Service Contract No 2007 / 147-446 - Swaziland

Service Contract No 2007 / 147-446 - Swaziland

Service Contract No 2007 / 147-446 - Swaziland

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Restructuring and DiversificationManagement Unit (RDMU)to coordinate the implementation ofthe National Adaptation Strategy tothe EU Sugar Reform, <strong>Swaziland</strong><strong>Service</strong> <strong>Contract</strong> <strong>No</strong> <strong>2007</strong> / <strong>147</strong>-<strong>446</strong>EuropeAid/125214/C/SER/SZ: Restructuring andDiversification Management Unit to coordinate theimplementation of the National Adaptation Strategy to theEU Sugar Reform, SWAZILANDEC General Budget – SU-21-0603SWAZILAND Technical Audit of Farmers AssociationH l o m a n i Far m e r s A s s o c i a t i o nSubmitted to:The Delegation of the European Commission to <strong>Swaziland</strong>4 th Floor Lilunga House, Somhlolo Road, Mbabane, <strong>Swaziland</strong>Ministry of Economic Planning and DevelopmentP.O. Box 602Mbabane H100, <strong>Swaziland</strong>

Your contact personswith GFA Consulting Group GmbH areDr. Susanne PecherAnke SchnoorRestructuring and Diversification Management Unit(RDMU)to coordinate the implementation of the National AdaptationStrategy to the EU Sugar Reform, <strong>Swaziland</strong>Technical Audit of Farmers AssociationAuthors: Tiekie de Beer,Designer Member of the South African IrrigationInstitute (SABI)&Bongani BhembeMission ReportAddressGFA Consulting Group GmbHEulenkrugstraße 82D-22359 HamburgGermanyPhone +49 (40) 6 03 06 – 111Fax +49 (40) 6 03 06 - 119Email: afrika@gfa-group.deHlomani Farmer Association Report - 2009Page ii

DISCLAIMERThe contents of this report are the sole responsibility of the RDMU and can in no waybe taken to reflect the view of the European Union.Hlomani Farmer Association Report - 2009Page iii

TABLE OF CONTENTSHlomani Farmers Association............................................................................................................................... iTABLE OF CONTENTS ................................................................................................................................. ivLIST OF TABLES ............................................................................................................................................ viLIST OF FIGURES ......................................................................................................................................... viiLIST OF APPENDICES ................................................................................................................................ viiiABBREVIATIONS ........................................................................................................................................... ix1 INTRODUCTION ............................................................................................... - 1 -2 BACKGROUND ON IRRIGATION DEVELOPMENT ....................................... - 2 -3 TECHNICAL AUDIT REPORT .......................................................................... - 6 -3.1.1 REVIEW OF THE IRRIGATION DESIGN CRITERIA AND SPECIFICATIONS .........................- 6 -3.1.1.1 Irrigation Design and Specifications by the contractor ..............................................................- 6 -3.1.1.1.1 DESIGN CRITERIA ............................................................................................................- 6 -3.1.1.2 Review of <strong>Contract</strong>or Irrigation Design Criteria and Specifications .........................................- 7 -3.1.1.2.1 Planning ................................................................................................................................- 7 -4 FIELD EVALUATION OF IRRIGATION SYSTEM ..........................................- 15 -4.1.1 Pumps And Pump Stations ...............................................................................................................- 15 -4.1.1.1 Pump Suction Side ...................................................................................................................- 15 -4.1.1.1.1 Suction Pipe Flow Rate .......................................................................................................- 15 -4.1.1.1.2 Requirements for Fittings ...................................................................................................- 16 -4.1.1.1.3 Suction Pipe Inlets ..............................................................................................................- 19 -4.1.1.1.4 Suction side losses ..............................................................................................................- 20 -4.1.1.1.5 Suction height .....................................................................................................................- 21 -4.1.1.2 Pump evaluation .......................................................................................................................- 22 -4.1.1.2.1 Power required on the pump shaft ......................................................................................- 23 -4.1.1.2.2 Output Power ......................................................................................................................- 24 -4.1.1.2.3 Pump Station General Evaluation .......................................................................................- 25 -4.1.2 Power Supply and Consumption .......................................................................................................- 27 -4.1.3 Supply System ..................................................................................................................................- 30 -4.1.3.1 Mainline size ............................................................................................................................- 30 -4.1.3.2 Mainline class ..........................................................................................................................- 30 -4.1.4 System capacity evaluation ...............................................................................................................- 31 -5 FIELD EVALUATION OF SPRINKLER IRRIGATION SYSTEM .................... - 32 -5.1 Pressure readings ................................................................................................................................- 33 -5.1.1 Pressure at hydrant ............................................................................................................................- 33 -5.1.2 Sprinkler pressure .............................................................................................................................- 34 -5.2 Delivery tests ........................................................................................................................................- 41 -5.2.1 Sprinkler discharge ...........................................................................................................................- 41 -6 ASSESSMENT OF OPERATION, MANAGEMENT AND MAINTENANCE OFTHE IRRIGATION SYSTEM .................................................................................. - 45 -6.1 Operation .............................................................................................................................................- 45 -Hlomani Farmer Association Report - 2009Page iv

6.2 Management Practices ........................................................................................................................- 48 -6.3 Maintenance Survey ...........................................................................................................................- 49 -7 CONSTRAINTS TO EFFICIENT SYSTEM PERFORMANCE ........................- 50 -8 RECOMMENDATIONS ...................................................................................- 54 -9 CONCLUSION ................................................................................................- 57 -10 LITERATURE REFERENCES .....................................................................- 59 -11 PRODUCT INFORMATION .........................................................................- 61 -12 APPENDICES .............................................................................................- 72 -Hlomani Farmer Association Report - 2009Page v

LIST OF TABLESTABLE 1. PUMP AND MOTOR SPECIFICATIONS AND MEASUREMENTS CONDUCTED ON ALL PUMPS .............. - 23 -TABLE 2. IRRIGATION PUMP EVALUATION......................................................................................................... - 24 -TABLE 3. OPTIMAL OPERATING PRESSURE VS NOZZLE DIAMETER FOR SPRINKLERS ........................................ - 34 -TABLE 4. PRESSURE AND NOZZLE SIZE MEASUREMENTS RESULTS .................................................................... - 37 -TABLE 5.DISCHARGE VARIATION CALCULATED FROM PHASE 1 FIELD MEASUREMENTS .................................. - 42 -TABLE 6.TECHNICAL PROPERTIES OF SPRINKLERS FOUND ON SITE AT 35M OPERATING PRESSURE ................ - 43 -TABLE 7. MAINTENANCE SCHEDULE FOR SPRINKLER IRRIGATION SYSTEMS ..................................................... - 49 -TABLE 8. MAINTENANCE PRACTICES IMPLEMENTED BY HLOMANI ................................................................... - 49 -Hlomani Farmer Association Report - 2009Page vi

LIST OF FIGURESFIGURE 1. RIVER PUMP STATION ALONG THE KOMATI RIVER ............................................................................. - 3 -FIGURE 2. PUMPING MAIN SEPARATING INTO THREE INDEPENDENT DELIVERY MAINS .................................... - 3 -FIGURE 3. NYAKATFO PILOT PROJECT BOUNDARY MAP ...................................................................................... - 4 -FIGURE 4. MCC FOR PHASE 3 RIVER PUMPS ........................................................................................................ - 4 -FIGURE 5.SAPWAT SCREEN INDICATING WATER REQUIREMENT FOR SPRINKLER IRRIGATION WITH RAINFALLTAKEN INTO ACCOUNT .............................................................................................................................. - 10 -FIGURE 6. REQUIRED RADIUS OF 90 BENDS (SOURCE: ARC (<strong>2007</strong>)) .................................................................. - 16 -FIGURE 7. 300MM 90° AND 45° BENDS ON PUMP’S SUCTION PIPELINES ......................................................... - 16 -FIGURE 8. CONCENTRIC AND ECCENTRIC REDUCERS ......................................................................................... - 17 -FIGURE 9. CORRECT INSTALLATION OF ECCENTRIC AND CONCENTRIC REDUCERS ........................................... - 18 -FIGURE 10. CONCENTRIC REDUCER IN DELIVERY MANIFOLD ............................................................................ - 18 -FIGURE 11. SPACING AND PLACING OF SUCTION PIPE INLETS........................................................................... - 19 -FIGURE 12. HLOMANI INTAKE SUMP ALONG KOMATI RIVER ............................................................................ - 19 -FIGURE 13. MINIMUM WATER DEPTH ABOVE SUCTION PIPE INLET ................................................................. - 20 -FIGURE 14. ATMOSPHERIC PRESSURE VS. HEIGHT ABOVE SEA LEVEL ............................................................... - 22 -FIGURE 15. POSITION OF PUMP HOUSE ALONG THE KOMATI RIVER ................................................................ - 25 -FIGURE 16. ACCESS LADDER INTO PUMP HOUSE............................................................................................... - 26 -FIGURE 17. PUMP EXCESSIVE COOLING LEAKS .................................................................................................. - 26 -FIGURE 18. LATERAL HYDRANT VALVE ............................................................................................................... - 33 -FIGURE 19. PRESSURE MEASUREMENT WITH A PITOT TUBE END PRESSURE GAUGE ............ - 35 -FIGURE 20. POSITIONS OF COMPLETE SPRINKLER PRESSURE MEASURES IN AN IRRIGATION BLOCK ............... - 36 -FIGURE 21. LATERAL HYDRAULIC VALVE ............................................................................................................ - 39 -FIGURE 22. MEASURING APPARATUS FOR SPRINKLER NOZZLE SIZE ................................................................. - 40 -FIGURE 23. DRAGLINE LEAKAGE ......................................................................................................................... - 40 -FIGURE 24. NYAKATFO SUGARCANE PRODUCTIVITY IN TONES CANE PER HECTARE ........................................ - 46 -FIGURE 25. ELECTRICITY COST FOR NYAKATFO PILOT PROJECT......................................................................... - 47 -Hlomani Farmer Association Report - 2009Page vii

