proven to performin harsh marine environments that can include extremetemperatures, humidity and high shock and vibration. Ourproducts include variable frequency converters; DC rectifiersfor helicopter starting; portable multiple-battery chargers andreliable uninterruptible power supply (UPS) systems for poweringcritical command, control, communication and navigationequipment on-board naval and marine ships.Heating, Ventilation, Air Conditioningand Refrigeration (HVAC/R)Shipboard environments require proper control over a wide rangeof temperatures to support sailors, systems, ships stores andfire suppression. <strong>DRS</strong> has extensive experience designing andmanufacturing rugged HVAC/Requipment specifically for shipapplications. Our Naval productsare designed to U.S. militaryspecifications and our commercialmarine products are designed to U.S.Coast Guard and American Bureau ofShipping regulations. We offer HVACequipment in many standardsizes and configurations as wellas program specific designs forunique applications.<strong>Integrated</strong> Logistical Support (ILS)<strong>DRS</strong>’ dedication to ILS requirements assures reliability,availability, maintainability and testability across all productlines, including military, commercial, consumer and industrialcustomers. Our capabilities enable us to provide life-cyclesupport for <strong>DRS</strong> manufactured equipment and to tailor specificILS elements to meet unique requirements. <strong>DRS</strong> staff isexperienced and can provide high-quality solutions to meet alllogistics requirements.Life Cycle Support<strong>DRS</strong> provides unequalled technical and post-delivery support.Our world-wide network of <strong>DRS</strong> professionals enable us to havequalified personnel on-location, to any location worldwide within36 hours.We stand ready to meet your system, component or serviceneeds. Contact us at drs.com for more information.| Install | Test | Support | Maintain 7

NEW PRODUCTS<strong>DRS</strong> drives success through innovation and excellence, with a century oftradition and performance providing power and control onboard every Navycombatant since World War II.At the heart of <strong>DRS</strong> success is our evolutionary design process, utilizing,integrating and improving the very best innovations across product lines andthrough successive iterations.Our products and services are found in fully integrated marine systems,ship propulsion and power generation, power distribution conversion andconditioning, as well as motor controls and drives, auxiliary motors andgenerators and shipboard HVAC.For our customers, our depth of experience and breadth of knowledge meansbattle-hardened dependability of parts, components and systems that meet allapplicable specifications and our own stringent quality requirements.

NEW PRODUCTSMIL-SPEC Process Controllers (MSPC)Highlights• Distributed system architecture control• Efficient and robust operation• Autonomous control• Expandable analog and discrete I/O• Expandable LED display• Analog readout displays• System diagnostics• Remote PROFIBUS communication• Navy electronic motor operator- Custom thermal overload trip curves- Full load current sensing from 0.5 to 150 Amps- Voltage sensing from 50 to 550 VoltsMilitary SpecificationsMIL-STD-461MIL-S-901, Grade AMIL-STD-167-1, 4-50 Hz<strong>DRS</strong> is the leader in providing MIL-SPEC solutions for thedemanding maritime market. The latest technology is used inour innovative designs. The self contained Process Controllerintegrates military off the shelf equipment with a MIL-SPECmotor controller to provide a small, lightweight, and costeffective solution. Utilized on the latest U.S. Navy ships forpump controls, the MIL-SPEC qualified Process Controller isdesigned to withstand rugged maritime conditions for the lifeof the ship.Whether for new shipbuilding or modernization programsMSPC is ideal for integrated control, condition basedmaintenance, power monitoring, and interfacing with shipnetwork communications.Controls and indicators are functionally grouped on thecontroller to optimize the human interface, visibility, and easeof use.From power distribution and electrical control productsto ship control automation, <strong>DRS</strong> offers advanced productdevelopment, world-class manufacturing and globalengineering services and support. That is why our productsare found on all U. S. Navy ships since WWII.Monitors• Current• Voltage• Line frequency• Apparent power• Real power• Reactive power• Power factor• Percent FLA• Percent nominal RMS voltage• Elapsed run time• Start count• Run time since startProtective Feature(Can be set as a trip or alarm)• Under current• Over current• Motor JAM trip level• Current imbalance• Under voltage• Over voltage• Voltage imbalance• Single phasing current trip level• Single phasing voltage trip levelUpdated list prices and PDF version of this catalog are available at <strong>DRS</strong>.com. 9

NEW PRODUCTSNavy Electronic Motor Operator(NEMO)NEMO is a product enhancement of our existingN2000 and N2001 products.<strong>DRS</strong>’s Navy Electronic Motor Operator answers the call formodern ship specifications requiring small, simplistic, costeffective and flexible control and communications. Utilizedon the latest U.S. Navy ships for motor control, HVAC control,and ABT control, the MIL-SPEC qualified Navy Electronic MotorOperator is designed to withstand rugged maritime conditionsfor the life of the ship.The <strong>DRS</strong>-PCT Navy Electronic Motor Operator (NEMO) iscomprised of an Electronic Control Module, an OverloadApplication Module, and a solid state Switch module. NEMOintegrates control, motor protection, power monitoring,network communications and local network I/O into a singleunit in accordance with MIL-DTL-2212. NEMO supplies 24VDCfor safe operator control. Configurable discrete inputs andoutputs are provided to satisfy most control applications.An LED display provides operating status, diagnostic andfault information. Two sets of parameters allow one moduleto protect fast and slow speed windings of a motor or toenergize/de-energize two separate loads. All interfaces tothe main power are galvanically isolated to ensure integrity ofthe main bus. The network connection design is modular andadaptable to meet current and future Navy machinery controlnetwork protocols.Features• Configurable control via mini USB port• Adapatble network communication• Local CAN network for I/O expansion• Four character LED display for status• Field upgradeable firmware• Operator safe 24VDC I/O• 5 inputs for control/monitor• 4 outputs for control/timing/alarm• MTBF – 188,000 Hrs at 40° C• Pluggable control terminals• Stud terminals for main power• Galvanic isolation to power lines• Dual parameter sets for fast and slowmotor winding protectionSpecificationsMIL-DTL-2212, including• MIL-STD-461, Surface / Submarine• MIL-S-901, Grade A• MIL-STD-167-1, 33 Hz• MIL-STD-1399, Section 300AEnvironmental PerformanceOperating temperature .......................................... -20 to 65° COperating humidity ................................ 95% Non-condensingStorage temperature .............................................. -40 to 85° CFunctional Ratings(Ratings are nominal unless stated)Power CharacteristicsSupply voltage .............................................................. 440 VACOptional ..................................................................... 115 VACSupply frequency .............................................................. 60 HzSupply isolation (1 minute) ....................................... 2500 VACCurrent sensing ................................................. 0.5 to 30 ArmsOptional ........................................................ 1.2 to 150 ArmsControl CharacteristicsI/O power supply voltage ............................................... 24 VDCI/O power supply capacity ................................................ 20 WInput on state voltage .......................................... 17 to 36 VDCInput on state burden ................................................. 17 mADCInput isolation to chassis ............................................ 500 VDCOutput voltage .............................................. 36 VDC maximumOutput load current ..................................... 100 mA maximumOutput leakage current .................................................. 0.1 mAVoltage drop ....................................................... 0.15 VDC MaxOutput isolation to chassis ......................................... 500 VDCPhysical CharacteristicsFour corner mounting holes......... 0.3 inch (0.8 cm) thick baseWeight................................................................7.7 lbs. (3498 g)Related DocumentationNEMO operation manual.....................................MC-007067/01NEMO engineering configuration tool manual.....MC-002410/23Switch module application manual........................MC-00705510New Products

Navy Electronic Motor Operator(NEMO)Navy Electronic Motor Operator ModelsApplication Current Sensing Control Voltage AssemblyOverload 0.5-30 Internal 440 MC-009557-01External 440 MC-009557-07115 MC-009557-051.2-150 Internal 440 MC-009557-04External 440 MC-009557-08115 MC-009557-06HVAC control 0.5-30 Internal 440 MC-009557-02HVAC monitoringMC-009557-03Bus transfer switch 0.5-30 External 115 MC-009557-09Automatic bus transferMC-009557-104265 N. 30th Street, Milwaukee, WI 53216 | Phone 414.875.2900 | Fax 414.875.4319 | Email IMS-BD@drs.com11

