Series R⢠Helical Rotary Liquid Chillers Model RTHD 175-450 ...

Series R⢠Helical Rotary Liquid Chillers Model RTHD 175-450 ...

Series R⢠Helical Rotary Liquid Chillers Model RTHD 175-450 ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

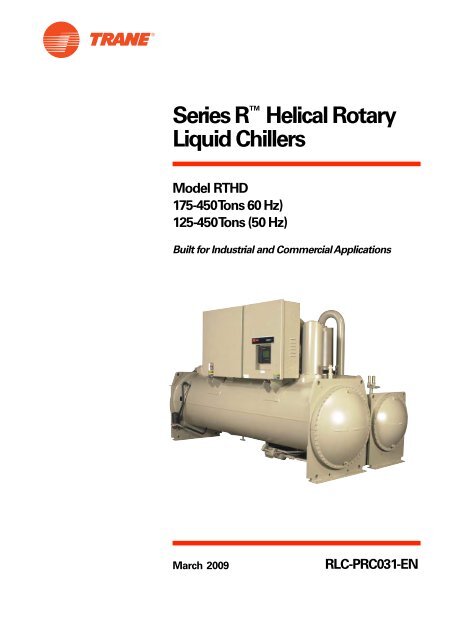

<strong>Series</strong> R <strong>Helical</strong> <strong>Rotary</strong><strong>Liquid</strong> <strong>Chillers</strong><strong>Model</strong> <strong>RTHD</strong><strong>175</strong>-<strong>450</strong> Tons 60 Hz)125-<strong>450</strong> Tons (50 Hz)Built for Industrial and Commercial ApplicationsMarch 2009RLC-PRC031-EN

IntroductionTo meet a wide range of applications inthe medium-tonnage, water-cooledmarket, Trane is proud to introduce themodel <strong>RTHD</strong> helical rotary liquid chiller.The introduction of this nextgenerationchiller an exciting stepforward in application versatility, easeof installation, control precision,reliability, energy-efficiency, andoperational cost-effectiveness. The new<strong>RTHD</strong> chiller is designed to deliverproven <strong>Series</strong> R performance, plus allthe benefits of an advanced heattransfer design and a low-speed, directdrivecompressor.Important Design Advancesand New FeaturesMajor design advances include:• Higher full-load energy efficiencyreduces both operating and life-cyclecosts.• CH530 controls enable:- scrolling access to inputs andoperating information via the LCDtouch-screen display;- freedom from interoperabilityconcerns with LonMarkcommunications;- job-specific communication optionsthat allow greater reportingflexibility.• Improved startup temperaturecapabilities and reduced sensitivity tocondenser water temperaturesalleviate the most common startupconcerns.• Removed <strong>Liquid</strong> Vapor Separator,providing lighter unit weight andsimplified refrigerant piping, for lessexpensive handling, separation, andinstallation.The industrial-grade design of the<strong>Series</strong> R helical rotary chiller is ideal forboth industrial and commercialmarkets, in applications such as officebuildings, hospitals, schools, retailbuildings, and industrial facilities. Thelinear unloading compressor, wideoperating temperature range,advanced controls, electronicexpansion valve, short anti-recycletimers, and industry-leadingefficiencies mean that this latest Trane<strong>Series</strong> R chiller is the perfect choice fortight temperature control in almost anyapplication temperatures, and underwidely varying loads.© 2004 American Standard Inc. All rights reserved.RLC-PRC031-EN

ContentsIntroductionFeatures and BenefitsOptionsControlsApplication ConsiderationsSelection Procedure<strong>Model</strong> NomenclatureGeneral DataElectrical Data and ConnectionsDimensions and WeightsMechanical SpecificationsConversion Table24681012141619222930RLC-PRC031-EN 3

Features andBenefitsApplication Versatility and HighPerformance• Screw compressor technology andthe electronic expansion valveprovide reliable performance in anexpanded range of operatingtemperatures.• Tight water temperature controlextends to operation of multiplechillers in parallel or seriesconfigurations, offering furthersystem design flexibility formaximum efficiency.• Advanced design enables chilledwater temperature control to +/- 0.5°F (.28°C) for flow changes up to10 percent per minute, plus handlingof flow changes up to 30 percent perminute for comfort cooling.• Two-minute stop-to-start and fiveminutestart-to-start anti-recycle timerallows tight chilled water temperaturecontrol in constant or transient lowloadapplications.• LonMark communications capabilityprovides excellent, trouble-freeinteroperability.• Generic Building AutomationSystem points are available for easyaccess to operational information.• Extensive information onprofessional design selection andlayout is available in a simple, highlyreadable electronic format.• Standard model <strong>RTHD</strong>configurations are in stock andavailable for immediate delivery, andTrane offers the fastest ship cycles inthe industry for built-to-order units.• Industrial / Low TemperatureProcess Cooling – Excellentoperating temperature range andprecise control capabilities enabletight control with single chiller orseries configuration.• Ice/Thermal Storage – Specifiersand operators benefit from dualsetpoint control and industry-leadingtemperature, efficiency, and controlcapabilities, plus outstanding supportthrough partnership with Calmac, astrong Trane partner providing proveninstallation examples, templates, andreferences that minimize design timeand energy costs.Simple, Economical Installation• Compact size makes the model<strong>RTHD</strong> well suited for the retrofit andreplacement market.• All units fit through standard doublewidthdoors.• Bolt-together construction makes forfast, easy unit disassembly.• Small <strong>RTHD</strong> footprint saves valuableequipment room space and alleviatesaccess concerns for most retrofit jobs.• Lightweight design simplifiesrigging requirements, furtherreducing installation timerequirements and costs.• Full factory refrigerant or nitrogenand oil charges reduce required fieldlabor, materials, and installation cost.• Only evaporator and condenserwater piping is required; no starterwater cooling (with its associatedsafety concerns) or field piping isnecessary.• Oil cooler and purge systemconnections have been eliminated.• Simple power connection simplifiesoverall installation.• Standard unit-mounted starter forWye-Delta and Solid State eliminatesadditional jobsite installationconsiderations and laborrequirements.• Trane has conducted extensivefactory testing, and also offers optionsfor in-person and/or documentedsystem performance verification.• CH530 controls easily interface withTracer Summit building automationsystems through single twisted-pairwire.4RLC-PRC031-EN

