liquid withdrawal / transfer valves - National Energy Equipment

liquid withdrawal / transfer valves - National Energy Equipment

liquid withdrawal / transfer valves - National Energy Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PLANT, TRUCk & TANk EQUIPMENT<br />

28<br />

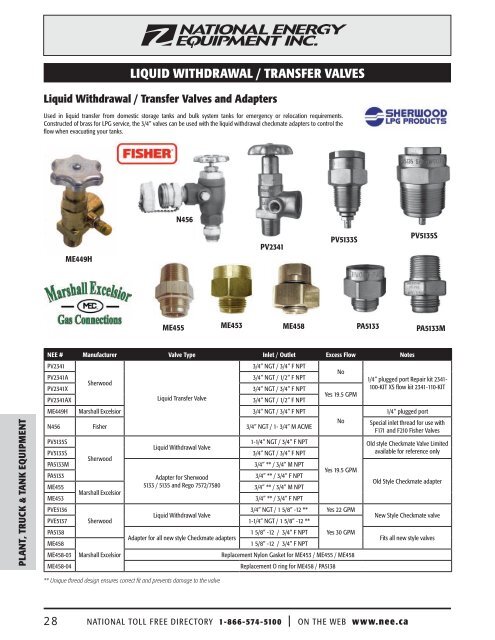

LIQUID WITHDRAWAL / TRANSFER VALVES<br />

Liquid Withdrawal / Transfer Valves and Adapters<br />

Used in <strong>liquid</strong> <strong>transfer</strong> from domestic storage tanks and bulk system tanks for emergency or relocation requirements.<br />

Constructed of brass for LPG service, the 3/4” <strong>valves</strong> can be used with the <strong>liquid</strong> <strong>withdrawal</strong> checkmate adapters to control the<br />

flow when evacuating your tanks.<br />

mE449h<br />

N456<br />

** Unique thread design ensures correct fit and prevents damage to the valve<br />

PV2341<br />

PV5133S<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca<br />

PV5135S<br />

mE455 mE453 mE458 Pa5133 Pa5133m<br />

NEE # manufacturer Valve Type Inlet / Outlet Excess Flow Notes<br />

PV2341<br />

3/4” NGT / 3/4” F NPT<br />

PV2341A 3/4” NGT / 1/2” F NPT<br />

Sherwood<br />

PV2341X 3/4” NGT / 3/4” F NPT<br />

PV2341AX Liquid Transfer Valve<br />

3/4” NGT / 1/2” F NPT<br />

ME449H Marshall Excelsior 3/4” NGT / 3/4” F NPT<br />

N456 Fisher 3/4” NGT / 1- 3/4” M ACME<br />

PV5135S<br />

1-1/4” NGT / 3/4” F NPT<br />

Liquid Withdrawal Valve<br />

PV5133S 3/4” NGT / 3/4” F NPT<br />

Sherwood<br />

PA5133M<br />

3/4” ** / 3/4” M NPT<br />

PA5133 Adapter for Sherwood<br />

3/4” ** / 3/4” F NPT<br />

ME455<br />

ME453<br />

Marshall Excelsior<br />

5133 / 5135 and Rego 7572/7580<br />

3/4” ** / 3/4” M NPT<br />

3/4” ** / 3/4” F NPT<br />

No<br />

Yes 19.5 GPM<br />

No<br />

Yes 19.5 GPM<br />

PVE5136<br />

3/4” NGT / 1 5/8” -12 ** Yes 22 GPM<br />

Liquid Withdrawal Valve<br />

PVE5137 Sherwood<br />

1-1/4” NGT / 1 5/8” -12 **<br />

PA5138<br />

ME458<br />

Adapter for all new style Checkmate adapters<br />

1 5/8” -12 / 3/4” F NPT<br />

1 5/8” -12 / 3/4” F NPT<br />

Yes 30 GPM<br />

ME458-03 Marshall Excelsior<br />

Replacement Nylon Gasket for ME453 / ME455 / ME458<br />

ME458-04 Replacement O ring for ME458 / PA5138<br />

1/4” plugged port Repair kit 2341-<br />

100-KIT XS flow kit 2341-110-KIT<br />

1/4” plugged port<br />

Special inlet thread for use with<br />

F171 and F210 Fisher Valves<br />

Old style Checkmate Valve Limited<br />

available for reference only<br />

Old Style Checkmate adapter<br />

New Style Checkmate valve<br />

Fits all new style <strong>valves</strong>

LIQUID WITHDRAWAL / TRANSFER VALVES<br />

Liquid Fill / Withdrawal and Vapor Return Valves<br />

The A1590 consists of a service valve, filling connection and excess flow valve. Made of ductile Iron and stainless steel,<br />