Type ENG-DAU-1Data Acquisition UnitEngineered <strong>Systems</strong>Small Remote Terminal Unit – Single ChassisParameterMax # of I/OCards CapacityType and Capacity I/ODescription(2) x 10 Slot ChassisTypical I/O Is a combo of those below:Max Discrete AC Input – 192Max Discrete AC Output – 96Max Discrete DC Input – 192Max Discrete DC Output – 192Max Analog Input – 48Max RTD/Thermo Input - 36Max Analog Output - 4817561756 XTRockwell Automation1794Vendor I/O Supported1794 XT1734When ordering specify• Power requirements• I/O type• Fieldbus type• Network and fieldbus media type• Redundancy requirements• Ethernet requirements• Number and type of analog I/O• Number and type of digital I/O• Number and type of specialty I/O• Number and type of communication I/O• Visual display/Human Machine Interface requirements• Required environmental qualifications• Required IMO certificationsField BusSiemensRockwell Automation:SiemensS7-300ET200MControlNetDeviceNetEthernet/IPProfiBusModbusModbus/TCPProfibusCanBusProfiNetModbusModbus/TCPGeneralA small, application flexible, MIL-SPEC grade I/O enclosure forengineered naval and marine machinery control applications.Supports both Rockwell Automation and Siemens Hardware.SpecificationsParameterEnclosure DimensionsEnclosure WeightEnclosure TypePower SupplyDescriptionEnclosure: H 22.82” x W 17.5” X D 10.6”Mountings: H 28.39” x W 20.0” X D 15.94”Door Open: H 28.39” x W 21.7” X D 32.42”UnpopulatedPopulatedDrip-proof type120V/220V AC24V DCRedundancyOptionalMediaOptionalProtocolsTCP/IP, UDP# of Ports OptionalEthernetRedundancyOptionalMediaOptional*MIL-STD 901D*MIL-STD 167-1MIL-SPEC*MIL-STD 461*MIL-STD 1399*MIL-STD 8100-60°C OperatingTemperature-20-70°C Operating with Extreme TemperatureI/O ModulesHumidity5-95% Noncondensing* Designed to specifications12New Products

Type ENG-DAU-1Data Acquisition UnitFeatures• Power supply• Optional processor• Fieldbus communications• (1) I/O chassis• Industry standard I/O modules• Internal terminal blocks for field wiring• External power connection with fusing and filtering• Optional signal conditioning• Optional local ethernet switch with downlink and local ports• Optional field bus and ethernet redundancy• Optional fiber optic field bus• Optional in chassis industrial PC• Optional panel mounted LCD display• Optional OpenSea control softwareTypical Writing DiagramDimensional Diagram4265 N. 30th Street, Milwaukee, WI 53216 | Phone 414.875.2900 | Fax 414.875.4319 | Email IMS-BD@drs.com13

Type ENG-DAU-2Data Acquisition UnitEngineered <strong>Systems</strong>Large Remote Terminal Unit – Three ChassisWhen ordering specify• Power requirements• I/O Type• Field bus type• Media• Redundancy requirements• Ethernet requirements• Number and type of analog I/O• Number and type of digital I/O• Number and type of specialty I/O• Number and type of communication I/O• Required environmental qualifications• Required IMO certificationsGeneralA large, application flexible, MIL-SPEC grade I/O enclosure forengineered naval and marine machinery control applications.Supports both Rockwell Automation and Siemens Hardware.SpecificationsParameterEnclosure DimensionsEnclosure WeightEnclosure TypePower Supply14New ProductsDescriptionEnclosure: H 48.0” x W 27.0” X D 12.24”Mountings: H 48.0 x W 27.0” x D 17.99Door Open: H 48.0” x W 53.0” X D 17.99”UnpopulatedPopulatedDrip-proof type120V/220V AC24V DCParameterDescriptionMax # of I/O(3) x 10 Slot ChassisCards CapacityTypical I/O Is a combo of those below:Max Discrete AC Input – 864Max Discrete AC Output – 432Max Discrete DC Input – 864Type and Capacity I/OMax Discrete DC Output – 864Max Analog Input – 432Max RTD/Thermo Input - 162Max Analog Output - 21617561756 XTRockwell Automation 1794Vendor I/O Supported1794 XT1734S7-300SiemensET200MControlNetDeviceNetEthernet/IPRockwell Automation:ProfiBusModbusModbus/TCPField BusProfibusCanBusSiemensProfiNetModbusModbus/TCPRedundancyOptionalMediaOptionalProtocolsTCP/IP, UDP# of Ports OptionalEthernetRedundancyOptionalMediaOptional*MIL-STD 901D*MIL-STD 167-1MIL-SPEC*MIL-STD 461*MIL-STD 1399*MIL-STD 8100-60°C OperatingTemperature-20-70°C Operating with Extreme TemperatureI/O ModulesHumidity5-95% Noncondensing* Designed to specifications

Type ENG-DAU-2Data Acquisition UnitFeatures• Power supply• Optional processor• Fieldbus communications• (3) I/O chassis’s• Industry standard I/O modules• Internal terminal blocks for field wiring• External power connection with fusing and filtering• Optional signal conditioning• Optional local ethernet switch with downlink and local ports• Optional field bus and ethernet redundancy• Optional fiber optic field bus• Optional in chassis industrial PC• Optional panel mounted LCD display• Optional OpenSea control softwareTypical Writing DiagramDimensional Diagram4265 N. 30th Street, Milwaukee, WI 53216 | Phone 414.875.2900 | Fax 414.875.4319 | Email IMS-BD@drs.com15

<strong>DRS</strong> 15kV VCBVacuum Circuit Breaker (VCB)Military SpecificationsMIL-S-901, Grade AMIL-STD-167-1, 4-21 HzMIL-STD-461MIL-STD-1399-300APhysical CharacteristicsCircuit breaker:Width.........................................................27.6 inches (70.1 cm)Height.......................................................32.2 inches (81.8 cm)Depth.......................................................25.1 inches (63.8 cm)Weight...........................................................430 lbs. (195.0 kg)Environmental PerformanceOperating temperature......................................... -30 to +65° COperating humidity.................................. 95% Non-condensingThe <strong>DRS</strong> 15kV VCB is a 1600 A medium voltage VacuumCircuit Breaker (VCB). This circuit breaker is based on aCOTS breaker that is militarized by <strong>DRS</strong> providing a small,lightweight, and cost effective solution. Utilized on the latestU.S. Navy ships for power distribution, the military hardenedVCB is designed to withstand rugged maritime conditions forthe life of the ship.This is the Navy’s first and only Vacuum Interrupter-BasedCircuit Breaker qualified for military use. The VacuumInterrupter design significantly reduces breaker size andweight as arc chutes are not needed. Maintenance is reducedsince no contact adjustments are required, only a periodiccheck of the integral wear indicator is needed. The VCB isdrawout (removable) for ease of inspection and replacement.From power distribution and electrical control productsto ship control automation, <strong>DRS</strong> offers advanced productdevelopment, world-class manufacturing and globalengineering services and support. That is why our productsare found on all U. S. Navy ships since WWII.Highlights• Maintenance free vacuum interrupter• Trip free operation• Interlocks for proper and safe operation• Built-in contact erosion indicator• Operations counter• Mechanical position indicator• Closing springs charged indicator• Mechanical and electric close capability• Mechanical and electric open capabilityFunctional Ratings(Ratings are nominal unless stated)Power characteristicsMax. continuous current...............................................1600AMax. voltage and frequency....................... 15,000VAC, 60HzMax. short circuit interrupting current......40,000A symmetricalShort circuit duration..............................................3 secondsMax. short circuit making current.................103,000A peakMax. trip time...............................................................3 cyclesMax. close time...........................................................5 cyclesMechanical endurance.................................... 10,000 cyclesNumber of poles.....................................................................3Voltage characteristicsDielectric withstand............................ 36,000 V for 1 secondBasic Impulse Level (BIL).......................................... 95,000VCorona extinction voltage level.................................. 17,500VAttachmentsElectrical closing device............................................StandardShunt trip device.......................................................StandardCharging motor protection........................................StandardGrounding contacts...................................................StandardAuxiliary switches – quantity...............................................15Auxiliary switches – ratings.... 120VAC, 15A / 125VDC, 10ASecondary disconnect pins.................................................5016New Products