Features andBenefitsState-of-the-Art, Precision Control• Microprocessor-based CH530controls monitor and maintainoptimal operation of the chiller and itsassociated sensors, actuators, relays,and switches, all of which are factoryassembledand extensively tested.• Easy interface with computershosting Tracer Summit buildingautomation/energy managementsystems allows the operator toefficiently optimize comfort systemperformance and minimize operatingcosts.• PID (proportional integral derivative)control strategy ensures stable,efficient chilled water temperaturecontrol, maintaining +/- 1°F (0.56°C)control by proactively reacting toinstantaneous load changes of up to50 percent.• Adaptive Control attempts tomaintain chiller operation underadverse conditions, when many otherchillers might simply shut down.• Easy-to-use operator interfacedisplays all operating and safetymessages, with complete diagnosticsinformation, on a highly readablepanel with a scrolling touch-screendisplay.• The <strong>RTHD</strong> features a complete rangeof chiller safety controls.• Over 120 diagnostic and operatingpoints are available, with standarddisplays including chiller currentdraw, condenser pressure, andevaporator pressure.Reliability and Ease of Maintenance• Direct drive, low-speed compressor– a simple design with only threemoving parts – provides maximumefficiency, high reliability, and lowmaintenance requirements.• Electronic expansion valve, withfewer moving parts than alternativevalve designs, offers highly reliableoperation.• Suction gas-cooled motor staysuniformly cool at lower temperaturesfor longer motor life.• The Trane helical rotary compressoris a proven design resulting fromyears of research and thousands oftest hours, including extensive testingunder extraordinarily severeoperating conditions.• Trane is the world’s largestmanufacturer of large helical rotarycompressors, with tens of thousandsof commercial and industrialinstallations worldwidedemonstrating a reliability rate ofgreater than 99 percent in the firstyear of operation.Operating and Life CycleCost-Effectiveness• Electronic expansion valve enablesexceptionally tight temperaturecontrol and extremely low superheat,resulting in more efficient full-loadand part-load operation thanpreviously available.• Precise compressor rotor tipclearance ensures optimal efficiency.• Condenser and evaporator tubesuse the latest heat transfer technologyfor increased efficiency.• The <strong>RTHD</strong> includes optionalelectrical demand limiting.• Chilled water reset based on returnwater temperature is standard.• High compressor lift capabilities andtight chilled water temperature controlallow highly efficient system designwith minimal operational concerns.Design capabilities include:• variable primary flow;• series chiller arrangements forevaporator and/or condenser;• low evaporator and condenser flow.RLC-PRC031-EN5

OptionsInsulationAll low temperature surfaces arecovered with factory installed 3/4 inch(19.05 mm) Armaflex II or equal (k=0.28)insulation, including the evaporator andwater boxes, suction line, and motorhousing. 3/8" foam insulation is usedon the liquid level sensor and gaspump assembly, including piping.Low-Temperature EvaporatorAddition of an oil cooler to the oil circuitenables evaporator operation down tominimum leaving water temperature of10°F (-12.2°C).High-Temperature CondenserAddition of an oil cooler to the oil circuitenables condenser operation up tomaximum leaving water temperatureof 114°F (45.6°C).Smooth-Bore Condenser TubesSmooth-bore copper or premium cupronickelcondenser tubes, 3/4”(19.05mm) in diameter with .035”(0.889mm) wall thickness, are availablefor high fouling water applications.Refrigerant Isolation ValvesFactory-installed condenser inlet andoutlet refrigerant valves allow isolationof the full refrigerant charge in thecondenser while servicing the chiller.Marine Water BoxesAddition of marine water boxes for thecondenser allows tube cleaning withoutwater pipe interference.300 psig Evaporator and CondenserWater BoxesWater boxes are designed for 300 psigmaximum waterside working pressure,and flange connections are provided forease of installation.2-Way Condenser Water Regulating ValveFor water regulation, a field-installed,2-way butterfly-type (lug-style) valve,with integral electrical operator andfactory-mounted valve actuator, isavailable. The single-phase, reversiblemotor can be factory-wired for 220VAC, 50 Hz; the 2-way valve is fieldwiredand controlled by the chillerregulating valve control output; valvesare available in 6" and 8" (152.4 and203.2 mm) sizes.Nitrogen ChargeUnit is shipped with a nitrogen holdingcharge in lieu of refrigerant.Seal Kit for ReassemblyIdeal for situations when the bolttogetherconstruction of the <strong>RTHD</strong> willbe separated for installation, this sealkit provides replacement gaskets andrings for reassembly.Solid State StarterSolid State Starter is unit-mounted witha NEMA 1 gasketed enclosure. Toextend starter life, contactors bypasscurrent from the silicon controlrectifiers (SCRs) after startup.Under/Over-Voltage ProtectionUnit receives protection againstvariations in voltage (current lag andspike protection is standard).Performance and Witness TestsARI-certified <strong>RTHD</strong> Performance andWitness Tests are available, based onrequested operating points, to certifychiller performance before delivery.Main Power DisconnectOptions:Non-fused DisconnectA UL-approved non-fused molded casedisconnect switch, factory pre-wiredwith terminal block power connectionsand equipped with a lockable externaloperator handele, is available todisconnect the chiller from main power.Standard Interrupting Capacity CircuitBreakerA UL-approved standard interruptingmolded case capacity circuit breaker,factory pre-wired with terminal blockpower connections and equipped with alockable external operator handle, isavailable to disconnect the chiller frommain power.6RLC-PRC031-EN

OptionsControl Options:Tracer Summit CommunicationsLink to factory-installed, testedcommunication board, via singletwisted-pair wiring, adds Tracer Summitcommunications to the system.LonTalk LCI-C InterfaceLonTalk (LCI-C) communicationscapabilities are available, withcommunication link via single twistedpairwiring to factory-installed, testedcommunication board.External Chilled Water SetpointExternal Chilled Water Setpoint iscommunicated to a factory-installed,tested communication board through a2-10Vdc or 4-20mA signal.External Current LimitingExternal Current Limit Setpoint iscommunicated to a factory-installed,tested communication board through a2-10Vdc or 4-20mA signal.External Base LoadingExternal Base Loading iscommunicated to a factory-installedand tested communication boardthrough a 2-10Vdc or 4-20mA signal.Ice Making ControlControls and safeties allow operationwith brine temperatures down to 20°F(-6.7°C) , and dual setpoints enableboth ice making and daytime comfortcooling.Programmable RelaysDefault-set, factory-installed,programmable relays allow theoperator to select four relay outputsfrom a list of eight. Available relays are:Alarm-Latching, Alarm-Auto Reset,General Alarm, Warning, Chiller LimitMode, Compressor Running, HeadPressure Relief Request, and TracerControl.Chilled Water Reset – Outdoor AirTemperatureControls, sensors, and safeties allowreset of chilled water temperature,based on temperature signal, duringperiods of low outdoor air temperature(chilled water reset based on returnchilled water temperature is standard).Condenser-Regulating Valve ControlChiller applies a Proportional IntegrativeControl (PID) algorithm to control waterregulating valve via 0-10Vdc signal.Percent of Full Run Load Amps OutputControl system indicates the activechiller percent of full run load amps,based on a 0-10Vdc signal.Condenser Pressure OutputControl system indicates chillerdifferential pressure or condenserpressure, based on a 0-10Vdc signal.Refrigerant Monitor InputControl system indicates refrigerantmonitor status of 0-100 or 0-1000 ppm(user selectable), based on a 2-10Vdc /4-20 mA signal.RLC-PRC031-EN7