LIST OF APPENDICESAppendix 1: SEB usage for river pump station phase 2Appendix 2: capital recovery factors (CRF)Appendix 3: soil map and block layoutHlomani Farmer Association Report - 2009Page viii

ABBREVIATIONSAbbreviationAEARCASAECUCVDUEACEUFAGARHDPEMCCNARNPSHPVCRSSCSABISESSASWADEUsDescriptionApplication EfficiencyAgricultural Research CouncilAmerican Society of Agricultural EngineersChristiansen’s uniformity coefficientCoefficient of VariationDistribution Uniformity coefficientEquivalent Annual CostEmitter UniformityFarmers AssociationGross Application RateHigh Density PolyethyleneMotor Control CentreNet Application RateNet Positive Suction HeadPolyvinyl ChlorideRoyal <strong>Swaziland</strong> Sugar CorporationSouth African Irrigation InstituteSystem Efficiency<strong>Swaziland</strong> Sugar Association<strong>Swaziland</strong> Water & Agricultural Development EnterpriseStatistical UniformityHlomani Farmer Association Report - 2009Page ix

1 I N T R O D U C T I O NAssociation general information1. Farm name: Swazi Nation Land2. Name of Association: Hlomani Farmers Association3. Location:Area:NyakatfoLatitude -2 875 000.00Longitude 58 000.00Altitude300 mMaximum Temperature36 0 CMinimum Temperature8 0 C4. Postal address: 44 Mayiwane5. Contact Details:Chairman – Mr. J. MagagulaFarm Supervisor – Mr. M. Magagula6. Area of farm (ha) 717. Crops irrigated: Sugar cane8. Designers name and details: RSSC (Mhlume)9. Date of evaluation: 8 July 200910. Evaluators: Tiekie de Beer and Bongani BhembeHlomani Farmer Association Report - 2009 Page - 1 -

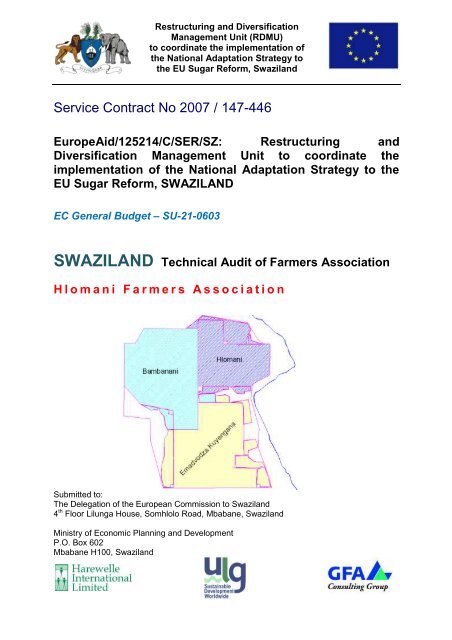

2 B A C K G R O U N D O N I R R I G A T I O ND E V E L O P M E N THlomani Farmers Association is one of three FAs comprising Nyakatfo Pilot Project. Theother two FAs are Bambanani Emobeni FA and Emadvodza Ayayengana FA. Nyakatfo pilotproject is in total 263 hectares and with Hlomani accounting for 71ha. The organizationalstructure of this enterprise is as follows;Nyakatfo PilotProject CentralCommitteeEmadvodzaAyayenganaExecutiveBambananiEmobeniExecutiveHlomaniExecutiveFarm manager 1Farm manager 2Farm manager 3Amongst others, the central committee is comprised of the chairpersons of all the FA and isheaded by Mr. Mvumdeni Sifundza. Hlomani FA chairman is Mr. Johannes Magagula and isconstituted by 14 members. The farm manager/supervisor of this FA is Mr. MgcibeloMagagula.The project‣ Nyakatfo project was implemented in two phases, the first in 1997 by Mhlume sugar andthe second by the FA in 2008. Phase one was 55 Ha developed and the second phasewas 16 Ha both dragline irrigation system.‣ All the three FAs share one pump station housing three KSB WKLn 150/3 pumps drivenby two pole 110kW electric motors. This pump station is position along the flood line ofthe Komati River.Hlomani Farmer Association Report - 2009 Page - 2 -

Figure 1. River pump station along the Komati River‣ From the river pump station one delivery main connecting the three pumps emerge andafter approximately 500m divides into three separate delivery pipelines supplying thethree associations.Figure 2. Pumping main separating into three independent delivery mains‣ The three pumps are owned and maintained by the three farmers associations.Hlomani Farmer Association Report - 2009 Page - 3 -

‣ The separation of the blocks is indicated by the following figure. Hlomani is 71ha,Bambanani is 86ha and Emadvodza is 106ha.Figure 3. Nyakatfo Pilot project boundary Map‣ This dragline irrigation system has 54m spaced laterals with 20 meters long draglines.Flow into the different association is monitored by a flow meters installed on the threedelivery mains (see figure 2 above)‣ The Motor Control Centres (MCC) of all pumps is well constructed.Figure 4. MCC for phase 3 river pumpsHlomani Farmer Association Report - 2009 Page - 4 -

‣ Phase one of this irrigation development was implemented only on Lesibovu series. Theextension of 16 ha implemented by Hlomani FA is on Ungabolima and Betusile soilseries. Ungabolima soil series are not suitable for cultivation described to be shallowrocky areas and river sands. Sugarcane planted on these blocks pronounces it all.‣ Hlomani sugarcane varieties are N23, 376 and N19 giving approximately 116 tonnes perhectare with 14.88% sucrose last production season.Hlomani Farmer Association Report - 2009 Page - 5 -

3 T E C H N I C A L A U D I T R E P O RT3.1.1 R E V I E W O F T H E I R R I G A T I O N D E S I G N C R I T E R I AA N D S P E C I F I C A T I O N S3.1.1.1 Irrigation Design and Specifications by the contractorDesign information from the designer and installer Mhlume sugar corporation could not beobtained. The design was therefore checked against <strong>Swaziland</strong> Sugar Industry Standard andSABI norms shown below.3.1.1.1.1 DESIGN CRITERIACropArea under irrigationGross ApplicationNet ApplicationIrrigated CycleSprinkler dischargeSprinkler SpacingPrecipitation RateStand timeAnnual Irrigation hoursSugar Cane47.6Ha52mm39 mm per cycle (6.5 mm/day)6/7 days (depending on soil type)0.39 l/s18m x 18m4.3mm/hr12 hours (depending on soil type)3 300 hoursHlomani Farmer Association Report - 2009 Page - 6 -

3.1.1.2 Review of <strong>Contract</strong>or Irrigation Design Criteria and Specifications3.1.1.2.1 PlanningOf the four major input of planning namely crop, climate, soil and irrigation system; the studyrevealed that crop and climate information used as supplied by the SSA (<strong>Swaziland</strong> SugarAssociation) Soil types were taken into consideration during design and or implementation ofphase one. Attached in appendices is a soil map of Hlomani Farmers Association indicatingmajor soil types the project was developed on.The purpose of this study was, therefore, to determine the quantity of water required by thecrops per cycle during peak demand periods and how often it was to be applied takingpractical operating practice into account.Taking soils into account the following planning schedule was developed;Peak Design-<strong>No</strong>rm For Sprinkler Irrigation At Hlomani Farmers Ass.1 GENERAL INFORMATION1,1 Owner Hlomani Farmers Association1,2 Farm Name - Number - Co-ordinates Swazi nation land1,3 Telephone number1,4 Area developed 86 Ha1,5 Water Allocation 86 l/s2 CLIMATE2,1 Month state Jan2,2 Weather station state Mhlume2,3 Evaporation mm/day 7mm A-Pan or 5mm Grass Factor3 MANAGEMENT3,1 Available working days per week days 73,2 Available working Hours per day hours 244 CROP BLOCK NO Lesibovu/Shortlands Betusile/Oakleaf4,1 Type state Sugar Sugar4,2 Area Ha 20 94,3 Plant spacing m NA NA4,4 Row spacing m 1.8 1.84,5 Effective root depth m 0.45 0.454,6 Plant time date August AugustHlomani Farmer Association Report - 2009 Page - 7 -

