fixed or semi-fixed foam fire protection systems for storage tanks - NIFV

fixed or semi-fixed foam fire protection systems for storage tanks - NIFV

fixed or semi-fixed foam fire protection systems for storage tanks - NIFV

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

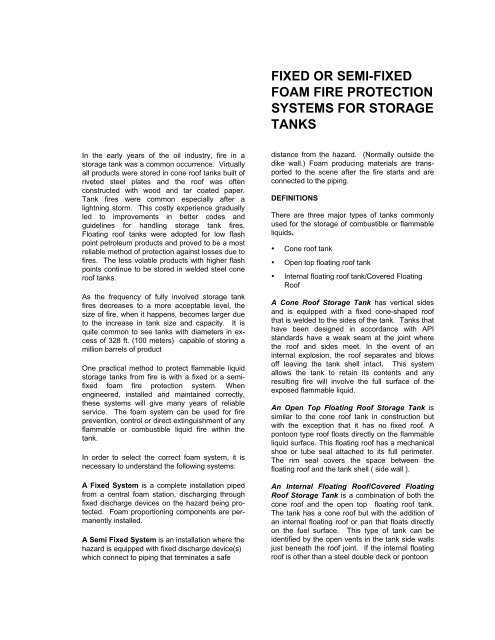

FIXED OR SEMI-FIXEDFOAM FIRE PROTECTIONSYSTEMS FOR STORAGETANKSIn the early years of the oil industry, <strong>fire</strong> in ast<strong>or</strong>age tank was a common occurrence. Virtuallyall products were st<strong>or</strong>ed in cone roof <strong>tanks</strong> built ofriveted steel plates and the roof was oftenconstructed with wood and tar coated paper.Tank <strong>fire</strong>s were common especially after alightning st<strong>or</strong>m. This costly experience graduallyled to improvements in better codes andguidelines f<strong>or</strong> handling st<strong>or</strong>age tank <strong>fire</strong>s.Floating roof <strong>tanks</strong> were adopted f<strong>or</strong> low flashpoint petroleum products and proved to be a mostreliable method of <strong>protection</strong> against losses due to<strong>fire</strong>s. The less volatile products with higher flashpoints continue to be st<strong>or</strong>ed in welded steel coneroof <strong>tanks</strong>.As the frequency of fully involved st<strong>or</strong>age tank<strong>fire</strong>s decreases to a m<strong>or</strong>e acceptable level, thesize of <strong>fire</strong>, when it happens, becomes larger dueto the increase in tank size and capacity. It isquite common to see <strong>tanks</strong> with diameters in excessof 328 ft. (100 meters) capable of st<strong>or</strong>ing amillion barrels of productOne practical method to protect flammable liquidst<strong>or</strong>age <strong>tanks</strong> from <strong>fire</strong> is with a <strong>fixed</strong> <strong>or</strong> a <strong>semi</strong><strong>fixed</strong><strong>foam</strong> <strong>fire</strong> <strong>protection</strong> system. Whenengineered, installed and maintained c<strong>or</strong>rectly,these <strong>systems</strong> will give many years of reliableservice. The <strong>foam</strong> system can be used f<strong>or</strong> <strong>fire</strong>prevention, control <strong>or</strong> direct extinguishment of anyflammable <strong>or</strong> combustible liquid <strong>fire</strong> within thetank.In <strong>or</strong>der to select the c<strong>or</strong>rect <strong>foam</strong> system, it isnecessary to understand the following <strong>systems</strong>:A Fixed System is a complete installation pipedfrom a central <strong>foam</strong> station, discharging through<strong>fixed</strong> discharge devices on the hazard being protected.Foam prop<strong>or</strong>tioning components are permanentlyinstalled.A Semi Fixed System is an installation where thehazard is equipped with <strong>fixed</strong> discharge device(s)which connect to piping that terminates a safedistance from the hazard. (N<strong>or</strong>mally outside thedike wall.) Foam producing materials are transp<strong>or</strong>tedto the scene after the <strong>fire</strong> starts and areconnected to the piping.DEFINITIONSThere are three maj<strong>or</strong> types of <strong>tanks</strong> commonlyused f<strong>or</strong> the st<strong>or</strong>age of combustible <strong>or</strong> flammableliquids.• Cone roof tank• Open top floating roof tank• Internal floating roof tank/Covered FloatingRoofA Cone Roof St<strong>or</strong>age Tank has vertical sidesand is equipped with a <strong>fixed</strong> cone-shaped roofthat is welded to the sides of the tank. Tanks thathave been designed in acc<strong>or</strong>dance with APIstandards have a weak seam at the joint wherethe roof and sides meet. In the event of aninternal explosion, the roof separates and blowsoff leaving the tank shell intact. This systemallows the tank to retain its contents and anyresulting <strong>fire</strong> will involve the full surface of theexposed flammable liquid.An Open Top Floating Roof St<strong>or</strong>age Tank issimilar to the cone roof tank in construction butwith the exception that it has no <strong>fixed</strong> roof. Apontoon type roof floats directly on the flammableliquid surface. This floating roof has a mechanicalshoe <strong>or</strong> tube seal attached to its full perimeter.The rim seal covers the space between thefloating roof and the tank shell ( side wall ).An Internal Floating Roof/Covered FloatingRoof St<strong>or</strong>age Tank is a combination of both thecone roof and the open top floating roof tank.The tank has a cone roof but with the addition ofan internal floating roof <strong>or</strong> pan that floats directlyon the fuel surface. This type of tank can beidentified by the open vents in the tank side wallsjust beneath the roof joint. If the internal floatingroof is other than a steel double deck <strong>or</strong> pontoon

type, the <strong>fire</strong> <strong>protection</strong> system should bedesigned f<strong>or</strong> full surface <strong>fire</strong>s ( similar to cone roof<strong>tanks</strong> ). F<strong>or</strong> the double deck <strong>or</strong> pontoon internalroofs of steel construction, a design f<strong>or</strong> seal area<strong>protection</strong> shall be permitted (same as openfloating roof <strong>tanks</strong>).Small quantities of flammable liquids aresometimes st<strong>or</strong>ed in h<strong>or</strong>izontal style <strong>tanks</strong> whichn<strong>or</strong>mally sit on saddles <strong>or</strong> in underground st<strong>or</strong>agefacilities. This section applies only to the threemaj<strong>or</strong> types of <strong>tanks</strong> as listed above.IDENTIFY THE FLAMMABLE LIQUIDThere are two basic classifications of flammableand combustible liquids:• Hydrocarbon ( non water miscible ) and• Polar Solvent ( water miscible )The Hydrocarbon family typically consists ofstandard petroleum products such as - Gasoline,Kerosene, Diesel, Jet Fuel, Heptane, Crude Oiletc. products that do not mix with water.The Polar Solvent group typically consists of -Ethanol, Methanol, Ketone, Acetone etc. <strong>or</strong> productsthat will mix readily with water.All Chemguard U.L. Listed and Standard GradeFoam Concentrates are suitable f<strong>or</strong> use onHydrocarbon fuel <strong>fire</strong>s <strong>or</strong> spills.Only Chemguard U.L. Listed and Standard GradeUltraGuard 3% and the 3%-6% ( at 6% prop<strong>or</strong>tioningrate ) Alcohol Resistant - Aqueous FilmF<strong>or</strong>ming Foam ( AR-AFFF ) concentrates aresuitable f<strong>or</strong> use on Polar Solvent Fuel <strong>fire</strong>s <strong>or</strong>spills.NOTE: Pure MTBE is only slightly water miscible( approx. 4% - 6% ).FLAMMABLE AND COMBUSTIBLE LIQUIDSPER NFPA 11Flammable liquids mean any liquid having a flashpoint below 100 o F ( 37.8 o C ) and having a vap<strong>or</strong>pressure not exceeding 40 psi (276 kpa)(absolute)at 100 o F ( 37.8 o C ).Flammable Liquids are subdivided as follows:Class I liquids include those having flash pointsbelow 100 o F ( 37.8 o C ) and may be subdivided asfollows:(a)(b)(c)Class IA liquids include those having flashpoints below 73 o F ( 22.8 o C ) and having aboiling point below 100 o F ( 37.8 o C ).Class IB liquids include those having flashpoints below 73 o F ( 22.8 o C ) and having aboiling point above 100 o F ( 37.8 o C ).Class IC liquids include those having flashpoints at <strong>or</strong> above 73 o F ( 22.8 o C ) and below100 o F ( 37.8 o C ).Combustible Liquids mean any liquid having aflash point at <strong>or</strong> above 100 o F ( 37.8 o C ). Theymay be sub-divided as follows:(a)(b)(c)Class II liquids include those having flashpoints at <strong>or</strong> above 100 o F ( 37.8 o C ) andbelow 140 o F ( 60 o C ).Class IIIA liquids include those having flashpoints at <strong>or</strong> above 140 o F ( 60 o C ) and below200 o F ( 93.3 o C ).Class IIIB liquids include those having flashpoints at <strong>or</strong> above 200 o F ( 93.3 o C ).FIRE PROTECTION OF STORAGE TANKSU.L. has established two different types of <strong>foam</strong>discharge outlets:• Type II Discharge Outlet - A <strong>fixed</strong> device thatdelivers <strong>foam</strong> onto the burning liquid and partiallysubmerges the <strong>foam</strong> and produces restrictedagitation of the surface. Examples of this type ofdevice are Foam Chambers and Foam Makers.• Type III Discharge Outlet - A <strong>fixed</strong> <strong>or</strong> p<strong>or</strong>tabledevice that delivers <strong>foam</strong> in a manner that causesthe <strong>foam</strong> to fall directly onto the surface of theburning liquid in such a manner that causesgeneral agitation. Examples of this type of deviceare Hose Stream Nozzles and Monit<strong>or</strong>s.There are two basic methods of <strong>fire</strong> <strong>protection</strong><strong>systems</strong> f<strong>or</strong> st<strong>or</strong>age <strong>tanks</strong>:• Sub-surface Base Injection• Over the Top - (Subdivided as follows)Foam ChambersFoam MakersP<strong>or</strong>table Foam Monit<strong>or</strong>Foam Tower

