Series 753-A FireLock® Dry Actuator/Anti-Flood Device - Victaulic

Series 753-A FireLock® Dry Actuator/Anti-Flood Device - Victaulic

Series 753-A FireLock® Dry Actuator/Anti-Flood Device - Victaulic

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

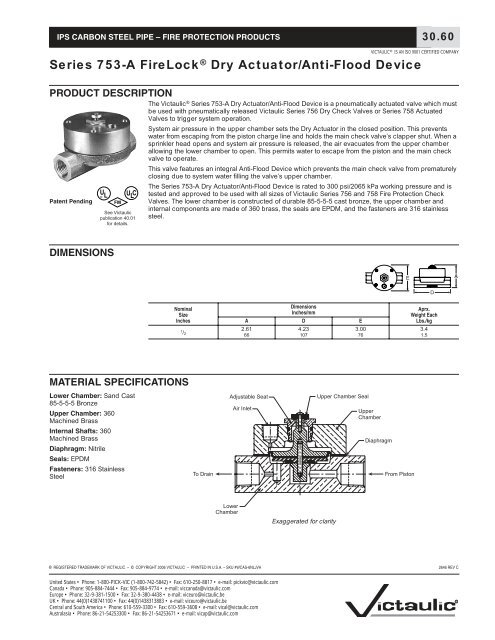

IPS CARBON STEEL PIPE – FIRE PROTECTION PRODUCTS30.60VICTAULIC ® IS AN ISO 9001 CERTIFIED COMPANY<strong>Series</strong> <strong>753</strong>-A FireLock ® <strong>Dry</strong> <strong>Actuator</strong>/<strong>Anti</strong>-<strong>Flood</strong> <strong>Device</strong>PRODUCT DESCRIPTIONThe <strong>Victaulic</strong> ® <strong>Series</strong> <strong>753</strong>-A <strong>Dry</strong> <strong>Actuator</strong>/<strong>Anti</strong>-<strong>Flood</strong> <strong>Device</strong> is a pneumatically actuated valve which mustbe used with pneumatically released <strong>Victaulic</strong> <strong>Series</strong> 756 <strong>Dry</strong> Check Valves or <strong>Series</strong> 758 ActuatedValves to trigger system operation.Patent PendingU L ®FMU L CSee <strong>Victaulic</strong>publication 40.01for details.System air pressure in the upper chamber sets the <strong>Dry</strong> <strong>Actuator</strong> in the closed position. This preventswater from escaping from the piston charge line and holds the main check valve’s clapper shut. When asprinkler head opens and system air pressure is released, the air evacuates from the upper chamberallowing the lower chamber to open. This permits water to escape from the piston and the main checkvalve to operate.This valve features an integral <strong>Anti</strong>-<strong>Flood</strong> <strong>Device</strong> which prevents the main check valve from prematurelyclosing due to system water filling the valve’s upper chamber.The <strong>Series</strong> <strong>753</strong>-A <strong>Dry</strong> <strong>Actuator</strong>/<strong>Anti</strong>-<strong>Flood</strong> <strong>Device</strong> is rated to 300 psi/2065 kPa working pressure and istested and approved to be used with all sizes of <strong>Victaulic</strong> <strong>Series</strong> 756 and 758 Fire Protection CheckValves. The lower chamber is constructed of durable 85-5-5-5 cast bronze, the upper chamber andinternal components are made of 360 brass, the seals are EPDM, and the fasteners are 316 stainlesssteel.DIMENSIONSEANominalSizeInchesDimensionsInches/mmA D EAprx.Weight EachLbs./kg1/ 22.61 4.23 3.00 3.466 107 76 1,5DMATERIAL SPECIFICATIONSLower Chamber: Sand Cast85-5-5-5 BronzeUpper Chamber: 360Machined BrassInternal Shafts: 360Machined BrassDiaphragm: NitrileSeals: EPDMFasteners: 316 StainlessSteelTo DrainAdjustable SeatAir InletUpper Chamber SealUpperChamberDiaphragmFrom PistonLowerChamberExaggerated for clarity® REGISTERED TRADEMARK OF VICTAULIC – © COPYRIGHT 2006 VICTAULIC – PRINTED IN U.S.A. – SKU #WCAS-6NLJVA 2646 REV CUnited States • Phone: 1-800-PICK-VIC (1-800-742-5842) • Fax: 610-250-8817 • e-mail: pickvic@victaulic.comCanada • Phone: 905-884-7444 • Fax: 905-884-9774 • e-mail: viccanada@victaulic.comEurope • Phone: 32-9-381-1500 • Fax: 32-9-380-4438 • e-mail: viceuro@victaulic.beUK • Phone: 44(0)1438741100 • Fax: 44(0)1438313883 • e-mail: viceuro@victaulic.beCentral and South America • Phone: 610-559-3300 • Fax: 610-559-3608 • e-mail: vical@victaulic.comAustralasia • Phone: 86-21-54253300 • Fax: 86-21-54253671 • e-mail: vicap@victaulic.com