5 SOIL Lesibovu/Shortlands Betusile/Oakleaf5,1 Effective soil depth m 1 15,2 Water holding capacity mm/m 180 1405,3 Easy available water (10-50 kPa) 50% mm/m 90 405,4 Easy available water in root zone mm 40.5 186 WATER6,1 C en S Classification of water C+S Komati River7 EMITTER7,1 Type type Vyrsa 70 Vyrsa 707,2 <strong>No</strong>zzle size mm 11/64 11/647,3 Discharge l/h 1390 13907,4 Working pressure kPa 350 3507,5 Application efficiency % 70 707,6 Emitter spacing m 18 187,7 Lateral spacing m 18 187,8 Wetted diameter m 36 367,9 Gross Application rate on wetted area mm/h 4.29 4.297,10 Nett Application rate on wetted area mm/h 3.33 3.338 SCHEDULING8,1 Crop factor (max) max 1.15 1.158,2 Evaporation mm/day 5 58,3 Evapotranspiration mm/day 5.75 5.758,4 Net Irrigation requirement mm/day 5.75 5.758,5 Gross Irrigation requirements mm/day 6.04 6.048,6 Theoretical cycle length day 7.04 3.138,7 Theoretical Stand time hour 12.16 5.408,8 Practical Cycle length day 6 38,9 Practical Stand time hours 12 68,10 Working days per week days 7 78,11 Irrigation hours per day hours 24 248,12Gross application rate per practicalcycle mm 51.48 25.748,13 Gross application per month mm 220.62 257.409 SCHEDULE OF BLOCKS THAT IRRIGATE TOGETHER10 HYDRAULICS10,1 Pressure difference over block m 40 4010,2Pressure at beginning of sub main orlateral m 40 4010,3 Velocity in mainline (max) m/s 1 1Hlomani Farmer Association Report - 2009 Page - 8 -

11PRACTICAL STAND TIME / START TIMEfor 6 Day Cycle length11,1 Position 111,2 Position 211,3 Position 311,4 Position 411,5 Position 511,6 Position 611,7 Position 711,8 Position 811,9 Position 911,10 Position 1011,11 Position 1111,12 Position 1211,13 Position 1 start at beginning againStart EndDay 106,00 Day 1 18,00Day 118,00 Day 2 06,00Day 206,00 Day 2 18,00Day 218,00 Day 3 06,00Day 3Day 306,0018,00Day 3Day 418,0006,00Day 406,00 Day 4 18,00Day418,00 Day 5 06,00Day 506,00 Day 5 18,00Day 518,00 Day 6 06,00Day 6 Day0606,0018,00Day 6Day 718,0006,00Day 806,0012 FILTER12,1 Type State12,2 Total total12,3 Filtration size micron12,4 Pressure loss over filter (clean) m12,5 Pressure lose over filter (dirty) m13 DESIGNER13,1 Name Tiekie de Beer13,2 Company Tiekie de Beer Consulting13,3 SABI Membership Designer FellowHlomani Farmer Association Report - 2009 Page - 9 -

Climatic information:Climatic information used when compiling the above schedule was obtained from SAPWATand a summary of which is shown by the figures below.Figure 5.SAPWAT screen indicating water requirement for sprinkler irrigation withrainfall taken into accountHlomani Farmer Association Report - 2009 Page - 10 -

Soil informationSoil properties used when compiling the afore schedule was obtained from the below charts.These are the two major soils found within the farm, an outline of which is shown on a soilmap attached in annexes.Hlomani Farmer Association Report - 2009 Page - 11 -

Hlomani Farmer Association Report - 2009 Page - 12 -

Hlomani Farmer Association Report - 2009 Page - 13 -

Hlomani Farmer Association Report - 2009 Page - 14 -

4 F I E L D E V A L U A T I O N O F I R R I G A T I O NS Y S T E M4.1.1 P u m p s A n d P u m p S t a t i o n s4.1.1.1 Pump Suction SideThe majority of problems occurring with pumps are usually the result of poor suction sidedesign and installation. The installation and design of the suction side must ensure thatturbulence occurring in the suction pipe and collection of air in high places in the suction pipeis prevented. In view of the above, the different suction side components were evaluated.4.1.1.1.1 Suction Pipe Flow RateThe suction pipe flow velocity of river and booster pumps was calculated as follows:353,68 QV m / s2d……………………….… (1)Where: V = flow velocity in pipe (m/s)Q = flow rate (m³/h)d = inner diameter of suction pipe (mm).The pumps design duty point is not known and for the purposes of the evaluation pumpdischarge was estimated by getting the multiply of Nyakatfo total irrigated area (263 ha),industry norms of 2.57 sprinklers per hectare (for a 12hour stand time and 6 day cycle),1.4m³/hr sprinkler discharge and 10% safety factor for pump discharge. Each of the threepumps must therefore generate 347m3/hr of flow to meet irrigation requirements. During theevaluation only one pump was in operation generating 67.81l/s (244.1m3/hr) discharge.Based from equation one above the flow velocity at design flow through the 300mm suctionmanifold is 1.41 m/s and is within recommended limit. According to the Agricultural ResearchCouncil, ARC (<strong>2007</strong>) the ideal suction pipe flow velocity must be 1.0 m/s, but suction pipeflow velocities up to 1.5 m/s are acceptable. The 300mm suction manifolds are therefore ofthe correct size.Hlomani Farmer Association Report - 2009 Page - 15 -

4.1.1.1.2 Requirements for Fittings90º BendsThe radius (mm) of a 90º bend must be, at least, as shown in Figure 6rdFigure 6. Required radius of 90 bends (source: ARC (<strong>2007</strong>))r 2d100mm …………………………………... (2)Where: r = radius of bend (mm)d = inner diameter of suction pipe (mm).Each of the three suction pipes are connected to two 300mm 90° bends and one 45° bendsof radius 400mm (figure 7). According to figure 6 and equation 2 above the required minimumis 700mm but because there is more than five time the suction and delivery pipe sizediameter pipe further on of these bends, the effects of the incorrect sizes on pumpperformance are insignificant.Figure 7. 300mm 90° and 45° bends on pump’s suction pipelinesHlomani Farmer Association Report - 2009 Page - 16 -

ReducersThe inlet on the pump suction side must be eccentric with the straight side towards the top, toprevent air collecting in the suction pipe and causing cavitation (ARC, 2006). The length ofboth eccentric and concentric reducers were evaluated against equation 3 (figure 8) below,adopted from the ARC.Figure 8. Concentric and eccentric reducers ( d ) ………………………... (3)52d1Where: = length of the reducer (mm)d1 = smaller inner diameter (mm)d2 = larger inner diameter (mm)300-200 eccentric reducers are installed on the suction pipe of all pumps and 150-200concentric reducers installed on the delivery side of these pumps. These reducers areinstalled as per the requirement but are of incorrect lengths. The eccentric reducers areinstalled with the straight side towards the top, to prevent air collecting in the pipe andconcentric reducers on the delivery pipe (figure 10). The required minimum length accordingto equation 3 above is 500mm and 250mm respectively, from site measurements thesereducers are 500mm and 145mm long.The unacceptable dimensions of the concentric reducers had negligible effects on theperformance of pumps and the entire system. Concentric reducers on the other hand aredirectly attached to the pump and the sudden restriction in size increases turbulenceoccurrences and cause irregular feeding of the pump hence cavitation. With such aninstallation wearing and maintenance cost of the pump would increase.Hlomani Farmer Association Report - 2009 Page - 17 -

Figure 9. Correct installation of eccentric and concentric reducersFigure 10. Concentric reducer in delivery manifoldHlomani Farmer Association Report - 2009 Page - 18 -

4.1.1.1.3 Suction Pipe InletsSpacing and placing of suction pipe inletsIn a well constructed sump the inlet of the suction pipe must be in accordance to therequirements of at least 0,5d (d = inner diameter of the suction pipe) from the bottom of thepump sump (figure 11) and at least 1,5d away from the side of the pump sump. There is nointake sump at this pump station, suction inlets are suspended on the banks of the KomatiRiver. The suction pipe inlets are at least 600mm from the bottom of the sump and 100mmfrom each other. The suction pipes are about 900mm from the embankment.1.5dd0.5dd3d 3d 1.5dFigure 11. Spacing and placing of suction pipe inletsFigure 12. Hlomani intake sump along Komati riverHlomani Farmer Association Report - 2009 Page - 19 -

The minimum water depth above suction pipe inlet depends on the suction pipe velocity andwas evaluated using the graph shown in figure 13 below. Site investigation revealed a waterdepth of approximately 400mm and with a maximum velocity of 1.95m/s the depth should beat least 0.8m. This shallow depth caused vortex thus significantly reducing pumpperformance.Foot valvesFigure 13. Minimum water depth above suction pipe inletThe area around the foot valves was clean and the total area of the openings from the suctionsieve was more than the minimum ARC requirement of 1.5 times larger than the crosssectionalarea of the suction pipe to prevent partial blockages of the suction sieve.Occasionally sand deposits inside the sump becomes too much such that pumping stops forcleaning to proceed.4.1.1.1.4 Suction side lossesDuring the evaluation of the pump station, attention was also given to the length of thesuction pipe and fittings that were used. Friction losses for pipes were calculated as for anyother pipe (using Hazen-Williams equation) and secondary losses for fittings were calculatedwith the aid of the following formula:Hlomani Farmer Association Report - 2009 Page - 20 -

hf6375kQ4d2………………………………….. (4)Where: hf = secondary friction loss in fitting (m)k = friction loss factor (annexure 1)Q = flow rate in the fitting (m³/h)d = inner diameter of the fitting (mm).A summation of friction loss across the non-return valve, the suction pipe, the 90° and 45°bend and the eccentric reducer of every pump, at ultimate flow, gives a total hf of 0.41m.Friction in the suction pipe has a direct effect of maximum suction height and consequentlythe available net positive suction head (NPSH) and it is discussed below.4.1.1.1.5 Suction heightThe essence of this evaluation was to determine the actual static suction head of the installedpumps and then compare it to the designers suction height assumption. The maximumsuction height was calculated using equation 5 below;hs(max) hdhfhvp NPSHrequired ………………. (5)Where: hs (max) = maximum suction height (m)hdhfhvp= atmospheric pressure on terrain (m)= suction side losses (friction losses, as well as secondary losses in fittings, m= vapour pressure of water (m)NPSH required = net positive suction head from the pump curve (m)Hlomani Farmer Association Report - 2009 Page - 21 -