SUB-SURFACE BASE INJECTIONThe sub-surface method of <strong>fire</strong> <strong>protection</strong>produces <strong>foam</strong> with a "High Back Pressure FoamMaker" located outside the st<strong>or</strong>age tank. Thissystem delivers the expanded <strong>foam</strong> mass throughpiping into the base of the tank. The pipe may bean existing product line <strong>or</strong> can be a dedicated <strong>fire</strong><strong>protection</strong> <strong>foam</strong> line. The expanded <strong>foam</strong> enteringthe tank through a discharge outlet is injected intothe flammable liquid. The discharge outlet mustbe a minimum of 1 ft. above any water that maybe present at the base of the tank. The <strong>foam</strong> willbe destroyed if injected into the water layer. Wheninjected into the fuel, the <strong>foam</strong> will rise through thefuel and f<strong>or</strong>m a vap<strong>or</strong> tight <strong>foam</strong> blanket on thefuel surface.Advantages of Sub-surface• The rising <strong>foam</strong> can cause the fuel in the tankto circulate which can assist in cooling the fuelat the surface.• If there is an explosion and <strong>fire</strong> that coulddamage the top of the tank, the sub-surfaceinjection system is not likely to suffer damage.• The discharging <strong>foam</strong> is m<strong>or</strong>e efficientlydirected to the fuel surface without anyinterruption from the thermal updraft of the<strong>fire</strong>.Disadvantages of Sub-surface• CANNOT be used in st<strong>or</strong>age <strong>tanks</strong> containingpolar solvent type fuels <strong>or</strong> products thatrequire the use of AR-AFFF type <strong>foam</strong>concentrates.• Not Recommended f<strong>or</strong> use in either FloatingRoof <strong>or</strong> Internal Floating Roof type <strong>tanks</strong>.• Caution must be used so that the maximum<strong>foam</strong> inlet velocity is not exceeded; otherwise,excessive fuel pickup by the <strong>foam</strong> as it entersthe tank will be experienced.• Not to be used f<strong>or</strong> <strong>protection</strong> of Class 1Ahydrocarbon liquids.HIGH BACK PRESSURE FOAM MAKERThe HBPFM device is mounted in the <strong>foam</strong> lineused to aspirate the <strong>foam</strong> solution bef<strong>or</strong>e it isdischarged into the st<strong>or</strong>age tank base. It willtypically give an expansion ratio of between 2 -1and 4 - 1. The device is capable of dischargingagainst considerable back pressure which can beas high as 40% of the operating pressure. Theback pressure is an accumulation of the headpressure of the fuel inside the st<strong>or</strong>age tank andany friction loss between the <strong>foam</strong> maker and thetank. A minimum of 100 psi inlet pressure into theHBPFM is n<strong>or</strong>mally required to ensure c<strong>or</strong>rectoperation. The <strong>foam</strong> velocity through the piping tothe tank from the HBPFM is very critical. Withflammable liquids, the <strong>foam</strong> velocity entering thetank should NOT exceed 10 ft. per second andwith combustible liquids the <strong>foam</strong> velocity shouldNOT exceed 20 ft. per second.The following chart shows the minimum dischargetimes and application rates f<strong>or</strong> Sub-surfaceapplication:Hydrocarbon Minimum MinimumType Fuel Discharge ApplicationTimeRateFlash point between 100 o F and 30 min. 0.10 gpm / ft.140 o F (37.8 o C and 93.3 o C) 4.1 L/min./mFlash point below 100 o F 55 min. 0.10 gpm / ft.(37.8 o C) liquids heated above 4.1 L/min./mtheir flash points.Crude Petroleum 55 min. 0.10 gpm / ft.4.1 L/min./mNOTE: The maximum application rate shall be0.20 gpm / ft. ( 8.1 L/min./m ).FOAM CHAMBERSTYPE II DISCHARGE DEVICEThe Foam Chamber is n<strong>or</strong>mally used on coneroof st<strong>or</strong>age <strong>tanks</strong>. The chamber is bolted <strong>or</strong>welded on the outside of the tank shell near theroof joint. A deflect<strong>or</strong> is mounted on the inside ofthe tank so that the discharging <strong>foam</strong> from the<strong>foam</strong> chamber will be diverted back against theinside of the tank wall.The <strong>foam</strong> chamber is mounted on the cone roofst<strong>or</strong>age tank wall shell in a vertical position justbelow the roof joint, <strong>or</strong> approximately 8" to 12"down from the roof joint to the center point of the<strong>foam</strong> chamber outlet.In sequence Chemguard Models FC 2.2, 3, 4 and6 <strong>foam</strong> chambers are to be mounted from approx.8" to approx. 12" down from the roof joint.