30.60OPERATION<strong>Dry</strong> <strong>Actuator</strong>The <strong>Series</strong> <strong>753</strong>-A <strong>Dry</strong> <strong>Actuator</strong>/<strong>Anti</strong>-<strong>Flood</strong> <strong>Device</strong> is located in the trim of pneumatically released <strong>Series</strong>756 and <strong>Series</strong> 758 check valves and acts as the “trigger” for these systems. It is divided into twochambers which are separated by a diaphragm. The upper chamber controls activation, while the loweracts as a water valve. During system charging, the fast fill line of the air maintenance device is openedand air begins to fill the system. At this time, the upper chamber of the <strong>Dry</strong> <strong>Actuator</strong>, which is connectedto the air maintenance device by copper tubing, also fills with air. This air pressure pushes a seal whichis attached to the diaphragm down against a seat in the lower chamber, closing the water valve. Waterpressure can then be permitted to enter the piston on the main check valve, locking the clapper intoplace. When system air pressure is released due to the opening of a sprinkler head, air pressureevacuates from the upper chamber. When the air pressure in the upper chamber becomes less thanapproximately 1 / 8 the water pressure in the lower chamber, the seal lifts from its seat and water is allowedto escape from the back of the piston, forcing main check valve operation.Integral <strong>Anti</strong>-<strong>Flood</strong> <strong>Device</strong>After main check valve operation, water enters the trim which initially charges the system with air. Thispart of the trim is connected to the <strong>Dry</strong> <strong>Actuator</strong> upper chamber which controls activation and, if flooded,could cause the system to prematurely shut. A check valve in the valve trim prevents most of this waterfrom entering the actuator, but in case of check valve malfunction, the upper chamber includes an <strong>Anti</strong>-<strong>Flood</strong> <strong>Device</strong>. A small vent hole in the top of this chamber is covered by a seal during system chargingand normal operation. During activation, a shaft connected to the diaphragm pushes this seal away fromthe vent hole allowing air pressure to be vented to atmosphere. This also permits any system water whichpassed through the check valve to be exhausted without filling the upper chamber and possibly shuttingthe system down.RECOMMENDED AIR PRESSURE FOR DRY AND PNEUMATIC ACTUATED SYSTEMS6050AIR PRESSURE – PSI4030201005 10 15 20 25 50 75 100 125 150 175 200 225 250 275 300MAXIMUM WATER SUPPLY PRESSURE - PSI (Peak)This product shall be manufactured by <strong>Victaulic</strong> or to <strong>Victaulic</strong> specifications. All products to be installed in accordance with current <strong>Victaulic</strong> installation/assembly instructions.<strong>Victaulic</strong> reserves the right to change product specifications, designs and standard equipment without notice and without incurring obligations.2 <strong>Series</strong> <strong>753</strong>-A FireLock ® <strong>Dry</strong> <strong>Actuator</strong>/<strong>Anti</strong>-<strong>Flood</strong> <strong>Device</strong>