SCA Timber in the UK - SCA Forest Products AB

SCA Timber in the UK - SCA Forest Products AB

SCA Timber in the UK - SCA Forest Products AB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

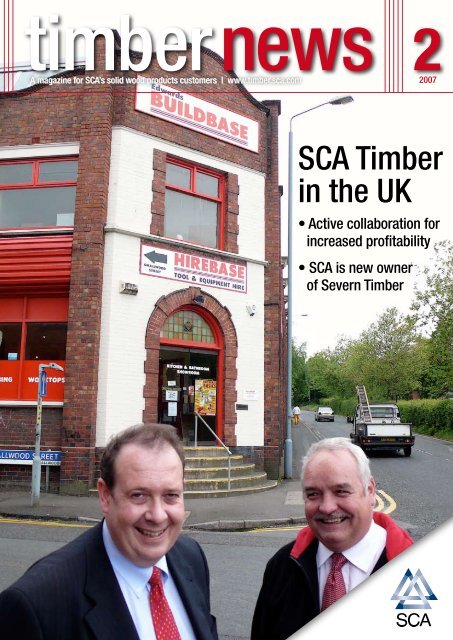

timbernewsA magaz<strong>in</strong>e for <strong>SCA</strong>’s solid wood products customers | www.timber.sca.com22007<strong>SCA</strong> <strong>Timber</strong><strong>in</strong> <strong>the</strong> <strong>UK</strong>• Active collaboration for<strong>in</strong>creased profitability• <strong>SCA</strong> is new ownerof Severn <strong>Timber</strong>

timbernewsStephen Thompstone, Buildbase,responsible for all <strong>the</strong> branches <strong>in</strong><strong>the</strong> Nor<strong>the</strong>rn Division, and Matt Henderson,Manager, Edwards Buildbase, Redditch.Cover photo: Mats WigardtIncreased<strong>in</strong>terest <strong>in</strong> wood6Irish DIY giant withsolid foothold <strong>in</strong> <strong>the</strong> <strong>UK</strong>7Three pillars <strong>in</strong> <strong>the</strong> <strong>UK</strong>8Managerial change at<strong>SCA</strong> <strong>Timber</strong> Supply10<strong>Timber</strong> market <strong>in</strong> focus10Solid woodprice boom slows11The story of <strong>the</strong> greenbath<strong>in</strong>g hut12<strong>SCA</strong> <strong>Timber</strong>, <strong>SCA</strong>’s solid woodoperation, covers eight sawmills andseven plan<strong>in</strong>g mills. The total annualvolume of solid wood products amountsto 1.7 million cubic metres.Solid wood operations are <strong>in</strong>cluded <strong>in</strong><strong>SCA</strong>’s <strong>Forest</strong> <strong>Products</strong> bus<strong>in</strong>ess area.Development work cont<strong>in</strong>ues– despite good timesMost timber-centric companies have, for awhile now, enjoyed a period of good economicgrowth, with volume and price trends be<strong>in</strong>g<strong>the</strong> pr<strong>in</strong>cipal driv<strong>in</strong>g forces. <strong>SCA</strong> <strong>Timber</strong> is noexception.In good times, it’s easy to sit back and feel happyand contented. But we’re conv<strong>in</strong>ced that it’s justas important to do <strong>the</strong> right th<strong>in</strong>gs dur<strong>in</strong>g both<strong>the</strong> good times and <strong>the</strong> bad. The process of productdevelopment mustn’t stop just because it’s easy tosell standardised products. Customer relationshipsthat have been nurtured over long periods must bema<strong>in</strong>ta<strong>in</strong>ed.A considered strategy is essential <strong>in</strong> order to do<strong>the</strong> right th<strong>in</strong>gs <strong>in</strong> <strong>the</strong> right order. In this issue of<strong>Timber</strong> News, we’ll be sett<strong>in</strong>g out <strong>SCA</strong> <strong>Timber</strong>’smarket strategy, our roadmap for <strong>the</strong> future.The acquisition of Severn <strong>Timber</strong>, which is alsocovered <strong>in</strong> this issue, is part of this strategy. We’renow better equipped to tackle <strong>the</strong> British woodbasedproduct sector. In <strong>the</strong> past, our <strong>in</strong>volvement<strong>in</strong> this key market was only as a small-scale supplierto <strong>the</strong> important professional builders’ merchantsector. We now have <strong>the</strong> elements <strong>in</strong> placealso to grow <strong>in</strong> this segment of <strong>the</strong> market.Our British operations have undergone somemajor changes. Acquisitions, <strong>the</strong> implementationof new logistics and distribution solutions, <strong>the</strong>implementation of a new management organisationand <strong>the</strong> <strong>in</strong>troduction of new skills have comb<strong>in</strong>edto put us <strong>in</strong> <strong>the</strong> position we’ve been striv<strong>in</strong>gfor. We now have <strong>the</strong> criteria to be a one-stop,competent supplier to both <strong>in</strong>dustry and <strong>the</strong> builders’merchant sector.In our o<strong>the</strong>r pr<strong>in</strong>cipal markets, we’re mak<strong>in</strong>gmajor <strong>in</strong>vestments <strong>in</strong> several key <strong>in</strong>dustrial segments.At <strong>the</strong> moment, we’re <strong>in</strong> <strong>the</strong> process of sett<strong>in</strong>gup a l<strong>in</strong>e <strong>in</strong> Tunadal Sawmill to producecomponents for <strong>the</strong> French door <strong>in</strong>dustry. Lastyear, our <strong>in</strong>itiative to produce defect-free w<strong>in</strong>dowcomponents was so well received by <strong>the</strong> Italian andBritish w<strong>in</strong>dow <strong>in</strong>dustries that we’re now look<strong>in</strong>gto expand <strong>the</strong>se programmes. We’re also at anadvanced stage <strong>in</strong> some o<strong>the</strong>r major componentprojects target<strong>in</strong>g <strong>the</strong> Scand<strong>in</strong>avian market.At <strong>the</strong> moment, <strong>the</strong> sawmill <strong>in</strong>dustry is a goodplace to be. But time and tide wait for no man. It’simportant that we keep up <strong>the</strong> pace of our developmentwork. We’ll cont<strong>in</strong>ue to acquire companies,develop products and build customerrelationships until we achieve <strong>the</strong> objectives we setourselves.And <strong>the</strong>n we’ll set new ones.Ulf LarssonPresident, <strong>SCA</strong> <strong>Timber</strong><strong>Timber</strong>News <strong>SCA</strong> <strong>Forest</strong> <strong>Products</strong> <strong>AB</strong>SE-851 88 Sundsvalltel +46 60 19 30 00www.timber.sca.com<strong>Timber</strong> News is publishedfour times a yearEditor-<strong>in</strong>-chief Björn LyngfeltProduction FryklundsRepro & pr<strong>in</strong>t<strong>in</strong>g TryckeribolagetSubscribe to <strong>Timber</strong> News, pleasecontact <strong>in</strong>grid.lofqvist@sca.comUlf Larsson, President, <strong>SCA</strong> <strong>Timber</strong>.Photo: Per-Anders Sjöqvisttimbernews | 2