these <strong>valves</strong> are suitable for LP and NH3 service. The A1592 is a combination fill and <strong>liquid</strong> <strong>withdrawal</strong> valve with excess<br />

flow intended for NH3 service. The A1596 and A1597 series <strong>valves</strong> have an excess flow valve on the inlet and an integral<br />

hydrostatic relief valve that vents hose pressure back to the container when it exceeds the container pressure by 50 PSI.<br />

NEE #<br />

Container<br />

Connection<br />

Outlet<br />

Connection<br />

Fill Connection application<br />

1/4” F NPT<br />

Side Outlet<br />

A1590B 1-1/4” M NPT 1-3/4” M ACME 1-3/4” M ACME LP or NH3, Filling or Vap. w/ Bleed Valve<br />

A1590P 1-1/4” M NPT 1-3/4” M ACME 1-3/4” M ACME Return<br />

Plugged<br />

A1592R 1-1/4” M NPT 1” F NPT 1-3/4” M ACME<br />

A1596R 1-1/4” M NPT 1” F NPT None<br />

A1597R 1-1/4” M NPT 1” F NPT None<br />

NH3, Filling or Liquid<br />

Withdrawal<br />

LP or NH3, Liquid<br />

Withdrawal<br />

w/ Hydrostatic<br />

valve<br />

30 GPM xs flw,<br />

built in rlf.<br />

50 GPM xs flw,<br />

built in rlf.<br />

A1598P 1-1/4” M NPT 1” F NPT None Plugged<br />

A1599P 1-1/4” M NPT None 1-3/4” M ACME<br />

NH3, Filling or Vapor<br />

Withdrawal<br />

w/ Back check<br />

Valve<br />

A1596 / A1597 / A1598 Liquid Withdrawal Rates A1590 / 1592 Filling Rates<br />

Valve Withrawal rate differential Closing rate<br />

a1596r<br />

LPG 35 GPM 13 PSIG<br />

NH3 30 GPM<br />

a1597 / a1598<br />

LPG 55 GPM 13 PSIG<br />

NH3 50 ppm<br />

Vapor or Liquid Service Valves<br />

Designed for bulk plant or truck piping systems, these valve can be used for LP gas or NH3 and are supplied with or<br />

without excess flow devices for <strong>liquid</strong> or vapor service.<br />

NEE # Tank Connection Outlet Excess Flow Features<br />

AL407P 3/4” M NPT 1/2” F NPT No Plugged 1/4” F NPT side outlet<br />

AL407EP 3/4” M NPT 1/2” F NPT Yes Plugged 1/4” F NPT side outlet<br />

AL409P 3/4” M NPT 3/4” F NPT No Plugged 1/4” F NPT side outlet<br />

AL409EP 3/4” M NPT 3/4” F NPT Yes Plugged 1/4” F NPT side outlet<br />

AL477EP 1-1/4” M NPT 1” F NPT Yes Plugged 1/4” F NPT side outlet<br />

AL477ER 1-1/4” M NPT 1” F NPT Yes With Hydrostat valve installed<br />

AL478EP 1-1/4” M NPT 1-1/4” F NPT Yes Plugged 1/4” F NPT side outlet<br />

AL479R 1 1/2” M NPT 1-1/4” F NPT No Plugged 1/4” F NPT side outlet<br />

a1590P<br />

differential Pressure, PSIg<br />

Service 5 10 20 30 40 50<br />

al409P<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 29<br />

gPm<br />

a1597r<br />

NH3 46 62 85 98 GPM 114 119 GPM<br />

LPG 39 56 76 90 GPM 104 114 GPM<br />

a1592<br />

NH3 25 38 52 61 GPM 70 78 GPM<br />

PLANT, TRUCk & TANk EQUIPMENT

PLANT, TRUCk & TANk EQUIPMENT<br />

Globe & Angle Valves<br />

Heavy duty and economy globe and angle <strong>valves</strong> are used in plant or truck piping<br />

systems to control gas flow. All <strong>valves</strong> are designed with a 1/4” F NPT plugged boss<br />

in the downstream side of the valve where a hydrostatic relief valve, pressure gauge<br />

or vent valve can be installed. All <strong>valves</strong> have teflon packing, non-rotating seat<br />

disc and ductile iron bodies. Economy <strong>valves</strong> have a threaded bonnet assembly<br />

and the heavy duty <strong>valves</strong> have a flanged bonnet. The Marshall Excelsior <strong>valves</strong><br />

have all stainless steel internal components making them suitable for LPG and NH3<br />

applications. The Fisher economy <strong>valves</strong> are only suitable for LP service.<br />

