2-Post lifts - Autec-VLT Automotive Equipment

2-Post lifts - Autec-VLT Automotive Equipment

2-Post lifts - Autec-VLT Automotive Equipment

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

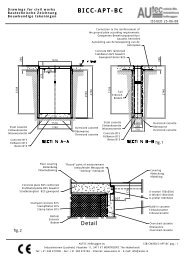

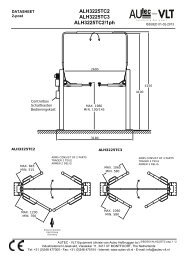

USER MANUAL2-<strong>Post</strong>ALM-2524ALM-2524/1PhALM-3024 ISSUED 21-09-99• the vehicle engine is switched off,the vehicle is in gear, and the handbrakeis engaged.• the vehicle is correctly positioned.• all weight and dimension limits areobserved.RISKS DURING VEHICLE LIFTINGThe following safety devices have beenintroduced to avoid overloading anddamage:• In the case of overload: thermalrelay will cut out.• in the case of damage to the loadbearingnut , a safety nut (ref1Fig.9) is automatically engaged.• to prevent overrun of the mobilepart,an electric limit switch and a steelplate stop are envisaged for the upperpart of the post (Fig.10).Fig.9RISKS FOR OPERATORPossible if the operator controlling thelift is not in the specified position at thecommand panel. When the platformsand vehicle are descending, the operatormust never be partly or completelyunderneath the moving structure. Duringthis phase the operator must remainin the command zone (Fig.11 + Fig.6).Fig.11RISKS FOR PERSONNELWhen the platforms and vehicle aredescending, personnel are prohibitedfrom entering the area beneath themoving parts of the lift (Fig.12). The liftoperator must not start the manoeuvreuntil it has been clearly established thatthere are no persons in potentiallydangerous positions.avoid impact with parts of the machinenot marked with special hazard colouring(Fig.13).Fig.13RISKS DUE TO VEHICLE MOVEMENT(Fig.14)Movement may be caused during operationswhich involve force sufficient tomove the vehicle. If the vehicle is ofconsiderable dimensions or weight ,movement may lead to overloading orunbalancing; all measures must betaken to avoid such an occurrence.Fig.12Fig.14Fig.10RISKS FOR PERSONSThis paragraph illustrates risks to whichthe operator, maintenance worker orany person near the operating area ofthe lift may be exposed in the case.RISK OF IMPACTCaused by parts of the lift or the vehiclethat are positioned at head height.When, due to operational reasons, thelift is immobilised at relatively low elevations( less than 1.75 m from theground) personnel must be careful toAUTEC Hefbruggen bvIndustrieterrein Ijsselveld, Vlasakker 11, 3417 XT MONTFOORT, The NetherlandsTel:+31(0)348 -477000 Fax:+31 (0)348-475104 E-mail: info@autec-vlt.nlRISK OF VEHICLE FALL FROM LIFTThis risk could be caused by the incorrectpositioning of the vehicle on thearm disk support plates (Fig.15). orincorrect positioning of the arm disksupport plates in relation to the lift.Prevent this by always positioningthe arm disk support plates underen/TA-ALM-2524-05

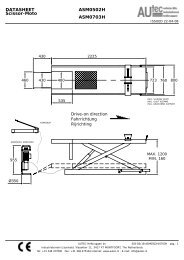

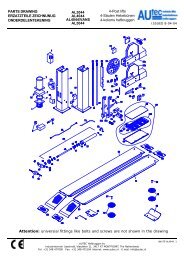

USER MANUAL2-<strong>Post</strong>OPERATING SEQUENCE1) Lifting pointsPosition rack arms underneath by thevehicle manufacturer recommended liftpoints, then adjust disk support plates tosame height. Whenever you lower thelift to the ground, before lifting again,recheck the position of the lift disk supportplates under the vehicle chassis.2) LiftingTurn the masterswitch to position 1,push the lift button. Release the liftbutton if the vehicle is lifted 40 cm fromthe ground. Check the position of thevehicle. If the vehicle is positionedcorrectly. Push the lift button again.3) ParkingRelease the lift button if the requiredheight is achieved, now switch themaster switch to position 0.ALM-2524ALM-2524/1PhALM-3024 ISSUED 21-09-997. MAINTENANCEMaintenance must be performed exclusively by expert personnel with thorough knowledgeof lift operation.During lift maintenance, take all necessary precautions to prevent accidental engagementof the lift:For lubricating the liftparts we recommend the following lubrication products( Fig.21):No. Texaco Shell ESSO Castrol1. Topbearing Molytex EP 2 Alvania HDX vet 2 Multipurpose vet+moly MS3 grease2. Side guidance Teflonspray Teflonspray Teflonspray Teflonspray3. Arm locking Molytex EP 2 Alvania HDX vet 2 Multipurpose vet+moly MS3 grease4. Chain Chainspray Chainspray Chainspray Chainspray5. Spindle Meropa 320 Omala 320 Spartan 320 Alfa SP320Plan of periodical lubrication1. Topbearing – 3 months2. Side guidance – 3 months3. Armlocking – 3 months4. Chain – 1 month5. Spindle – 1 month4) DescentAfter ensuring that no obstacles arepresent beneath the lift, turn masterswitch back to position 1, then press thedescend button to lower the vehicle tothe desired height or to the ground. If anobstacle hampers carriage during thisphase, the safety cabel will operate toimmobilise the lift.Mind: This is not a crushing preventionfor persons.Fig.21AUTEC Hefbruggen bvIndustrieterrein Ijsselveld, Vlasakker 11, 3417 XT MONTFOORT, The NetherlandsTel:+31(0)348 -477000 Fax:+31 (0)348-475104 E-mail: info@autec-vlt.nlen/TA-ALM-2524-07