Profitable growth– for both <strong>SCA</strong> and its customersWith a hold<strong>in</strong>g of some 2.5 million hectares <strong>in</strong> nor<strong>the</strong>rn Sweden, <strong>SCA</strong>is <strong>the</strong> biggest private forest owner <strong>in</strong> Europe. <strong>Forest</strong>s grow slowly andproduce high quality sawlogs.Photo: Olle HedvallIn <strong>the</strong> space of a little over 10years, both <strong>the</strong> solid wood productsmarket and <strong>SCA</strong> <strong>Timber</strong>have undergone a radical transformation.In <strong>the</strong> case of <strong>SCA</strong><strong>Timber</strong>, this transformation hasbeen <strong>the</strong> result of a number ofstrategic choices and <strong>in</strong>vestments.The acquisition of Severn<strong>Timber</strong> is <strong>the</strong> latest, but by nomeans <strong>the</strong> last, step <strong>in</strong> <strong>the</strong>implementation of this strategy.Towards <strong>the</strong> end of <strong>the</strong> lastcentury, conditions <strong>in</strong> <strong>the</strong>sawmill <strong>in</strong>dustry were not<strong>the</strong> best. Profitability was low.Raw materials were expensive.Wood was fac<strong>in</strong>g stiff competitionon all fronts from materials thatwere cheaper, more flexible andmore modern. Deals were, to alarge extent, be<strong>in</strong>g made <strong>in</strong> a cha<strong>in</strong><strong>in</strong> which middlemen were cloud<strong>in</strong>gup customer requirements and<strong>the</strong> route from raw material tocustomer was long-w<strong>in</strong>ded andexpensive.“We realised that th<strong>in</strong>gs had tochange,” says Ulf Larsson, Presidentof <strong>SCA</strong> <strong>Timber</strong>. “To make thischange a reality, we were forced toreview, understand and test allaspects of our bus<strong>in</strong>ess, from <strong>the</strong>raw materials <strong>in</strong> <strong>the</strong> forest to ourproduction facilities, our products,our route out to <strong>the</strong> market andour customers.“Our aim is to become <strong>the</strong> mostprofitable supplier of solid woodproducts <strong>in</strong> Europe. It doesn’tToday, Developed <strong>Timber</strong> accounts for 50% of <strong>SCA</strong> <strong>Timber</strong>’s total sales. TheDeveloped <strong>Timber</strong> concept covers products that are adapted to <strong>the</strong>ir particular use,be it <strong>in</strong>dustrial components or f<strong>in</strong>ished wood products <strong>in</strong>tended for <strong>the</strong> builders’merchant market.Photo: Per-Anders Sjöquistsound like an objective our customerswould have reason to celebrate,but for us to be profitable, ourcustomers must be profitable.”One of <strong>the</strong> start<strong>in</strong>g po<strong>in</strong>ts for<strong>the</strong> strategy work was <strong>the</strong> rawmaterials base. With a hold<strong>in</strong>g ofsome 2.5 million hectares <strong>in</strong>nor<strong>the</strong>rn Sweden, <strong>SCA</strong> is <strong>the</strong> biggestprivate forest owner <strong>in</strong> Europe.The forests grow slowly and producehigh quality sawlogs.“We’ve worked through ourentire product programme to discover<strong>the</strong> full potential of <strong>the</strong> rawmaterials we have,” says Larsson.“Quality is not an absolute concept,it’s about whe<strong>the</strong>r a productis fit for purpose.”The Developed <strong>Timber</strong> conceptwas launched <strong>in</strong> 1995 and by 2006such products represented 50% ofall <strong>SCA</strong> <strong>Timber</strong> sales. These productsare adapted to <strong>the</strong>ir particularuse, be it <strong>in</strong>dustrial components orf<strong>in</strong>ished wood products <strong>in</strong>tendedfor <strong>the</strong> builders’ merchant market.Wood that is adapted to meet <strong>the</strong>needs of <strong>in</strong>dustrial customers <strong>in</strong>cludesproducts that are dried toachieve a specific moisture content,selected raw materials thatare produced with a specific levelof quality or components that areready for <strong>the</strong> next stage of f<strong>in</strong>ish<strong>in</strong>g,e.g. glued, defect-free componentsused <strong>in</strong> w<strong>in</strong>dow manufacture.83 | timbernews

The right market– geographic concentration for comparative advantagesMa<strong>in</strong> markets<strong>SCA</strong> has strong sales organizations, local fu<strong>the</strong>rprocess<strong>in</strong>g operations and advanced distributionplatforms.Niche marketsConcentrated product range and ma<strong>in</strong>ly own sales.O<strong>the</strong>r marketsFocus on a number of Selected Costumersand buffer for short-term fluctuations <strong>in</strong>supply and demand.% net sales of <strong>SCA</strong> <strong>Timber</strong>DistributionProduction24%11%22%US North Africa JapanThe right market channel49%37%14%Sales viawholesalersIndustry salesSupply Cha<strong>in</strong> Management% net sales of <strong>SCA</strong> <strong>Timber</strong>“We want to develop,and <strong>the</strong> only way we cando that is by work<strong>in</strong>gwith customers who alsowant to develop,” saysUlf Larsson, President of<strong>SCA</strong> <strong>Timber</strong>.WholesalerNegative growthWoodIndustryGrowth 2-3%Growth figures are estimated for <strong>the</strong> period 2005-2007 and refer to ma<strong>in</strong> markets(net growth excl. price development).Builder’sMerchantsDIY andBuilder’sMerchantsGrowth DIY -2%,BM +5%<strong>Products</strong> for <strong>the</strong> builders’ merchant market <strong>in</strong>cludeplaned products, usually pre-packed and given abarcode and <strong>the</strong> customer’s brand<strong>in</strong>g.The traditional route to market for <strong>the</strong> sawmill<strong>in</strong>dustry was via middlemen, with products pass<strong>in</strong>gthrough <strong>the</strong> hands of multiple exporters, importersand wholesalers. These middlemen still fulfil animportant role <strong>in</strong> <strong>the</strong> marketplace and represent40 % of all <strong>SCA</strong> <strong>Timber</strong>’s sales, although this figureis fall<strong>in</strong>g.Direct <strong>in</strong>dustry sales have <strong>in</strong>creased dramaticallyand now account for approximately 40 % of <strong>SCA</strong>’ssales activities.“It’s clear that direct contact and direct sales areimportant to <strong>the</strong> timber <strong>in</strong>dustry,” says Larsson. “Formany of our customers, we are now a fully <strong>in</strong>tegratedpart of <strong>the</strong>ir production process. We supply <strong>the</strong>irraw material stocks with components and cont<strong>in</strong>uallyadapt <strong>the</strong> flow to fit <strong>in</strong> with <strong>the</strong>ir productionl<strong>in</strong>e. The result is a collaborative relationship thatlowers costs and <strong>in</strong>creases <strong>the</strong> value of <strong>the</strong> productioncha<strong>in</strong>.”A grow<strong>in</strong>g part of <strong>SCA</strong>’s sales activities <strong>in</strong>volves <strong>the</strong>builders’ merchant sector. Logistics and distributionplay a crucial role here <strong>in</strong> what is known as ‘SupplyCha<strong>in</strong> Management’. Customers <strong>in</strong> this sector focusei<strong>the</strong>r on <strong>the</strong> professional craftsman or builder or on<strong>the</strong> direct-to-consumer DIY trade. The latter is experienc<strong>in</strong>grapid growth, whilst <strong>the</strong> former is consum<strong>in</strong>gsignificantly greater volumes of wood-basedproducts.“In order to be able to meet <strong>the</strong> demands of <strong>the</strong>secustomer segments, we’ve had to acquire completelynew expertise and new resources,” says Larsson. “Weneed to produce sufficiently large volumes of uniformproducts, perhaps packed accord<strong>in</strong>g to customerrequirements. We <strong>the</strong>n need to ensure that <strong>the</strong>se productsare distributed <strong>in</strong> an efficient manner to a largenumber of build<strong>in</strong>g materials dealers. What wemanufacture ourselves is supplemented with productsthat have been f<strong>in</strong>ished by partners and subcontractors,or by products that we procure fromo<strong>the</strong>r manufacturers.“In 2003, we acquired <strong>the</strong> British distributor BCL<strong>in</strong> order to become a better supplier, primarily to <strong>the</strong>British DIY market. By acquir<strong>in</strong>g Severn <strong>Timber</strong>,we’ve <strong>in</strong>creased our ability to supply <strong>the</strong> buildersmerchant market segment.”Despite <strong>the</strong> fact that <strong>SCA</strong> <strong>Timber</strong> is one of <strong>the</strong> 10biggest solid wood product manufacturers <strong>in</strong> Europe,<strong>the</strong> company’s production represents only 2% oftotal wood product consumption <strong>in</strong> Europe.“We must concentrate on markets where <strong>the</strong> productswe manufacture command a high value,” cont<strong>in</strong>uesLarsson. “Logistics account for a significantproportion of our costs, so by ga<strong>the</strong>r<strong>in</strong>g larger volumesfor specific markets we can identify better andtimbernews | 4