Figure 14. Atmospheric pressure vs. height above sea levelThe suction height was measured to be approximately 1.5 meters. The NPSH required(NPSHr) of the pump is 4m (from a pump curves). From the above formula the maximumallowable suction height is 5.19m and this calculation confirms that river pumps were installedwith a correct suction height.Further analysis compared NPSH available to NPSH required. The NPSH requirements of1.5 meters are well within the available NPSH (NPSHa) of 7.19 meters. A safety factor of 0.5is factored in this calculation as per manufacture’s requirement. This conform to therecommendation of NPSHr

Table 1. pump and motor specifications and measurements conducted on all pumpsPUMP SPECIFICATIONS FROM INFORMATION PLATE AND MEASUREMENTSModel KSB WKLn 150/3Number of units 3Estimated design duty point347m³/hr @ 84mPump efficiency, % 80Impellor diameter mm F/SFlow rate M3/hr 244.1Pressure under normal operation M 72MOTOR SPECIFICATIONS FROM INFORMATION PLATE AND MEASUREMENTSMotor size, kW 110Revolution speed rpm 1480Motor efficiency, % 93.6Power factor, cos Q 0.86Current (measured) V 400Voltage (measured) A 1504.1.1.2.1 Power required on the pump shaftThe power required on the pump shaft was calculated when the total pump head and deliverywas measured. The pump efficiency was obtained from the pump curve.Power required on the pump shaft was calculated with the following formula and establisheswhether motors were sized accurately.P g H Q36,000………………………………………. (6)Where: P = power required on the pump shaft (kW)ρ = density of water (1000 kg/m³)g = gravity acceleration (9.81 m²/s)H = pump pressure at service point (m)Hlomani Farmer Association Report - 2009 Page - 23 -

Q = pump delivery at service point (m³/h)η = pump efficiency at service point (%).Based on the estimated duty point shown in table 1 above the required power on the pumpshaft is a theoretical value of 99.3 kW. According the ARC, <strong>2007</strong>, the power output of themotor must be 10-15% greater than the power required on the pump shaft and correspondsto 109.2kW. Under this consideration, the 110kW motor is of the correct specification.4.1.1.2.2 Output PowerThe required power, P of all the pumps was then compared with the output power (Pu)requiredof the electric motor obtained from measurements of voltage and current. The output powerof the motor was calculated using equation 7 below3IV cosP u……………………………………….. (7)1000Where: Pu = output power of the motor (input power of the pump) (kW)I = average measured current (A)V = average measured voltage (V)η = motor efficiency (fraction)cos ø = power factor (factor).The output power of both motors is indicated in table 2 below,Table 2. irrigation pump evaluationKSB WKLn 150/3P motor (information plate) kW 110P required kW 99.3Pu (motor output power) kW 83.6ClassificationAcceptableAccording to the ARC the configuration of the different power units must conform to theexpression Pu = P < Pmotor. As mentioned earlier the 110kW motor is acceptably designedHlomani Farmer Association Report - 2009 Page - 24 -

ut based on the motor output power the pump is running under capacity. This claim wasconfirmed by water meter reading which was below the expected pump discharge.4.1.1.2.3 Pump Station General Evaluation‣ The pump house is constructed along the Komati river flood line with concrete blocks.When the river level raise water seeps through these blocks and fill the pump house.Recently a lot of money was spent to rewind all three motors after they were flooded.Figure 15. Position of pump house along the Komati river‣ The access ladder into this pump house is very steep and without hand rails. This is notsafe.Hlomani Farmer Association Report - 2009 Page - 25 -

Figure 16. Access ladder into pump house‣ A small drainage sump was constructed on the floor of this pump house but is noteffective in its purpose. The floor does not have the correct slope to drain all its water intothis sump. Also, there is no drainage pump.‣ All pumps have excessive cooling leaksFigure 17. Pump excessive cooling leaks‣ Bermad control valves connected in all pumps are malfunctioning and there are nomechanical pump control valves.Hlomani Farmer Association Report - 2009 Page - 26 -

‣ The pump house is used as a storeroom and this reduces ventilation, working space andincreases risks.‣ The pump house is not well ventilated.‣ There is no carriage (gantry and winch) for the pump and/or motor for maintenancepurposes‣ Some pressure gauges, and voltmeter are not functioning and electric cables aredisoriented inside the pump station.Pump AlignmentThe alignment of the pump and the motor was also evaluated. This was done by placing theedge of a straight steel ruler over the coupling flanges at four points, 90º apart. This straightedge rested equally on all points on the flanges to ensure parallel alignment. The distancebetween the coupling levels at 90º intervals was also measured. A Vernier calliper was used.Measurements were the same on all the points, and on all pumps and that meant the unitwas squarely aligned.4.1.2 P o w e r S u p p l y a n d C o n s u m p t i o nPower consumptionA basic economic analysis was undertaken to ascertain the trade-off between capital andenergy costs. For this economic analysis the Equivalent Annual Cost method (EAC) wasused. The EAC adjusts the costs of items to a stream of equal amounts of payment overspecified periods (equivalent annual costs) in order to enable comparison.Items costed were:‣ Infield irrigation (tape and fittings including flusher lines and valves - considered aspolythene). Including installation costs.‣ Distribution system - pipelines (main lines and submains - considered as PVC).Including installation costs.‣ Pumping plant (including pump control valves, flow meters, electrical components,motors etc). Included installation costs. Where no new pumps were included, all andany supplementary equipment/operations connected with pumping e.g. upgrades,new impellors, new switchgear, new valves were included‣ Primary filter station (only filters and associated pipework, valves etc).Hlomani Farmer Association Report - 2009 Page - 27 -

Excluded were:‣ All existing infrastructure (e.g. AC pipe, balancing dam, MCC housing, etc)‣ Buildings (e.g. cluster houses, pump stations, filter station structure)‣ Valves external to pump stations and filter stations.‣ Irrigation controller systems‣ Fertigation systemsThe operational costs for the schemes were confined to energy costs and maintenance(excluded labour. Admin etc).Interest rate: 10%Useful life (this analysis)Infield irrigation (Tape etc):10 yearsPVC/Poly pipe:Filters:Pumping equipment and electricsMaintenanceInfield irrigation: 3%Distribution - pipelines: 2%Pumping plant: 1%Filters: 3%20 years15 years15 yearsCapital Recovery Rate (CRF)factors:Volume water applied per hectare:SEB tariff – Consumption:Maximum demand:Efficiency of pumping plant(See attached table)9000mI\3/ha/annum0.22 E/kWh69.42 E/kVaCalculate at design duty pointHlomani Farmer Association Report - 2009 Page - 28 -

EAC COMPUTATION MATRIXThese costs have been calculated only for Phase Two of theProjectITEM COST ITEM Main Bid1 Infield irrigationCapital cost (E) -Useful life (years) 10Annual maintenance (%) 3EAC of infield irrigation (E) -2 Distribution systemCapital cost (E) -Useful life (years) 20Annual maintenance (%) 2EAC of Distribution system (E) -3 Pumping plantCapital cost (E) -Useful life (years) 15Annual maintenance (%) 1EAC of Pumping plant (E) -4 FiltersCapital cost (E) -Useful life (years) 15Annual maintenance (%) 3EAC of Filters (E) -5 Annual Energy Cost (E) 296,432.37Total EAC (E) -Energy cost as a % of total EAC -For sprinkler irrigation a 40% EAC value is accepted. A higher and a lower figure indicatesover design and under design respectivelyHlomani Farmer Association Report - 2009 Page - 29 -