When the <strong>foam</strong> chamber is mounted c<strong>or</strong>rectly, theinternal glass seal of the chamber will be justslightly higher in elevation than the roof joint onthe st<strong>or</strong>age tank.Each <strong>foam</strong> chamber mounted on a cone roofst<strong>or</strong>age tank SHOULD have its own individuallyvalved riser supplying the <strong>foam</strong> solution fromoutside the dike area. F<strong>or</strong> c<strong>or</strong>rect operation, aminimum of 40 psi is required at the inlet to the<strong>foam</strong> chamber.FOAM MAKERSTYPE II DISCHARGE DEVICEThe <strong>foam</strong> maker is n<strong>or</strong>mally used to aspirate <strong>foam</strong>solution bef<strong>or</strong>e being discharged inside a dike(bund) area <strong>or</strong> when used with external floatingroof <strong>tanks</strong> to supply <strong>foam</strong> to the rim seal area.The discharge pipe down stream of the <strong>foam</strong>maker is sized to slow the velocity of theexpanded <strong>foam</strong> and shaped to deflect the <strong>foam</strong>back against the inside of the dike wall <strong>or</strong> onto asplash board <strong>or</strong> the tank shell wall when used f<strong>or</strong>floating roof seal <strong>protection</strong>.The splash board is to be mounted above the topof the floating roof tank. The c<strong>or</strong>rect sizedischarge pipe from the <strong>foam</strong> maker should beinstalled per the inf<strong>or</strong>mation supplied in the dike<strong>protection</strong> system design inf<strong>or</strong>mation.When mounted on a st<strong>or</strong>age tank <strong>or</strong> used in adike <strong>protection</strong> system, the <strong>foam</strong> maker can bemounted in either a h<strong>or</strong>izontal <strong>or</strong> vertical positionwithout any detrimental effect on <strong>foam</strong>perf<strong>or</strong>mance.It is recommended that a minimum 12" length ofstraight pipe be installed upstream from the <strong>foam</strong>maker during the installation.When using the Chemguard Model CGFM 1.5Foam Maker f<strong>or</strong> a dike <strong>fire</strong> <strong>protection</strong> system, a3" diameter pipe with minimum length of 28" and amaximum of 100" must be connected to the <strong>foam</strong>maker outlet ( down stream side ). This length ofdischarge pipe allows f<strong>or</strong> the c<strong>or</strong>rect <strong>foam</strong>expansion to take place and slows the dischargevelocity. The Model CGFM 2.5 Foam Makerrequires a length of 4" pipe to be connected to thedischarge side of the maker. This length of pipeshould also be a minimum of 28" but can have amaximum length of 120". The discharge pipe inboth instances should be directed back againstthe inside wall of the dike. This installation allowsa m<strong>or</strong>e gentle application to the flammable liquidwithin the dike and lessen the submergence of the<strong>foam</strong>.Criteria f<strong>or</strong> sizing a <strong>foam</strong> system f<strong>or</strong> a cone roofst<strong>or</strong>age tank.• Identify the fuel inside the tank.• Type of <strong>foam</strong> concentrate to be used.• Calculate the fuel surface area (TTR 2 ). *****• Application rate.• Type of discharge device required and quantity(based on fuel flash point and tank diameter).• Calculate discharge duration.• Supplementary hose lines required and dischargeduration.• Quantity of <strong>foam</strong> concentrate required.• Establish bill of materials.NOTE:To determine the quantity of <strong>foam</strong> concentrate ina given quantity of <strong>foam</strong> solution, use the followingf<strong>or</strong>mula:Multiply the <strong>foam</strong> solution byx .01 if using a 1% type of concentratex .03 if using a 3% type of concentratex .06 if using a 6% type of concentrateEXAMPLECone roof tank - 150 ft. diameterFuel - GasolineFoam Concentrate - 3% AFFFSurface area - 75' x 75' x 3.1417 = 17,672 sq. ft.App. Rate @ .10 gpm per sq. ft. ( Per NFPA 11).10 x 17,672 sq. ft. = 1,767.2 gpm of <strong>foam</strong>solution required

Discharge device - Foam Chamber, Qty. 4requiredDischarge Duration - 55 min. 1,767.2 x 55 =97,196 gallons of <strong>foam</strong> solution x .03 =2,915.88 gallons of 3% AFFF concentraterequired.Supplementary Hose Lines required ( Per NFPA11) - Qty. 3 required ( each minimum 50 gpm ) (Tank dia. over 120 ft. )Hose Line discharge duration ( Per NFPA 11) -30 min. ( Tank dia. over 95 ft. ) 3 x 50 = 150 x30 = 4,500 gallons of <strong>foam</strong> solution x .03 =135 gallons of 3% AFFF. 3,051 (135 + 2,916)gallons of <strong>foam</strong> concentrate required.A suitable bill of materials of maj<strong>or</strong> componentsf<strong>or</strong> the above system using a bladder tank couldbe.• 1 x 3,200 Gallon h<strong>or</strong>izontal style bladder tank.• 1 x 6" Between flange style ratio controller.• 4 x Model FC6 <strong>foam</strong> chambers each with aflow rate of 395 to 1,050 gpm depending onincoming pressure.• 1 x 2 1/2" Threaded type ratio controller (F<strong>or</strong>supplementary system).• 3 x 50 gpm handline nozzles.• <strong>foam</strong> concentrate.NOTE:This chart identifies the number of Foam Chambersrequired f<strong>or</strong> the <strong>protection</strong> of a flammableliquid contained in a vertical cone roof atmosphericst<strong>or</strong>age tank where the discharge device isattached to the tank. Where two <strong>or</strong> m<strong>or</strong>e outletsare required, the outlets are to be equally spacedaround the tank periphery and each outlet is to besized to deliver <strong>foam</strong> at approximately the samerate.Tank Diameter Meters Minimum Number(<strong>or</strong> equivalentof dischargearea)outletsUp to 80 ft. 24 1Over 80 to 120 24 to 36 2Over 120 to 140 36 to 42 3Over 140 to 160 42 to 48 4Over 160 to 180 48 to 54 5Over 180 to 200 54 to 60 6It is suggested that f<strong>or</strong> <strong>tanks</strong> above 200 ft. (60 m)in diameter at least one additional discharge outletbe added f<strong>or</strong> each additional 5,000 sq. ft. ( 465sq. m. ) of liquid surface <strong>or</strong> fractional part.This chart indicates the number of SUPPLE-MENTARY hose streams required f<strong>or</strong> various size<strong>tanks</strong>. Each hose stream must be capable of aminimum flow rate of 50 gpm of <strong>foam</strong> solution.Diameter of Largest Minimum Number ofTankHose Streams RequiredUp to 65 ft. ( 19.5 m ) 165 to 120 ft. ( 19.5 to 36 m ) 2Over 120 ft. ( 36 m ) 3This chart shows the Minimum discharge time andapplication rate f<strong>or</strong> Type II <strong>fixed</strong> <strong>foam</strong> dischargedevices on Cone Roof st<strong>or</strong>age <strong>tanks</strong>.Hydrocarbon Application DischargeType Rate TimeFlash point between 0.10 gpm/ft. 30 min.100 o F and 140 o F (4.1 L/min./m)(37.8 o C and 93.3 o C)Flash point below 100 o F 0.10 gpm/ft. 55 min.(37.8 o C) <strong>or</strong> liquids heated (4.1 L/min./m)above their flash pointsCrude Petroleum 0.10 gpm/ft. 55 min.(4.1 L/min./m)• Flammable liquids having a boiling point of lessthan 100 o F might require higher rates ofapplication. These should be determined bytest.• F<strong>or</strong> high-viscosity liquids heated above 200 o F,lower initial rates of application of <strong>foam</strong> may bedesirable to minimize frothing and thesubsequent expulsion of the st<strong>or</strong>ed liquid fromthe st<strong>or</strong>age tank. Good judgment should beused in applying <strong>foam</strong>s to <strong>tanks</strong> containing hotoils, burning asphalts <strong>or</strong> burning liquids thathave boiling points above the boiling point ofwater.• The above table includes Gasohols andunleaded gasolines containing no m<strong>or</strong>e than10% oxygenated additives by volume. Wherethese additives exceed 10% by volume <strong>or</strong>where the flammable liquid is a polar solvent <strong>or</strong>water miscible product, <strong>fire</strong> <strong>protection</strong> isn<strong>or</strong>mally supplied by the AR-AFFF type <strong>foam</strong>concentrates. In those instances check with