cheaper logistics solutions.”Scand<strong>in</strong>avia, France and <strong>the</strong> <strong>UK</strong><strong>in</strong>cl. Ireland are <strong>SCA</strong>’s ma<strong>in</strong> markets,mak<strong>in</strong>g up 58% of total sales.<strong>SCA</strong> <strong>Timber</strong> provides a wide rangeof products and services on <strong>the</strong>semarkets, as well as storage andadvanced distribution. In <strong>the</strong>sema<strong>in</strong> markets, <strong>SCA</strong> <strong>Timber</strong> focuseson many different segments.In addition to <strong>the</strong>se ma<strong>in</strong> markets,<strong>SCA</strong> <strong>Timber</strong> is also active <strong>in</strong>a number of niche markets. Theseare equally as important as <strong>the</strong>ma<strong>in</strong> markets, <strong>the</strong> difference be<strong>in</strong>gthat <strong>SCA</strong> specialises <strong>in</strong> just a fewsegments. It may <strong>in</strong>volve supply<strong>in</strong>gbuild<strong>in</strong>g materials to companies <strong>in</strong><strong>the</strong> eastern USA, provid<strong>in</strong>g componentsto <strong>the</strong> Italian w<strong>in</strong>dow ando<strong>the</strong>r appearance timber <strong>in</strong>dustriesor products for house construction<strong>in</strong> Japan. These niche marketsaccount for 24% of <strong>SCA</strong> <strong>Timber</strong>’sturnover.O<strong>the</strong>r markets account for 15%of sales. Although selected customersare given priority <strong>in</strong> respectof sales <strong>in</strong> <strong>the</strong>se markets, <strong>the</strong>y doconstitute a valuable complementthat equalises fluctuations <strong>in</strong> demandand production volumes.“We need customers that canmake us profitable and enable usto do <strong>the</strong> same <strong>in</strong> return,” saysLarsson. “As we evolve from conduct<strong>in</strong>gdeals via middlemen tocollaborat<strong>in</strong>g on an <strong>in</strong>creas<strong>in</strong>glycloser and deeper level with ourcustomers, it’s important for bothourselves and our customers thatwe make <strong>the</strong> right choices. Wewant to develop, and <strong>the</strong> only waywe can do that is by work<strong>in</strong>gwith customers who also want todevelop.“We want to work with successfulcustomers, customers whoare profitable, who are grow<strong>in</strong>gand have a high level of expertise.They must also have a cont<strong>in</strong>ualneed for <strong>the</strong> products and expertisewe can provide. One of <strong>the</strong> criteriafor this is that <strong>the</strong>y purchaseproducts that are profitable for<strong>SCA</strong> <strong>Timber</strong>. Above all, we prioritisecustomers who want to activelycollaborate with us <strong>in</strong> orderto lower common costs.”<strong>SCA</strong> buys British wood f<strong>in</strong>ish<strong>in</strong>g company<strong>SCA</strong> <strong>Timber</strong> has bought Britishcompany Severn <strong>Timber</strong>. Severn<strong>Timber</strong> turns sawn solid woodproducts <strong>in</strong>to planed and treatedproducts at its base <strong>in</strong> Welshpooland is a major supplier ofsolid wood products to <strong>the</strong> Britishbuilders’ merchant sector.“This is an important acquisitionfor <strong>SCA</strong> <strong>Timber</strong>,” saysUlf Larsson, President of <strong>SCA</strong><strong>Timber</strong>.The <strong>UK</strong> is one of <strong>SCA</strong> <strong>Timber</strong>’spriority markets. The acquisitionfits <strong>in</strong> well with <strong>SCA</strong><strong>Timber</strong>’s strategy of <strong>in</strong>creas<strong>in</strong>g itsproportion of f<strong>in</strong>ished products byreach<strong>in</strong>g build<strong>in</strong>g materials retailersthat focus on <strong>the</strong> ‘professional’market (construction companies,carpenters and craftsmen).“We now occupy a strong positionas a lead<strong>in</strong>g supplier to <strong>the</strong> BritishDIY market. In addition, <strong>the</strong>acquisition has also streng<strong>the</strong>nedour position as a supplier to <strong>the</strong>professional builders’ merchantsector as this is Severn <strong>Timber</strong>’sma<strong>in</strong> focus,” says Anders Ek, <strong>SCA</strong><strong>Timber</strong>’s Market<strong>in</strong>g Director.<strong>SCA</strong> and Severn <strong>Timber</strong> have collaboratedon a number of occasionsover <strong>the</strong> years, focus<strong>in</strong>g on <strong>the</strong>f<strong>in</strong>ish<strong>in</strong>g, distribution and sale ofsolid wood products.“Severn <strong>Timber</strong> affords <strong>SCA</strong> adirect channel for f<strong>in</strong>ished solidwood products, from <strong>the</strong> forest to<strong>the</strong> builders’ merchant,” says AlunGape, President of Severn <strong>Timber</strong><strong>Products</strong>.Gape started Severn <strong>Timber</strong> <strong>in</strong>1983 and cont<strong>in</strong>ues to run <strong>the</strong> bus<strong>in</strong>essfollow<strong>in</strong>g its acquisition by<strong>SCA</strong>.Severn <strong>Timber</strong> has three modernplan<strong>in</strong>g l<strong>in</strong>es with a total capacityof around 60,000 m 3 planed woodproducts and <strong>the</strong> ability to treatapproximately 10,000 m 3 . Severn<strong>Timber</strong> has a turnover of around£11 million and employs a staff of50. As a result of <strong>the</strong> deal, <strong>SCA</strong><strong>Timber</strong> now has 150 employees <strong>in</strong><strong>the</strong> <strong>UK</strong>.Misan L<strong>in</strong>dqvistAnders Ek, <strong>SCA</strong> <strong>Timber</strong>’s Market<strong>in</strong>g Director and Alun Gape,President of Severn <strong>Timber</strong>, are pleased with <strong>the</strong> deal.Photo: Jan Svedjebrant5 | timbernews