ControlsLCD Touch-Screen Displaywith Multi-Language SupportThe standard DynaView displayprovided with the CH530 control panelfeatures an LCD touch-screen, allowingaccess to all operational inputs andoutputs. This display supports elevenlanguages: English, Chinese, Dutch,French, German, Italian, Japanese,Korean, Portugese, Spanish and Thai.Additional Display Features Include:• LCD touch-screen with LEDbacklighting, for scrolling access toinput and output operatinginformation• Weather-proof enclosure for reliableoperation in non-standard indoorenvironments• Spin value buttons to allowcontinuously variable setpoints whenapplicable• Radio and action buttons for easy,one-time actions and settings• Single-screen, folder/tab-styledisplay of all available information onindividual components (evaporator,condenser, compressor, etc.)• Automatic and immediate stopcapabilities for standard or immediatemanual shutdown• Manual override indication• Password entry/lockout system toenable or disable display• Fast, easy access to available chillerdata in tabbed format, including:— Modes of operation, includingnormal cooling and icemaking— Water temperatures and setpoints— Loading and limiting status andsetpoints— Average line current— Outdoor air temperature— Start/stop differential timers— Auto/Manual mode for EXV, slidevalve, and head pressure control— Pump status and override— Chilled water reset, start point,ratio, and outdoor start point— External setpoints, including:- chilled water- current limit- ice building- base loading— Display specifics, including:- date- format- time- display lockout- display units- language setting- Reports, listed on a single tabbedscreen for easy access, including:• ASHRAE, containing allguideline 3 report information• Evaporator• Condenser• Compressor— Evaporator, condenser, andcompressor reports containing alloperational information onindividual components, including:- Water and air temperatures- Refrigerant levels, temperatures,and approach- Oil pressure- Flow switch status- EXV position- Head pressure control command- Compressor starts and run-time- Line phase percent RLA, amps,and volts— Alarm and diagnostic information,including:- Flashing alarms with touch-screenbutton for immediate address ofalarm condition- Scrollable list of last ten activediagnostics- Specific information on applicablediagnostic from list of over onehundred- Automatic or manual resettingdiagnostic types8RLC-PRC031-EN

ControlsTrane Chiller PlantAutomationTrane’s depth of experience in chillersand controls makes us a well-qualifiedchoice for automation of chiller plantsusing air-cooled <strong>Series</strong> R ® chillers ® . Thechiller plant control capabilities of theTrane Tracer Summit ® buildingautomation system are unequaled inthe industry. Our chiller plantautomation software is fully preengineeredand tested. It is a standardsoftware application, not customprogramming which can prove to bedifficult to support, maintain, andmodify.Energy EfficiencyTrane chiller plant automationintelligently sequences starting ofchillers to optimize the overall chillerplant energy efficiency. Individualchillers are designated to operate asbase, peak, or swing based on capacityand efficiency. Sophisticated softwareautomatically determines which chillerto run in response to currentconditions. The software alsoautomatically rotates individual chilleroperation to equalize runtime and wearbetween chillers.Trane chiller plant automation enablesunique energy-saving strategies. Anexample is controlling pumps, andchillers from the perspective of overallsystem energy consumption. Thesoftware intelligently evaluates andselects the lowest energy consumptionalternative.Regulatory ComplianceDocumentationComprehensive documentation ofrefrigerant management practices isnow a fact of life. Trane chiller plantautomation generates the reportsmandated in ASHRAE Guideline 3.Keeping Operators InformedA crucial part of efficiently running achiller plant is assuring that theoperations staff is instantly aware ofwhat is happening in the plant.Graphics showing schematics ofchillers, piping, pumps, and towersclearly depict the chiller plant system,enabling building operators to easilymonitor overall conditions. Statusscreens display both current conditionsand upcoming automated controlactions to add or subtract chillercapacity. <strong>Series</strong> R and other chillerscan be monitored and controlled froma remote location.Tracer Summit features standard reporttemplates listing key operating data fortroubleshooting and verifyingperformance. Reports for each type ofTrane chiller and three and six-chillersystems are also standard. Detailedreports showing chiller runtimes aid inplanning for preventative maintenance.Swift Emergency ResponseWe understand the importance ofmaintaining chilled water productionwhile protecting your chillers fromcostly damage. If no water flow isdetected to a chiller’s piping, the startsequence is aborted to protect thechiller. The next chiller in the sequenceis immediately started to maintaincooling.In the event of a problem, the operatorreceives an alarm notification anddiagnostic message to aid in quick andaccurate troubleshooting. A snapshotreport showing system status just priorto an emergency shutdown helpsoperators determine the cause. Ifemergency conditions justify animmediate manual shutdown, theoperator can override the automaticcontrol.Integrated Comfort CapabilitiesWhen integrated with a Tracer Summitbuilding management systemperforming building control, Tranechiller plant automation coordinateswith Tracer Summit applications tooptimize the total building operation.With this system option, the fullbreadth of Trane’s HVAC and controlsexperience are applied to offersolutions to many facility issues. If yourproject calls for an interface to othersystems, Tracer Summit can share datavia BACnet , the ASHRAE opensystems protocol.LonTalk Chiller ControlsLonTalk is a communications protocoldeveloped by the Echelon Corporation.The LonMark association developscontrol profiles using the LonTalkcommunication protocol. LonTalk is aunit level communications protocol,unlike BACNet used at the systemlevel.LonTalk Communications Interface for<strong>Chillers</strong> (LCI-C) provides a genericautomation system with the LonMarkchiller profile inputs/outputs. Inaddition to the standard points, Traneprovides other commonly usednetwork output variables for greaterinteroperability with any automationsystem. The complete reference list ofTrane LonTalk points is available on theLonMark website. Trane controls oranother vendor’s system can use thepredefined list of points with ease togive the operator a complete picture ofhow the system is running.Hardwire PointsRemote devices wired from the controlpanel are another reliable method ofproviding auxiliary control to a buildingautomation system. Inputs andoutputs can be communicated via atypical 4-20 mA electrical signal (or anequivalent Vdc signal of 0-10 or 2-10) orby utilizing contact closures.• External Chilled Water Setpoint• External Current Limit Setpoint• Condenser-Regulating Valve Control• Percent of Full Run Load AmpsOutput• Condenser Pressure Output• Refrigerant Monitor Input• Programmable RelaysAllows the selection of 4 relay outputsfrom a list of eight different defaultsettings: Alarm-Latching, Alarm-AutoReset, General Alarm, Warning, ChillerLimit Mode, Compressor Running,Head Pressure Relief Request, andTracer Control. These contact closuresmay be used to trigger jobsite suppliedaudible or visual alarms• Ice Making ControlProvides an interface with ice makingcontrol system and safeties, enablingboth ice making and daytime comfortcooling• Chilled Water Temperature ResetSupplies controls, sensors and safetiesto reset the chilled water temperaturesetpoint based upon return watertemperature (standard) or outdoor airtemperature (optional)RLC-PRC031-EN9