<strong>DRS</strong> LV - PEMSLow Voltage Power Electronic ModulesDrive PEMHighlights• High efficiency• Fault tolerance• Excellent power quality• High power density• Modular (drawer mounted)• Scalable systems (multiple units in parallel)• Liquid cooled• 4th generation IGBT’s• Low voltage distortion for direct connect drive applications• Communication interfaces include fiber optic, ethernet,and CAN• All applications are capable of bidirectional power flowMilitary SpecificationsMIL-S-901, Grade A (mitigated enclosure)MIL-STD-167-1MIL-STD-461MIL-STD-1399Physical CharacteristicsDrive only:Width.................................................... 16.5 inches (70.1 cm)Height................................................... 14.6 inches (81.8 cm)Depth....................................................... 32 inches (63.8 cm)Weight.......................................................300 lbs. (195.0 kg)Power Converter PEMThe <strong>DRS</strong> LV - PEMS is a complete series of Low VoltagePower Electronic Modules. This next generation of powerconversion equipment is based on <strong>DRS</strong>’ experience in 3level power converters for Drive, DC/AC Inverter and DC/DCconverter applications. This next generation of PEMS offersa significant increase in power density and decrease in costover the previous generation.Potential applications include VFD’s, soft starters, frequencyconverters, point of use power conversion (AC/DC, DC/AC,DC/DC, AC/AC), propulsion drives or power conversion basedpower systems.From power distribution and electrical control productsto ship control automation, <strong>DRS</strong> offers advanced productdevelopment, world-class manufacturing and globalengineering services and support.Power converter (with output filtering):Width.................................................... 16.5 inches (70.1 cm)Height...................................................29.6 inches (81.8 cm)Depth....................................................... 32 inches (63.8 cm)Weight.......................................................800 lbs. (195.0 kg)Environmental PerformanceOperating air temperature.................................... -40 to +70° COperating humidity...................................95% non-condensingOperating water temperature...................................1 to +43° CFunctional Ratings(Ratings are nominal unless stated)Power characteristicsMax. continuous current.........................750A/phase (drive),600A/phase (inverter),900A (converter)Max. output voltage and frequency................. 690 VAC 60hz(400hz option),1200VDCNumber of output poles..4 (drive), 3 (inverter), 2 (converter)Voltage characteristicsdielectric withstand....................... 5,000 VDC for 60 second4265 N. 30th Street, Milwaukee, WI 53216 | Phone 414.875.2900 | Fax 414.875.4319 | Email IMS-BD@drs.com17

ACB-2020Low Voltage Air Circuit BreakerPhysical CharacteristicsCircuit breaker:Width.................................................... 16.5 inches (41.9 cm)Height...................................................18.2 inches (46.2 cm)Depth....................................................16.8 inches (42.7 cm)Weight......................................................... 200 lbs. (90.7 kg)Cassette:Width....................................................18.3 inches (46.5 cm)Height...................................................20.8 inches (52.8 cm)Depth.....................................................17.7 inches (45.0 cm)Weight......................................................... 120 lbs. (54.4 kg)Navy Type ACB-2020 is an 800-2000A low voltage AirCircuit Breaker utilizing the latest technology electronic tripunit. This circuit breaker is based on a COTS breaker that ismilitarized by <strong>DRS</strong> providing a small, lightweight, and costeffective solution. Utilized on the latest U.S. Navy ships forpower distribution, the MIL-SPEC qualified air circuit breaker isdesigned to withstand rugged maritime conditions for the lifeof the ship.Whether for new shipbuilding or modernization programs<strong>DRS</strong>’s ACB-2020 is ideal for integrated control, conditionbased maintenance, power monitoring, and interfacing withship network communications. The built-in electronic trip unitcan be remotely accessed for diagnostics, breaker status,ampere, voltage and power monitoring.Controls and indicators are functionally grouped on thebreaker faceplate to optimize the human interface, visibility,and ease of use. For maximum safety, a modern, through-thedoordesign permits access to the breaker levering system,trip unit, controls and indicators with the door closed.Highlights• Electronic trip unit with long, short, and instantaneoustrip curve settings• 24 character LED display for status• System diagnostics:- Cause of trip- Trip log- Waveform capture- Breaker health monitor- Remote signal contacts- Programmable contacts- Electronic operations counterEnvironmental PerformanceOperating temperature......................................... -20 to +70° COperating humidity...................................95% non-condensingFunctional Ratings(Ratings are nominal unless stated)Power characteristicsMax. continuous current...............................................2000AMax. voltage and frequency.............................500VAC, 60HzMax. interrupting rating.......................85,000 A symmetricalRated short time current........................................... 85,000ARated short time current duration............................. 0.5 SecNumber of poles.....................................................................3AttachmentsElectrical closing mechanism...................................StandardShunt trip device.......................................................StandardRemote close function............................................... OptionalVertical bus stab adapters......................................... OptionalAuxiliary switches – quantity.................................................8Auxiliary switches – ratings....... 120VAC, 15A / 480VAC, 5AMechanical lockout device.......................................StandardMechanical position indicator..................................StandardSecondary disconnect..........................8 @ 15A and 4 @ 10ACell switch...........................................................120VAC, 15AProtective features(Can be set as a trip or alarm)• Time over current• Ground fault• Over voltage• Over frequency• Reverse power• Zonal interlocking• Under voltage• Under frequency• Voltage unbalance• Phase rotationMilitary SpecificationsMIL-C-17587MIL-S-901, Grade AMIL-STD-167-1, 4-50 Hz18New Products

<strong>DRS</strong>-4040Low Voltage Air Circuit BreakerMilitary SpecificationsDesigned to MIL-C-17587MIL-S-901, Grade AThe <strong>DRS</strong>-4040 is a 2400-4000A low voltage Air CircuitBreaker utilizing the latest technology electronic trip unit.This circuit breaker is based on a COTS breaker that ismilitarized by <strong>DRS</strong> providing a small, lightweight, and costeffective solution. Utilized on the latest U.S. Navy ships forpower distribution, the military hardened air circuit breaker isdesigned to withstand rugged maritime conditions for the lifeof the ship.Whether for new shipbuilding or modernization programs the<strong>DRS</strong>-4040 is ideal for integrated control, condition basedmaintenance, power monitoring, and interfacing with shipnetwork communications. The built-in electronic trip unit canbe remotely accessed for diagnostics, breaker status, ampere,voltage and power monitoring.Controls and indicators are functionally grouped on thebreaker faceplate to optimize the human interface, visibility,and ease of use. For maximum safety, a modern, through-thedoordesign permits access to the breaker levering system,trip unit, controls and indicators with the door closed.Highlights• Electronic trip unit with long, short, and instantaneoustrip curve settings• 24 character LED display for status• System diagnostics:- Cause of trip- Trip log- Waveform capture- Breaker health monitor- Remote signal contacts- Programmable contacts- Electronic operations counter• Remote communications (Modbus, Profibus, Incom,PowerNet, TripLink)• Metering: Amps, Volts, Hz, kW, kVA, kVAr, THD, IHD,Power Factor, Crest Factor• Pad-lockable levering device shutter• Optional remote close module• Optional remote communications modulePhysical CharacteristicsCircuit breaker:Width....................................................35.3 inches (89.7 cm)Height...................................................18.2 inches (46.2 cm)Depth....................................................16.8 inches (42.7 cm)Weight.......................................................365 lbs. (165.6 kg)Cassette:Width.................................................... 37.0 inches (94.0 cm)Height...................................................20.8 inches (52.8 cm)Depth.....................................................17.7 inches (45.0 cm)Weight......................................................... 120 lbs. (54.4 kg)Environmental PerformanceOperating temperature......................................... -20 to +70° COperating humidity...................................95% non-condensingFunctional Ratings(Ratings are nominal unless stated)Power characteristicsMax. continuous current...............................................4000AMax. voltage and frequency.............................500VAC, 60HzMax. interrupting rating.......................85,000 A symmetricalRated short time current........................................... 85,000ARated short time current duration............................. 0.5 SecNumber of poles.....................................................................6AttachmentsElectrical closing mechanism...................................StandardShunt trip device.......................................................StandardRemote close function............................................... OptionalVertical bus stab adapters......................................... OptionalAuxiliary switches – quantity.................................................8Auxiliary switches – ratings....... 120VAC, 15A / 480VAC, 5AMechanical lockout device.......................................StandardMechanical position indicator..................................StandardSecondary disconnect..........................8 @ 15A and 4 @ 10ACell switch...........................................................120VAC, 15AProtective Features(Can be set as a trip or alarm)• Time over current• Ground fault• Over voltage• Over frequency• Reverse power• Zonal interlocking• Under voltage• Under frequency• Voltage unbalance• Phase rotation4265 N. 30th Street, Milwaukee, WI 53216 | Phone 414.875.2900 | Fax 414.875.4319 | Email IMS-BD@drs.com19