“We’re a typical ‘one-stop-shop’. The branch has everyth<strong>in</strong>g you need to build a house or landscape a garden,” says MattHenderson, Branch Manager at Edwards Buildbase <strong>in</strong> Redditch.British build<strong>in</strong>g customersshow <strong>in</strong>creased <strong>in</strong>terest <strong>in</strong> woodThe Grafton Group sells build<strong>in</strong>g materials underseveral different brands to both DIYers and professionalbuilders <strong>in</strong> <strong>the</strong> <strong>UK</strong> and Ireland. The Britishcha<strong>in</strong> Buildbase alone has more than 150 branches.“A large proportion of all <strong>the</strong> solid wood productswe sell are supplied by <strong>SCA</strong>,” says StephenThompstone, Divisional Director of Buildbase’sNor<strong>the</strong>rn Division.At Buildbase <strong>in</strong> Redditch, justoutside Birm<strong>in</strong>gham <strong>in</strong> <strong>the</strong>Midlands region of England,Fence posts were sold here dur<strong>in</strong>g <strong>the</strong> early 20th century.Today, <strong>the</strong> build<strong>in</strong>g is home to one of Brita<strong>in</strong>’s Buildbasebranches.<strong>the</strong>re is an old sign that rem<strong>in</strong>dsvisitors of <strong>the</strong> store’s orig<strong>in</strong>s. In1911, J. Thomas Edwards starteda small bus<strong>in</strong>ess <strong>in</strong> <strong>the</strong> town, sell<strong>in</strong>gfence posts to local farmers.Over <strong>the</strong> years, Edwards openedmore branches throughout <strong>the</strong>Midlands.Dur<strong>in</strong>g <strong>the</strong> 1990s, this smallfamily-owned company was subsumed<strong>in</strong>to <strong>the</strong> Grafton Groupunder <strong>the</strong> name Edwards Buildbase.“We’re your typical ‘one-stopshop’”,expla<strong>in</strong>s Matt Henderson,Branch Manager and boss of 25Buildbase employees. “WheneverBuildbase makes an acquisition,<strong>the</strong> orig<strong>in</strong>al name and local profileof <strong>the</strong> bus<strong>in</strong>ess is reta<strong>in</strong>ed.”Matt Henderson’s branch haseveryth<strong>in</strong>g you need to build ahouse or landscape a garden, fromnails, saws and hammers to toilets,bricks and solid wood products.Local build<strong>in</strong>g contractors cometo Edwards Buildbase <strong>in</strong> Redditchto load <strong>the</strong>ir vans with build<strong>in</strong>gmaterials. However, <strong>the</strong> branchalso attracts private <strong>in</strong>dividualswho are undertak<strong>in</strong>g woodwork<strong>in</strong>gprojects, offer<strong>in</strong>g <strong>the</strong>m homedelivery of <strong>the</strong>ir purchases.“We offer a good level of serviceto all sorts of customers,”expla<strong>in</strong>s Matt as he takes us on aguided tour of <strong>the</strong> fully-stockedpremises.A lot has happened <strong>in</strong> <strong>the</strong> yearss<strong>in</strong>ce J. Thomas Edwards opened<strong>the</strong> doors of his shop. At that time,<strong>the</strong> shop mostly sold fence postsand barbed wire. Now it sellseveryth<strong>in</strong>g for build<strong>in</strong>g and renovationprojects, with <strong>the</strong> exceptionof glass.Approximately a quarter of <strong>the</strong>products on <strong>the</strong> branch shelvesand <strong>in</strong> <strong>the</strong> warehouse are FSC-certifiedsolid wood products. In asmall service mill, a planed bandsaw and sp<strong>in</strong>dle moulder are usedto produce short runs of customisedcomponents ordered by customers.“Many timber merchants aredecommission<strong>in</strong>g out <strong>the</strong>ir oldequipment, but we’ve decided tokeep hold of ours,” says Matt. “It’sa valued service.”However, an <strong>in</strong>creas<strong>in</strong>gly largeproportion of solid wood prod-timbernews | 6

ucts, such as carpentry timber andcomponents, sold <strong>in</strong> Redditch aremade from developed timber. Aprime example of this is <strong>the</strong> completedoor frames that are supplied<strong>in</strong> shr<strong>in</strong>k wrapped packag<strong>in</strong>g from<strong>SCA</strong> <strong>Timber</strong> <strong>in</strong> Stoke-on-Trent.“Interest <strong>in</strong> timber is <strong>in</strong>creas<strong>in</strong>gall <strong>the</strong> time,” says Matt. “DIY programmeson TV and an <strong>in</strong>creasedawareness of <strong>the</strong> environmentmean that wood has taken greatstrides towards replac<strong>in</strong>g o<strong>the</strong>rmaterials.This is not unique to Buildbase<strong>in</strong> Redditch. The same trend isemerg<strong>in</strong>g <strong>in</strong> all Buildbase branchesthroughout <strong>the</strong> <strong>UK</strong>.”Stephen Thompstone, who isresponsible for all <strong>the</strong> company’sbranches <strong>in</strong> <strong>the</strong> Nor<strong>the</strong>rn Division,from Oxford <strong>in</strong> <strong>the</strong> south to <strong>the</strong>Shetland Isles <strong>in</strong> <strong>the</strong> north, saysthat timber based products makeup approximately 20 % of Buildbase’ssales.“We’re see<strong>in</strong>g a steady <strong>in</strong>crease<strong>in</strong> both our total turnover and <strong>the</strong>proportion of solid wood products,”he says.<strong>SCA</strong> has been one of <strong>the</strong> biggestsuppliers of solid wood productsto Buildbase for many years. Thecollaborative relationship beganwhen Buildbase approached Welshpool-basedSevern <strong>Timber</strong> <strong>Products</strong>to supply planed solid woodproducts.As <strong>SCA</strong> and STP became closer,<strong>the</strong> collaborative relationshipJohn Buffel (left), <strong>SCA</strong> <strong>Timber</strong> <strong>UK</strong>,visit<strong>in</strong>g Paul Smith, Branch Managerat Selco <strong>in</strong> Stirchley.between <strong>SCA</strong> and Buildbase alsobegan to develop. Today, around90 % of all f<strong>in</strong>ished wood sold <strong>in</strong>Buildbase branches comes from<strong>SCA</strong>.“Our customers demand a widerange of FSC-labelled high qualitytimber,” expla<strong>in</strong>s Stephen. “Andwe value ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g long-termrelationships with our suppliers.”Text & photographs: Mats WigardtIrish DIY giantwith solid foothold <strong>in</strong> <strong>the</strong> <strong>UK</strong>The Grafton Group is <strong>the</strong> market leader <strong>in</strong> <strong>the</strong>Irish DIY and builders’ merchant sector. In <strong>the</strong><strong>UK</strong>, <strong>the</strong> company is enjoy<strong>in</strong>g steady growth, andis now one of <strong>the</strong> biggest players <strong>in</strong> <strong>the</strong> Britishbuilders’ merchants market.In 1902, William Thomas Chadwick founded abus<strong>in</strong>ess under <strong>the</strong> name Chadwicks (Dubl<strong>in</strong>)Limited. The aim was to supply cement to Irishbuild<strong>in</strong>g contractors.Shortly after <strong>the</strong> end of <strong>the</strong> Second World War,William Chadwick died and <strong>the</strong> company was takenover by <strong>the</strong> founder’s two sons. In 1965, new ownerstook over and it became a listed company.In <strong>the</strong> mid-1980s, <strong>the</strong> company’s remit expandedfrom that of cement manufacturer to builders’ merchant.Dur<strong>in</strong>g this period, <strong>the</strong> first DIY superstore<strong>in</strong> Ireland was opened.In 1988, <strong>the</strong> company changed its name to <strong>the</strong>Grafton Group and made its first acquisition <strong>in</strong> <strong>the</strong><strong>UK</strong>.This kick-started a particularly expansive periodfor <strong>the</strong> Grafton Group, with <strong>the</strong> company mak<strong>in</strong>ga number of acquisitions <strong>in</strong> both <strong>the</strong> <strong>UK</strong> and Ireland.In <strong>the</strong> late 1990s, <strong>the</strong> Grafton Group beganmak<strong>in</strong>g serious <strong>in</strong>roads <strong>in</strong>to <strong>the</strong> British DIY/builders’merchant market.In 1998, Grafton became <strong>the</strong> first Irish companyto acquire a British listed company, British Dredg<strong>in</strong>g,whose 17 outlets were to form <strong>the</strong> basis for <strong>the</strong>Buildbase cha<strong>in</strong>.In 2004, Grafton made its 100th company acquisition,averag<strong>in</strong>g one a month s<strong>in</strong>ce 1998.Today, <strong>the</strong> Grafton Group is active with<strong>in</strong> <strong>the</strong> plumbers’merchant and builders’ merchant sectors, aswell as <strong>the</strong> grow<strong>in</strong>g DIY market. Operat<strong>in</strong>g underbrands <strong>in</strong>clud<strong>in</strong>g Chadwickd, Buildbase, HeitonBuckley, Jackson, Selco, Plumbase, Euromix, Woodiesand Atlantic Home Care, <strong>the</strong> company hasmore than 500 branches and factories employ<strong>in</strong>gsome 11,000 people. <strong>SCA</strong> provides a large proportionof <strong>the</strong> solid wood products sold <strong>in</strong> <strong>the</strong> GraftonGroup’s various DIY and builders’ merchant branches.Last year, <strong>the</strong> company enjoyed a turnover ofapproximately £2 billion. The company’s ExecutiveChairman is Michael Chadwick. To f<strong>in</strong>d out moreabout <strong>the</strong> company, visit: www.graftonplc.comEdwards Buildbase <strong>in</strong> Redditch has its own small timber service mill – a facilitygreatly appreciated by customers.Mats Wigardt7 | timbernews