4.1.3 S u p p l y S y s t e mThe evaluation of the supply system is discussed under the following headings;4.1.3.1 Mainline sizeSABI norm suggests that for raising main lines with a diameter of 200mm or smaller amaximum of 1.5m friction for each 100 m pipe length (1.5%) is allowed (ARC, 2003).Mainlines with pipe sizes greater than 200mm are evaluated by determining the mosteconomical pipe diameter; capital and annual cost for different pipe diameters werecompared and the following equation is used;dkQ0.37i …..……………………….……… (8)Where: di = inside diameter of pipe, mmK= constant derived from annual irrigation hoursQ= flow rate (m 3 /h)For annual irrigation hours of 3300, adopted by the sugar industry, the most economical pipesize diameter from the pump station was calculated for 946.274 m³/hr system capacity to be357.2mm inside diameter. This corresponds to a 400mm class 9 pipe with 364.1mm insidediameter. The main delivery pipeline from the pump station to where the allocation to thedifferent association is distributed starts of as a 500mm/9 and reduces to 400mm steel. Fromthis pipeline, three diversions of 200mm steel are made supplying water to EmadvodzaAyayengana, Bambanani Emobeni and Hlomani FA blocks.Hlomani FA is 71 hectares with 255.5 m3/hr system capacity. The actual size, lengths,classes and orientation of the rest of the mainline could not be ascertained. An undisputedconclusion, therefore, on whether Hlomani supply system was correctly designed or notcannot be drawn until details on pipe size, pipe classes, and distances occupied by thedifferent sizes are obtained.4.1.3.2 Mainline classThe WKLn 150/3 pumps generate a maximum pressure of 84m. Class nine pipes musttherefore be installed from the pump station. As mentioned earlier the pumping main from theHlomani Farmer Association Report - 2009 Page - 30 -

pump station to the point where the mainlines of the different FAs separate is class nine. Thissection is therefore correctly designed. From this point forward there are no design details onpipe sizes and class. Amongst others, pipe bursts are one major indicator of underspecification in pipe classes and none were experienced in project.4.1.4 S y s t e m c a p a c i t y e v a l u a t i o n‣ Three WKLn 150/3 pump are installed in a pump station designed for four pumping units‣ This pump station supplies water to infields owned by three farmers association,Emadvodza Ayayengana, Bambanani Emobeni and Hlomani FA.‣ The three FAs have a total irrigated area of 263 hectares. Total system capacity wasevaluated by getting the multiple of the total irrigated area, industry norms of 2.57sprinklers per hectare (for a 6 day cycle), 1.4m³/hr sprinkler discharge and 10% safetyfactor for pump discharge. The three WKLn 150/3 pumps must therefore generate at least1 040.9m³/hr (347 m3/hr/pump) to meet irrigation requirements.‣ System pressure requirements were estimated to be at least 84m.‣ The pump duty point of 347m3/hr flow and 84m head is within the operating range of theinstalled pumps. The 110kW four pole motors driving these pumps are correctly rated inthis regard.‣ Flow and pressure measurements reflected that these pumps are operating below theirdesign duty point.‣ The number of pumps started with every irrigation is regulated by the farm managers ofthe different FAs.Hlomani Farmer Association Report - 2009 Page - 31 -

5 F I E L D E V A L U A T I O N O F S P R I N K L E R I R R I G A T I O NS Y S T E MBlock Area (ha) 71Type of sprinkler systemDragline irrigation systemName of DesignerName of contractorMhlume Sugar Company Limited (P1)Mhlume Sugar Company Limited (P1) andMathokoza Sifundza (P2)DesignMeasuredHydrant pressure (m) - -Sprinkler spacing (m x m) 18 18Lateral spacing (m) 54 35 – 62Stand pipe height (m) 3 3Pressure regulator Yes <strong>No</strong>Dragline diameter (mm) 20 20Dragline length (m) 2 12 – 20Hlomani Farmer Association Report - 2009 Page - 32 -

5 . 1 P r e s s u r e r e a d i n g sThe following pressure readings were taken:5.1.1 P r e s s u r e a t h y d r a n tHydrants and pressure controlThe irrigation system installed by Mhlume has hydrants that are equipped with the correcttype of hydraulic valve but without the installation of a pressure-regulating pilot. They areall equipped with mechanical chokes instead and all blocks that were installed by Hlomanieither have no hydrants and/or mechanical valves. These blocks are supplied by extendingthe sub main and in some cases the laterals were extended to new areas.Pressure-regulating pilots (on the valve head) reduce a higher inlet pressure to a lowerconstant outlet pressure, regardless of fluctuating flow rates and or varying inlet pressure.The pilot would sense down-stream pressure and modulates open or close, causing the mainvalve to throttle, thus maintaining constant delivery pressure.When down –stream pressure falls below the pilot setting, the pilot and main valve wouldmodulate open to increase pressure and maintain pilot setting. When downstream pressurerises above the pilot setting, the pilot and main valve would throttle close to decreasepressure and maintains pilot setting. The pilot has an adjusting screw to preset the desiredpressure.Figure 18. Lateral hydrant valveHlomani Farmer Association Report - 2009 Page - 33 -

5.1.2 S p r i n k l e r p r e s s u r eThe optimal operating pressure (kPa) of the sprinkler should be between 60 and 70 times thenozzle diameter (mm). This is applicable to nozzles of 3 to 7 mm diameter (ARC, 2006).Table 3. Optimal Operating Pressure Vs <strong>No</strong>zzle Diameter for Sprinklers<strong>No</strong>zzle diameterOperating pressure (kPa)Mm inches x 60 x 701,591 / 16 "1,985 / 64 "2,383 / 32 "2,787 / 64 "3,181 / 8 " 191 2223,573,974,374,765,165,565,956,359 / 64 " 214 2505 / 32 " 238 27811 / 64 " 262 3063 / 16 " 286 33313 / 64 " 310 36115 / 64 " 333 38915 / 64 " 357 4271 / 4 " 381 445Pressure at sprinklers was measured with a pressure gauge, fitted with a pitot tube (Figure19). The point of the pitot tube was held about 2 mm in front of the nozzle opening in the pathof the jet of water to measure the “vena contracta”. Therefore, the velocity pressure, whichindicates the pressure head and is equivalent to the total pressure, was measured.Hlomani Farmer Association Report - 2009 Page - 34 -

Figure 19. Pressure measurement with a pitot tube end pressure gaugeThe standpipes were three metres high and the pressure of the sprinklers was measured at aheight of one metre above the ground, then 2 m (or 20 kPa) was subtracted from thepressure registered on the pressure gauge, in order to determine the sprinkler pressure atnormal operating height.The choice of the sprinklers at which measurements were to be taken, was influenced by thedifferent pressure zones in a specific irrigation block. In view of the undulating terrain (manyheight differences) in this project the total system was in operation as for normal irrigationbefore the evaluation. According to the ARC (2006) the number of measuring points must berepresentative of the block and the choice depended on the topography of the block, as wellas the distance from the pump station. As per these recommendations completemeasurements were taken at distances 0, L/4, L/2, 3L/4 and L on the lateral and at the samedistance on the sprinkler lines (Figure 20).Hlomani Farmer Association Report - 2009 Page - 35 -

0 L/4 L/2 3L/4 LL3L/4LL/2Test blockL/4Test emitter0HydrantFigure 20. Positions of complete sprinkler pressure measures in an irrigation blockPressure variation was calculated using equation 9 below and a summary of the results isoutlined in table 4.Pmax PP Pavemin………………………………………….. (9)Pressure measurement results for the different sections are indicated in the following table.Hlomani Farmer Association Report - 2009 Page - 36 -

Table 4. Pressure and nozzle size measurements resultsMeasuring point Type of sprinkler/nozzle MeasurednozzlediameterMeasurednozzlepressureEmadvodza Ayayengana VYRSA 70 11/64" nozzle 4.5 250Emadvodza Ayayengana Rain bird 14070 5/32 4 190Emadvodza Ayayengana Rain bird BH30 5/32" nozzle 5 170Emadvodza Ayayengana VYRSA 70 11/64" nozzle 4.4 190Emadvodza Ayayengana VYRSA 70 11/64" nozzle 4.5 230Emadvodza Ayayengana VYRSA 70 11/64" nozzle 5 170Emadvodza Ayayengana VYRSA 70 11/64" nozzle 4.4 310Emadvodza Ayayengana VYRSA 70 11/64" nozzle 4.5 310Emadvodza Ayayengana VYRSA 70 11/64" nozzle 5 310Emadvodza Ayayengana Rain bird 14070 5/32 4 300Hlomani VYRSA 70 11/64" nozzle 4.5 350Hlomani Rain bird 14070 5/32 4 280Hlomani Rain bird 14070 5/32 4 360Hlomani VYRSA 70 11/64" nozzle 5 300Hlomani VYRSA 70 11/64" nozzle 4.5 350Hlomani Rain bird 14070 5/32 4 360Bambanani Emobeni VYRSA 70 11/64" nozzle 4.4 280Bambanani Emobeni Rain bird 14070 5/32 4 280Bambanani Emobeni RC 140 11/64" nozzle 4.4 290Bambanani Emobeni VYRSA 70 11/64" nozzle 4.4 200Bambanani Emobeni VYRSA 70 11/64" nozzle 4.4 230Bambanani Emobeni RC 140 11/64" nozzle 4.5 290Averages 4.24 4.43 272.73According to the SABI norms, pressures in the block may not vary more than 20% from theaverage pressure. Pressure measurement results as indicated by the above table reflect anunacceptable pressure variation of 69.7% for Nyakatfo Pilot Project and 24% for Hlomaniblocks. The average system operating pressure of the entire system is 272.73kPa and isbelow the recommended sprinkler operating pressure of 350kPa. In consideration of Hlomaniblocks only an average sprinkler operating pressure of 333 kPa was measured, which isslightly below recommendations. The least amount of pressure was recommended on blocksdesigned and installed by Nyakatfo. Excluding these blocks Nyakatfo average sprinkleroperating pressure increases to 290kPa and pressure variation reduces to 65.5%.Hlomani Farmer Association Report - 2009 Page - 37 -

