Assignment 1- Materials Characterization (First year M.Tech)

Assignment 1- Materials Characterization (First year M.Tech)

Assignment 1- Materials Characterization (First year M.Tech)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

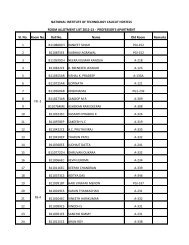

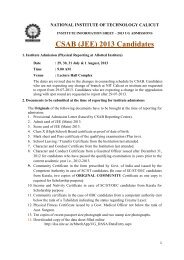

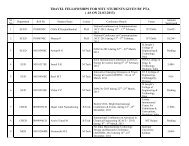

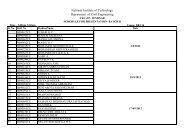

<strong>Assignment</strong> 1- <strong>Materials</strong> <strong>Characterization</strong> (<strong>First</strong> <strong>year</strong> M.<strong>Tech</strong>)1. Nine strips of pure, fully annealed copper wire deformed plastically by being passedbetween a pair of rotating rollers so that the strips were made thinner and longer. Theincrease in length produced were 1 , 10 ,20,30,40,50,60,70,and 100 percentrespectively. The diamond pyramid hardness of each piece was measured afterrolling. The results are given in the following table.Nominal strain 0.01 0.1 0.2 0.3 0.4 0.5 0.6 0.7 1.0Hardness(MN m -2 ) 423 606 756 870 957 1029 1080 1116 1170Assuming that a diamond –pyramid hardness test creates a further nominal strain, onaverage, of 0.08 and that the hardness value is 3 times the true strain, construct the curve ofnominal stress against nominal strain. ( Hint: add 0.08 to each value of nominal strain in thetable)Using the plot , find i) tensile strength of copper ii) the strain at which tensile failurecommences iii) the percentage reduction in cross sectional area at this strain iv) the workrequired to initiate tensile failure in a cubic metre of annealed copper.Why can copper survive a much higher extension during rolling than during a tensile test?(Answers : 217MPa, 0.6 approximately, 38 % , 109MJ)2. The following data were obtained in a tensile test on a specimen with 50mm gauge lengthand a cross sectional area of 160mm 2 .Extension(mm) 0.050 0.1 0.15 0.2 0.25 0.3 1.25 2.5 3.75 5 6.25 7.50Load (kN) 12 25 32 36 40 42 63 80 93 100 101 90Jagadeesha T, Assistant Professor, Department of Mechanical Engineering, NIT Calicut. Page 1

The total elongation of the specimen just before final fracture was 16 percent, and thereduction in area at the fracture was 64 percent. Find the maximum allowable working stressif this is to equal i) 0.25 x tensile strength ii) 0.6 x0.1 percent proof stress.( Answers 160MPa , 131 MPa)3. One type of hardness test involves pressing a hard sphere ( radius r) into the test materialunder a fixed load F, and measuring the depth, h, to which the sphere sinks into the material ,plastically deforming it. Derive an expression for the indentation hardness, H , of the materialin terms of h, F, and r . Assume ( h