Three pillars <strong>in</strong> <strong>the</strong> <strong>UK</strong>With three complementary bus<strong>in</strong>esses, <strong>SCA</strong> <strong>Timber</strong> has agood platform from which to supply <strong>the</strong> British solid woodproducts market.The wholesaler <strong>in</strong> Hull, <strong>the</strong> distribution centre and woodf<strong>in</strong>ish<strong>in</strong>g operation <strong>in</strong> Stoke-on-Trent and <strong>the</strong> recentlyacquired wood f<strong>in</strong>ish<strong>in</strong>g company Severn <strong>Timber</strong> <strong>in</strong> Welshpoolprovide a good mix for future efforts <strong>in</strong> <strong>the</strong> <strong>UK</strong> market.Wholesaler <strong>in</strong> Hull<strong>SCA</strong> <strong>Timber</strong> Supply’s term<strong>in</strong>al depot and wholesale operationis strategically located <strong>in</strong> <strong>the</strong> port city of Hull, a lead<strong>in</strong>gport for overseas trade, particularly <strong>in</strong> respect of sawnsolid wood products.Every two weeks, vessels from <strong>SCA</strong> <strong>Timber</strong>’s sawmills arrive at<strong>the</strong> K<strong>in</strong>g George Dock. The ships are loaded with high qualitywood-based products made from raw materials orig<strong>in</strong>at<strong>in</strong>g <strong>in</strong> <strong>the</strong>p<strong>in</strong>e and spruce forests of nor<strong>the</strong>rn Sweden.The term<strong>in</strong>al <strong>in</strong> Hull receives 215,000 cubic metres of sawnsolid wood products every year, and has a total storage capacityof 25,000 square metres, 15,000 of which are under cover. Solidwood products are stored here before be<strong>in</strong>g transported to customers<strong>in</strong> <strong>the</strong> timber <strong>in</strong>dustry and builders’ merchant sector, as wellas to our own operations <strong>in</strong> Stoke-on-Trent and Welshpool.Industrial customers, such as those <strong>in</strong> <strong>the</strong> w<strong>in</strong>dow and door<strong>in</strong>dustries, are visited by <strong>SCA</strong> <strong>Timber</strong> Supply’s local sales representativeson a regular basis. This closeness promotes healthycollaboration and establishes a dialogue on <strong>the</strong> development ofoperations based on a ‘w<strong>in</strong>-w<strong>in</strong>’ relationship for both parties. Ouraim is to get closer to high volume customers <strong>in</strong> <strong>the</strong> f<strong>in</strong>ish<strong>in</strong>g cha<strong>in</strong>,<strong>in</strong> order to allow us, <strong>in</strong> a cost effective manner, to offer productsthat have been adapted to customers’ manufactur<strong>in</strong>g processes.Deliveries from <strong>SCA</strong> <strong>Timber</strong>’s sawmills <strong>in</strong> nor<strong>the</strong>rn Sweden arrive at <strong>the</strong>K<strong>in</strong>g George Dock <strong>in</strong> Hull.Photo: Ingrid LöfqvistDistribution centre <strong>in</strong> Stoke-on-TrentThe geographical location of <strong>SCA</strong> <strong>Timber</strong>’s distributioncentre, <strong>SCA</strong> <strong>Timber</strong> Supply, <strong>in</strong> Stoke-on-Trent has manyadvantages.Stoke lies at <strong>the</strong> heart of <strong>the</strong> populous Midlands region of<strong>the</strong> <strong>UK</strong>, with a substantial proportion of <strong>the</strong> English populationliv<strong>in</strong>g with<strong>in</strong> a 100 km radius. Many of <strong>the</strong> company’scustomers are active <strong>in</strong> both <strong>the</strong> DIY trade and <strong>the</strong> builders’merchant sector. These customers rely on hav<strong>in</strong>g a solid woodproducts supplier that can offer an holistic solution and providea skilfully crafted range of products, as well as warehous<strong>in</strong>g anddistribution options.<strong>SCA</strong> <strong>Timber</strong> Supply’s ‘supply cha<strong>in</strong>’ concept* has been developedprimarily for <strong>the</strong> DIY market and is based on weekly deliveriesto almost 1,000 DIY superstores throughout <strong>the</strong> <strong>UK</strong>.Orders are placed via EDI (Electronic Data Interchange), automatedprocedures that simplify trade between customer andsupplier. <strong>Products</strong> <strong>in</strong> stock are packed and given barcodes. Inorder to be as complete a supplier of wood-based products aspossible, we complement our own product range with productsfrom o<strong>the</strong>r manufacturers.One part of <strong>SCA</strong> <strong>Timber</strong> Supply handles <strong>the</strong> delivery of consumerproducts to DIY stores. These products <strong>in</strong>clude melam<strong>in</strong>ecoatedchipboard, edge glued panels, PAR planed solid woodtimbernews | 8