Variable Speed/Frequency Drives<strong>DRS</strong> is a leader in providing Variable Frequency Drives tomilitary or marine grade specifications. Our rugged VariableSpeed Drives can be found wherever speed/frequency isa key operating parameter. We provide a wide range ofdrive offerings to our customers by leveraging our strongengineering capabilities, full understanding of applicable MIL-SPEC’s or Commercial requirements gained from a history ofsuccessfully deployed products.From power distribution and electrical control productsto ship control automation, <strong>DRS</strong> offers advanced productdevelopment, world-class manufacturing and globalengineering services and support. That is why our productsare found on all U. S. Navy ships since WWII.15HP Variable Frequency Drive (VFD)The 15HP VFD utilizes a Commercial-Off-The-Shelf (COTS)solution that provides low cost, induction motor control.This 15HP drive takes advantage of <strong>DRS</strong> designed filtercomponents to meet strict EMI requirements for conductedand radiated emissions. Using a unique COTS drive allows forfuture and back-fit applications where the existing motor isnot inverter grade. This VFD is best suited for pump and fanapplications where variable speed control and high efficiencypower electronics can save energy. Network capabilities allowflexibility of control from automated systems to local manualuser control.Highlights• Variable speed control of induction motors• 440VAC, 3 phase input• 460VAC, 3 phase output• Motor protection• Meets:- MIL-STD-461- MIL-STD-1399, 300- MIL-STD-901- MIL-STD-167• 15HP @ 50°C• Bulkhead mount design• Ethernet and profibus network capability• Digital and analog I/O for local and remote user stations• Fan cooled• Drip proof250HP Variable Frequency DriveThe 250HP VFD utilizes a Commercial-Off-The-Shelf (COTS)solution that provides low cost, induction motor control.This 250HP drive takes advantage of <strong>DRS</strong> designed filtercomponents to meet strict EMI requirements for conductedand radiated emissions. Using a unique COTS drive allows forfuture and back-fit applications where the existing motor isnot inverter grade. This VFD is best suited for pump and fanapplications where variable speed control and high efficiencypower electronics can save energy. Network capabilities allowflexibility of control from automated systems to local manualuser control.Highlights• Variable speed control of induction motors• 650VDC input• 460VAC, 3 phase output• Motor protection• Meets:- MIL-STD-461- MIL-STD-1399, 300- MIL-STD-901- MIL-STD-167• 250HP @ 50°C• Floor & bulkhead mount design• Ethernet and profibus network capability• Digital and analog I/O for local and remote user stations• Fan cooled• Drip proof20New Products

High Frequency DriveThe High Frequency Drive (HFD) utilizes <strong>DRS</strong> drive technology.The HFD utilizes an active, power factor corrected frontend combined with a buck topology that yields the ability tocontrol standard 460VAC motors as well as lower voltagemachines. A high switching frequency reduces the size offilter components creating a highly power dense package.Plug-in option cards provide options for resolver, hall-effector encoder position feedback as well as network cards andI/O expansion. The HFD is capable of driving induction andbrushless DC (BLDC) permanent magnet motors increasingits capability for applications such as pumps, blowers, valveactuators and chillers.Highlights• Variable frequency control of induction and brushless DC(BLDC) permanent magnet motors• 440VAC, 3 phase input• 110VAC – 460VAC, 3 phase output• Embedded web server for drive configuration andmonitoring / diagnostics• Motor protection• Meets:- MIL-STD-461- MIL-STD-1399, 300- MIL-STD-901- MIL-STD-167• 20HP @ 50°C, fan cooled• 5HP @ 50°C, convection cooled• Bulkhead, hard-mount design• Networks: Ethernet, Profibus, CAN/DeviceNet, USB• Digital and analog I/O for local and remote user stations• Splash proofSteering Gear Actuation System (SGAS)The Steering Gear Actuation System (SGAS) drive has beendesigned using innovative power electronics and packagingtechniques. Three drive sections along with an integraldynamic braking section are provided in the cabinet alongwith redundant control and monitoring of drive, motor andcabinet status and faults. The drive has been designed tocontrol permanent magnet AC motors and has provision toaccept resolver feedback but could be modified to interfacewith induction machines. It is well suited to provide highperformance in position, velocity or torque control types ofapplications.Highlights• Control of three (3) individual PM AC motors• 650 VDC input• Maximum of 460 VAC, 3 phase variable voltage /frequency output• 3 drive sections @ 50ºC• Integral dynamic brake for regenerative applications• Redundant drive control and system monitoring• Chilled water cooled with condensation managementsystem• Rugged compact design• Cabinet IP54 rated• Redundant ethernet connectivity• Meets:- MIL-STD-461- MIL-STD-1399, 300- MIL-STD-901- MIL-STD-167These are just some examples of our drive offerings. Todiscuss your particular drive applications please contact ourfactory directly.4265 N. 30th Street, Milwaukee, WI 53216 | Phone 414.875.2900 | Fax 414.875.4319 | Email IMS-BD@drs.com21

Low Voltage Switchgear<strong>DRS</strong> is a leader in providing Low Voltage Switchboards andload centers to military or marine grade specifications.Utilized on the latest U.S. Navy ships for power distribution,the military hardened switchgear is designed to withstandrugged maritime conditions for the life of the ship.<strong>DRS</strong> has supplied switchgear with an unprecedented levelof automation for ship applications. This includes generatorcontrols, synchronization, load shedding, and protectivefeatures. The switchgear can also provide custom HMIscreens for power monitoring, control, diagnostics, conditionbased maintenance, and interfacing with ship networkcommunications.From power distribution and electrical control productsto ship control automation, <strong>DRS</strong> offers advanced productdevelopment, world-class manufacturing and globalengineering services and support. That is why our productsare found on all U. S. Navy ships since WWII.Highlights• Drip proof or spray tight enclosures• Wide range of standard distribution units• AC or DC switchgear• Arc fault detection• Optional insulated bus bars• Remote monitoring and control to SCADA• Modbus/Profibus communicationsMilitary SpecificationsABS NVRMIL-S-901, Grade AMIL-STD-167-1MIL-STD-461MIL-STD-1399 Section 300Commercial <strong>Marine</strong> SpecificationsABS SVRIEEE 45<strong>Integrated</strong> Generator Controls• Start and automatically parallel generators to the bus• Automatically parallel to and from shore power• Automatically recover from a dark ship condition• Automatically start or stop generators based on loaddemands via the power management system• Automatically perform load sharing among generators (KWand VAR) in a split or monolithic bus• Provide digital under voltage and over current protection• Two stage load shed capability22New Products