The following is an outline some of the factors affecting the above pressure reading;Poor Hydraulic DesignA hydraulic check or a design was not conducted before the 16 ha expansion by theassociation. Sub-mains and/or laterals of adjacent blocks were used to extend into these newareas, consequently increasing flow in the sub-main and increasing head losses due tofriction. Sprinkler operating pressure drops not only on the extended area but also on theblock from which the extension is connected. Friction losses in these sections are higher thanthe recommended 1.5m/100m. pressure variation and the low operating pressure in theseblocks is also affected by the fact that 32mm HDPE laterals are used for this new draglinesystem.Pumps running under capacityPump flow and pressure measurements reflected these pumps were operating undercapacity. For the pumps to meet system pressure and flow requirements each pump mustoperate at least at 347m3/hr flow and 84m head. The pump in operation during theassessment was operating at 72m and 65m before and after the Bermad valve respectively.Hydraulic Valves:Hydraulic valves maintain the design lateral/block pressure ensuring uniform pressurethroughout the system. This dragline irrigation system was installed in such a way that alllaterals have individual isolation valves. These hydrants are equipped with Gulf hydraulicvalves but without pilots for pressure regulation. A mechanical choke was installed on thevalve head instead. Pressure regulating pilots must be installed and preset to give at least350kPa sprinkler operating pressure on all blocks.Currently the control valves are vandalised, incomplete and not properly looked after (figure21). All block implemented by the FA does not have any isolation valves; they are dependenton the valve of the block from which they are supplied.Hlomani Farmer Association Report - 2009 Page - 38 -

Figure 21. Lateral hydraulic valveSprinkler pressure regulators:The project was implemented on an uneven topography with approximately 20m elevationdifferent between the project and this directly affect sprinkler operating pressure. When flowis downhill pressure is gained and the reverse is true. Sprinkler pressure regulators were notinstalled hence the increased pressure variation. Pressure regulators are a necessity in thisproject and will have to be incorporated into the system. Some blocks are fairly flat and othersteep. When considering the quantity of the pressure regulators this fact must be kept inmind.<strong>No</strong>zzle wearing:Measurements of the amount of sprinkler nozzle wear (mm) taken from Hlomani irrigationblocks averaged 4.2% reaching a maximum of 12%. An increase of 5% in nozzle areameans a 10% increase in flow and power demand, which means additional operating costsand over-irrigation. The ARC therefore recommends sprinkler replacement if wear is greaterthan 5% and in this project this exercise is almost due. <strong>No</strong>zzle wearing is hastened, amongstothers, by the age of the irrigation system (12 years), no intake sump, improper operation andmaintenance schedules, etc.Sprinkler nozzles were measured after the system was switched off with a specially machinedapparatus (Figure 22).Hlomani Farmer Association Report - 2009 Page - 39 -

Figure 22. Measuring apparatus for sprinkler nozzle sizeLeaksTimely maintenance and repair of minor leaks are often neglected in this system. The leaks inthe pipes of the supply network of this irrigation system caused a drop in operating pressureand an increase in pump flow. This increase in pump duty reduces the efficiency at which thepump operates, causing further pressure and delivery reductions. A drop in the operatingpressure causes a change in the performance of sprinkler, as shown in table 4 above. Theeffective application rate of the system decreased. Mainly, these leaks are observed insprinklers, sprinkler stand-dragline connections, broken dragline, pipelets, hydromatics,mainline, etc. it is important that all leaks are located quickly and repaired. A leak preventionprogram should include regular replacement of damaged draglines.Figure 23. Dragline leakageHlomani Farmer Association Report - 2009 Page - 40 -

Old AgePhase one of the irrigation system was installed in 1997, almost 12 years ago, and as yearselapsed, system efficiency reduces due to equipment wearing out. As a matter of urgencysome equipment must be replaced and the rest maintained for optimal performance. Apartfrom nozzles, sprinklers, due to old age, are underperforming. Some draglines have morethan the allowed tolerance of three joints and hydraulic valves are missing/broken pilots.These and other equipment has to be replaced.Possible ways of improving the hydraulic variation include readjustment of pressureregulating device (installing pilots on all Gulf valves) repair and/or removal of pinchedlateral/sub-main lines and the redesign of the hydraulic system.5 . 2 D e l i v e r y t e s t sThe following delivery tests were conducted:5.2.1 S p r i n k l e r d i s c h a r g eAccording to the ARC the difference in discharge in a specific irrigation block may not vary bymore than 10% from the average discharge, hence this evaluation. The discharge of thesprinklers was tested by collecting water into a container of known volume with a hose pipeconnected to the sprinkler nozzle. A minimum container size of 20 litres is recommended andtogether with a stopwatch the time it took to fill the container was recorded. The open end ofthe hose pipe was not held under water in the container, but also not so high that the watersplashed out of the container.Measurements were again taken at distances 0, L/4, L/2, 3L/4 and L on the lateral and thesprinkler line. The same points where pressure measurements were done were used and bytaking the time it took to fill the container, the discharge was calculated with the followingformula and results are shown in table 5.qe=average volume water measured incontaineraverage duration to fill container (sec)(litres)36001000…………… (10)m3/hourWhere q e = sprinkler discharge [m 3 /h]Hlomani Farmer Association Report - 2009 Page - 41 -

Nyakatfo flow variation was above the recommended maximum of 10% averaging a high of62.14%. Average sprinkler application was found to be 1.23m3/hr instead of 1.4m3/hrstipulated in the <strong>Swaziland</strong> sugar industry standards. In consideration of only Hlomaniirrigation blocks flow variation dropped to 45.05% and 1.32m3/hr average sprinkler discharge.Table 5.Discharge variation calculated from phase 1 field measurementsType of sprinkler/nozzle sizeMeasured nozzle discharge (m3/hr)VYRSA 70 11/64" nozzle 1.30Rain bird 14070 5/32 1.26Rain bird BH30 5/32" nozzle 1.39VYRSA 70 11/64" nozzle 0.91VYRSA 70 11/64" nozzle 1.28VYRSA 70 11/64" nozzle 1.49VYRSA 70 11/64" nozzle 1.02VYRSA 70 11/64" nozzle 1.52VYRSA 70 11/64" nozzle 1.64Rain bird 14070 5/32 1.03VYRSA 70 11/64" nozzle 1.68Rain bird 14070 5/32 1.08Rain bird 14070 5/32 1.09VYRSA 70 11/64" nozzle 1.55VYRSA 70 11/64" nozzle 1.44Rain bird 14070 5/32 1.10VYRSA 70 11/64" nozzle 1.06Rain bird 14070 5/32” nozzle 0.92RC 140 11/64" nozzle 1.19VYRSA 70 11/64" nozzle 0.99VYRSA 70 11/64" nozzle 1.03RC 140 11/64" nozzle 1.09Minimum Discharge (m 3 /hr) 0.91Maximum Discharge (m 3 /hr) 1.68Average Discharge (m 3 /hr) 1.23Flow variation (%) 56.83Hlomani Farmer Association Report - 2009 Page - 42 -

Sprinkler operating pressure and sprinkler discharge are directly proportional. When pressuredecreases, sprinkler nozzle discharge also decreases and vice versa. This therefore, meansall factors contributing to the low system pressure also contribute to the sprinkler nozzledischarge. The sprinklers that recorded a high operating pressure but low application rate hadleaking draglines, tripods, and/or hydromatic-pipelet connection.The effects of different nozzles/emitters and different sprinkler packages observed Hlomaniwere evaluated using the table below. Different emitters respond differently to the sameamount of pressure and table 6 below indicates the properties of the different sprinklerpackages found on site.Table 6.Technical properties of sprinklers found on site at 35m operating pressureSprinkler Package <strong>No</strong>zzle size Discharge (m3/hr Wetted Radius (m)VYRSA 70 11/64’’ 1.36 15.9Rain bird 14070 5/32’’ 1.14 14.8Rain bird BH30 5/32’’ 1.14 14.8Three sprinkler packages with two different nozzle sizes were identified as shown in table 6above. Flow variation due to the different sprinkler – nozzle combinations is 18.13% and thiscontributed to the project’s high flow variation. The average application rate of the abovecombination is 1.21m3/hr and is below the design application of 1.4m3/hr. This figureindicates that even on highly efficient pumping and supply system, irrigation efficiency will notimprove, at least not until uniformity in this regard is obtained. This different combination hasan effect also on the wetting diameter due to their different body trajectory angles.Gross application rate (GAR)The gross application rate (GAR) of the sprinkler was thereafter calculated, by means of thefollowing formula;GAR qe1000A ....…………………………………. (11) mm/hWhere; GAR = Gross Application RateA = wetted area (m 2 )Hlomani Farmer Association Report - 2009 Page - 43 -

The GAR is a fraction of emitter discharge and sprinkler spacing as indicated by equation 11above. The average GAR for Nyakatfo is 3.84mm/hr and 4.1mm/hr for Hlomani. Therecommended GAR is 4.2mm/hr and this means that Hlomani FA is slightly under-irrigating.Hlomani Farmer Association Report - 2009 Page - 44 -