Packed and barcoded products are loaded, under cover, at <strong>SCA</strong> <strong>Timber</strong> Supply’s distribution facility <strong>in</strong> Stoke-on-Trent.Photo: Ingrid Löfqvistproducts, mould<strong>in</strong>gs, garden timber and kitchen worktops.One product that is <strong>in</strong> <strong>in</strong>creas<strong>in</strong>g demand at <strong>the</strong> momentis specially-adapted chipboard used for loft conversions.The o<strong>the</strong>r part of <strong>SCA</strong> <strong>Timber</strong> Supply’s distribution operationprovides builders’ merchants with standardised products,primarily for professional use <strong>in</strong> <strong>the</strong> construction andjo<strong>in</strong>ery <strong>in</strong>dustries. The centre <strong>in</strong> Stoke is currently undergo<strong>in</strong>ga programme of development work <strong>in</strong> order tobecome an even better supplier to this market segment.Shorter delivery times and a more bespoke product rangesare important elements of this.The Stoke operation also runs a complementary woodf<strong>in</strong>ish<strong>in</strong>g facility with a plan<strong>in</strong>g mill and packag<strong>in</strong>g l<strong>in</strong>e.Most of <strong>the</strong> products f<strong>in</strong>ished are door frame components,which are packed <strong>in</strong> accordance with customer requirementsand marked with a barcode. The capacity of <strong>the</strong>pack<strong>in</strong>g l<strong>in</strong>e is around 600 sets per hour. The facility alsocarries out service plan<strong>in</strong>g of PAR and mould<strong>in</strong>gs.The distribution centre and warehouse has a capacityof 250,000 square metres under cover. In addition, it canalso accommodate <strong>the</strong> load<strong>in</strong>g of four trucks at <strong>the</strong> sametime. A fur<strong>the</strong>r 200,000 square metres of storage is availableoutdoors.*The Supply Cha<strong>in</strong> Management (SCM) concept replaces<strong>the</strong> traditional buyer and seller roles with a supplier andcustomer structure <strong>in</strong> which, for example, a def<strong>in</strong>ed productrange is automatically delivered to a number of saleslocations based on agreed stock levels.Wood f<strong>in</strong>ish<strong>in</strong>g companySevern <strong>Timber</strong>Welshpool-based Severn <strong>Timber</strong> is <strong>the</strong> third element <strong>in</strong> <strong>SCA</strong><strong>Timber</strong>’s focus on <strong>the</strong> British market.Severn <strong>Timber</strong> <strong>Products</strong> f<strong>in</strong>ishes approximately 70,000 cubicmetres of sawn solid wood products, turn<strong>in</strong>g <strong>the</strong>m <strong>in</strong>to planedand impregnated products, primarily for <strong>the</strong> builders’ merchantsector. The company’s facilities have benefited from a recent programmeof <strong>in</strong>vestment, which has seen <strong>the</strong> <strong>in</strong>troduction of threemodern plan<strong>in</strong>g l<strong>in</strong>es. The product range on offer comprisesplaned solid wood products (spruce and p<strong>in</strong>e), mould<strong>in</strong>gs andwooden floor<strong>in</strong>g.<strong>SCA</strong> <strong>Timber</strong> has been <strong>the</strong> pr<strong>in</strong>cipal supplier of sawn solidwood products to Severn <strong>Timber</strong> for many years and has alsocollaborated on a number of issues concern<strong>in</strong>g <strong>the</strong> f<strong>in</strong>ish<strong>in</strong>g, distributionand sale of solid wood products. As a supplier, <strong>SCA</strong> hasbeen praised for its awareness of environmental issues, which hasbeen made manifest <strong>in</strong> its use of FSC-certified forest <strong>in</strong> Nor<strong>the</strong>rnSweden which it manages responsibly, with checks at all stagesfrom sapl<strong>in</strong>g to product.Severn <strong>Timber</strong> f<strong>in</strong>ishes sawn solid wood products, turn<strong>in</strong>g <strong>the</strong>m <strong>in</strong>toplaned and treated products at its facility <strong>in</strong> Welshpool <strong>in</strong> Wales.Photo: Jan Svedjebrant9 | timbernewsTexts: Ingrid Löfqvist

Managerial change at <strong>SCA</strong> <strong>Timber</strong> SupplyAlthough he has no previous professionalexperience of <strong>the</strong> timber <strong>in</strong>dustry, NeilEmsley, <strong>the</strong> new Operations Director at<strong>SCA</strong> <strong>Timber</strong> Supply <strong>in</strong> Stoke-on-Trent,has always been <strong>in</strong>terested <strong>in</strong> <strong>the</strong> environmentand products made from naturalmaterials.I’ve always had an appreciation for productsmade from natural materials, particularlywood. <strong>SCA</strong> impressed me with itscommitment to <strong>the</strong> environment, us<strong>in</strong>g itsown FSC-certified forest as a raw materialsbase and ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g control over <strong>the</strong> entiresupply cha<strong>in</strong>. Such an approach is veryimportant to <strong>the</strong> timber <strong>in</strong>dustry,” saysEmsley.He took up his post as Operations Directorfor <strong>SCA</strong> <strong>Timber</strong> Supply at <strong>the</strong> beg<strong>in</strong>n<strong>in</strong>gof February 2007, assum<strong>in</strong>g responsibilityfor production, warehous<strong>in</strong>g, procurementand logistics. He jo<strong>in</strong>ed <strong>SCA</strong> from F<strong>in</strong>del Plc,where he managed <strong>the</strong>ir customer servicesdepartment. Prior to that, he had been Headof Procurement at Adidas.“Here at <strong>SCA</strong> <strong>Timber</strong> Supply I can reallyput my previous experience from sales, warehous<strong>in</strong>g,production plann<strong>in</strong>g and logisticsto good use. We’ve got several <strong>in</strong>terest<strong>in</strong>gdevelopment projects bubbl<strong>in</strong>g away, <strong>in</strong>clud<strong>in</strong>ga review of our warehous<strong>in</strong>g and transportoperations, <strong>the</strong> aim of which is tofur<strong>the</strong>r improve <strong>the</strong> service we provide to<strong>the</strong> builders’ merchant sector,” says Emsley.Ingrid LöfqvistNeil Emsley, Operations Director at <strong>SCA</strong><strong>Timber</strong> Supply.<strong>Timber</strong> market <strong>in</strong> focusAt <strong>the</strong> beg<strong>in</strong>n<strong>in</strong>g of May, <strong>SCA</strong> <strong>Timber</strong>held a sem<strong>in</strong>ar <strong>in</strong> Birm<strong>in</strong>gham to which<strong>UK</strong> customers and collaboration partnerswere <strong>in</strong>vited.Lars-Göran Olsson, a market analystfrom <strong>the</strong> Swedish <strong>Forest</strong> IndustriesFederation, was on hand. He gave anoverview of developments <strong>in</strong> <strong>the</strong> solid woodproducts market over <strong>the</strong> past few years.“We have witnessed <strong>the</strong> fastest development<strong>in</strong> <strong>the</strong> price of sawn timber <strong>in</strong> Swedens<strong>in</strong>ce <strong>the</strong> 1970s,” he stated, cit<strong>in</strong>g a numberLars-Göran Olsson, a market analyst from <strong>the</strong> Swedish<strong>Forest</strong> Industries Federation.of explanations, <strong>in</strong>clud<strong>in</strong>greduced fell<strong>in</strong>g <strong>in</strong> Canada as<strong>the</strong> result of log shortages <strong>in</strong><strong>the</strong> east, turbulence <strong>in</strong> <strong>the</strong>Russian timber market,<strong>in</strong>creased demand <strong>in</strong> Europeand <strong>in</strong>creased <strong>in</strong>terest <strong>in</strong> biofuels.Anders Ek, <strong>SCA</strong> <strong>Timber</strong>’sMarket<strong>in</strong>g Director, said thatdemand for sawn solid woodproducts <strong>in</strong> Europe cont<strong>in</strong>uesto be very high. In fact, demand is sohigh that, <strong>in</strong> <strong>the</strong> long term, timber stocksmay be <strong>in</strong>sufficient to meet demand,particularly <strong>in</strong> <strong>the</strong> construction sector.He predicts that, start<strong>in</strong>g <strong>in</strong> <strong>the</strong> secondhalf of 2008, <strong>the</strong> USA will make a comebackas an important export market forEuropean wood producers and thatcustomers and suppliers will become<strong>in</strong>creas<strong>in</strong>gly close.Rob Simpson, MD of <strong>SCA</strong> <strong>Timber</strong>Supply, summed up <strong>SCA</strong>’s presence <strong>in</strong><strong>the</strong> British market by stat<strong>in</strong>g that, afterScand<strong>in</strong>avia, <strong>the</strong> <strong>UK</strong> was <strong>the</strong> company’ssecond most important market. Lastyear, <strong>the</strong> market took delivery of260,000 m3 timber, equivalent to 15 %Rob Simpson, MD of <strong>SCA</strong> <strong>Timber</strong> Supply.of <strong>the</strong> total volume produced by <strong>SCA</strong>’ssawmills.“Follow<strong>in</strong>g <strong>the</strong> acquisition of Severn<strong>Timber</strong> <strong>Products</strong> of Welshpool, we’ve<strong>in</strong>creased our ability to make fur<strong>the</strong>r<strong>in</strong>roads <strong>in</strong>to <strong>the</strong> builders’ merchant andDIY market,” he said.Stephen Thompstone of Buildbasesummed up his feel<strong>in</strong>gs about <strong>the</strong> sem<strong>in</strong>ar:“It was valuable to get all <strong>the</strong> <strong>in</strong>formation<strong>in</strong> one place. It gave me and my colleagues<strong>the</strong> opportunity to focus on ourown roles <strong>in</strong> <strong>the</strong> changes that are nowunderway <strong>in</strong> <strong>the</strong> timber market.”Mats WigardtPhoto: Prestige Photographytimbernews | 10