Chemguard to establish recommended applicationrates. The minimum discharge durationis 55 min.The following chart indicates the minimumoperating time of the supplementary hosestream(s) f<strong>or</strong> various size <strong>tanks</strong>.Diameter of LargestTankMinimum OperatingTimeUp to 35 ft. ( 10.5 m ) 10 min.35 to 95 ft. ( 10.5 to 28.5 m ) 20 min.Over 95 ft. ( 28.5 m ) 30 min.Equipment List using a Foam Pump Skid Assy.f<strong>or</strong> a 150 ft. dia. tank containing gasoline.1 x Atmospheric Foam Concentrate St<strong>or</strong>ageTank 3,100 Gallons1 x Electric powered Foam Pump Prop<strong>or</strong>tioningskid with prepiped 6" ratio controller ( FoamChambers ) and prepiped 2 1/2" ratiocontroller ( Supplementary Hose Lines )4 x Model FC4 <strong>or</strong> FC6 Foam Chambers3 x 50 gpm Hand Line nozzles3,051 x Gallons 3% AFFF ( plus any additionalf<strong>or</strong> testing of the system )NOTE:When protecting multiple st<strong>or</strong>age <strong>tanks</strong> the <strong>foam</strong>system is to be sized to protect the single largesthazard.Fig. 9 depicts a manual <strong>foam</strong> pump skid <strong>systems</strong>howing all necessary piping, valves, dischargedevices, ratio controller, <strong>foam</strong> pump and <strong>foam</strong>st<strong>or</strong>age tank f<strong>or</strong> the above system.Fig. 10 shows a Cone Roof St<strong>or</strong>age Tank with aSemi-Fixed Foam System.The following example shows the <strong>foam</strong> systemrequirements f<strong>or</strong> seal <strong>protection</strong> of a 150 ft.diameter open top floating roof tank.Type of Tank - Open Top Floating Roof TankDiameter of Tank - 150 ft.Type of Fuel - GasolineFoam Dam installed on roof - Yes - 2 ft. fromtank wall and 2 ft. in heightSq. ft. area of annular ring - 930 sq. ft.Application Rate - .30 gpm per sq. ft. ( PerNFPA 11).30 x 930 sq. ft. = 279gpm of <strong>foam</strong> solution required.Type of Discharge Device - Foam MakersDischarge Duration - 20 min.279 x 20 = 5,580 gallons of <strong>foam</strong> solution - x.03 ( 3% AFFF ) = 167.4 gallons of <strong>foam</strong>concentratedQuantity of Foam Makers Required ( Per NFPA11) 6 required.Add supplementary hose lines per example f<strong>or</strong>Cone Roof Tank with Foam Chambers.NOTE:The number of <strong>fixed</strong> <strong>foam</strong> discharge points on anopen top floating roof tank is determined by thecircumference of the tank.The maximum spacing between discharge pointsis 40 ft. ( 12.2 m ) of tank circumference whenusing a 12" ( 305 mm ) high <strong>foam</strong> dam and every80 ft. ( 24.4 m ) of tank circumference when usinga 24" ( 610 mm ) high <strong>foam</strong> dam.In acc<strong>or</strong>dance with NFPA 11Foam Dam Design - The <strong>foam</strong> dam should becircular and constructed of at least No. 10 USStandard Gage Thickness ( .134 in./3.4 mm )steel plate. The dam is to be welded <strong>or</strong> otherwisesecurely fastened to the floating roof. The <strong>foam</strong>dam is designed to retain <strong>foam</strong> at the seal area ata sufficient depth to cover the seal area whilecausing the <strong>foam</strong> to flow laterally to the point ofseal rupture.Dam height is to be at least 12" ( 305 mm ) andshould extend at least 2" ( 51 mm ) above anymetal secondary seal <strong>or</strong> a combustible secondaryseal using a plastic <strong>foam</strong> log.It is to be at least 2" ( 51 mm ) higher than anyburnout panels in metal secondary seals.

Foam dams are to be at least 1 ft. ( 0.3 m ) butno m<strong>or</strong>e than 2 ft. ( 0.6 m ) from the edge of thefloating roof.Foam solution & rain water is to be drained by,slotting the bottom of the dam on the basis of 0.04sq. in. of slot area per sq. ft. (278 mm sq./sq. m)of diked area while restricting the slots to 3/8 in.(9.5 mm) in height. Excessive dam openings f<strong>or</strong>drainage should be avoided to prevent loss of<strong>foam</strong> through the drainage slots.SUB-SURFACE SYSTEM( Sub-surface injection of <strong>foam</strong> is generally notrecommended f<strong>or</strong> fuels that have a viscositygreater than 2,000 ssu ( 440 centistokes ) at theirminimum anticipated st<strong>or</strong>age temperature ).Example of a Sub-Surface Base Injection SystemCone Roof Tank - 80 ft. diameterFuel - GasolineFoam Concentrate - 3%-6% AR-AFFFSurface Area - =40' x 40' x 3.1417 = 5,026.7 sq. ft.App. Rate - .10 gpm per sq. ft..10 x 5,027 sq. ft. = 502.7 gpm of <strong>foam</strong> solutionDischarge Duration - 55 min.Quantity of Foam Concentrate required -503 (502.7 ) x 55 x .03 = 829.95 gallonsDischarge Device - Qty. 1 High Back PressureFoam Maker ( " Foam generat<strong>or</strong> " )Number of Discharge outlets inside tankQty. 1 (Tank 80 ft. <strong>or</strong> less) (Per NFPA 11)Supplementary hose lines per example f<strong>or</strong> ConeRoof Tank.The following chart shows the number of dischargeoutlets required inside the tank.Tank DiameterNumber of Discharge Outlets RequiredFlash Point below Flash Point 100 o F100 o F (38 o C) (38 o C) <strong>or</strong> HigherUp to 80 ft. ( 24 m ) 1 1Over 80 to 120 ft. ( 24 - 36 m ) 2 1Over 120 to 140 ft. ( 36 - 42 m ) 3 2Over 140 to 160 ft. ( 42 - 48 m ) 4 2Over 160 to 180 ft. ( 48 - 54 m ) 5 2Over 180 to 200 ft. ( 54 - 60 m ) 6 3Over 200 ft. ( 60 m ) 6 3Plus 1 outlet f<strong>or</strong>Plus 1 outlet f<strong>or</strong>each additionaleach additional5,000 sq. ft. 7,500 sq. ft.(465 sq. m) (697 sq. m)Equipment list f<strong>or</strong> the above example using abladder tank <strong>foam</strong> supplied <strong>foam</strong> system.• 1 x 900 Gallon vertical style bladder tank.• 1 x 4" Between flange style ratio controller.• 1 x 2 1/2" Threaded type ratio controller ( f<strong>or</strong>supplementary hose lines ).• 1 x Model CFM500 High Back Pressure FoamMaker ( HBPFM ).• Supplementary hand line nozzles and <strong>foam</strong>concentrate.Determining Number of Discharge Outlets f<strong>or</strong>Subsurface Base Injection.The number of discharge outlets required is basedon the tank diameter and the flash point of thefuel as shown in the above chart.FOAM MONITORS AND HANDLINESMonit<strong>or</strong>s are not to be considered as the primarymeans of <strong>protection</strong> f<strong>or</strong> <strong>fixed</strong> roof <strong>tanks</strong> over 60 ft.in diameter. Foam handlines are not to beconsidered as the primary means of <strong>protection</strong> f<strong>or</strong><strong>tanks</strong> over 30 ft. in diameter <strong>or</strong> those over 20 ft. inheight.Application Rates Using Monit<strong>or</strong>s <strong>or</strong>HandlinesThe minimum <strong>foam</strong> solution application rate isbased on the assumption that all discharging <strong>foam</strong>will reach the area being protected. In consideringactual solution flow requirements, considerationshould be given to potential <strong>foam</strong> losses fromclimatic conditions and thermal updraft of the <strong>fire</strong>,etc.The following chart shows application density andduration f<strong>or</strong> monit<strong>or</strong>s and handlines on <strong>tanks</strong>containing hydrocarbons.Hydrocarbon Type Minimum MinimumApplication Rate Dischargegpm/ft 2 (L/min.)/m 2 Time(min.)Flash point between100 o F and 140 o F(37.8 o C and 93.3 o C) 0.16 6.5 50Flash point below 100 o F(37.8 o C) <strong>or</strong> liquids heatedabove their flash points 0.16 6.5 65Crude Petroleum 0.16 6.5 65

Included in the above table are gasohols andunleaded gasolines containing no m<strong>or</strong>e than 10percent of an oxygenated additive by volume.On <strong>tanks</strong> containing water miscible/polar solventflammable liquids the recommended <strong>foam</strong> applicationduration is 65 minutes.Flammable liquids having a boiling point less than100 o F and products that have been burning f<strong>or</strong>some time can develop a heat layer which mightrequire <strong>foam</strong> solution application rates as high as.2 <strong>or</strong> .25 gpm per sq. ft.Where monit<strong>or</strong>s <strong>or</strong> handlines are used to protectst<strong>or</strong>age <strong>tanks</strong> containing polar solvent <strong>or</strong> watermiscible liquids the discharge duration shall be aminimum of 65 minutes at the recommendedapplication rate.FSFPrv 995