NEE # Type Size F NPT Style Features<br />

N301-04 Fisher 1/2” Globe Heavy Duty<br />

N350-04 Fisher 1/2” Globe Economy<br />

N401-04 Fisher 1/2” Angle Heavy Duty<br />

N450-04 Fisher 1/2” Angle Economy<br />

N301-06 Fisher 3/4” Globe Heavy Duty<br />

N350-06 Fisher 3/4” Globe Economy<br />

N401-06 Fisher 3/4” Angle Heavy Duty<br />

N450-06 Fisher 3/4” Angle Economy<br />

N301-08 Fisher 1” Globe Heavy Duty<br />

N401-08 Fisher 1” Angle Heavy Duty<br />

N310-10 Fisher 1-1/4” Globe Heavy Duty<br />

N410-10 Fisher 1-1/4” Angle Heavy Duty<br />

N310-12 Fisher 1-1/2” Globe Heavy Duty<br />

N410-12 Fisher 1-1/2” Angle Heavy Duty<br />

N310-16 Fisher 2” Globe Heavy Duty<br />

N410-16 Fisher 2” Angle Heavy Duty<br />

N310-24 Fisher 3” Globe Heavy Duty<br />

N410-24 Fisher 3” Angle Heavy Duty<br />

N310F-24 Fisher 3” ANSI Flanged Globe Heavy Duty<br />

N410F-24 Fisher 3” ANSI Flanged Angle Heavy Duty<br />

ME825-4 Marshall Excelsior 1/2” Globe Economy<br />

ME815-4 Marshall Excelsior 1/2” Angle Economy<br />

30<br />

Economy<br />

globe Valve<br />

GLOBE & ANGLE VALVES<br />

Economy<br />

angle Valve<br />

NEE # Type Size F NPT Style Features<br />

ME825-6 Marshall Excelsior 3/4” Globe Economy<br />

ME815-6 Marshall Excelsior 3/4” Angle Angle<br />

ME825-8 Marshall Excelsior 1” Globe Heavy Duty<br />

ME815-8 Marshall Excelsior 1” Angle Heavy Duty<br />

ME825-10 Marshall Excelsior 1-1/4” Globe Heavy Duty<br />

ME815-10 Marshall Excelsior 1-1/4” Angle Heavy Duty<br />

ME825-16 Marshall Excelsior 2” Globe Heavy Duty<br />

ME815-16 Marshall Excelsior 2” Angle Heavy Duty<br />

AL410P Squibb Taylor 1/2” Globe Economy<br />

AL411P Squibb Taylor 1/2” Angle Economy<br />

AL308P Squibb Taylor 3/4” Globe Heavy Duty<br />

AL412P Squibb Taylor 3/4” Globe Economy<br />

AL309P Squibb Taylor 3/4” Angle Heavy Duty<br />

AL413P Squibb Taylor 3/4” Angle Economy<br />

AL310P Squibb Taylor 1” Globe Heavy Duty<br />

AL311P Squibb Taylor 1” Angle Heavy Duty<br />

AL312P Squibb Taylor 1-1/4” Globe Heavy Duty<br />

AL313P Squibb Taylor 1-1/4” Angle Heavy Duty<br />

AL314P Squibb Taylor 1-1/2” Globe Heavy Duty<br />

AL315P Squibb Taylor 1-1/2” Angle Heavy Duty<br />

AL316P Squibb Taylor 2” Globe Heavy Duty<br />

AL317P Squibb Taylor 2” Angle Heavy Duty<br />

AL316FP Squibb Taylor 2” ANSI Flanged Globe Heavy Duty<br />

AL317FP Squibb Taylor 2” ANSI Flanged Angle Heavy Duty<br />

AL320P Squibb Taylor 3” Globe Heavy Duty<br />

AL321P Squibb Taylor 3” Angle Heavy Duty<br />

AL320FP Squibb Taylor 3” ANSI Flanged Globe Heavy Duty<br />

AL321FP Squibb Taylor 3” ANSI Flanged Angle Heavy Duty<br />

heavy duty<br />

angle Valve<br />

E-Z Turn Knob<br />

Sold Separately<br />

Shown in Open<br />

Position<br />

heavy duty<br />

globe Valve<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca

ComBo VaLVes, Liquid LeVeL gauges & VaPor return VaLVes<br />

Combo Valves<br />

Designed for installation in many LPG containers to give positive visual indication of tank pressure and<br />

