Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

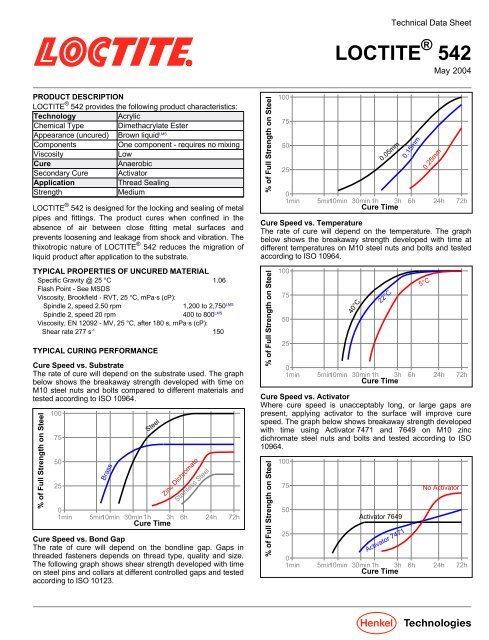

<strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>LOCTITE ® 542May-2004PRODUCT DESCRIPTIONLOCTITE ® 542 provides the following product characteristics:TechnologyAcrylicChemical Type Dimethacrylate EsterAppearance (uncured) Brown liquid LMSComponentsOne component - requires no mixingViscosityLowCureAnaerobicSecondary Cure ActivatorApplicationThread SealingStrengthMediumLOCTITE ® 542 is designed for the locking and sealing of metalpipes and fittings. The product cures when confined in theabsence of air between close fitting metal surfaces andprevents loosening and leakage from shock and vibration. Thethixotropic nature of LOCTITE ® 542 reduces the migration ofliquid product after application to the substrate.TYPICAL PROPERTIES OF UNCURED MATERIALSpecific Gravity @ 25 °C 1.06Flash Point - See MSDSViscosity, Brookfield - RVT, 25 °C, mPa·s (cP):Spindle 2, speed 2.50 rpm1,200 to 2,750 LMSSpindle 2, speed 20 rpm400 to 800 LMSViscosity, EN 12092 - MV, 25 °C, after 180 s, mPa·s (cP):Shear rate 277 s -1 150TYPICAL CURING PERFORMANCECure Speed vs. SubstrateThe rate of cure will depend on the substrate used. The graphbelow shows the breakaway strength developed with time onM10 steel nuts and bolts compared to different materials andtested according to ISO 10964.% of Full Strength on Steel100755025BrassSteel01min 5min10min 30min 1h 3h 6h 24h 72hCure TimeZinc DichromateStainless SteelCure Speed vs. Bond GapThe rate of cure will depend on the bondline gap. Gaps inthreaded fasteners depends on thread type, quality and size.The following graph shows shear strength developed with timeon steel pins and collars at different controlled gaps and testedaccording to ISO 10123.% of Full Strength on Steel1007550250.05mm01min 5min10min 30min 1h 3h 6h 24h 72hCure Time0.15mm0.25mmCure Speed vs. TemperatureThe rate of cure will depend on the temperature. The graphbelow shows the breakaway strength developed with time atdifferent temperatures on M10 steel nuts and bolts and testedaccording to ISO 10964.% of Full Strength on Steel10075502540°C22°C01min 5min10min 30min 1h 3h 6h 24h 72hCure TimeCure Speed vs. ActivatorWhere cure speed is unacceptably long, or large gaps arepresent, applying activator to the surface will improve curespeed. The graph below shows breakaway strength developedwith time using Activator 7471 and 7649 on M10 zincdichromate steel nuts and bolts and tested according to ISO10964.% of Full Strength on Steel100755025Activator 7649Activator 7471Cure Time5°CNo Activator01min 5min10min 30min 1h 3h 6h 24h 72h