Medium Voltage SwitchgearMilitary SpecificationsMIL-S-901, Grade AMIL-STD-167-1MIL-STD-461MIL-STD-1399 Section 300<strong>DRS</strong> is a leader in providing Medium Voltage Switchgearto military requirements. <strong>DRS</strong> can provide switchgear upto 15kV, in a compact and rugged enclosure that is a 40%reduction in volume over typical commercial switchgear.Utilized on the latest U.S. Navy ships for power distribution,the military hardened switchgear is designed to withstandrugged maritime conditions for the life of the ship.The switchboards provide custom HMI screens forpower monitoring, control, diagnostics, conditionbased maintenance, and interfacing with ship networkcommunications. Built-in safety features are provided to keepthe operator out of harms way while operating the circuitbreakers.Protective Relaying Features(Can be set as a trip or alarm)• Current differential• Time over current• Zonal interlocking• Ground fault• Under voltage• Over voltage• Under frequency• Over frequency• Voltage unbalance• Reverse power• Phase rotation• Loss of field• Negative phase sequence• Volts per HertzSupplemental Devices• Compact foldable lifting cart• Manual ground and test device• VCB electrical test boxHighlights• Metal clad construction for operator safety• Meets 95kV BIL rating• Two-high breaker arrangement is standard• Vacuum circuit breakers provide low maintenance, long life• Fluidized bed epoxy coated bus bar• Silicone (non-PVC) insulating boots• Remote communications (Modbus, Profibus)• HMI for metering, control, and diagnostics• Circuit breaker condition-based monitoring4265 N. 30th Street, Milwaukee, WI 53216 | Phone 414.875.2900 | Fax 414.875.4319 | Email IMS-BD@drs.com23

Motor Control & OPERATOR INTERFACE Specification and DocumentSOur customer’s mantra is our mantra -Pride, Purpose, Performance.Pride - <strong>DRS</strong> has a rich history of providing robust equipment to the U.S. Navyand its international allies. In recent history, <strong>DRS</strong> has become the largest Hull,Mechanical, and Electrical provider for the CVN 78 Class Aircraft Carrier, the DDG1000 Destroyer, and the Lockheed Martin Freedom Class of Littoral Combat Ships.Purpose - <strong>DRS</strong>’ heritage of products reaches back to 1904, when it deliveredits first motor controller products. This heritage continues today into the U.S.Navy’s new platforms including key positions on the DDG 51 restart efforts (motorcontrollers, hybrid-electric drives, next generation power distribution and conversionprograms) support of the Ohio Submarine Replacement Program, the LockheedMartin Littoral Combat Ship, and the LHA 7 Amphibious Assault Ship design.Performance - <strong>DRS</strong> has demonstrated that it has the design capabilities andbench depth to meet the demanding needs of today’s Navy. <strong>DRS</strong>’ extensive fieldservice support and shipyard interaction has provided a unique perspective onproduct design. Our newest motor controller designs include a next generationoverload and a revolutionary lightweight enclosure. The designers of this enclosuredismissed conventional thought on motor controller design while incorporatingcustomer needs for installation. The results are an astonishing new cabinetwith open corners and an integral back panel that significantly reduces in houseproduction costs and shipyard/shipboard installation time and materials.Pride, Purpose, Performance at <strong>DRS</strong> we live it everyday.

Controlling Standards/SpecificationsMIL-DTL-2212 is the controlling specification for motor controlequipment used on Naval vessels. It invokes 24 other MilitarySpecifications and Standards. Some of these are:MIL-E-917MIL-S-901MIL-STD-167-1Electric Power Equipment, Basic RequirementsShock Tests, High Impact; Shipboard Machinery,Equipment and <strong>Systems</strong>, Requirements forMechanical Vibrations of Shipboard Equipment(I – Environmental and II – Internally Excited)DOD-STD-1399 Interface Standard for Shipboard <strong>Systems</strong>Section 300– Electric Power, Alternating CurrentProtective EnclosuresThe controlling specifications for Navy motor control equipmentrequire dripproof enclosures as a general minimum. Other types ofenclosures may be required depending on the application. Theseinclude splashproof, submersible and explosion proof.The Navy definitions of these enclosure types are shown below.DripproofAn enclosure constructed so that enclosed equipment operatessatisfactorily in the presences of falling drops of liquid or solidparticles. This protection must be provided for up to 45° of inclinationfrom the vertical.Explosion ProofEnclosed equipment operates safely in the presence of anyconcentration of a specified gas or vapor. The enclosure must beconstructed to withstand the explosion of the gas or vapor withinit and show no distortion or significant damage as a result. It shallcontain the explosion and other sparks and flashes so that the gasor vapor surrounding the enclosure is not ignited. Class I, Group D,MIL-E-2036.SplashproofAn enclosure constructed so that equipment within it operatessatisfactorily in the presence of a coarse spray of liquid or solidparticles. The spray is to be directed at all exposed surfaces and thesurface to which the controller is mounted. The test duration is fiveminutes at a water flow rate of 15 gallons per minute.SubmersibleAn enclosure constructed so that equipment within operatessatisfactorily when submerged in water up to a specified depth. Waterleakage is not permitted. The most common test is 15 feet for 24hours.WatertightAn enclosure constructed to prevent entry of water from a solidstream striking it on any surface and at any angle. The test required asolid stream of water from a one inch nozzle, sprayed from a 10 footdistance, with a flow rate of 65 gallons per minute. The test duration is60 minutes. An alternative test method is submersion in water so theenclosure is covered, the test duration is five minutes. Entry of waterduring the test shall be cause for rejection.The Navy definition of dripproof and splashproof permit the entry ofsome liquid or solid particulate into the enclosure cavity. The enteringcontaminant, however, may not affect the operation of the equipmentwithin the enclosure.A comparison of similar Navy and NEMA enclosure grades follows:NavyClassificationNEMATypeNavyRequirementDripproof 12 Protection to 45 °inclinationWatertight 4 60 minute hosetest at 65 gallonsper minuteSubmersible 6 Minimum -15 ftof submersion for24 hoursNEMARequirementNo inclinationrequirement5 minute hosetest at 65 gallonsper minute6 ft of submersionfor 30 minutesCorrosion protection is an obvious necessity for motor controlequipment in a seagoing environment. <strong>DRS</strong>-PCT provides corrosionprotection for its Navy motor control equipment through the use ofcorrosion-resistant materials and high quality finishes. All enclosuresare designed and tested to pass a standard 200 hour salt spray test.MC DOCUMENTATIONUpdated list prices and PDF version of this catalog are available at <strong>DRS</strong>.com. 25