ApplicationConsiderationsCondenser Water TemperaturesReduced sensitivity to condenser waterstartup temperatures is one majorenhancement in the newest-generationwater-cooled <strong>Series</strong> R chiller. With themodel <strong>RTHD</strong> chiller, a condenser watercontrol method is necessary only if theunit starts with entering watertemperatures below 55°F (12.8°C), orbetween 45°F (7.2°C) and 55°F (12.8°C), when a temperature increase of1°F (0.56°C) per minute to 55°F (12.8°) is not possible.When the application requires startuptemperatures below the prescribedminimums, a variety of options areavailable. To control a 2-way or 3-wayvalve, Trane offers a CondenserRegulating Valve Control option for theCH530 controls. This option enables theCH530 controls to send a signal foropening and closing the valve asnecessary to maintain chillerdifferential pressure. The 2-way valvesare available as a ship-with option.Tower bypass is also a valid controlmethod if the chiller temperaturerequirements can be maintained.Trane <strong>Series</strong> R chillers start and operatesuccessfully and reliably over a rangeof load conditions with controlledentering condenser water temperature.Reducing the condenser watertemperature is an effective method oflowering chiller power input required,but the ideal temperature foroptimizing total system powerconsumption will depend on theoverall system dynamics. From asystem perspective, someimprovements in chiller efficiency maybe offset by the increased tower fanand pumping costs required to achievethe lower tower temperatures. Contactyour local Trane systems solutionprovider for more information onoptimizing system performance.The minimum acceptable refrigerantpressure differential betweencondenser and evaporator is 23 psid.The chiller control system will attemptto obtain and maintain this differentialat startup, but for continuous operationa design should maintain a 25°F (13.9°C) differential from evaporatorleaving water temperature tocondenser leaving water temperature.Variable Evaporator Flow and ShortEvaporator Water LoopsVariable evaporator flow is an energysavingdesign strategy which hasquickly gained acceptance as advancesin chiller and controls technology havemade it possible. With its linearunloading compressor design andadvanced CH530 controls, the <strong>RTHD</strong>has excellent capability to maintainleaving water temperature controlwithin +/-0.5°F (0.28°C) , even forsystems with variable evaporator flowand small chilled water volumes.Some basic rules should be followedwhenever using these system designand operational savings methods withthe <strong>RTHD</strong>. The proper location of thechilled water temperature controlsensor is in the supply (outlet) water.This location allows the building to actas a buffer, and it assures a slowlychanging return water temperature. Ifthere is insufficient water volume in thesystem to provide an adequate buffer,temperature control can be lost,resulting in erratic system operationand excessive compressor cycling. Toensure consistent operation and tighttemperature control, the chilled waterloop should be at least two minutes. Ifthis recommendation cannot befollowed, and tight leaving watertemperature control is necessary, astorage tank or larger header pipeshould be installed to increase thevolume of water in the system.For variable primary flow applications,the rate of chilled water flow changeshould not exceed 10 percent of designper minute to maintain +/-0.5°F (0.28°C) leaving evaporator temperaturecontrol. For applications in whichsystem energy savings is mostimportant and tight temperaturecontrol is classified as+/-2°F (1.1°C), up to 30 percentchanges in flow per minute arepossible. Flow rates should bemaintained between the minimum andmaximum allowed for any particularchiller configuration.10RLC-PRC031-EN

ApplicationConsiderations<strong>Series</strong> Chiller ArrangementsAnother energy-saving strategy is todesign the system around chillersarranged in series, on the evaporator,condenser, or both. The actual savingspossible with such strategies dependson the application dynamics andshould be researched by consultingyour Trane Systems SolutionsRepresentative and applying the TraneSystem Analyzer program. It is possibleto operate a pair of chillers moreefficiently in a series chillerarrangement than in a parallelarrangement. It is also possible toachieve higher entering-to-leavingchiller differentials, which may, in turn,provide the opportunity for lowerchilled water design temperature,lower design flow, and resultinginstallation and operational costsavings. The Trane screw compressoralso has excellent capabilities for “lift,” which affords an opportunity forsavings on the evaporator andcondenser water loops. Like seriesarrangements on the evaporator, seriesarrangements on the condenser mayenable savings. This approach mayallow reductions in pump and towerinstallation and operating costs.Maximizing system efficiency requiresthat the designer balance performanceconsiderations for all systemcomponents; the best approach may ormay not involve multiple chillers, orseries arrangement of the evaporatorsand/or condensers. This ideal balanceof design integrity with installation andoperating cost considerations can alsobe obtained by consulting a Tranerepresentative and applying the TraneSystem Analyzer program.Water TreatmentThe use of untreated or improperlytreated water in chillers may result inscaling, erosion, corrosion, and algaeor slime buildup. It is recommendedthat the services of a qualified watertreatment specialist be engaged todetermine what treatment, if any, isadvisable. Trane assumes noresponsibility for the results of usinguntreated or improperly treated water.Water PumpsWhere noise limitation and vibrationfreeoperation are important, Tranestrongly encourages the use of <strong>175</strong>0-rpm (60 Hz), 1<strong>450</strong>-rpm (50 Hz) pumps.Specifying or using 3600-rpm (60 Hz),3000-rpm (50 Hz) condenser water andchilled water pumps must be avoided,because such pumps may operate withobjectionable levels of noise andvibration. In addition, a low frequencybeat may occur due to the slightdifference in operating rpm between3600-rpm (60 Hz), 3000-rpm(50 Hz) water pumps and <strong>Series</strong> Rchiller motors. Important Note: Thechilled water pump must not be usedto stop the chiller.Acoustic ConsiderationsFor chiller sound ratings, installationtips, and considerations on chillerlocation, pipe isolation, etc., refer to theTrane Water-Cooled <strong>Series</strong> R <strong>Chillers</strong>Sound Ratings and Installation Guide.Using the information provided in thisbulletin, contact a certified soundconsultant to aid in proper mechanicalroom design and treatment.Figure 1. Typical series chiller arrangementRLC-PRC031-EN11

SelectionProcedureTrane <strong>Series</strong> R chiller performance israted in accordance with the ARIStandard 550/590-2003 CertificationProgram. Chiller selection assistanceand performance information can beobtained by using the <strong>Series</strong> R chillerselection program, available throughlocal Trane sales offices.PerformanceThe computerized <strong>Series</strong> R chillerselection program providesperformance data for each possiblechiller selection at both full-load andpart-load design points, as required.It should be noted that changing thenumber of water passes or the waterflow rates will generally alter theperformance of a particular chiller. Toattain maximum benefit from the widerange of chiller models and optionsavailable, designers are encouraged tofirst develop performancespecifications and then use the chillerselection program to optimize allselections. This will help ensureselection of the compressorevaporator-condensercombinationthat most closely meets the jobrequirements. To optimize systemperformance, all selections should alsobe balanced with other systemcomponents.Fouling FactorsARI Standard 550 includes a definitionof clean tube fouling. Therecommended standard foulingadjustments are 0.0001 hr-sq ft-deg F/Btu (0.0176 sq m-deg C/kW) for theevaporator and 0.00025 hr-sq ft deg F/Btu (0.044 sq m-deg C/kW) for thecondenser, from an increment of 0.0000 “clean.” Chiller specificationsshould be developed using the mostcurrent standard fouling factors.Part Load PerformanceActual air-conditioning system loadsare frequently less than full-load designconditions. Depending on the numberof chillers on the job and the loadprofile, chillers may operate at full loada small percentage of the time. Withtheir excellent part-load performancecharacteristics and highly energyefficientoperation, <strong>Series</strong> R chillers canprovide significant operating savings atthese part-load conditions.System ConsiderationsPart-load chiller operation is frequentlyassociated with reduced condenserwater temperatures. However, ratherthan focusing only on the chiller, it isimportant to balance thesetemperatures to achieve the mostefficient system operation possible. Atpart-load operation, the heat rejected tothe cooling tower is less than at fullloadoperation.Part-load chiller operation is alsotypically associated with reducedoutside wet bulb temperatures,resulting in improved cooling towerperformance. The net result of reducedheat rejection and lower wet bulbtemperatures can be cooler condenserwater entering the chiller, ultimatelyimproving unit performance. However,this does not improve pump or towerefficiency. To achieve the most efficientsystem operation possible, it is best tominimize the total power draw of thechiller, tower, and pumps, which maynot mean limiting the condenser watertemperature to what the tower canprovide. To determine specific unit andsystem part-load performance forchiller selection purposes, use the<strong>Series</strong> R chiller computer selectionprogram or contact the local Tranesales office.12RLC-PRC031-EN