STORAGE TANKPROTECTION WITH HIGHFLOW MONITORSTECHNIQUE IN EXTINGUISHING LARGETANK FIRESLarge st<strong>or</strong>age tank <strong>fire</strong>s are very complex eventsand satisfact<strong>or</strong>y extinguishment requiresmethodical planning and the effective use ofresources. At this time, existing Codes andStandards do not provide guidelines f<strong>or</strong> using highflow monit<strong>or</strong> <strong>foam</strong> applications f<strong>or</strong> large tank <strong>fire</strong>s.The existing Codes and Standards do providegood recommendations f<strong>or</strong> <strong>fixed</strong> <strong>fire</strong> <strong>protection</strong><strong>systems</strong>. Full surface <strong>fire</strong>s involving largediameter <strong>tanks</strong> have occurred around the w<strong>or</strong>ld.Extinguishment of such <strong>fire</strong>s has not been totallysuccessful. With the introduction of large capacity<strong>foam</strong> monit<strong>or</strong>s, new varieties of <strong>foam</strong>concentrates and improvements in applicationtechniques there has been some degree ofsuccess in achieving extinguishment.The largest fully involved tank <strong>fire</strong> that has beensuccessfully extinguished was 150 ft. (46 meter).The extinguishment was carried out with a largecapacity monit<strong>or</strong>/cannon applying non-aspirated<strong>foam</strong> "over-the-top" onto the burning surface. It isbelieved that present <strong>fire</strong> fighting technology iscapable of extinguishing fully involved tank <strong>fire</strong>sup to 197 ft. (60 meters) in diameter. In the<strong>or</strong>y itmay be technically feasible to extinguish tank <strong>fire</strong>sin excess of 200 ft. (61 meters) using the "overthe-top"method of employing very large capacitymobile monit<strong>or</strong>s with improved types of <strong>foam</strong>concentrates. The logistics f<strong>or</strong> mounting suchmassive operations must be fully considered.APPLICATION RATENFPA 11 application rate f<strong>or</strong> mobile equipment isoften interpreted as 0.16 gpm/ft 2 . (6.5 L/min./m 7 ).The code also states that flammable liquidshaving a boiling point of less than 100 o F (37.8 o C)may require higher rates of application. In additionflammable liquids with a wide range of boilingpoints such as Crude Oil may require applicationrates of 0.2 gpm/ft 2 . (8.1 L/min./m 2 ) <strong>or</strong> m<strong>or</strong>e. Theapplication rate stated in the code is based on theassumption that all the <strong>foam</strong> solution reaches theburning surface.Note: The rates are intended f<strong>or</strong> Liquid HydrocarbonFuels. Polar solvent liquids are destructiveto regular <strong>foam</strong>s and require the use ofalcohol resistance <strong>foam</strong>s. Chemguard, Inc.should be consulted to determine the recommendedapplication rate.In view of the above, rates and practicalexperience gained in incidents involving fullsurface <strong>fire</strong>s involving large st<strong>or</strong>age <strong>tanks</strong>, itwould be m<strong>or</strong>e appropriate to consider 0.25gpm/ft 2 . (10.4 L/min./m 2 ) which is equal to a 60%increase f<strong>or</strong> mobile <strong>systems</strong>. F<strong>or</strong> burning crudeoil tank a rate of 0.32 gpm/ft 2 . (12.9 L/min./m 2 )may be m<strong>or</strong>e appropriate.The elevated application rates provide a betterchance of ensuring <strong>foam</strong> reaching the burningsurface thus increasing the probability f<strong>or</strong> extinguishment.Consideration f<strong>or</strong> such high ratestake into account fall out from the delivery system,losses due to strong thermal updraft, break downof <strong>foam</strong> as it travels through the flames to reachthe burning fuel and destruction of the <strong>foam</strong> dueto the hot fuel and any hot metal surface.WATER AND FOAM CONCENTRATE RE-QUIRED FOR FIGHTING LARGE TANK FIRESWater supply both in terms of pressure, flow rateand adequate amount of <strong>foam</strong> concentrate areamong the most imp<strong>or</strong>tant fact<strong>or</strong>s f<strong>or</strong> launching asuccessful extinguishing operation. Unless adequateand uninterrupted supply is guaranteed, anattempt to extinguish a fully involved large tank<strong>fire</strong> is doomed to failure at the very onset of theoperation.

The amount of water and the flow rate needed toproduce 3% <strong>foam</strong> solution to generate <strong>foam</strong> tofight a large tank <strong>fire</strong> can be found in Table 1.The quantity of 3% <strong>foam</strong> concentrate and the flowrate needed to produce 3% <strong>foam</strong> solution togenerate <strong>foam</strong> to fight a large tank <strong>fire</strong> can befound in Table 2.COOLING INVOLVED TANK AND THE PRO-TECTION OF ADJACENT TANKS FROM RADI-ATED HEAT SOURCEtank <strong>fire</strong> could be expected to fully involve aneighb<strong>or</strong>ing identical tank in approximately 1.5hours under the following conditions.- 4 m/sec.(14 km/hr.) wind towards neighb<strong>or</strong>ingtank- intertank separation of 0.5 diameter(82 ft.) (25 m)- neighb<strong>or</strong>ing tank having pontoon roof andinadequate water spray <strong>protection</strong>Altering any of the above conditions can changethe time f<strong>or</strong> ignition of the adjacent tank:With reference to existing guidelines, the amountof water needed to cool the involved tank shell isestimated by tank size:Base CaseChange of conditions:= 1.5 hrs.100 ft. (30 meter) diameter 750 gpm (3m 3 /min.)120 ft. (36 meter) diameter 1000 gpm (4m 3 /min.)160 ft. (48 meter) diameter 1250 gpm (5m 3 /min.)220 ft. (67 meter) diameter 1500 gpm (6m 3 /min.)Cooling water required to protect each adjacenttank not shielded from the tank on <strong>fire</strong> is 500 gpm(2 m 3 /min.).In practice water applied to the shell of a largetank on <strong>fire</strong> is ineffective in preventing it frombuckling and def<strong>or</strong>ming. In the late stages ofextinguishment, cooling water applied on the areaabove the liquid level would help the <strong>foam</strong> stay incontact with the tank shell. The cooling streamsshould be stopped when <strong>foam</strong> attack has startedto conserve water and to concentrate on extinguishment.The need f<strong>or</strong> protecting adjacent <strong>tanks</strong> can bestbe illustrated with inf<strong>or</strong>mation and data publishedin a recent study done on large tank <strong>fire</strong>s.Although not yet fully validated it neverthelessprovides valuable inf<strong>or</strong>mation f<strong>or</strong> pre-<strong>fire</strong>planningpurposes.The time required to create an escalation conditionin an adjacent tank depends upon a numberof fact<strong>or</strong>s including: tank size, separation, type,initial boiling point of flammable liquid in the <strong>tanks</strong>,water cooling, tank design, wind speed anddirection.F<strong>or</strong> example, a full surface <strong>fire</strong> involving a 164 ft.(50m) diameter open top, floating roof naphthaCalm (no wind condition)= 2.8 hrs.Intertank separation increased to 1.0 D (50 m)= 3.0 hrs.Intertank separation increased to 2.0 D (100 m)= 17.0 hrs.Water <strong>protection</strong> on side facing exposure= 2.8 hrs.Double deck roof on exposed tank= 1.5 hrs.Water <strong>protection</strong> on side facing exposure +double deck roof= 24.0+hrs.Tank diameters only 30 m but with 0.5 Dseparation = 0.5 hrsNeighb<strong>or</strong>ing tank contains kerosene, not naphtha= 22.0 hrs.Some conclusions drawn from the results are:−−−−−escalation is likely f<strong>or</strong> unprotected <strong>tanks</strong> ofvolatile material with n<strong>or</strong>mal separation unlessthe <strong>or</strong>iginal <strong>fire</strong> is extinguished quicklycalm conditions only delay the escalationpotentialincreased separation alone only delays theescalation potentialwater spray <strong>protection</strong> <strong>or</strong> roof insulation alonedoes prevent escalationwater spray and roof insulation together areeffective− smaller diameter <strong>tanks</strong> at n<strong>or</strong>mal separationare at greater risk of escalation than largerdiameter tank− lower volatility fuels provide m<strong>or</strong>e responsetime f<strong>or</strong> <strong>fire</strong> fighter