MC DOCUMENTATIONFeatures<strong>DRS</strong> AC controllers, components and pilot devices are designed andbuilt to meet the requirements of MIL-DTL-2212.Additional features include:• Temperature Rating – 50°C as required by MIL-DTL-2212.• Compensation – Overload relays are insensitive to variations inAmbient temperature.• Diagram – Heat resistant, durable copy of controller diagram isattached to inside of controller.• Voltage – 440V and 115V; other voltages available upon request.• High Shock – MIL-S-901, Grade A, Class 1, Type A requirements.• Vibration – MIL-STD-167-1 to 33 Hz as standard• Operational – Equipment will operate at inclinations up to 45°from the normal mounting orientation.Documentation and Other InformationEquipment documentation is an important consideration for motorcontrol equipment to be used at sea. <strong>DRS</strong>-PCT provides extensivedocumentation configured to support the end-user.For example, standard plans provide the physical and electricalinformation necessary to install and maintain a controller. CertificationData Sheets provide important reference information for identifyingthe application, manufacturer, applicable drawing numbers, andquantities involved. Tech manuals support repair and maintenanceactivities by providing disassembly and adjustment information,repair parts data and electrical diagrams useful for troubleshooting.The documentation that is available from <strong>DRS</strong>-PCT to support its NavyMotor control equipment is described in the following sections:Drawings (Standard Plan) p. 26Certification Data (CD) Sheets p. 26Packaging p. 27Provisioning Technical Documentation (PTD) p. 27Quality Assurance p. 27Technical Manuals p. 27TestingThe prices for motor controllers and accessories include thestandard inspections and routine tests required by MIL-DTL-2212.They do not include First Article Testing or factory providedinstallation supervision.AC Controllers, components and pilot devices are designed andbuilt to meet the requirements of MIL-DTL-2212. IAW with MIL-DTL-2212 a representative sample of controllers, components andpilot devices are periodically subjected to Conformance Testing. Thetested and related types of controller, component and pilot devicesare placed on QPL-2212 for general use in Naval applications.DC Controllers and components were last qualified to meet the QPLrequirements of MIL-C-2212F. Representative samples of thesedevices are subjected to periodic non-witnessed ConformanceTesting IAW MIL-C-2212F which precludes inclusion on the currentQPL-2212 listing.<strong>DRS</strong>-PCT does not imply a full suite of QPL testing is completedfor every variation of controller, component and pilot devicemanufactured. If additional individual qualification testing isrequired, <strong>DRS</strong>-PCT will provide a separate quote for those specificallyrequested tests. If qualification testing is required, <strong>DRS</strong>-PCT mustbe notified prior to the placement of a Purchase Order.In addition, pricing for any special inspections, or installationsupport can be provided upon request.DrawingsDrawings and certification data are normally provided for approvalpurposes or when required by a purchase specification.The information included in these documents follow.Standard PlanThe Standard Navy Plan provided for <strong>DRS</strong>-PCT Navy motor controlequipment conforms to the requirements of MIL-DTL-2212. Includedare the following (minimum):1. Manufacturer’s name and Cat. I.D. of apparatus.2. Applicable specifications.3. Weight of controller.4. Outline drawing and dimensions of enclosure, locationof mounting holes, center of gravity.5. Description of operation, adjustments.6. List of repair parts.7. Connection and schematic diagrams.8. List of material, overload heater table.9. Descriptive data of controller, i.e. enclosure, rating,operation, type, etc.10. Descriptive and electrical design data of coils, resistors,transformers, etc.11. Approval status.Certification Data (CD Sheets)Certification Data Sheets provided conform to the requirements ofDOD-STD-100C. The standard form is an 8-1/2” x 11”. Informationprovided is as follows:1. Navy Contract No. of Shipbuilder’s Order No.2. Manufacturer’s Number3. Subcontractor’s Order Number4. Applications:a. Auxiliaryb. No. of controls per vesselc. Motor hp ratingd. Full load amps.e. Voltsf. Heater Coil Cat. No.5. Number of controllers involved6. Number of controllers per vessel7. Number of sets of repair parts per vessel contract8. Number of vessels involved9. Vessel of hull numbers10. Drawing numbers of associated equipmentCopies of Standard Plans and CD SheetsThe plan price includes one full size reproducible (vellum) plusadditional paper copies when ordered with the control. Otherrequirements are priced by request and in accordance with thefollowing table.26Motor Control and Operator Interface Specification and Documents

Paper, Vellum or Electronic Reproduction of controller andaccessory plans, ordered separately.Paper or Electronic Reproductions of Certification Data (CD)sheets.Reduced size copies of standard plans –First 50 or fewer copies.Each additional 50 copies.35 mm Aperture cards, in accordance with MIL-M-9868/1.PackagingPackaging and packing of Controllers andComponentsA. Commercial (Level C)………………………..No ChargeB. Military – Per any military standard of specification or“Packaging Requirement Code”1. Enclosed controllers and accessories:5% or minimum of $188. Per order2. Open controllers, components or accessories:12% or minimum of $188. per orderPackaging and Packing of Repair PartsA. Commercial (bulk) – Package marking only –No Preservation........................................ No ChargeB. Military – Per any military standard or specification or“Packaging Requirement Code”......... 12%Minimum $188. per orderBar Code Marking$295 per order plus $20 per item and each additional destination.FCA Destination .......................................... 12%Provisioning Technical DocumentationProvisioning Technical Documentation (PTDs) can recommend onboardand stock repair part levels. These recommendations arenormally made on NAVSHIPS forms 4786 and 4786A in accordancewith MIL-P-15137. Alternatively, Short Form Provisioning data(SFPPL) can be provided on NAVSEA forms 4423/3 and 4423/3A inaccordance with MIL-STD-1552 and MIL STD 1561.Price: Forms 4786 & 4786A – included if requested at time oforder, if not $250 fee will apply.Forms 4432/3 & 4423/3A - $550.Repair PartsRepair Parts are normally an optional and unpriced item on an initialcontract or order. When such an option is exercised, the required partsare added to the contract or order based on the Government’s selectionof items and quantities from the standard Provisioning TechnicalDocumentation (PTD) forms. Consult the factory for current pricing.Non-magnetic ConstructionSpecial situations require the use of motor control equipment thatpresents a low “magnetic profile.” One example is a mine sweeper.Reducing the magnetic profile requires the use of non-ferrous (i.e.non-magnetic) materials where feasible. Additional steps may benecessary to counteract the impact of ferrous materials and magneticstructures that cannot be eliminated.Navy qualified non-magnetic control will be provided when required.Contact the factory for price information.Quality AssuranceThe <strong>DRS</strong>-PCT Milwaukee facility is ISO 9000 certified and qualityprograms exceed the requirements of MIL-I-45208A - “InspectionSystem Requirements”. <strong>DRS</strong>-PCT motor controllers, components,and accessories are designed and manufactured in conformancewith MIL-C-2212 and MIL-DTL-2212 and applicable subtier MilitarySpecifications, as indicated in this catalog. Most <strong>DRS</strong>-PCT productsare listed on the Qualified products list (QPL) of the specificationindicated in this catalog.The Quality Assurance documentation normally provided includesGovernment Source Inspections, Certificate of Compliance, Certificateof Identicality, and a copy of the final test report. Applicable pricingcan be provided upon request.Quiet Control (MIL-STD-740)MIL-STD-740 defines acceptable levels for airborne and structureborne noise when “Quiet” operation is required. Airborne noise isundesired sound carried through the air. Structure borne noise isan undesired vibration carried through a solid medium such as theship’s hull.Navy motor control equipment and components can be provided tomeet the requirements of MIL-STD-740B. Special manufacturingmethods, parts selection and verification test are necessary toguarantee compliance. Prices for quiet components, controls andnoise testing are gladly provided upon request.Technical ManualsStandard Tech Manual Inserts conforming to MIL-DTL-2212 will besupplied when ordered. These provide ample information for theinstallation, maintenance and repair of our Navy qualified motorcontrol equipment. Included are the following:1. Title Page2. Table of Contents3. Copies of applicable CD Sheets4. Reduced size copies of applicable Navy Plans5. Applicable component Technical PublicationsPreliminary copies will be supplied for approval. The final copies willconsist of black and white reproducibles.Standard Tech Manual InsertsFirst 5 copies or part thereof when orderedwith controlEach additional 50 copiesPriceNo ChargeProvided byrequestComplete Tech Manuals conforming to MIL-M-15071 or similarspecifications can be provided if required. Please contact the factory.4265 N. 30th Street, Milwaukee, WI 53216 | Phone 1.800.552.2829 | Fax 414.875.4764 | Email IMS-BD@drs.com27

MOTOR CONTROL AND OPERATOR INTERFACEExceptional engineering, proven solutions<strong>DRS</strong> marries exceptional engineering capability with a long history ofsuccessfully fielded products to deliver proven solutions. Our motor controllers,variable frequency drives, electronic motor operators, starters and UPS unitsare the natural choice for critical applications specified for the U.S. Navy andother Maritime applications. MIL-STD Naval specifications are only the start.<strong>DRS</strong> products are battle-tested and hardened, having proven themselves timeand again, providing continuous, flawless operations in theharshest environments.<strong>DRS</strong> commands a 60-year service record other providers can only envy:building and supporting motor controllers, starters and accessory productssince World War II.<strong>DRS</strong> products are also ever evolving as our company looks to future Navyneeds, with innovative products including our Navy Electronic Motor Operators(NEMO).<strong>DRS</strong> delivers. As we develop innovations and improvements, weincorporate the very best ideas across product lines and throughsuccessive product iterations.