<strong>liquid</strong> reaching the maximum allowable <strong>liquid</strong> level.<br />

NEE # Alternate<br />

Tank<br />

Connection<br />

Outlet Connection<br />

J415 ME830<br />

2 x 1/4” F NPT<br />

3/4” M NPT<br />

J415-1 - Vent Valve and 0-400 PSI pressure gauge<br />

Liquid Level gauges<br />

PVE10D<br />

PV10B<br />

PV10D PV10DB<br />

Canada’s Leader in energy ProduCts equiPment 31<br />

J415<br />

J415-1<br />

Used to determine when a container is filled to the 80% level. These <strong>valves</strong> are available with or<br />

without diptubes and have a no 54 drill hole orifice to limit the <strong>liquid</strong> flow when the tank coupling<br />

is not orificed (except PV10DRF).<br />

PV10DRF MEJ410<br />

PVE10D<br />

Vapor return Valves<br />

NEE # Alternate Inlet Description<br />

PVE10D MEJ400 1/4” M NPT Brass bleeder valve<br />

PV10BD-12.0 MEJ410-120 1/4” M NPT With 12” dip tube (can be cut to length)<br />

PV10ARF 1/4” M NPT 1/4” flare male outlet, 90°<br />

PV10DRF 1/4” M NPT 1/4” flare male outlet, 90° (no #54 orifice)<br />

J402S MEJ402S 1/4” M NPT Stainless Steel bleeder valve w/ T handle<br />

A1911 1/4” M NPT Stainless Steel bleeder valve w/ knurled handle<br />

1931-24B MEJ401 Replacement stem and seat disc asembly<br />

1449<br />

Stainless Steel 1/4” F x M snubber with # 54 drill hole orifice<br />

for use in non-orificed tank openings<br />

011 Plastic stop filling dial<br />

Used for vapor equalizing to speed up the filling process. The PV1876 has an upper positive back check valve and a lower excess flow valve. Attachment of the vapor hose<br />

fitting with its projecting nozzle, opens the back check valve to permit flow in both directions.<br />

NEE # Container Connection ACME Thread Repair Kit<br />

PV1876 3/4” NPT 1 1/4” M ACME 1876-100-KIT<br />

ME108 1-1/4” Plastic ACME Cap<br />

ME108-1 Cap w/ ring and chain<br />

PV1876<br />

PLant, truCK & tanK equiPment

PLANT, TRUCk & TANk EQUIPMENT<br />

Filler Valves<br />

Available in a variety of designs for<br />

domestic, lift truck, bulk and motor<br />

fuel containers, they normally<br />

contain a combination soft seated<br />

upper back check and a metal to<br />

metal lower back check seat.<br />

32<br />

FILLER VALVES & UNLOADING ADAPTERS<br />

Larger heavy duty filler <strong>valves</strong> are<br />

used on ASME tanks in bulk plants,<br />

as well as mobile bobtail and<br />

transport trucks and are available<br />

in single and double back check<br />

configurations.<br />

NEE # Container / Inlet Connection Filler Connection Back Check Type Fill rate at 10 PSI differential<br />

PV1855SD 3/4” NPT 1 3/4” ACME Double 19 GPM<br />

PV1855SD-30 3/4” NPT 1 3/4” ACME - 30° angle fill Double 19 GPM<br />

PV1855SD-90 3/4” NPT 90° 1/2” Male Flare Double 19 GPM<br />

PV1855SPD 3/4” NPT 3/4” F NPT Double 19 GPM<br />

PV1855BRCN 1/2” SAE Flare 1 3/4” ACME Single 19 GPM<br />

PV623B 1-1/4” NPT 1 3/4” ACME Double 70 GPM<br />

D138 2” NPT 2 1/4” ACME Single 105 GPM<br />

D140 2” NPT 2 1/4” ACME Double 100 GPM<br />

D139 3” NPT 3 1/4” ACME Single 275 GPM<br />

D141 3” NPT 3 1/4” ACME Double 225 GPM<br />

1850-3 1-3/4” Plastic ACME cap 1-3/4” Plastic ACME cap 1-3/4” Plastic ACME cap 1-3/4” Plastic ACME cap<br />