Cooling of adjacent <strong>tanks</strong> is best achieved with<strong>fixed</strong> <strong>systems</strong> that are designed to provide effectivewater film coverage of all exposed metalsurfaces. A cooling water rate of 0.05 gpm/ft 2 .(2.0 L/min./m 2 ) is sufficient to abs<strong>or</strong>b 90% ofincoming radiant heat. Any increase in thecooling water rate does not increase the coolingeffect significantly. The figure of 10.2 L/min./m 2by NFPA 15 relates mainly to the <strong>protection</strong> ofpressurized vessels such as LPG <strong>tanks</strong> subject todirect flame impingement.OVER THE-TOP-APPLICATION TECHNIQUEWITH LARGE CAPACITY FOAM MONITORSA present concept in extinguishing large tank <strong>fire</strong>sis to employ Large Capacity Non-aspirated FoamMonit<strong>or</strong>s to apply <strong>foam</strong> "over-the-top" of theinvolved tank onto the burning fuel surface.Although they are n<strong>or</strong>mally known as nonaspiratedmonit<strong>or</strong>s, these monit<strong>or</strong>s are capable ofproducing <strong>foam</strong> with an expansion ratio of about3.1 to 4.5 when used with alcohol resistance type<strong>foam</strong> concentrates.Chemguard has large capacity <strong>foam</strong> monit<strong>or</strong>scurrently available have capacities ranging from2,000 to 4,000 gpm (7,570 L/min.). The equipmentoperates at inlet pressure between 100 to130 psig (690 to 890 kPa) and have a range ofabout 250 to 300 feet (61-99 meter).AR-AFFF type <strong>foam</strong> concentrate is preferred andit should be transp<strong>or</strong>ted in bulk totes <strong>or</strong> trailershaving large capacities. The logistics f<strong>or</strong> transp<strong>or</strong>ting<strong>foam</strong> in 5 gallon pails <strong>or</strong> 55 gallon drumsto the <strong>fire</strong> scene should not be considered, f<strong>or</strong>obvious reasons.Large diameter hose should be used to supply theflow required f<strong>or</strong> large volume <strong>foam</strong> attack. Theuse of 5" (125 mm) diameter hose is preferreddue to low frictional loss and is relatively easy touse. It must be remembered that it is extremelydifficult to move the hose once it is charged withwater. F<strong>or</strong> quick estimation, provide one 5" (125mm.) hose line f<strong>or</strong> every 1,000 gpm (3.8 m 3 /min.)flow requirement. At this flow rate the friction lossis 8.0 psig (55 kPa) f<strong>or</strong> every 100 feet (30.5 m).Table 3 provides inf<strong>or</strong>mation on friction loss ofsome large diameter hoses.The “over-the-top” <strong>foam</strong> technique attacks theburning tank with either a very large capacitymonit<strong>or</strong> that meets the required application rate <strong>or</strong>combines several monit<strong>or</strong>s to f<strong>or</strong>m a MassStream discharging with the wind to concentrateon a selected landing zone within the tank.This extremely high “local application rate/density”promotes survivability of the <strong>foam</strong> journey throughthe <strong>fire</strong> to establish a foothold on a relatively smallarea of the burning surface. Once the <strong>foam</strong>blanket at the landing zone is established it canthen be expanded by making adjustments to theMass Stream. The added advantage of largevolume application in a small area may help t<strong>or</strong>educe “local fuel temperature” and the associatedactual vap<strong>or</strong> presssure which in turn can help inlowering the <strong>fire</strong> severity. These fact<strong>or</strong>s requireconsideration because as the fuel temperatureapproaches the boiling point of water, it is difficultf<strong>or</strong> the <strong>foam</strong> to survive. As fuel temperatureincreases the true vap<strong>or</strong> temperature will increaseto overcome the effectiveness of the <strong>foam</strong>blanket.Large volume <strong>foam</strong> attack should be launched asquickly as possible; however, it must be stressedthat application must not be carried out until allequipment and logistic supp<strong>or</strong>t are in place. Thelonger a tank is allowed to burn, the danger ofescalation becomes greater, the fuel temperatureincreases making it m<strong>or</strong>e difficult to extinguish,the exposed tank shell def<strong>or</strong>ms (n<strong>or</strong>mally theexposed steel curls inwards to create nooks andcrevices) making it difficult f<strong>or</strong> <strong>foam</strong> to cover allthe burning surface. In the case of crude oil, thepossiblility of having a “boilover” increases withtime.The ability to deal with large tank <strong>fire</strong>s depends onmethodical pre-<strong>fire</strong> plan, regular training andexervises. The most imp<strong>or</strong>tant fact<strong>or</strong>, however,rests on minimizing the risk of having a fullyinvolved large tank <strong>fire</strong> through good engineeringdesign, effective management and maintenanceprograms.STPrv995

OVER-THE-TOP FOAM APPLICATION TECHNIQUEWITH LARGE CAPACITY FOAM MONITORSWindFoamMonit<strong>or</strong>FuelD021rv895

TABLE 1WATER FLOW RATE TO PRODUCE 3% FOAM SOLUTIONTO FIGHT FIRES IN TANKSMINIMUM QUANTITIESTANK DIAMETER WATER FLOW RATE TOTAL WATER REQUIRED TO SUSTAIN65 MINUTES OF OPERATIONFeet Meter Application Rate Application Rate Application Rate Application Rate0.16 gpm./ft 2 . 6.5 L/min./m 2 0.25 gpm./ft 2 . 10.4 L/min./m 2 0.16 gpm./ft 2 .6.5 L/min./m 2 0.25 gpm./ft 2 . 10.4 L/min./m 2Gallon Meter 3 Gallon Meter 3100 30.5 1218 4598 1904 7357 79170 299 123760 478110 33.5 1474 5563 2304 8902 95796 362 149750 579120 36.6 1754 6621 2742 10594 114005 430 178214 689130 39.6 2058 7770 3218 12433 133797 505 209154 808140 42.7 2387 9012 3732 14420 155173 586 242570 937150 45.7 2741 10345 4284 16553 176133 672 278460 1076160 48.8 3118 11770 4874 18834 202675 765 316826 1224170 51.8 3520 13288 5503 21262 226801 864 357666 1382180 54.9 3946 14897 6169 23837 256511 968 400982 1549190 57.9 4397 16598 6873 26558 285804 1079 446774 1726200 61.0 4872 18391 7616 29425 316680 1195 495040 1913210 64.0 5371 20276 8397 32444 349140 1318 545782 2109220 67.1 5895 22253 9216 35606 383183 1446 598998 2315230 70.1 6443 24322 10072 38916 418809 1581 654690 2530240 73.2 7016 26483 10967 42376 456019 1721 712858 2754250 76.2 7613 28736 11900 45981 494813 1868 773500 2989260 79.2 8234 31081 12871 49733 535189 2020 836618 3233270 82.3 8879 33518 13880 53632 577149 2179 902210 3486280 85.3 9549 36047 14927 57679 620693 2343 970278 3749290 88.4 10243 38667 16013 61872 665820 2513 1040822 4022300 91.4 10962 41380 17136 66213 712530 2690 1113840 4304CHARrv895

TABLE 2FOAM CONCENTRATE (3%) TO PRODUCE 3% FOAM SOLUTIONTO FIGHT FIRES IN TANKSMINIMUM QUANTITIESTANK DIAMETER 3% FOAM CONCENTRATE FLOW RATE TOTAL 3% FOAM CONCENTRATE REQUIREDTO SUSTAIN 65 MINUTES OF OPERATIONFeet Meter Application Rate Application Rate Application Rate Application Rate0.16 gpm./ft 2 . 6.5 L/min./m 2 0.25 gpm./ft 2 . 10.4 L/min./m 2 0.16 gpm./ft 2 .6.5 L/min./m 2 0.25 gpm./ft 2 . 10.4 L/min./m 2Gallon Meter 3 Gallon Meter 3100 30.5 38 142 59 228 2470 9.25 3835 14.79110 33.5 46 172 71 275 2989 11.19 4640 17.89120 36.6 55 205 85 328 3557 13.31 5522 21.30130 39.6 64 240 100 385 4174 15.62 6481 24.99140 42.7 74 279 116 446 4841 18.12 7617 28.99150 45.7 86 320 133 512 5558 20.80 8629 33.27160 48.8 97 364 151 582 6323 23.67 9818 37.86170 51.8 110 411 171 658 7138 26.72 11063 42.74180 54.9 123 461 191 737 8003 29.95 12425 47.92190 57.9 137 513 213 821 8917 33.38 13844 53.39200 61.0 152 569 236 910 9880 36.98 15340 59.16210 64.0 168 627 260 1003 10893 40.77 16912 65.22220 67.1 184 688 286 1101 11955 44.75 18561 71.58230 70.1 201 752 312 1204 13066 48.91 20287 78.23240 73.2 219 819 340 1311 14227 53.25 22090 85.18250 76.2 238 889 369 1422 15438 57.78 23969 92.43260 79.2 257 962 399 1538 15697 62.50 25925 99.97270 82.3 277 1037 430 1659 18006 67.40 27957 107.81280 85.3 298 1115 463 1784 19365 72.48 30068 115.94290 88.4 320 1196 496 1913 20773 77.75 32252 124.37300 91.4 342 1280 531 2048 22230 83.21 34515 133.10CHARrv895