SelectionProcedureUnit Performance with Fluid MediaOther Than Water<strong>Series</strong> R chillers can be provided with awide variety of fluid media other thanwater, including ethylene glycol andpropylene glycol— in the evaporator,condenser or both. <strong>Chillers</strong> usingmedia other than water are excludedfrom the ARI 550/590-2003 CertificationProgram, but are rated in accordancewith ARI Standard 550/590-2003. Tranefactory performance tests are onlyperformed with water as the coolingand heat-rejection media. Whenconsidering selection of media otherthan water, contact the local Trane salesoffice for chiller selections and factoryperformance testing information.Fluid media other than water lowersthe heat transfer coefficient, andtherefore reduces chiller performance.In general, it is good practice to holdthe percent glycol added to within theminimum allowed by the Traneselection program, based on either (a)unit operating temperatures, or (b) theoperating temperatures the evaporatoror condenser water will experienceunder its full range of conditions.Adding more glycol than required forthe specific application is equivalent toselecting a less efficient chiller. Lowerviscosityglycols such as ethylene willhave less adverse impact on chillerperformance than higher-viscosityglycols such as propylene.Evaporator and Condenser PressureDropPressure drop data is determined bythe <strong>Series</strong> R chiller computer selectionprogram available through local Tranesales offices.Dimensional DrawingsDimensional drawings provided forselection purposes illustrate overallmeasurements of the unit. Therecommended service clearances arethose required to easily service the<strong>Series</strong> R chiller.All catalog dimensional drawings aresubject to change, and currentsubmittal drawings should bereferenced for more detaileddimensional information. Dimensionaldrawings are also available from theselection program. Contact the localTrane sales office for submittalinformation.Electrical Data TablesCompressor motor electrical data isprovided in the data section for eachcompressor size. Rated load amperes(RLA), locked rotor wye amperes (LRA)and expected inrush for the Wye-deltaand Solid State Starter configurationsare shown.Although the terms “LRA” and“expected inrush” are often usedinterchangeably, the distinction appliedhere is that LRA is the rated inrush forthe motor, but expected inrush is thatallowed by the starter, based on thespecific configuration.Selecting starters in the Wye-delta orSolid State configuration lowersexpected inrush vs. the Delta (or“across-the-line”) configuration. ASolid State Starter configuration lowersthe expected inrush by approximately50 percent, while Wye-Delta lowers itby approximately 66 percent.The RLA is based on the motor’sperformance when reaching full ratedhorsepower. The kW rating of themotor will equal or exceed the kWrequirement indicated by the <strong>Series</strong> Rcomputer selection program at designconditions. If motor kW draw at designconditions is less than the kW rating ofthe motor, the RLA at designconditions is determined bymultiplying the motor RLA (at thedesired voltage) by this ratio: designkW/motor kW rating. This calculation isperformed within the <strong>Series</strong> R chillercomputer selection program, makingRLA available as part of the designpredictions. Predicted values includepower factor variation from point topoint.A voltage utilization range is tabulatedfor each voltage listed. <strong>Series</strong> R chillersare designed to operate satisfactorilyover a utilization range of ±10 percentof the standard design voltages: 380 V,415 V for 50 Hertz, 3-phase.RLC-PRC031-EN13

<strong>Model</strong>NomenclatureR T H D C B 1 R X A 0 X L B 1 A 3 L A L B 1 A 2 L A L1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27Digit 1-4 Basic Product Line<strong>RTHD</strong>=Water-cooled <strong>Series</strong> RDigit 5 Manufacturing PlantU=Water Chiller Business Unit,Pueblo CO USAE=Epinal Business Unit, CharmesE=China Business UnitDigit 6-7 CompressorB1=B1 compressorB2=B2 compressorC1=C1 compressorC2=C2 compressorD1=D1 compressorD2=D2 compressorD3=D3 compressor (50HZ only)E3=E3 compressor (50HZ only)Digit 8 Unit Power SupplyC=230V/60Hz/3Ph powerD=380V/60Hz/3Ph powerR=380V/50Hz/3Ph powerT=400V/50Hz/3Ph powerU=415V/50Hz/3Ph powerF=460V/60Hz/3Ph powerDigit 9 Design SpecialsX=NoneC=Specials denoted elsewhereS=Specials not denoted elsewhereDigit 10-11 Design SequenceA0=Factory/ABU assigned, start withA0Digit 12 Agency ListingX=No agency listingU=C/UL listing3=CCC-Chinese Compulsory CodeDigit 13 Pressure Vessel CodeA=ASME pressure vessel codeC=Canadian codeL=Chinese codeS=SpecialDigit 14-15 EvaporatorB1=B1 evaporatorB2=B2 evaporatorC1=C1 evaporatorC2=C2 evaporatorD1=D1 evaporatorD2=D2 evaporatorD3=D3 evaporatorD4=D4 evaporatorD5=D5 evaporatorE1=E1 evaporatorF1=F1 evaporatorF2=F2 evaporatorG1=G1 evaporatorG2=G2 evaporatorG3=G3 evaporatorDigit 16 Evap Tube typeA=StandardDigit 17 Evaporator Passes2=2 pass evaporator3=3 pass evaporator4=4 pass evaporatorDigit 18 Evaporator WaterConnectionL=Left hand evaporator connectionR=Right hand evaporatorconnectionDigit 19 Evaporator Connection TypeA=Standard flange connectionS=SpecialDigit 20 Evaporator Water SidePressureL=150PSI/10.5Bar evaporator waterpressureH=300PSI/21Bar evaporator waterpressureDigit 21-22 CondenserB1=B1 condenserB2=B2 condenserD1=D1 condenserD2=D2 condenserE1=E1 condenserE2=E2 condenserE3=E3 condenserE4=E4 condenserE5=E5 condenserF1=F1 condenserF2=F2 condenserF3=F3 condenserG1=G1 condenserG2=G2 condenserG3=G3 condenserDigit 23 Condenser Tube TypeA=Enhanced fin-copperB=Smooth bore-copperC=Smooth bore-90/10 Cu/NiDigit 24 Condenser Passes2=2 passDigit 25 Condenser WaterConnectionL=Left hand evaporator connectionR=Right hand evaporatorconnectionDigit 26 Condenser Connection TypeA=Standard flange connectionC=MarineS=SpecialDigit 27 Condenser Water SidePressureL=150PSI/10.5Bar evaporator waterpressureH=300PSI/21Bar evaporator waterpressure14RLC-PRC031-EN