<strong>SCA</strong> <strong>in</strong>vests <strong>in</strong> Tunadal sawmill<strong>SCA</strong> is <strong>in</strong>vest<strong>in</strong>g 40 million SEK <strong>in</strong> a new progressive kilnat Tunadal sawmill. The new kiln will have a capacity ofmore than 100,000 cubic metres and will allow <strong>the</strong> sawmillto <strong>in</strong>crease production and fur<strong>the</strong>r process<strong>in</strong>g.In February <strong>SCA</strong> decided to <strong>in</strong>vest <strong>in</strong> seven new chamberkilns at Tunadal sawmill, an <strong>in</strong>vestment now <strong>in</strong> progress.“With <strong>the</strong> new progressive kiln, we will have state of <strong>the</strong>art kilns for <strong>the</strong> sawmill’s full capacity, ” says Jerry Larsson,sawmill manager. “A modern dry<strong>in</strong>g plant is crucial for produc<strong>in</strong>gcustomer-specific and fur<strong>the</strong>r processed products. Thisis ano<strong>the</strong>r step <strong>in</strong> <strong>the</strong> process of develop<strong>in</strong>g Tunadal <strong>in</strong>to aspruce sawmill match<strong>in</strong>g <strong>the</strong> most competitive mills <strong>in</strong> Europe.”The Tunadal sawmill is supplied with heat from <strong>the</strong> Korstawaste-based heat plant, owned by <strong>the</strong> Community of Sundsvall,which has drastically reduced <strong>the</strong> sawmill’s electricityconsumption. The district heat<strong>in</strong>g network <strong>in</strong> Sundsvall is <strong>in</strong>its turned supplied with spare heat from <strong>SCA</strong>’s Ortviken papermill.In 2006 <strong>the</strong> Tunadal sawmill produced 330,000 cubicmetres of solid wood products and had a workforce of 155.…and <strong>in</strong> Jämtlamell<strong>SCA</strong> is also <strong>in</strong>vest<strong>in</strong>g seven million SEK <strong>in</strong> <strong>the</strong> Jämtlamellsawmill <strong>in</strong> Stugun <strong>in</strong> nor<strong>the</strong>rn Sweden. The dry<strong>in</strong>g kilnswill be modernised and upgraded. The <strong>in</strong>vestment will <strong>in</strong>crease<strong>the</strong> sawmill’s production capacity and its capacity to producecustomer-specific products.“We have seen a very positive development s<strong>in</strong>ce <strong>SCA</strong>became a part-owner last spr<strong>in</strong>g,” says Lars-Olof Alm, sawmillmanager <strong>in</strong> Stugun. “The conditions for a cont<strong>in</strong>ued positivedevelopment are greatly improved by <strong>SCA</strong>’s confidence <strong>in</strong> lett<strong>in</strong>gus carry through <strong>in</strong>vestments.”S<strong>in</strong>ce <strong>SCA</strong> acquired a m<strong>in</strong>ority share <strong>in</strong> Jämtlamell <strong>AB</strong> <strong>in</strong>2006, <strong>SCA</strong> has already <strong>in</strong>vested six million SEK <strong>in</strong> <strong>the</strong> sawmill,which have allowed for <strong>in</strong>creased production. Jämtlamell hada positive productivity development last year. It’s sales andprofitability also improved.The Jämtlamell sawmill <strong>in</strong> Stugun produced 140,000 cubicmetres of solid-wood products 2006 and has a workforce of85.Solid wood price boom slowsIn <strong>the</strong> past 12 months, wood hasbeen a scarce commodity. High consumption<strong>in</strong> many of our marketsand difficulties <strong>in</strong> produc<strong>in</strong>g sufficientvolumes have contributed tothis situation. However, <strong>the</strong> picturechanged dur<strong>in</strong>g <strong>the</strong> spr<strong>in</strong>g.The high prices, coupled with <strong>the</strong>effects of two damag<strong>in</strong>g spr<strong>in</strong>g storms,resulted <strong>in</strong> <strong>the</strong> production of a significantamount of sawlogs, substantially<strong>in</strong>creas<strong>in</strong>g production levels,particularly <strong>in</strong> Central Europe. Consequently,prices have slowed. In <strong>the</strong>case of Central European solid woodproducts, prices have fallen somewhatfrom <strong>the</strong> peak levels reached dur<strong>in</strong>g<strong>the</strong> w<strong>in</strong>ter.Consumption <strong>in</strong> our European marketsis generally good. The Swedish market iscurrently stronger than it has been <strong>in</strong>many years, with <strong>the</strong> build<strong>in</strong>g sector exhibit<strong>in</strong>gdouble-digit growth. O<strong>the</strong>r strongmarkets <strong>in</strong>clude Norway, Denmark, <strong>the</strong>Ne<strong>the</strong>rlands and <strong>the</strong> <strong>UK</strong>. The Germanand French markets cont<strong>in</strong>ue to operateat a high level, although <strong>the</strong>y are show<strong>in</strong>gsigns of slow<strong>in</strong>g down.The major overseas markets of <strong>the</strong>USA and Japan are experienc<strong>in</strong>g a substantialbuild<strong>in</strong>g sector decl<strong>in</strong>e. Thenumber of new builds <strong>in</strong> <strong>the</strong> USA hasreduced by approximately 25 % comparedto <strong>the</strong> same time last year, whilst <strong>the</strong>Japanese market has slowed down by7 %.However, my perception of wood as abuild<strong>in</strong>g material rema<strong>in</strong>s unchanged. Inrecent years, wood has streng<strong>the</strong>ned itsposition. Although we have seen unusuallysteep price rises dur<strong>in</strong>g <strong>the</strong> past year,<strong>the</strong> price of many alternative raw materialshas risen even more. Put simply, <strong>the</strong>reis a dist<strong>in</strong>ct lack of raw materials <strong>in</strong> <strong>the</strong>global economy. The reason for this is <strong>the</strong>strong growth experienced by <strong>the</strong> majorAsian economies, particularly those ofCh<strong>in</strong>a and India.However, production rates dur<strong>in</strong>g <strong>the</strong>spr<strong>in</strong>g have become a problem. I estimatethat production <strong>in</strong> Germany and Austriahas <strong>in</strong>creased by 15 % as <strong>the</strong> result of <strong>the</strong>large amount of available sawlogs and <strong>the</strong>unusually mild w<strong>in</strong>ter wea<strong>the</strong>r.Production is also <strong>in</strong>creas<strong>in</strong>g <strong>in</strong> Scand<strong>in</strong>avia,albeit at a more modest rate.Production <strong>in</strong>creased by 5 % dur<strong>in</strong>g<strong>the</strong> period January-April, split equallybetween p<strong>in</strong>e and spruce.Sawmill order books are look<strong>in</strong>g healthy.The Swedish sawmills are report<strong>in</strong>gvery strong sales on <strong>the</strong>ir domesticmarket. However, orders from exportmarkets are down on <strong>the</strong> same time lastyear, ma<strong>in</strong>ly from <strong>the</strong> USA, but also fromJapan.Stocks <strong>in</strong> <strong>the</strong> Scand<strong>in</strong>avian sawmillswere low at <strong>the</strong> end of April, but aresee<strong>in</strong>g signs of an <strong>in</strong>crease <strong>in</strong> F<strong>in</strong>land. Incontrast, stock levels <strong>in</strong> <strong>the</strong> Central Europeansawmills are very high. At <strong>the</strong> sametime, <strong>SCA</strong> <strong>Timber</strong>’s stock level is currentlyas low as it ever has been, with 8 % ofproduction be<strong>in</strong>g stockpiled.The Scand<strong>in</strong>avian p<strong>in</strong>e stock has fallenby 11 % compared to <strong>the</strong> same period lastyear. Spruce stocks have fallen by 15 %.Anders Ek, Market<strong>in</strong>g Director11 | timbernews