TABLE 3FRICTION LOSS PER 100 FEET / 30.5 METERSFRICTION LOSS IN WATER SUPPLY LINE EXPRESSED AS PSIG & kPa LOSS PER 100 FEET / 30.5 METERS OF HOSEFLOW 4 INCH SUPPLY LINE 4-1/2 INCH SUPPLY LINE 5 INCH SUPPLY LINE 6 INCH SUPPLY LINEUSGPM LITER/MIN. PSIG kPa PSIG kPa PSIG kPa PSIG kPa100 369 0.20 1 0.10 1 0.06 1 0.05 0.3200 737 0.80 6 0.40 3 0.32 2 0.20 1300 1106 1.80 12 0.90 6 0.72 3 0.45 3400 1474 3.20 22 1.00 10 1.28 9 0.80 6500 1843 5.00 34 2.50 17 2.00 14 1.25 9600 2211 7.20 50 3.60 25 2.88 20 1.80 12700 2580 9.80 68 4.90 34 3.92 27 2.45 17800 2948 12.80 88 6.40 44 5.12 35 3.20 22900 3317 16.20 112 8.10 56 6.48 45 4.05 281000 3685 20.00 138 10.00 69 8.00 55 5.00 341100 4054 24.20 167 12.10 83 9.68 67 6.05 421200 4422 28.80 199 14.40 99 11.52 79 7.20 501300 4791 33.80 233 16.90 117 13.52 90 8.45 581400 5160 39.20 270 19.60 135 15.68 108 9.80 681500 5628 45.00 310 22.50 155 18.00 124 11.25 781600 5897 51.20 353 25.60 177 20.48 141 12.80 881700 6265 57.80 399 28.90 199 23.12 156 14.45 1001800 6634 64.80 447 32.40 223 25.92 179 16.20 1121900 7002 72.20 496 36.10 249 28.88 199 18.05 1242000 7371 80.00 552 40.00 276 32.00 221 20.00 1382100 7739 88.20 608 44.10 304 35.28 243 22.05 1522200 8106 96.80 667 48.40 334 38.72 267 24.20 1672300 8476 105.80 729 52.90 366 42.32 292 26.45 1822400 8845 115.20 794 57.60 397 46.08 308 28.80 1992500 9214 125.00 862 62.50 431 50.00 345 31.25 215CHARrv195

FIG. 9EXAMPLE OF BALANCE PRESSURE PUMPSKID WITH TWO PROPORTIONERSPressure Vacuum VentAtmospheric TankFlush OutletConnectionPressure ReliefValveFlush InletConnectionStrainerBalancingValveFoamConcentratePumpSystem 1: Foam solutionto manifold supplying 4 <strong>foam</strong>chambers on cone roof tank.WaterInletSystem 2: Foam solution toseparate st<strong>or</strong>age tank system<strong>or</strong> hose reels, if required.RatioControllerD004rv895

FIG. 10SEMI-FIXED FOAM SYSTEM WITH MOBILEAPPARATUS SUPPLYING THE FOAM SOLUTIONFoamChamberAeratedFoamFoam ChamberTopside Applicationon Cone Roof TankOS & Y ValveFUELDike WallFoam Solutionfrom MobileApparatusD085rv995

Water LevelFUELSUB-SURFACE INJECTION APPLICATIONON CONE ROOF TANKFoamBlanketRuptureDiscAeratedFoam(optional)CheckGate ValveValveTest PointDike WallHigh Back PressureFoam MakerFoamSolutionD003rv995

TYPICAL OUTLETS FOR SUB-SURFACE INJECTIONINSIDE CONE ROOF STORAGE TANKSConnections f<strong>or</strong> Sub-surface Foam MakersGate ValveCheck Valve2OutletsRupture Disc(optional)ValvedTest ConnectionDike Wall3Outlets4OutletsD023rv195

TYPICAL SUB-SURFACE TANK PROTECTION INLET DESIGNA. Straight-In C. H<strong>or</strong>izontal ELLRecommendedRecommendedTank ShellE. H<strong>or</strong>izontal TeeRecommendedTeeValveWaterBottomPlano90 ELLElev.Plan Elev.B. Vertical ELLNot RecommendedoD. 180 ELLNot Recommendedo180 ELLA. Best f<strong>or</strong> Cone Roof TanksB. Possible to Block with Sedimento90 ELLC. Good f<strong>or</strong> Floating Roof Tanks(FRT)D. Not Good f<strong>or</strong> FRT, Gives Stream BacklashE. Best f<strong>or</strong> Floating Roof TankD019rv195

EXPANDED FOAM VELOCITY vs PIPE SIZE2 1/2", 3", 4", 6", 8", 10", 12", 14"Standard Schedule 40 PipeAll dimensions in inches (millimeters)unless otherwise notedEXPANDED FOAM RATEM/SECFT/SEC9.1 30FOAM VELOCITY vs PIPE SIZE - 16", 18"Standard Schedule 40 Pipe16"(400)18"(460)FOAM VELOCITY6.1 203 100All dimensions in inches (millimeters)unless otherwise noted.GPMLPM200075704000151396000227108000302781000037848120004542014000529901600060560EXPANDED FOAM RATED038rv195

FRICTION LOSS OF EXPANDED FOAMTHROUGH VARIOUS SIZE PIPESThese subsurface graphs depict the friction loss characteristics of <strong>foam</strong> with an expansion of 4 to 1 and inletvelocities f<strong>or</strong> various pipe sizes. The 4 to 1 ratio is the value to be used f<strong>or</strong> friction loss and inlet velocitycalculations.605021/2"PIPE DIAMETER40303" PIPE DIAMETER2010FOR SI UNITS1 gpm = 3.785 l / min.1psi=6.895kPa1ft.=0.305 m0 200 400 600 800 1000 1200 1400 1600 1800FOAM FLOW - gpm50404" PIPE DIAMETER302010FOR SI UNITS1gpm=3.785/min.1psi=6.895kPa1ft.=0.305m0 400 800 1200 1600 2000 2400 2800 3200FOAM FLOW - gpmD075rv195

50FOR SI UNITS1gpm=3.785 l / min.1psi=6.895 kPa1 ft. = 0.305 m406" PIPE DIAMETER30208" PIPE DIAMETER1010" PIPE DIAMETER01600 2400 3200 4000 4800 5600 6400 7200 8000 8800FOAM FLOW - gpm25FOR SI UNITS1 gpm = 3.785 l / min.1psi=6.895kPa1ft.=0.305m201510514" PIPE DIAMETER0 4000 8000 12000 16000 20000 24000 28000 32000FOAM FLOW - gpmD076rv195

FOAM CHAMBER INSTALLATIONFIXED SYSTEM USING A BLADDER TANKFoamChamberSolution FlowProp<strong>or</strong>tionerBall ValveN<strong>or</strong>mally ClosedBall ValveN<strong>or</strong>mally OpenSwing CheckHydraulic ActuatedBall ValveBladder TankWaterSupplyD010rv1296

InternalFloatingRoofFOAM CHAMBER TOPSIDE APPLICATIONON INTERNAL FLOATING ROOF TANKVentFoamChamberAeratedFoamFUELDike WallFoam SolutionD003rv195

INSTALLATION OF FOAM MAKER & SPLASH BOARDON FLOATING ROOF TANKSSheet steel splash board can be rectangular <strong>or</strong> cut as shownmounted on top of shell reinf<strong>or</strong>ced with suitable supp<strong>or</strong>ts.Minimum dimensions will depend on minimum clearance neededbetween <strong>foam</strong> discharge outlet and top position of roof."A" Dimension is the height of the <strong>foam</strong> maker outletabove the top edge of the tank shell. The minimumheight must clear the top position of the floating roof."L" Shield Length3/8 of "L"12"Foam Maker"A"1/2 of "A"Wind GirderFoam solution piping to other <strong>foam</strong> makers maybe located above <strong>or</strong> below wind girder <strong>or</strong>at grade level.Swing JointFoam SolutionSupply Piping2' 0"Splash BoardDeflect<strong>or</strong>Foam Dam12"RoofUrethane SealTank ShellD040rv195