<strong>Model</strong>NomenclatureA X X Q X C X A A B X Y 1 7 4 A A X H X X X X X X X X28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54Digit 28 Condenser Leaving WaterTempA=Standard (

General DataNominal DataNominal Compressor B1 B2 C1 C2 D1 D2 D3 E3Tonnage (60 Hz) <strong>175</strong>-200 200-225 225-275 275-325 325-400 375-<strong>450</strong> N/A N/ATonnage (50 Hz) 125-150 150-<strong>175</strong> <strong>175</strong>-225 225-275 275-325 300-350 325-375 375-<strong>450</strong>Notes:1. Chiller selections can be optimized through the use of the ARI-Certified <strong>Series</strong> R selection program and by contacting your localTrane sales office.General DataEvaporator Condenser RefrigerantCompressor Evaporator Condenser Water Storage Water Storage Refrigerant ChargeCode Code Code Gallons Liters Gallons Liters Type lb kgB1 B1 B1 41 155 28 106 HFC-134a 410 186B1 C1 D1 55 208 31 117 HFC-134a 490 222B2 B2 B2 45 170 29 110 HFC-134a 410 186B2 C2 D2 58 220 34 129 HFC-134a 490 222C1 D6 E5 45 170 29 110 HFC-134a 490 222C1 D5 E4 52 197 32 121 HFC-134a 490 222C1 E1 F1 82 310 60 226 HFC-134a 525 238C2 D4 E4 52 197 32 121 HFC-134a 490 222C2 D3 E3 78 295 47 178 HFC-134a 490 222C2 F2 F3 107 405 61 231 HFC-134a 625 284D1 D1 E1 69 261 44 166 HFC-134a 475 216D1 F1 F2 102 386 57 216 HFC-134a 625 284D1 G1 G1 136 515 79 299 HFC-134a --- ---D2 D2 E2 74 280 47 178 HFC-134a 475 216D2 F2 F3 107 405 61 231 HFC-134a 625 284D2 G2 G1 144 545 79 299 HFC-134a --- ---D3/E3 D2 E2 74 280 47 178 HFC-134a 475 216D3/E3 F2 F3 107 405 61 231 HFC-134a 625 284D3/E3 G2 G1 144 545 79 299 HFC-134a --- ---16RLC-PRC031-EN

General DataWater Flow RatesMinimum/Maximum Evaporator Flow Rates (Gallons/Minute )Two Pass Three Pass Four PassEvaporator Nominal Nominal NominalCode Min Max Conn Size (In.) Min Max Conn Size (In.) Min Max Conn Size (In.)B1 253 1104 8 168 736 6 —- —- —-B2 288 1266 8 192 844 6 —- —- —-C1 320 1412 8 213 941 6 —- —- —-C2 347 1531 8 232 1022 6 —- —- —-D1 415 1812 8 275 1206 8 —- —- —-D2 <strong>450</strong> 1980 8 300 1320 8 —- —- —-D3 486 2131 8 324 1417 8 —- —- —-D4 351 1542 8 234 1028 8 —- —- —-D5 351 1542 8 234 1028 8 —- —- —-D6 293 1287 8 196 860 8 —- —- —-E1 <strong>450</strong> 1980 8 300 1320 8 —- —- —-F1 563 2478 10 376 1655 8 —- —- —-F2 604 2667 10 404 1780 8 —- —- —-G1 —- —- —- 505 2218 10 379 1666 8G2 —- —- —- 550 2413 10 411 1807 8Notes:1. Minimum flow rates are based on water only.2. All water connections are flange connections.Minimum/Maximum Evaporator Flow Rates (Liters/Second)Two Pass Three Pass Four PassEvaporator Nominal Nominal NominalCode Min Max Conn Size (mm) Min Max Conn Size (mm) Min Max Conn Size (mm)B1 16 70 200 11 46 150 —- —- —-B2 18 80 200 12 53 150 —- —- —-C1 20 89 200 13 59 150 —- —- —-C2 22 97 200 15 65 150 —- —- —-D1 26 114 200 17 76 200 —- —- —-D2 28 125 200 19 83 200 —- —- —-D3 31 134 200 20 89 200 —- —- —-D4 22 97 200 15 65 200 —- —- —-D5 22 97 200 15 65 200 —- —- —-D6 18 81 200 12 54 200 —- —- —-E1 28 125 200 19 83 200 —- —- —-F1 36 156 250 24 104 200 —- —- —-F2 38 168 250 25 112 200 —- —- —-G1 —- —- —- 32 140 250 24 105 200G2 —- —- —- 35 152 250 26 114 200Notes:1. Minimum flow rates are based on water only.2. All water connections are flange connections.Minimum/Maximum Condenser Flow Rates(Gallons/Minute)Two PassCondenserNominalCode Min Max Conn Size (In.)B1 193 850 6B2 212 935 6D1 193 850 6D2 212 935 6E1 291 1280 8E2 316 1390 8E3 325 1420 8E4 245 1080 8E5 206 910 8F1 375 1650 8F2 355 1560 8F3 385 1700 8G1 444 1960 8G2 535 2360 8Notes:1. Minimum flow rates are based on water only.2. All water connections are flange connections.Minimum/Maximum Condenser Flow Rates(Liters/Second)Two PassCondenserNominalCode Min Max Conn Size (mm)B1 12 54 150B2 13 59 150D1 12 54 150D2 13 59 150E1 18 81 200E2 20 88 200E3 21 90 200E4 15 68 200E5 13 57 200F1 24 104 200F2 22 98 200F3 24 107 200G1 28 124 200G2 34 149 200Notes:1. Minimum flow rates are based on water only.2. All water connections are flange connections.RLC-PRC031-EN17