6 A S S E S S M E N T O F O P E R A T I O N , M A N A G E M E N TA N D M A I N T E N A N C E O F T H E I R R I G A T I O NS Y S T E M6 . 1 O p e r a t i o nAs-built drawings and design information not availableThe fact that no design or installation information is available consigns a huge constraint onmanagement. Forward planning on aspects related to the irrigation infrastructure cannot bedone, i.e. replacement stock purchase; item like pipes, fittings, etc are procured afterbreakages because the details of that particular pipe, fitting, etc is obtained from the brokenpart. This increases their down time and negatively impacts on crop production.Operation and maintenance manual not availableThe different components forming the irrigation system require different operating proceduresand these are obtained from an operation and maintenance manual. This document, like allother documents, is not available and for efficient performance of these components, it mustbe compiled. The consequence of not having this document is seen during this evaluation inthat incorrect sequences are followed in opening and closing the pump. Also, this documenthelps in the formulation of a maintenance plan and provides guidelines to be followed duringmaintenance.Financial viability for smallholder growerThe late conclusion of loan agreements (seasonal loans) results in the late delivery of inputsand late application of fertilizers and chemicals, which reduces yields and sucrose content,resulting in reduced financial returns per hectare and inability to recoup invested capital. Inaddition, the absence of any dividends for distribution to farming association members at theend of each season can lead to a decline in the cohesion of farmers’ associations/cooperatives,a cohesion which is essential to increasing on-farm efficiency.The graph below indicates Nyakatfo productivity since inception. Sugarcane yields have beendeclining over the years with the least yield of 64.18 tonnes per hectare recorded in 1994.The highest yield ever were received 2003 and was 103.1 tonnes per hectare which is belowthe recommended average of 120 t/ha. On average this FA is producing a low of 86t/ha.Hlomani Farmer Association Report - 2009 Page - 45 -

Average Tonnes Cane per Hectare1201008060402001994 1995 1996 2003 2004 2005 2006 <strong>2007</strong> 2008Average TCH 64.18 64.94 73.91 103.1 99.49 85.79 88.97 92.67 100.83Figure 24. Nyakatfo sugarcane productivity in tones cane per hectareInterest RatesIt can be argued that even relatively large reductions in interest rates have not had anysignificant impact on the sustainability of this sector. The sector appears to have deterioratedto one of a sustained financial crisis. This, therefore, calls for an integrated programme ofaction, to look at:‣ Discounted tariffs with regards to bank charges, including administration fees.‣ A re-look at the repayment period with regard to capital loans, with a view to having itextended from the current 7 years to at least 10 yearsConsidering the reduction of interest rates on all loans to a level not exceeding 12% perannum, such measures would allow smallholder growers to realize some return on theirinvestment and to be able to eventually pay dividends to the investing members. Alternativelyother financial arrangements can be put in place without any prejudice to the commercialoperations of the financial institutions currently engaged with the sector (SSA, 2008).ElectricityEnergy costs are too high. During dry periods the pumps run continuously for 24 hours perday and 7 days a week, there is a need to have the tariffs looked at and, maybe have thetariff rate discounted for sugar cane growers to enable them to be sustainable in thebusiness. It is imperative to train the farm manager and/or pump attendants on when and howmany pumps to start at a time as this affect electricity maximum demand.Hlomani Farmer Association Report - 2009 Page - 46 -

Jan-08Feb-08Mar-08Apr-08May-08Jun-08Jul-08Aug-08Sep-08Oct-08<strong>No</strong>v-08Dec-08Currently this Nyakatfo is paying approximately E1, 512.00 per hectare per year (figure 25)and the amounts spent annually are indicated below. The average electricity bill is E33156.06and is shared by the three FAs.70,000.0060,000.0050,000.0040,000.0030,000.0020,000.00AMOUNTAVERAGE10,000.00-Figure 25. Electricity cost for Nyakatfo Pilot ProjectAppendix three shows a calculation of the amount of energy used by this FA and compares itto what should have been used per season. This maximum demand calculation gives anindication of the amount small growers spend on electricity and how much could have beensaved when pumps are operated correctly.Production CostsSugar prices are on a continual downward spiral whereas production costs have taken theopposite direction, so that if no immediate plan of action is formulated to address theproblem, most smallholder growers will slowly but surely perish. Fertilizers, herbicides, farminputs, labour costs are making it difficult for the farmers to use the best farming practices.Maybe a solution to that could also be a consortium that can be formed for the sugarcanegrowing industry to have a muscle where buying of farm inputs is concerned (SSA, 2008).Transport costsSmallholder growers feel transporters have established a gold mine at the expense ofgrowers. A large chunk of sugarcane revenue goes to the transporters and growers feel thatthere is a need to address this issue and look at ways to improve the current situation. Thenon performance of transport operators leads to a heavy loss in cane quality which also leadsHlomani Farmer Association Report - 2009 Page - 47 -

to a serious financial loss to the growers. The issue of mill distance from the farm is, in anumber of instances, of major concern. The mere construction of a bridge (s) across astream(s) would go a long way towards reducing these distances and, consequently, theattaching costs.MillersSmallholder cane growers feel that millers also have a significant role to play in assistingsmallholder growers technically, financially and otherwise. Bulk purchasing comes to mindhere as the millers are endowed with the financial muscle (economies of scale) which couldresult in discounted input prices for growers (SSA, 2008).6 . 2 M a n a g e m e n t P r a c t i c e sSchedulingEffective scheduling ensures that the correct amount of water is applied at the right time andthe correct place. As a scheduling method Hlomani FA uses the give and take method. Thismethod utilizes long term evaporation means and rainfall is accounted through rain gaugereadings. A12 hour stand time starting at 6am to 6pm was adopted with a week irrigationcycle. Occasionally the irrigation cycle increases to almost two weeks.Given:12 hours every 7 daysThus: 12 Standing time (hours)7 Cycle length (days)Already calculated: Xg = 3.84 mmThus: hours x Xg every 7 daysThus: 46.0 mm 7 daysGross mm per day = 5.5 mm/dayThus: Net mm per day = 4.13 mm/dayBased on this observation and the above calculation of net application per day, only 4.13mmis applied per day and sugarcane requires at least 6.5mm/day. Because of the low GANyakatfo schemes are by far under-irrigating. However, Hlomani has a higher net applicationof 4.9mm per day but still below daily sugarcane irrigation requirements.Hlomani Farmer Association Report - 2009 Page - 48 -

6 . 3 M a i n t e n a n c e S u r v e yWhen the impact of maintenance practices was evaluated, it was decided to classify theexisting maintenance practices followed by the producer, according to existing literaturesources as acceptable if it will not influence the performance of the system adversely andunacceptable/ineligible if it will impair the performance. The acceptable values are viewed asthe absolute minimum values for the sustaining of an acceptable Us value in the systemTable 7. Maintenance schedule for sprinkler irrigation systemsMonitorInspect the system for leakagesCheck system pressure and system flow<strong>Service</strong> air valves and hydrantsCheck sprinklers for wear and replace springs, washers andnozzles where necessaryWith eachcycleXXAnnuallyFlush mainlines -XXTable 8. Maintenance practices implemented by HlomaniMonitor Results ClassificationInspect the system for leakages Attend to leaks only UnacceptableCheck system pressure and system flow Never Unacceptable<strong>Service</strong> air valves and hydrants Never UnacceptableCheck sprinklers for wear and replace springs,washers and nozzles where necessaryNeverUnacceptableFlush mainlines Annually UnacceptableHlomani Farmer Association Report - 2009 Page - 49 -

7 C O N S T R A I N T S T O E F F I C I E N T S Y S T E MP E R F O R M A N C EPUMP STATION‣ A proper intake structure was not constructed on the suction position. The suction inlets(foot valves) are suspended at the end of the Komati River. The foot valves are notprotected in any way and are intermittently in direct contact with the bottom of the channeland debris carried with the river water.‣ Incorrectly sized fittings in suction and delivery manifolds affect system performance. Theeffects of these are severe on the eccentric reducer because it is directly attached to thepump and the sudden restriction in size increases turbulence occurrences and causeirregular feeding of the pump hence cavitation. With such an installation wearing andmaintenance cost of the pump will increase.‣ The water depth above suction inlets is below recommended minimums, and is expectedto further decrease during the dry season. Under this condition air is sucked in withirrigation water and cavitates the pump. The effects of the shallow depth on the pumpswere reflected through vortex and pump cavitation. This significantly reduced pumpefficiency and performance. It was also noted that the water level in the canal fluctuatesand is occasionally within the above recommendations, especially during the wet season.‣ The design pump duty point of 347m3/hr flow and 84m head is within the operating rangeof the installed WKLn 150/3 pumps. The 110kW four pole motors driving these pumps arecorrectly rated in this regard.‣ The pump house is constructed along the Komati river flood line with concrete blocks.When the river level raise water seeps through these blocks and fill the pump house.Recently a lot of money was spent to rewind all three motors after they were flooded.‣ The river pump house is characterised by poor floor drainage, no working space (used asstoreroom), unhygienic and hazardous conditions, etc.‣ Mechanical pump control valves are leaking and some are faulty‣ Flow measurements and pressure measurements of the pump in operation during theevaluation indicated that it was operating below optimum.‣ The pumping units are not serviced but repaired as faults develop.‣ This pump station is designed for four pumping units and three are installed. There is noback up and during repairs and/or maintenance the crop is stress for over a month onsome occasions. The third pump is hardly operated.Hlomani Farmer Association Report - 2009 Page - 50 -