USER MANUAL2-<strong>Post</strong>ALM-2524ALM-2524/1PhALM-3024 ISSUED 21-09-998. TROUBLE SHOOTINGThe trouble searching and the possible repair intervention need the observance of ALL THE SAFETY PRECAUTIONS shown inthis manual.PROBLEMS POSSIBLE REASON CURE The lift doesn’t rise while pushing the lift The fuse is burnt Replace the fusebutton Lift overload Conform to the scheduled capacity Microswitch(es) not working Replace the microswitch (call for assistance) The chain is broken Replace chaine Fault in electric system Call assistance The lift don’t finish the path of lift Thermal cut-out disconnection Resetting the thermal cut out Lift overload Conform to the scheduled capacity Line voltage too low Check the line voltage Motor driving belts slack Pull the driving belts The lift do not descend while pushing the Object under lift Remove the objectbutton Fault in electric system Call for assistance Lift blocked Safety cable broken Replace cable (call assistance) Safety limit switch blocked Check gearing chain. Check the bearingnut (call forassistance)SPARE ORDERING PROCEDURETo order the spare parts it is necessary to: indicate the lift serial number and the year of manufacturingFor spare parts we refer to the next TIB-pages available on request:UNI-TE-ALM-2524-01 / UNI-TE-ALM-2524-02 / UNI-TE-ALM-2524-03 / UNI-TE-ALM-2524-04ACCESSOIRES ALM-2524 ( Fig.22)The lifting pad extensionset ALM 2524/V12 and ALM-2524/V20 are options for the ALM 2524 <strong>lifts</strong>. Every set comprises of 4 lifting extensions.The lifting pad extensions are used:• for vehicles with high level lifting points• lifting points that lay more to the inside of the carbody. Without use of the extension the carbody will touch the lifting armsINSTALLATIEThe installation of the set is very simple. The extension is placed on the top of the normal lifting pads and secured with the locking device.Fig.22AUTEC Hefbruggen bvIndustrieterrein Ijsselveld, Vlasakker 11, 3417 XT MONTFOORT, The NetherlandsTel:+31(0)348 -477000 Fax:+31 (0)348-475104 E-mail: info@autec-vlt.nlen/TA-ALM-2524-08

USER MANUAL2-<strong>Post</strong>ALM-2524ALM-2524/1PhALM-3024 ISSUED 21-09-999. CERTIFICATE OF CONFORMITYAUTEC Hefbruggen b.v.Vlasakker 11NL 3417 XT MontfoortThe Netherlandshereby declares that the lift typeA: ALM-2524B: ALM-2524 / 1-PhC: ALM-3024has been manufactured in accordance with thespecificationsFOLLOWING THE GUIDELINES OF 14-06-89((89/392/EEG), ammended by guidelines 91/368/EEG,93/44/EEG, EN 60204-1, EN 414, EMC 89/336/EEG,73/23/EEG, EN 292-1: 1992, EN 292-2: 1992, EN 394,EN418, Pr EN 1493 aug. 1994 and that the lift complies withthe said specifications an guidelines, and after inspection thelift has been awarded with a CE-certificateA,B: NL97 400 849803C: NL97 400 849804issued in 1997 by:Liftinstituut, Buikslotermeerplein 381,<strong>Post</strong>bus 36027,1020 AM AmsterdamThe NetherlandsAUTEC Hefbruggen bvIndustrieterrein Ijsselveld, Vlasakker 11, 3417 XT MONTFOORT, The NetherlandsTel:+31(0)348 -477000 Fax:+31 (0)348-475104 E-mail: info@autec-vlt.nlen/TA-ALM-2524-09