Type 6922AC/DC Manual Across-the-Line StarterStarter in watertight enclosureWhen ordering specify<strong>Catalog</strong> number• Horsepower• Voltage• Full load motor current• Type of motor with which starter is to be used• ApplicationSpecifications• MIL-SPEC.................MIL-DTL-2212• Enclosure................Dripproof or watertight• Operation................Manual• Type.........................Across-the-line• Function..................Motor starting• Duty.........................Continuous• Protection................Low voltage release effect -Overload protection - thermal type relayCompensation - Change in rating does not exceed 5% foreach 10°C change in ambient between 20°C and 70°CAdjustability - Adjustable from 90 to 110% of relay ratingType of reset - Hand from STOP button• Performance.......... Manual• Ambient temp........ 50°C• Insulation............... Class B• Emergency Run...... By holding START button depressedMax. hpStarter440V 3-Phase Dripproof WatertightCat. No. Lbs. Net Cat. No. Lbs. Net7 1/2 6922H36B 9.5 6922H37D 16.5Starter price does not include heater coils. Select Heater Coils from table on following page.MOTOR CONTROLTypical Wiring DiagramApproximate Dimensions in Inches and Shipping WeightsUpdated list prices and PDF version of this catalog are available at <strong>DRS</strong>.com. 29

AC Manual Across-the-Line StarterOverload Heater Coil SelectionGeneralThe 9104 Heater Coils listed at right are foruse on Type 6922 Manual Starters.Motor Amperes 1<strong>Catalog</strong> Motor Amperes 1Min. Max.NumberMin. Max.<strong>Catalog</strong>NumberMOTOR CONTROLHeater SelectionSelect Heater Coils based on motornameplate full load current.Heater coils are rated to protect 40°Cmotors. Open and dripproof motors havea service factor of 1.15 where the motorand the controller are at the same Ambienttemperature.For other conditions:A. For 50°C, 55°C, 75°C rise motors andenclosed motors having a servicefactor of 1.0, select a heater coiltwo sizes smaller.B. Ambient temperature of controllerlower than the motor by 26°C, useone size smaller heater coil.C. Ambient temperature of controllerhigher than the motor by 26°C, use onsize larger coil.Ultimate tripping current of heater isapproximately 1.20 times the minimumcurrent rating listed in the tables.NOTE: There are some coils which requireminimum order quantity.0.3200.3440.3710.3980.4250.4620.5010.5410.5840.6300.6720.7310.7900.8600.9181.011.081.161.271.361.471.581.691.831.972.172.322.542.750.3430.3700.3970.4240.4610.5000.5400.5830.6290.6710.7300.7890.8590.9171.001.071.151.261.351.461.571.681.821.962.162.312.532.743.009104H38129104H38139104H38149104H38159104H38169104H38179104H38189104H38199104H38209104H38219104H38229104H38239104H37549104H37559104H37569104H37579104H37589104H37599104H37609104H37619104H37629104H37639104H37649104H37659104H37669104H37679104H37689104H37699104H37703.013.243.563.844.174.514.955.305.806.266.807.308.008.759.6010.511.412.313.314.415.416.418.019.320.822.224.126.43.233.553.834.164.504.945.295.796.256.797.297.998.749.5910.411.312.213.214.315.316.317.919.220.722.124.026.328.89104H37719104H37729104H37739104H37749104H37759104H37769104H37779104H37789104H37799104H37809104H37819104H37829104H37839104H37849104H37859104H37869104H37879104H37889104H37899104H37909104H3791 29104H3792 29104H3793 29104H3794 29104H3795 29104H3796 29104H3797 29104H3798 21 Based on starter in a maximum 50°C ambient.2 These coils are quantity sensitive and have minimum order size of five (5) pieces.30Motor Control and Operator Interface

Type 6956AC Magnetic Contactors - EnclosedContactor Only – No Overload RelaySpecifications• MIL-SPEC . . . . . . . .MIL-DTL-2212• Enclosure . . . . . . .. Dripproof type• Poles . . . . . . . . . . .. Three poles• Operation . . . . . . .. Magnetic• Duty . . . . . . . . . . ... Continuous• Protection . . . . . . .. Low voltage release or lowvoltage protection (dependingupon type of master)• Performance . . . . Non-automatic or automatic(depending on type of master)• Ambient temp. . . .. 50°C .• Insulation. . . . . . . .Class B, except coils, Class A6956EDWhen ordering specify• Type number• Ampere rating• Voltage• Frequency• Type of enclosure• LVR or LVP (type of pilot device)• Application• Type and number of interlocks requiredAC Magnetic ContactorsFor open panels or watertightenclosures, refer to factorySize0123455 SPMax. Amps Enclosed18274590135270420Heater Loads (kW)Size0123455 SP110V1.92.94.99.914.829.746.2440VSingle-Phase Three-Phase7.91119395811818413203468100205320Sample Wiring DiagramApproximate 1 Dimensions and WeightsDimension in Inches Wt.SizeWide A Wide B Wide C Lbs.10/123458.259.3811.3811.3818.1311.2513.1315.7515.7523.136.507.888.758.7511.50Design variables will affect size and/or weight.182536371004265 N. 30th Street, Milwaukee, WI 53216 | Phone 1.800.552.2829 | Fax 414.875.4764 | Email IMS-BD@drs.com31

AC Magnetic StartersGeneral DataMaximum Horsepower Ratings – 60 HertzNavy StarterMaximum HorsepowerSize 115V, 1-Phase 440V, 3-PhaseTypes 6962 and 6963 Single Speed Across-the-Line0123455SP6Types 6967 and 6968 Two Speed Across-the-Line440V, 3-PhaseConstant or Variable Torque Constant Horsepower123423455 SP6--237-1/2--------102550100110V7-1/2152550----6962EDWhen ordering specify• <strong>Catalog</strong> or type number• Specifications applying• Voltage• Horsepower rating• Frequency• Type of enclosure• Full load motor current• Local or remote master switch• Scheme of operation (LVP or LVR)• Non-automatic or automatic• Application• Type of motor with which starter will be used• Any special contract requirements involving operation,construction, plans, packing, etc.Type 6966 Reduced Voltage Autotransformer51025501002003754007-1/2204075440V2550100200375400Specifications• MIL-SPEC................ MIL-DTL-2212• Enclosure............... Dripproof, watertight (other typesavailable, contact factory)• Operation............... Magnetic• Type........................ Electromagnetic• FunctionType 6962.............. Motor startingType 6963.............. Motor starting and reversingType 6966.............. Reduced voltage motor startingType 6967.............. Motor starting and speed selectionType 6968.............. Motor starting, reversing andspeed selectionType 6969.............. Special• Duty........................ Continuous• Protection............... Low voltage protection and lowvoltage release types• OverloadProtection............... Eutectic thermal type relay (N750)See Page 53Compensation....... Less than 3% change for each 10°variation in ambient between 20°and 70°CAdjustability........... -10%, +10% of heater ratingReset...................... Hand (local) or electrical (remote)• Performance.......... Non-automatic or automatic(depending on type of masterswitch used)• Ambient temp........ 50°C• Insulation............... Class B, except contactor coils, Class A• Emergency Run Optional, by separate emergencyRUN button• Rating..................... AC only 60 HzTable of Contactor Type NumbersNavyStarterSize0123455 SP6Number of Contactorsper StarterNonreversingReversing11111111Main Contactor--2222222Typenumber ofContactorN1291N850N894N846N862N878N1178N630EnclosedAmpereRating18274590135270420540Type numberof ControlRelay (WhenFurnishedfor SpecialPurposes)N1154N1154N1154N1154N1154N1154N1154N115432Motor Control and Operator Interface