General DataBrine Flow RatesMinimum/Maximum Evaporator Flow Rates (GPM)Two Pass Three Pass Four PassEvaporator Nominal Nominal NominalCode Min Max Conn Size (In.) Min Max Conn Size (In.) Min Max Conn Size (In.)B1 303 1104 8 200 736 6 —- —- —-B2 346 1266 8 233 844 6 —- —- —-C1 346 1412 8 254 941 6 —- —- —-C2 375 1531 8 276 1022 6 —- —- —-D1 498 1812 8 330 1206 8 —- —- —-D2 541 1980 8 357 1320 8 —- —- —-D3 584 2131 8 389 1417 8 —- —- —-D4 422 1542 8 281 1028 8 —- —- —-D5 422 1542 8 281 1028 8 —- —- —-D6 352 1287 8 233 860 8 —- —- —-E1 487 1980 8 357 1320 8 —- —- —-F1 676 2478 10 454 1655 8 —- —- —-F2 725 2667 10 487 1780 8 —- —- —-G1 —- —- —- 606 2218 10 454 1666 8G2 —- —- —- 660 2413 10 492 1807 8Notes:1. Minimum flow rates are based on brine solution.2. All water connections are flange connections.Minimum/Maximum Evaporator Flow Rates (Liters/Second)Two Pass Three Pass Four PassEvaporator Nominal Nominal NominalCode Min Max Conn Size (mm) Min Max Conn Size (mm) Min Max Conn Size (mm)B1 19 70 200 13 46 150 —- —- —-B2 22 80 200 15 53 150 —- —- —-C1 22 89 200 16 59 150 —- —- —-C2 23 97 200 17 65 150 —- —- —-D1 31 114 200 21 76 200 —- —- —-D2 34 125 200 23 83 200 —- —- —-D3 37 134 200 25 89 200 —- —- —-D4 27 97 200 18 65 200 —- —- —-D5 27 97 200 18 65 200 —- —- —-D6 22 81 200 15 54 200 —- —- —-E1 28 125 200 23 83 200 —- —- —-F1 43 156 250 29 104 200 —- —- —-F2 46 168 250 31 112 200 —- —- —-G1 —- —- —- 38 140 250 29 105 200G2 —- —- —- 42 152 250 31 114 200Notes:1. Minimum flow rates are based on brine solution.2. All water connections are flange connections.Minimum/Maximum Condenser Flow Rates(GPM)Two PassCondenserNominalCode Min Max Conn Size (In.)B1 230 850 6B2 255 935 6D1 230 850 6D2 255 935 6E1 350 1280 8E2 380 1390 8E3 390 1420 8E4 295 1080 8E5 250 910 8F1 <strong>450</strong> 1650 8F2 430 1560 8F3 460 1700 8G1 530 1960 8G2 650 2360 8Notes:1. Minimum flow rates are based on brine solution.2. All water connections are flange connections.Minimum/Maximum Condenser Flow Rates(Liters/Second)Two PassCondenserNominalCode Min Max Conn Size (mm)B1 15 54 150B2 16 59 150D1 15 54 150D2 16 59 150E1 22 81 200E2 24 88 200E3 25 90 200E4 19 68 200E5 16 57 200F1 28 104 200F2 27 98 200F3 29 107 200G1 33 124 200G2 41 149 200Notes:1. Minimum flow rates are based on brine solution.2. All water connections are flange connections.18RLC-PRC031-EN

Electrical Dataand ConnectionsCompressor Motor Electrical Data (60 Hertz)Nominal Voltage 200 230 380 460 575Compressor Voltage 180/ 208/ 342/ 414/ 516/Code Utilization Range 220 254 418 506 633Max kW 174 174 174 174 174B1, B2 RLA @ Max kW 557 484 291 241 198LRAY 970 818 488 400 329LRAD 3103 2617 1561 1280 1053Max kW 249 249 249 249 249C1, C2 RLA @ Max kW 812 698 421 349 279LRAY 1173 936 558 469 375LRAD 3634 2901 1727 1453 1162Max kW 329 329 329 329 329D1, D2 RLA @ Max kW 888 888 549 455 367LRAY 1690 1532 850 730 612LRAD 5477 4966 2755 2366 1984Notes:1. See Selection Procedure Section for details.2. The RLA @ Max kW is based on the performance of the motor developing full rated horsepower.3. Electrical component sizing should be based on actual jobsite operating conditions. This factor can be obtained through the useof the <strong>Series</strong> R chiller selection program available through local Trane sales offices.Compressor Motor Electrical Data (50 Hertz)Nominal Voltage 380 400 415Compressor Voltage 342/ 360/ 374/Code Utilization Range 418 440 457Max kW 139 145 148B1, B2 RLA @ Max kW 233 233 233LRAY 391 412 428LRAD 1229 1296 1348Max kW 201 209 213C1, C2 RLA @ Max kW 349 349 349LRAY 456 480 498LRAD 1414 1488 1544Max kW 271 280 284D1, D2, D3 RLA @ Max kW 455 455 455LRAY 711 748 776LRAD 2303 2424 2515Max kW 288 301 306E3 RLA @ Max kW 488 488 488LRAY 711 748 776LRAD 2303 2424 2515Notes:1. See Selection Procedure Section for details.2. The RLA @ Max kW is based on the performance of the motor developing full rated horsepower.3. Electrical component sizing should be based on actual jobsite operating conditions. This factor can be obtained through the useof the <strong>Series</strong> R chiller selection program available through local Trane sales offices.Electrical ConnectionsStarter Panel Selection Lug SizeConnection RLA L1-L3 (Each Phase)Terminals Only 000-760 (2) #4-500 MCM761-888 (4) 4/0-500 MCMMain Circuit 000-185 (1) #4-350 MCMBreaker or 186-296 (2) 2/0-250 MCMNon-Fused 297-444 (2) 3/0-350 MCMDisconnect Switch 445-592 (2) #1-500 MCM593-888 (4) 4/0-500 MCMNote:1. Lug sizes are independent of starter type.RLC-PRC031-EN19

Electrical Dataand Connections20RLC-PRC031-EN

Electrical Dataand ConnectionsRLC-PRC031-EN21

Dimensions andWeightsShipping and Operating WeightsCompressor Evaporator Condenser Operating Weight Shipping WeightCode Code Code (lbs) (kg) (lbs) (kg)B1 B1 B1 9,867 4,476 9,292 4,215B1 C1 D1 10,554 4,787 9,837 4,462B2 B2 B2 10,019 4,545 9,402 4,265B2 C2 D2 10,653 4,832 9,953 4,515C1 D6 E5 13,397 6,077 12,780 5,797C1 D5 E4 13,673 6,202 12,973 5,884C1 E1 F1 15,818 7,<strong>175</strong> 14,718 6,676C2 D4 E4 13,672 6,201 12,972 5,884C2 D3 E3 15,044 6,824 14,002 6,351C2 F2 F3 17,560 7,965 16,168 7,334D1 D1 E1 15,385 6,978 14,443 6,551D1 F1 F2 17,537 7,955 16,187 7,342D1 G1 G1 20,500 9,299 18,600 8,437D2, D3 D2 E2 15,570 7,062 14,562 6,605D2, D3 F2 F3 18,220 8,264 16,820 7,629D2, D3 G2 G1 20,700 9,389 18,700 8,482E3 D2 E2 15,728 7,134 14,720 6,677E3 F2 F3 18,356 8,326 16,956 7,691E3 G2 G1 20,800 9,435 18,800 8,528Notes:1. All weights +- 3%.2. Shipping weights include standard 150 psig water boxes, refrigerant charge, and oil charge.3. Operating weights include refrigerant, oil, and water charges.22RLC-PRC031-EN

Dimensions andWeightsBBB ConfigurationRecommended ClearancesFront36" (914 mm)Back36" (914 mm)Either End36" (914 mm)Other End*108" (2743 mm)Top36" (914 mm)* Clearance for tube removalNote:1. Dimensions are based on 3 Pass Evap / 2 PassCond and LH/LH water connections. Refer tosubmittals for exact configuration.2. Refer to the Nominal Capacity Data table in theGeneral Data section for capacity ranges of eachcompressor.RLC-PRC031-EN23

Dimensions andWeightsBCD ConfigurationRecommended ClearancesFront36" (914 mm)Back36" (914 mm)Either End36" (914 mm)Other End*126" (3200 mm)Top36" (914 mm)* Clearance for tube removalNote:1. Dimensions are based on 3 Pass Evap / 2 PassCond and LH/LH water connections. Refer tosubmittals for exact configuration.2. Refer to the Nominal Capacity Data table in theGeneral Data section for capacity ranges of eachcompressor.24RLC-PRC031-EN