MAIN LINE‣ The main delivery pipeline from the pump station to where the allocation to the differentassociation is distributed starts of as a 500mm/9 and reduces to 400mm steel. Thissection is correctly designed. From this pipeline, three diversions of 200mm steel aremade supplying water to Emadvodza Ayayengana, Bambanani Emobeni and Hlomani FAblocks.‣ The actual sizes, lengths, classes and orientation of the rest of the mainline could not beascertained. An undisputed conclusion, therefore, on whether Hlomani supply systemwas correctly designed or not cannot be drawn until details on pipe size, pipe classes,and distances occupied by the different sizes are obtained.‣ The mainline has a leak and this reduces system pressure and flow hence theunacceptable flow and pressure variation.‣ Some Air valves were leaking – overall system efficiency compromisedSPRINKLER INFIELD IRRIGATION‣ All gulf valves on hydrants were equipped with a mechanical choke instead of a pressureregulatingpilot.‣ A hydraulic check or a design was not conducted before the 16 ha expansion. Sub-mainsand/or laterals of adjacent blocks were used to extend into these new areas,consequently increasing flow in the sub-main and increasing head losses due to friction.‣ Pressure measurement results reflected an unacceptable pressure variation of 69.7% forNyakatfo Pilot Project and 24% for Hlomani blocks. The average system operatingpressure of the entire system is 272.73kPa and is below the recommended sprinkleroperating pressure of 350kPa. In consideration of Hlomani blocks only an averagesprinkler operating pressure of 333 kPa was measured, which is also belowrecommendations.‣ The average GAR for Nyakatfo is 3.84mm/hr and 4.1mm/hr for Hlomani FA. Therecommended GAR is 4.2mm/hr and this means that Hlomani FA is slightly underirrigating.‣ Sprinklers are not equipped with pressure regulators and were running on differentpressures and deliveries.‣ Three sprinkler packages with two different nozzle sizes were identified in Hlomani. Flowvariation due to the different sprinkler – nozzle combinations is 18.13% and thiscontributed to the project’s high flow variation. The average application rate of the aboveHlomani Farmer Association Report - 2009 Page - 51 -

combination is 1.21m3/hr and is below the design application of 1.4m3/hr. The differentnozzle sizes packages have an effect also on the wetting diameter due to their differentbody trajectory angle.‣ There are a lot of leaks in the system and this drastically reduced pressure.‣ Infields are characterized by reduced sprinkler operating pressure resulting mainly fromprofuse leaks; the increase in flow (from the leaks) increases friction head losses in thelateral consequently reducing sprinkler operating pressure. These leaks are observedmainly in sprinklers, sprinkler stands and dragline connections, and broken draglines.‣ The irrigation system was installed over 12 years ago, and as years elapsed, the systemefficiency reduces due to equipment wearing out. As a matter of urgency some equipmentmust be replaced and the rest maintained for optimal performance. For example, therecommended useful life of pumping units and electrics is 15 years.‣ The whole irrigation development has no drainage and subsurface and surface drains arerequired.‣ Timely maintenance and repair of minor leaks are often neglected in this system. Theleaks in the pipes of the supply network of this irrigation system caused a drop inoperating pressure and an increase in pump flow. This increase in pump duty reduces theefficiency at which the pump operates, causing further pressure and delivery reductions.‣ Measurements of the amount of sprinkler nozzle wear (mm) taken from Hlomani blocksaveraged 4.2% reaching a maximum of 12%. An increase of 5% in nozzle area means a10% increase in flow and power demand, which means additional operating costs andover-irrigation.OVERALL MANAGEMENT AND MAINTENANCEOperations‣ Financial viability for smallholder grower‣ High Interest Rates‣ Electricity cost high‣ High Transport costs‣ High Production CostsManagement and maintenance‣ <strong>No</strong> scheduling measurements were followed and under the current irrigation patterns theirrigation system cannot meet sugarcane irrigation requirement.Hlomani Farmer Association Report - 2009 Page - 52 -

‣ The frequent faults of pumps, floppy infields and mainlines place a huge constraint onmanagement.‣ Areas that require drainage are difficult to manage and identified sections of bad soils aredeveloped.‣ Without an operation and maintenance manual, management have difficulty in operatingand maintaining the system. Incorrect operation procedures are followed and impropermaintenance schedules adopted.‣ Old equipment reduces efficiency of system. This equipment includes hydromatics,draglines, tripod stands, sprinkler and nozzles. The most economic decision would be toreplace this equipment instead of maintenance.‣ The different soil series on which the project is developed has different water holdingproperties and require different irrigation patterns. These are difficult to manage.‣ Farmers do not have the required expertise on irrigation matters and end up makingexpensive mistakes.Hlomani Farmer Association Report - 2009 Page - 53 -

8 R E C O M M E N D A T I O N STo evaluate the constraints of the project properly we have decided to categorised therecommendations in four categories namelyA. Immediately: This has to been done direct after harvesting.B. Short term: This has to been done this seasonC. Medium term: This has to been done before replantD. Long term: This has to be rectified with replant.PUMP STATIONShort term:‣ Rehabilitate pump station, i.e. reduce gradient of access ladder, install drainage pumpand pipe work, implement soil and water conservation measures, etc E 80 000.00‣ Do routine maintenance on pumps and all equipment. E 20 000.00‣ Replace all incorrectly dimensioned fittings on the suction and delivery manifold with thecorrect size E 5 000.00‣ Establish arrangement with a reliable contractor to assist with the maintenance of allequipment.Medium term:‣ Replace all incorrectly dimensioned fittings (bends and reducers) on the suction anddelivery manifold with the correct size E 10 000.00‣ Construct a proper intake structure (sump) at the river pump station. E 250 000.00‣ Refurbish pump station civil works to avoid water seeping through brickwork into pumpingunits. E 100 000.00MAIN DISTRIBUTION LINEImmediately:‣ Establish exact orientation, size, and class of mainline E 20 000.00‣ Fix all leaking Air valves and control valves. E 2 500.00‣ Install additional air valves E 7 500.00Hlomani Farmer Association Report - 2009 Page - 54 -

‣ Attend to leaks on mainlines and air-valves E 10 000.00Medium term:‣ Redesigned and installed mainline to section that are under-designed E 90 000.00SPRINKLER INFIELD IRRIGATIONImmediately:‣ Rehabilitate hydraulic valves and install pressure regulating pilot E10 000.00‣ Installed additional hydraulic valves on block without hydraulic valves E 10 000.00‣ Install identical sprinklers with identical nozzle sizes and of the acceptable dischargeE 15 000.00‣ Fix all damaged sprinkler stands and replace leaking draglines and other malfunctioningequipment E 10 000.00‣ Equip all sprinklers with pressure regulators. E 20 000.00‣ Correct hydraulic design fault of blocks implemented by the FA E 105 000.00Medium term:‣ Replant all blocks containing low yielding sugarcane varieties E 20 000.00‣ Rehabilitate access/haulage roads E 140 000.00Long term:‣ Replant the areas that perform badly E 50 000.00‣ Install proper sub-surface drainage where possible E 150 000.00‣ Abandon soils with a poor potential, and plant alternative cropsOVERALL MANAGEMENT AND MAINTENANCEOperations‣ Considering the reduction or termination of interest rates on all loans, such measureswould allow smallholder growers to realize some return on their investment and to be ableto eventually pay dividends to the investing members. Alternatively other financialHlomani Farmer Association Report - 2009 Page - 55 -

arrangements can be put in place without any prejudice to the commercial operations ofthe financial institutions currently engaged with the sector.‣ There is a need to have the electricity tariffs looked at and, maybe have the tariff ratediscounted for sugar cane growers to enable them to be sustainable in the business.Pump attendance must be trained on economic ways of operating pumps.‣ A consortium could be formed for the sugarcane growing industry to have a muscle wherebuying of farm inputs is concerned. This could reduce production costsManagement‣ Compilation of an operation and maintenance manual to assist in the implementation of aproper maintenance and operation strategies for the association.‣ A proper scheduling tool must be adopted and, where possible, blocks scheduledaccording to soil type.‣ Establish arrangement with a reliable establishment to assist with the maintenance of allequipment.‣ Replace all old equipment‣ Strengthen training of FA on operation and maintenance of irrigation systemHlomani Farmer Association Report - 2009 Page - 56 -

9 C O N C L U S I O NNyakatfo pilot project is comprised of three associations Emadvodza Ayayengana, Hlomani,and Bambanani Emobeni FA. Nyakatfo is 263 ha in total and Hlomani is 71ha, the smallest ofthe three. This dragline irrigation development was designed and installed by Mhlume SugarCompany in 1997. Material was supplied by Irricon and representing Mhlume during theimplementation was Mr. Kennedy Dlamini and Mr P. Scot. After a few years, in 2008, theirrigation system was extending by Hlomani FA.Pump StationVarious challenges are faced by Hlomani regarding their pump station, the critical of which isthat the pump house is constructed along the Komati river flood line with concrete blocks.When the river level raise water seeps through these blocks and fill the pump house.Recently a lot of money was spent to rewind all three motors after they were flooded.A proper intake structure was not constructed on the suction position. The suction inlets (footvalves) are suspended at the end of the Komati River. The foot valves are not protected inany way and are intermittently in direct contact with the bottom of the channel and debriscarried with the river water.Flow measurements and pressure measurements of the pump in operation during theevaluation indicated that it was operating below optimum. This pump station is designed forfour pumping units and three are installed. There is no back up and during repairs and/ormaintenance the crop is stress for over a month on some occasions. The third pump is hardlyoperated.The design pump duty point of 347m3/hr flow and 84m head is within the operating range ofthe installed WKLn 150/3 pumps. The 110kW four pole motors driving these pumps arecorrectly rated. This pump station is therefore correctly designed.Short and medium term recommendation to rehabilitation this pump station will costapproximately E465 000.00 inclusive of constructing an intake sump and getting all pumpsrunning to full capacity.Hlomani Farmer Association Report - 2009 Page - 57 -