Type 6962H Non-ReversingStandard (Non-engineered) AC Motor StartersAcross-the-Line, Single SpeedWhen ordering specify• <strong>Catalog</strong> number• Horsepower rating• Full load motor currentSpecifications• MIL-SPEC. . . . . . . . . MIL-DTL-2212• Enclosure . . . . . . . .Dripproof with wraparound cover• Voltage. . . . . . . . . ..440V AC, 60 Hz, 3-phase only• Operation. . . . . . . ..MagneticRemote Control – With Provision for Remote START/STOP Pushbutton (LVP) or ON/OFF Selector Switch (LVR)Remote START/STOP Pushbutton (LVP)Remote ON/OFF Selector Switch (LVR)<strong>Catalog</strong> number<strong>Catalog</strong> numberSizeWithoutWith Provisions forWithoutWith Provisions forAdditionalRemoteRemoteAdditionalRemoteRemoteFeatures Protective Device Emergency Run Features Protective Device Emergency RunWithout Indicating Light (1 Pilot Circuit Fuse)12346962H154A26962H161A26962H170A26962H178A26962H154A66962H161A46962H170A46962H178A4With Provision for Indicating Light (3 Pilot Circuit Fuses)12346962H155A26962H163A26962H172A26962H180A2--------6962H154A36962H161A36962H170A36962H178A36962H155A36962H163A36962H172A36962H180A36962H154A46962H161A76962H171A26962H179A26962H155A46962H163A46962H173A26962H181A2----------------6962H154A56962H161A86962H171A36962H179A36962H155A56962H163A56962H173A36962H181A3Dim. TableReferenceBEGHBEGHLocal Control – With START/STOP Pushbutton (LVP) or ON/OFF Selector Switch (LVR) – 440A – 60 HzSTART/STOP Pushbutton in Cover (LVP)With Provisions forON/OFF SelectorSwitch in Cover (LVR)WithoutWith Local EmergencyRunwith Local EmergencySize Additional FeaturesRun1234<strong>Catalog</strong>numberWithout Indicating Light6962H156A26962H165A26962H174A26962H182A2Dim.Ref.ADFH<strong>Catalog</strong>number6962H157A26962H166A26962H175A26962H183A2Dim.Ref.ADFHRemote Pushbuttons(1 Pilot Fuse)<strong>Catalog</strong>number6962H159A26962H168A26962H177A26962H185A2Dim.Ref.BEGHRemote SafetySwitch (1 Pilot Fuse)<strong>Catalog</strong>number6962H159A36962H168A36962H177A36962H185A3Prices of starters do not include overload heater coils. Two required per controller. Heater Coil Selection, Page 60.Dim.Ref.BEGH<strong>Catalog</strong>number6962H158A26962H167A26962H176A26962H184A2Dim.Ref.BEGHSTART/STOPPushbutton andMAN/AUTO SelectorSwitch in Cover (LVP)with Provisions forRemote 2-Wire AutomaticDevice<strong>Catalog</strong>number6962H160A26962H169A2----Dim.Ref.CJ----Approximate Dimensions and WeightsReferenceLetterWideADimensions in InchesHighBDeepCWeight Lbs.ABCDE8.388.2411.749.389.3811.3015.5615.3012.8017.306.686.686.448.068.062025353035FGHJ11.3811.3811.3813.7415.3019.8019.8016.808.948.948.948.06404547404265 N. 30th Street, Milwaukee, WI 53216 | Phone 1.800.552.2829 | Fax 414.875.4764 | Email IMS-BD@drs.com33

Type 6967H Non-ReversingStandard (Non-engineered) AC Motor StartersWhen ordering specify• <strong>Catalog</strong> number• Horsepower rating• Full load motor currentSpecifications• MIL-SPEC................ MIL-DTL-2212• Enclosure............... Dripproof with wraparound cover• Voltage.................... 440V AC, 60 Hz, 3-phase only• Operation............... Magnetic. Two speed, Two-Winding LVPLocal Control — FAST/SLOW/STOP<strong>Catalog</strong> numberWith Provisions forMaximum Local FAST/SizeHorsepower SLOW/STOPOnly1210256967H21A26967H28A2RemoteFAST/SLOW/STOP--6967H26A2Remote FAST/SLOW/STOP andMOTOR RUN Lights 1and RemoteEM-START/EM-STOP--6967H27A2Remote Control Only<strong>Catalog</strong> numberWith Provisions forSizeWideADimensions in InchesHighBDeepCWeight Lbs.Size12MaximumHorsepower1025RemoteFAST/SLOW/STOP6967H21A26967H28A2Remote FAST/SLOW/STOP andMOTOR RUN Lights 1and RemoteEM-START/EM-STOP--6967H29A21211.813.815.316.86.58.13247Prices of Starters do not include overload heater coils. Four required percontroller. Heater Coil Selection, Page 60.1 Motor run light for each speed.Approximate Dimensions and Weights34Motor Control and Operator Interface

Type 6962 Non-Reversing and Type 6963 ReversingEngineered AC Magnetic StartersAcross-the-Line, Single SpeedWhen ordering specify• Base type number. Example 6962-3• Voltage and frequency• Type of enclosure• Full load motor current• Low voltage protection or low voltage release• Features required• Desired circuit operation• Description of application• Any special instructionsSpecifications• MIL-SPEC................ MIL-DTL-2212• Enclosure............... Dripproof or watertight• Operation............... Magnetic• Rating..................... 440V AC, 60 Hz, 3-Phaseother voltages availableApproximate Dimensions and Shipping Weights - DripproofApproximate Dimensions and Shipping Weights - WatertightDripproof Enclosure 1Watertight Enclosure 1ControllerSizeWideADimensions in InchesHighBDeepCShippingWeight Lbs.ControllerSizeWideADimensions in InchesHighBDeepCShippingWeight Lbs.Type 6962 Non-reversingType 6962 Non-reversing01212.012.012.018.018.018.09.59.59.53535350129.59.513.519.019.019.07793435523455 SP612.014.022.1322.1335.518.018.028.1328.1360.09.59.511.511.524.045511201207903455 SP6Contact FactoryType 6963 ReversingType 6963 Reversing1212.014.018.020.09.59.535471213.2815.3821.1321.1399506034Contact Factory34Contact Factory1 Dimensions and weights shown are for the base controller only. The addition of optional features will affect the size and weight.4265 N. 30th Street, Milwaukee, WI 53216 | Phone 1.800.552.2829 | Fax 414.875.4764 | Email IMS-BD@drs.com35

Type 6967 Non-Reversing and Type 6968 ReversingEngineered AC Magnetic StartersTwo Speed, Across-the-LineWhen ordering specify• Type number• Applicable specifications• Two-winding or single-winding reconnected• Horsepower rating at high and low speeds• Full load motor current at high and low speeds• Voltage and frequency• Low voltage release or low voltage protection• Non-automatic or automatic• Local or remote master• Type of enclosure• ApplicationSpecifications• MIL-SPEC................ MIL-DTL-2212• Enclosure............... Dripproof or watertight• Operation............... Magnetic• Rating..................... 440V AC, 60 Hz, 3-Phaseother voltages availableMaximum Horsepower RatingsMaximum Horsepower 3-Phase, 60 HzSize Constant or Variable Torque Constant Horsepower440V440V12341025501007-1/2204075DiagramApproximate Dimensions and Weights --Watertight enclosure dimensions on application. Designvariables prevent accurate dimensions.SizeWideANon-reversing - Dripproof123414.1314.1316.1316.13Reversing - Dripproof123416.1316.1322.1322.13Dimensions in InchesHighB18.1320.1322.1322.1320.1324.1328.1332.13DeepC9.389.389.389.389.389.389.389.38Weight Lbs.45557385607913214136Motor Control and Operator Interface

Type 6966Engineered AC Magnetic StartersAutotransformer, Reduced Voltage TypeWhen ordering specify• Type number• Application specifications• Horsepower• Voltage and frequency• Full load motor current• Type of enclosure• Local or remote control• Low voltage protection or low voltage release• Non-automatic or automatic• ApplicationTypical Wiring DiagramSpecifications• MIL-SPEC................ MIL-DTL-2212• Enclosure............... Dripproof• Operation............... Magnetic• Rating..................... 440V AC, 60 Hz, 3-PhaseOther voltages availableApproximate Dimensions in Inches and Weights –Type 6966-1 1SizeDripproof Enclosure1123456WideA2020202632.5034.25Dimensions in InchesHighB424242608490DeepC1414142428.2530.25Design variables prevent accurate dimensions.Weight Lbs.190200300700127517004265 N. 30th Street, Milwaukee, WI 53216 | Phone 1.800.552.2829 | Fax 414.875.4764 | Email IMS-BD@drs.com37