TDS LOCTITE ® 542, May-2004TYPICAL PROPERTIES OF CURED MATERIALPhysical Properties:Coefficient of Thermal Expansion, ASTM D 696, K -1 80×10 -6Coefficient of Thermal Conductivity, ASTM C 177, 0.10W/(m·K)Specific Heat, kJ/(kg·K) 0.30TYPICAL PERFORMANCE OF CURED MATERIALAdhesive PropertiesAfter 24 hours @ 22 °CBreakaway Torque, ISO 10964:M10 steel nuts and bolts N·m 15(lb.in.) (130)Prevail Torque, ISO 10964:M10 steel nuts and bolts N·m 9(lb.in.) (80)Breakloose Torque, ISO 10964, Pre-torqued to 5 N·m:M10 steel nuts and bolts N·m 25(lb.in.) (220)Max. Prevail Torque, ISO 10964, Pre-torqued to 5 N·m:M10 steel nuts and bolts N·m 25(lb.in.) (220)Compressive Shear Strength, ISO 10123:Steel pins and collars N/mm² ≥6.50 LMS(psi) (940)TYPICAL ENVIRONMENTAL RESISTANCECured for 1 week @ 22 °CBreakloose Torque, ISO 10964, Pre-torqued to 5 N·m:M10 zinc phosphate steel nuts and boltsHot StrengthTested at temperature100% RT Strength755025Heat AgingAged at temperature indicated and tested at 22°C100% Initial Strength at RT755025120°C00 1000 2000 3000 4000 5000Hours150°CChemical/Solvent ResistanceAged under conditions indicated and tested at 22°C.% of initial strengthEnvironment °C 100 hr 500 hr 1000 hrMotor Oil 125 100 100 100Unleaded Petrol 22 100 100 95Brake fluid 22 100 100 95Water Glycol 50/50 87 90 90 90Ethanol 22 100 100 95Acetone 22 100 80 80GENERAL INFORMATIONThis product is not recommended for use in pure oxygenand/or oxygen rich systems and should not be selected asa sealant for chlorine or other strong oxidizing materials.For safe handling information on this product, consult theMaterial Safety <strong>Data</strong> <strong>Sheet</strong> (MSDS).Where aqueous washing systems are used to clean thesurfaces before bonding, it is important to check forcompatibility of the washing solution with the adhesive. Insome cases these aqueous washes can affect the cure andperformance of the adhesive.This product is not normally recommended for use on plastics(particularly thermoplastic materials where stress cracking ofthe plastic could result). Users are recommended to confirmcompatibility of the product with such substrates.00 50 100 150Temperature, °CDirections for useFor Assembly1. For best results, clean all surfaces (external and internal)with a <strong>Loctite</strong> cleaning solvent and allow to dry.2. If the material is an inactive metal or the cure speed is toslow, spray all threads with Activator 7471 or7649 and allow to dry.3. Apply a 360° bead of product to the leading threads of themale fitting, leaving the first thread free. Force thematerial into the threads to thouroughly fill the voids. Forbigger threads and voids, adjust product amountaccordingly and apply a 360° bead of product on thefemale threads also.4. Using accepted trade practices, assemble and wrenchtighten fittings until proper alignment is obtained.5. Properly tightened fittings will seal instantly to moderatepressures. For maximum pressure resistance and solventHenkel <strong>Loctite</strong> Americas+860.571.5100Henkel <strong>Loctite</strong> Europe+49.89.9268.0Henkel <strong>Loctite</strong> Asia Pacific+81.45.758.1810For the most direct access to local sales and technical support visit: www.loctite.com

TDS LOCTITE ® 542, May-2004resistance allow the product to cure a minimum of 24hours.For Disassembly1. Remove with standard hand tools.2. Where hand tools do not work because of excessiveengagement length or large diameters (over 1"), applylocalized heat to approximately 250°C. Disassemblewhile hot.For Cleanup1. Cured product can be removed with a combination ofsoaking in a <strong>Loctite</strong> solvent and mechanical abrasionsuch as a wire brush.<strong>Loctite</strong> Material Specification LMSLMS dated September-1, 1995. Test reports for each batchare available for the indicated properties. LMS test reportsinclude selected QC test parameters considered appropriate tospecifications for customer use. Additionally, comprehensivecontrols are in place to assure product quality andconsistency. Special customer specification requirements maybe coordinated through Henkel <strong>Loctite</strong> Quality.StorageStore product in the unopened container in a dry location.Storage information may be indicated on the product containerlabeling.Optimal Storage: 8 °C to 21 °C. Storage below 8 °C orgreater than 28 °C can adversely affect product properties.Material removed from containers may be contaminated duringuse. Do not return product to the original container. HenkelCorporation cannot assume responsibility for product whichhas been contaminated or stored under conditions other thanthose previously indicated. If additional information is required,please contact your local <strong>Technical</strong> Service Center orCustomer Service Representative.Conversions(°C x 1.8) + 32 = °FkV/mm x 25.4 = V/milmm / 25.4 = inchesN x 0.225 = lbN/mm x 5.71 = lb/inN/mm² x 145 = psiMPa x 145 = psiN·m x 8.851 = lb·inN·mm x 0.142 = oz·inmPa·s = cPNoteThe data contained herein are furnished for information onlyand are believed to be reliable. We cannot assumeresponsibility for the results obtained by others over whosemethods we have no control. It is the user's responsibility todetermine suitability for the user's purpose of any productionmethods mentioned herein and to adopt such precautions asmay be advisable for the protection of property and of personsagainst any hazards that may be involved in the handling anduse thereof. In light of the foregoing, Henkel Corporationspecifically disclaims all warranties expressed or implied,including warranties of merchantability or fitness for aparticular purpose, arising from sale or use of HenkelCorporation’s products. Henkel Corporation specificallydisclaims any liability for consequential or incidentaldamages of any kind, including lost profits. The discussionherein of various processes or compositions is not to beinterpreted as representation that they are free fromdomination of patents owned by others or as a license underany Henkel Corporation patents that may cover suchprocesses or compositions. We recommend that eachprospective user test his proposed application before repetitiveuse, using this data as a guide. This product may be coveredby one or more United States or foreign patents or patentapplications.Trademark usageLOCTITE is a trademark of Henkel CorporationReference 1Henkel <strong>Loctite</strong> Americas+860.571.5100Henkel <strong>Loctite</strong> Europe+49.89.9268.0Henkel <strong>Loctite</strong> Asia Pacific+81.45.758.1810For the most direct access to local sales and technical support visit: www.loctite.com