The story of <strong>the</strong> green bath<strong>in</strong>g hutOnce upon a time, <strong>the</strong> sounds of laughter and talk<strong>in</strong>gcould be heard com<strong>in</strong>g from <strong>the</strong> small, g<strong>in</strong>gerbreadstylework hut out on Revsundssjön. It was a placewhere <strong>the</strong> head forester would relax with his guests,go<strong>in</strong>g swimm<strong>in</strong>g <strong>in</strong> <strong>the</strong> lake or play<strong>in</strong>g skittles. Now,this little idyll is fac<strong>in</strong>g an uncerta<strong>in</strong> future.In <strong>the</strong> late 19th and early 20thcenturies, <strong>the</strong> village of Stavre on<strong>the</strong> shore of Revsundssjön <strong>in</strong>nor<strong>the</strong>rn Sweden was an importantcentre for <strong>the</strong> forestry <strong>in</strong>dustry. Itwas home to <strong>the</strong> adm<strong>in</strong>istrativeoffices of many of <strong>the</strong> major forestcompanies, and when forestrybegan to be mechanised, <strong>SCA</strong>opened a forestry school <strong>in</strong> <strong>the</strong> villageto tra<strong>in</strong> fellers and drivers.In around 1880, Skönviks <strong>AB</strong>,which became part of <strong>SCA</strong> <strong>in</strong>1929, built a bath<strong>in</strong>g hut out onRevsundssjön.Built on wooden stilts anchoredto stone piers at <strong>the</strong> bottom of <strong>the</strong>lake, <strong>the</strong> bath<strong>in</strong>g hut was designedto be used by <strong>the</strong> lead<strong>in</strong>g officialsof <strong>the</strong> area, with <strong>the</strong> head foresterhead<strong>in</strong>g <strong>the</strong> queue. Their families,local wholesalers and visit<strong>in</strong>gguests were also welcome to enjoy<strong>the</strong> facilities.A long wooden bridge l<strong>in</strong>ked<strong>the</strong> bath<strong>in</strong>g hut to <strong>the</strong> shore. Thebridge was used to play skittles –an early predecessor to ten-p<strong>in</strong>bowl<strong>in</strong>g. Inside <strong>the</strong> hut, a hatch leddown to a wooden bath, wellhidden from pry<strong>in</strong>g eyes, that wasfilled with lake water. The verandawas situated on <strong>the</strong> second floor.For a few years dur<strong>in</strong>g <strong>the</strong> 1940s,<strong>the</strong> hut was used as a ski workshopby carpenter Jean Melander.You could come and buy custommadeskis or get your old oneswaxed and recurved.It’s been several years s<strong>in</strong>ce anyonehas used <strong>the</strong> hut, and <strong>the</strong> presentowner lives <strong>in</strong> Stockholm.Over <strong>the</strong> years, <strong>the</strong> effects of iceand waves have taken <strong>the</strong>ir toll on<strong>the</strong> bridge, and it’s been a long times<strong>in</strong>ce anyone actually used <strong>the</strong> hutto ba<strong>the</strong> <strong>in</strong>. Today, <strong>the</strong> entire structureof <strong>the</strong> hut has a perceptiblelean, <strong>the</strong> pa<strong>in</strong>t is flak<strong>in</strong>g off and itis only accessible by boat.But <strong>the</strong> old bath<strong>in</strong>g hut is set tosurvive a few years more. Karl-Erik Rodl<strong>in</strong>g, a former strawberrygrower and current resident ofStavre, who has himself replaced anumber of <strong>the</strong> stilts on which <strong>the</strong>hut is built, believes that a lick ofpa<strong>in</strong>t and new roof<strong>in</strong>g felt wouldgo a long way.Mats WigardtThe bath<strong>in</strong>g hut <strong>in</strong> Revsundssjön was built dur<strong>in</strong>g <strong>the</strong> latter part of <strong>the</strong> 19th century.On <strong>the</strong> black and white photo, taken sometime around 1885, you can see <strong>the</strong> longbridge that is now just a distant memory.Photo: Mats WigardtAfter a day experienc<strong>in</strong>g nature and develop<strong>in</strong>g a sense of adventure, <strong>the</strong> Sami banquet wasa taste of heaven.Katar<strong>in</strong>a Rimpi (right) gave a talkabout her own ethnic group, <strong>the</strong>Sami.