Dimensions andWeightsCDE, DDE, EDE ConfigurationRecommended ClearancesFront36" (914 mm)Back36" (914 mm)Either End36" (914 mm)Other End*108" (2743 mm)Top36" (914 mm)* Clearance for tube removalNote:1. Dimensions are based on 3 Pass Evap / 2 PassCond and LH/LH water connections. Refer tosubmittals for exact configuration.2. Refer to the Nominal Capacity Data table in theGeneral Data section for capacity ranges of eachcompressor.RLC-PRC031-EN25

Dimensions andWeightsCEF ConfigurationRecommended ClearancesFront36" (914 mm)Back36" (914 mm)Either End36" (914 mm)Other End*126" (3200 mm)Top36" (914 mm)* Clearance for tube removalNote:1. Dimensions are based on 3 Pass Evap / 2 PassCond and LH/LH water connections. Refer tosubmittals for exact configuration.2. Refer to the Nominal Capacity Data table in theGeneral Data section for capacity ranges of eachcompressor.26RLC-PRC031-EN

Dimensions andWeightsCFF, DFF, EFF ConfigurationRecommended ClearancesFront36" (914 mm)Back36" (914 mm)Either End36" (914 mm)Other End*126" (3200 mm)Top36" (914 mm)* Clearance for tube removalNote:1. Dimensions are based on 3 Pass Evap / 2 PassCond and LH/LH water connections. Refer tosubmittals for exact configuration.2. Refer to the Nominal Capacity Data table in theGeneral Data section for capacity ranges of eachcompressor.RLC-PRC031-EN27

Dimensions andWeightsDGG, EGG ConfigurationRecommended ClearancesFront36" (914 mm)Back36" (914 mm)Either End36" (914 mm)Other End*126" (3200 mm)Top36" (914 mm)* Clearance for tube removalNote:1. Dimensions are based on 3 Pass Evap / 2 PassCond and LH/LH water connections. Refer tosubmittals for exact configuration.2. Refer to the Nominal Capacity Data table in theGeneral Data section for capacity ranges of eachcompressor.28RLC-PRC031-EN

MechanicalSpecificationsGeneralExposed metal surfaces are paintedwith air-dry beige, direct-to-metal,single-component paint. Each unitships with full operating charges ofrefrigerant and oil. Molded neopreneisolation pads are supplied forplacement under all support points.Startup and operator instruction byfactory-trained service personnel areincluded.Compressor and MotorThe unit is equipped with a semihermetic,direct-drive, 3600-rpm (3000rpm @ 50 Hz) rotary compressor thatincludes a capacity control slide valve,oil sump heater, and differentialpressure refrigerant oil flow system.Four pressure-lubricated, rollingelementbearing groups support therotating assembly.The motor is a suction gas-cooled,hermetically sealed, two-pole, squirrelcage induction-type.Unit-Mounted StarterThe unit is supplied with a NEMA 1type enclosure with top power-wiringaccess and three-phase, solid stateoverload protection. The starter isavailable in a Wye-Delta configuration,factory-mounted and fully pre-wired tothe compressor motor and controlpanel. A factory-installed, factory-wired600VA control power transformerprovides all unit control power (120 VACsecondary) and CH530 module power(24 VAC secondary). Optional starterfeatures include circuit breakers,ground fault circuit breakers, andmechanical, non-fused disconnects.Evaporator and CondenserShells are carbon steel plate. Theevaporator and condenser aredesigned, tested, and stamped inaccordance with ASME Code forrefrigerant-side/working-side pressure of 200 psig.All tube sheets are made of carbonsteel; tubes are mechanically expandedinto tube sheets and mechanicallyfastened to tube supports. Evaporatortubes are 1.0-inch (25.4 mm) diameterand condenser tubes are 0.75-inch(19.05 mm) diameter. Both types can beindividually replaced. Standard tubesare externally finned, internallyenhanced seamless copper with landsat all tube sheets.All water pass arrangements areavailable with flange connections (150or 300 psig waterside). All connectionsmay be either right- or left-handed.Waterside shall be hydrostaticallytested at 1.5X design working pressure.Refrigerant CircuitAn electronically controlled expansionvalve is provided to maintain properrefrigerant flow.Unit Controls (CH530)The microprocessor-based controlpanel is factory-installed and factorytested.The control system is poweredby a control power transformer, andwill load and unload the chiller throughadjustment of the compressor slidevalve. Microprocessor-based chilledwater reset based on return water isstandard.The CH530 microprocessorautomatically acts to prevent unitshutdown due to abnormal operatingconditions associated with lowevaporator refrigerant temperature,high condensing temperature, and/ormotor current overload. If an abnormaloperating condition continues and theprotective limit is reached, the machineshould shut down.The panel includes machine protectionshutdown requiring manual reset forthe following conditions:• low evaporator refrigeranttemperature and pressure• high condenser refrigerant pressure• low oil flow• critical sensor or detection circuitfaults• motor current overload• high compressor dischargetemperature• lost communication betweenmodules• electrical distribution faults: phaseloss, phase imbalance, or phasereversal• external and local emergency stop• starter transition failureThe panel also includes machineprotection shutdown with automaticreset for the following correctableconditions:• momentary power loss• under/over voltage• loss of evaporator or condenserwater flowWhen a fault is detected, the controlsystem conducts more than 100diagnostic checks and displays results.The display will identify the fault,indicate date, time, and operatingmode at time of occurrence, andprovide type of reset required and ahelp message. The diagnostic historywill display the last ten diagnostics withtheir times and dates of occurrence.Clear Language Display PanelFactory-mounted to the control paneldoor, the operator interface has an LCDtouch-screen display for operator inputand information output. This interfaceprovides access to the followinginformation: evaporator report,condenser report, compressor report,ASHRAE Guideline 3 report, operatorsettings, service settings, service tests,and diagnostics. All diagnostics andmessages are displayed in “clearlanguage.”Data contained in available reportsincludes:• Water and air temperatures• Refrigerant levels and temperatures• Oil pressure• Flow switch status• EXV position• Head pressure control command• Compressor starts and run-time• Line phase percent RLA, amps, andvoltsAll necessary settings and setpoints areprogrammed into the microprocessorbasedcontroller via the operatorinterface. The controller is capable ofreceiving signals contemporaneouslyfrom a variety of control sources, inany combination, and priority order ofcontrol sources can be programmed.The control source with prioritydetermines active setpoints via thesignal it sends to the control panel.Control sources may be:• the local operator interface(standard)• a hard-wired 4-20 mA or 2-10 VDCsignal from an external source(interface optional; control source notsupplied)• Generic BAS (optional points;control source not supplied)• LonTalk LCI-C (interface optional;control source not supplied)• Trane Tracer Summit system(interface optional)RLC-PRC031-EN29

Conversion Table30RLC-PRC031-EN

Applications in this catalog specificallyexcluded from the ARI certification programare:• Low temperature applications, includingice storage•Glycol•50Hz units below 200 nominal tonsTranewww.trane.comLiterature Order NumberDateSupersedesRLC-PRC031-ENMarch 2009November 2007For more information, contactyour local sales office ore-mail us at comfort@trane.com.Trane has a policy of continuous product and product data improvement and reserves the right to changedesign and specifications without notice.