EXAMPLES OF TYPICAL TOP AND BELOW SEALAPPLICATIONS FOR FLOATING ROOF TANKSFoamMakerAerated FoamFoam DamBraceFoam SolutionFoam MakerWeather ShieldAspiratedFoamSealFoamSolutionPontoonRoofTypical Top of Seal ApplicationTypical Below Seal ApplicationD005rv195

SEAL AREA PROTECTION USING A FOAM MAKEROR HANDLINE NOZZLE FROM LADDER AREAQuick Opening ValveFoam MakerSiameseSiameseFoamFoamOutletHydranf<strong>or</strong>Handline ConnectionBack Board MountedHigher than UppermostPosition of RoofStairwayPlatf<strong>or</strong>mStairwayLadderWind GirderFoam DamBraceFoam Solution PipingFloating RoofTank ShellProductD022rv195

DikeMonit<strong>or</strong>(Typical)WaterSupplyTANK AND DIKE PROTECTION WITH FOAM MONITOR SYSTEMTank TankTankFoamConcentrateOS & Y ValveMonit<strong>or</strong>RatioControllerOS & YValveD033rv195

STORAGE TANK PROTECTIONTopside ApplicationsExisting <strong>or</strong> NewFoam ChamberFoam MakerFoam Delivery PipeFoam SolutionDelivery PipingDikeDikeFixed Foam Chamber Foam MakerA-BFoamChamberP<strong>or</strong>table FoamTube <strong>or</strong> TowerMechanical FoamGenerat<strong>or</strong> ConversionFoam SolutionDelivery PipingDike DikeA-BPowderConversionP<strong>or</strong>table Foam TowerF<strong>or</strong>cing Foam MakerSolution Foam SolutionDelivery Delivery Piping PipingFoam SolutionDelivery HosesD016rv195

TYPICAL ARRANGEMENT FOR SUB-SURFACE SYSTEMSINTO A CONE ROOF STORAGE TANKTank ShellRupture Disc(optional)SwingCheckValveGateValveFrom High BackPressure Foam MakerAt Least 1 ft.(0.3m)Water BottomFoamFlowValved Test ConnectionD012rv195

N<strong>or</strong>malWaterBottomSTORAGE TANK PROTECTIONSub-surface Applications(Hydrocarbon Fuels Only)FoamDeliveryPipingHigh Back PressureFoam MakerProductLineDike DikeSolutionDeliveryPipingDedicated Foam SolutionLine ApplicationProduction Line ApplicationAlthough dedicated lines may be used to apply <strong>foam</strong> using the subsurface method,additional economies may be realized by using existing product lines f<strong>or</strong> <strong>foam</strong>injection.In some installations a total tank farm may be covered by using a single subsurfaceinjection station at the product line manifold.The piping pressure losses and the inlet injection velocity must be verified by calculation.This is to be done with each product line which is a candidate f<strong>or</strong> subsurface injection.SolutionPipingHigh Back PressureFoam MakerD017rv195

STORAGE TANK PROTECTION SUMMARYFixed-Roof (Cone) TanksPontoon <strong>or</strong> Double-Deck Floating Roof TanksNumberRequiredHydrocarbonApplicationRatesNot applicable.Not Applicable.Mechanical Shoe Seal.1-F<strong>or</strong>each130ft.(39.6m)of tank circumference(no <strong>foam</strong> dam required)Tube Seal - Over 6 in. (15.2 cm) fromtopofsealtotopofpontoon with <strong>foam</strong> outlets under metal weather shield <strong>or</strong>secondary seal.1-F<strong>or</strong>each60ft.(18.3m)oftankcircumference(no <strong>foam</strong> dam required)Tube Seal - Less than 6in.(15.2cm)fromtopofsealtotop of pontoon with <strong>foam</strong> outlets under metal weathershield <strong>or</strong> secondary seal.1-F<strong>or</strong>each60ft.(18.3m)oftankcircumference[<strong>foam</strong> dam at least 12 in. (30.5 cm) high required].0.30 gpm. (1.14 L/min.) per sq. ft. (sq. m) of annular ringarea with <strong>foam</strong> dam <strong>or</strong> with <strong>foam</strong> application under metalweather seal <strong>or</strong> secondary seal. 0.50 gpm (1.9 L/min.) persq. ft.. (sq. m f<strong>or</strong> all other applications).DischargeTimesNot Applicable.20 min. - with <strong>foam</strong> dam <strong>or</strong> under metal weather shield <strong>or</strong>secondary seal.PolarSolventsNot Applicable.Not covered by NFPA 11.Size ofTankHydrocarbonApplicationRatesMonit<strong>or</strong>s f<strong>or</strong> <strong>tanks</strong> up to 60 ft. (18.3 m) indiameter.Hand hoselines f<strong>or</strong> <strong>tanks</strong> less than 30 ft.(9.2 m) in diameter and less than 20 ft.(6.1 m) high.20.16 gpm/ft.2[(6.5 L/min.)/(m )]Monit<strong>or</strong>s not recommended.Handlines are suitable f<strong>or</strong> extinguishment of rim <strong>fire</strong>sin open-top floating roof <strong>tanks</strong>.20.16 gpm/ft.2(6.5 L/min./m )F<strong>or</strong> rim <strong>fire</strong>s in open-top floatingroof <strong>tanks</strong>.DischargeTimesFlash point below 100 F (37.8 C)ooFlash point 100 F - 140 FCrude Oiloo65 min.50 min.65min.Use same times as f<strong>or</strong> open-top floating roof tank rim<strong>fire</strong>s.NumberRequiredSame as table f<strong>or</strong> <strong>foam</strong> chambers.Not Recommended.HydrocarbonApplicationRates2 2Minimum 0.1 gpm/ft. [(4.1 L/min.)/m. ] ofliquid surface.2 2Maximum 0.2 gpm/ft. [(8.2 L/min.)/m. ]Foam velocity from outlet shall not exceed10 ft. per sec. (3.05 m per sec.) f<strong>or</strong> Class 1Bliquids <strong>or</strong> 20 ft. per sec. (6.1 m per sec.) f<strong>or</strong>all other liquids.Not Recommended.DischargeTimesoFlash point 100 F (37.8 C)ooto 140 F (194.4 C)ooFlash point below 100 F (37.8 C)Crude Petroleumo30 min.55 min.55 min.Not Recommended.PolarSolventsNot Recommended.Not Recommended.2 2 2 2F<strong>or</strong> S1units: 1 gpm/ft. = 40.746 (L/min.)/m ; 1 ft. = 0.305 m; 1 ft. = 0.0929 m ; 1 in. = 0.0245 m;o oC = F - 32/1.8.D056rv0200

STORAGE TANK PROTECTION SUMMARYFixed-Roof (Cone) Tanks andPan-Type Floating Roof TanksPontoon <strong>or</strong> Double-Deck FloatingRoof Tanks, (Open-Top <strong>or</strong>Covered) Annular Seal AreaNumberof FoamOutletsRequiredUp to 80 ft. (2.44 m) dia.81 to 120 ft. (24.7 - 36.6 m) dia.121 to 140 ft. (36.9 - 42.7 m) dia.141 to 160 ft. (43 - 48.8 m) dia.161 to 180 ft. (49 - 54.9 m) dia.181 to 200 ft. (55.2 - 61 m) dia.Over 210 ft. (61.2 m)1Foam Chamber2Foam Chambers3Foam Chambers4Foam Chambers5Foam Chambers6FoamChambers1additional f<strong>or</strong> each5,000 sq. ft.1f<strong>or</strong>each 40 ft. (12.2 m) of circumferencewith a 12-inch (30.5 cm) high <strong>foam</strong> dam.1f<strong>or</strong>each 80 ft. (24.4 m) of circumferencewith a 24-inch (61 cm) high <strong>foam</strong> dam.HydrocarbonApplicationRates0.10 gpm (0.38 L/min.) per sq. ft. (sq. m) of liquid surface. 0.30 gpm (1.14 L/min.) per sq. ft. (sq. m)of annular ring area between tank walland <strong>foam</strong> dam.PolarSolventRatesSee Manufacturer's Approval Rep<strong>or</strong>t.Not covered by NFPA 11.HydrocarbonDischargeTimeso o o oFlash Pt. 100 F - 140 F (37.8 C - 194.4 C)ooFlash Pt. below 100 F (37.8 C)Crude PetroleumType I20 min.30 min.30 min.Type II30 min.55 min.55 min.20 min.PolarSolventsType IType II30 min.55 min.Not covered by NFPA 11.D057rv195