1850-10 1-3/4” Plastic ACME cap, with strap 1-3/4” Plastic ACME cap, with strap 1-3/4” Plastic ACME cap, with strap 1-3/4” Plastic ACME cap, with strap<br />

G216B 1 3/4” O ring 1 3/4” O ring 1 3/4” O ring 1 3/4” O ring<br />

MEW2 1 3/4” ACME Washer 1 3/4” ACME Washer 1 3/4” ACME Washer 1 3/4” ACME Washer<br />

Unloading Adapters<br />

PV1855Sd-30<br />

PV1855SPd<br />

d140 / d141<br />

Sherwood’s unloading adapters allow Liquid LPG to be evacuated from older domestic tanks where<br />

the 1-3/4” ACME fill valve is installed in a coupling that is attached to a tube that allows <strong>liquid</strong> to<br />

be evacuated from the bottom of the tank for emergency, or when the tank needs to be relocated.<br />

Counter-clockwise turning of the handwheel will mechanically open the main poppet and back check<br />

under tank pressure. Use of these unloading adapters with other manufacturer’s filler <strong>valves</strong> is not<br />

recommended and may damage the filler valve or cause excessive leaking.<br />

NEE # Outlet Valve to be Opened repair Kit<br />

PV902A 3/4” NPT PV623A 902-100-KIT<br />

PV903A 3/4” NPT PV623B / PV1855SD 903-100-KIT<br />

PV903B 1/2” NPT PV623B / PV1855SD 903-100-KIT<br />

PV1855Sd-90<br />

d138 / d139<br />

PV1855BrCN<br />

PV623B<br />

OLDER STyLE<br />

PV902a<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca<br />

PV1855Sd<br />

NEWER STyLE<br />

PV903a /<br />

PV903B

Marshall Excelsior Hose End Valves<br />

HOSE END VALVES<br />

Available in various sizes and configurations for applications ranging from cylinder filling to high flow bulk tank and automotive refueling.<br />

Marshall Excelsior’s Hose end valve is pressure tested to 600 PSI and features a user friendly handle, minimal product loss at disconnect<br />

of the ME 800 (less than 0.5cc), self locking 360º rotating handle, powder coated body and a high flow design. Suitable for LPG and NH3<br />

applications.<br />

NEE # Type/application Inlet Outlet Notes<br />

ME800<br />

ME800EXT<br />

ME800WS<br />

ACME hose end<br />

valve<br />

Long ACME hose<br />

end valve<br />

ACME hose end<br />

valve w/ swivel<br />

1” F NPT<br />

ME800-USRK Upper Seal replacement kit<br />

1-3/4” F<br />

ACME<br />

ME800-SARK Stem Assembly replacement kit<br />

ME800-LSRK Lower Seal replacement kit<br />

ME810-4<br />

1/2” F NPT 1/2” F NPT<br />

ME810-6<br />

Angle hose end<br />

valve<br />

3/4” F NPT 3/4” F NPT<br />

ME810-8 1” F NPT 1” F NPT<br />

ME820-4<br />

1/2” F NPT 1/2” F NPT<br />

ME820-6<br />

Globe hose end<br />

valve<br />

3/4” F NPT 3/4” F NPT<br />

ME820-8 1” F NPT 1” F NPT<br />

Squibb Taylor Hose End Valves<br />

With locking /<br />

rotating handle<br />

6” longer for hard<br />

to reach areas<br />

With 1” EZ-Turn<br />

swivel installed<br />

For ME800<br />

Squibb Taylor’s Hose End Valve features ductile iron construction, steel bonnet,<br />

aluminum locking handle and is suitable for LPG and NH3 service.<br />

NEE # Type/application Inlet Outlet<br />

AL343 ACME hose end valve* 1” F NPT 1-3/4” F ACME<br />

AL345P Angle hose end valve 1” F NPT 1” F NPT<br />

AL416P Globe hose end valve 1/2” F NPT 1/2” F NPT<br />

AL417P Globe hose end valve 3/4” F NPT 3/4” F NPT<br />

AL344P Globe hose end valve 1” F NPT 1” F NPT<br />

* with locking / rotating handle<br />

al417P<br />

mE810<br />

mE820<br />

al343<br />

mE800<br />

al345P<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 33<br />

PLANT, TRUCk & TANk EQUIPMENT

PLANT, TRUCk & TANk EQUIPMENT<br />

Quick Acting Valves<br />

34<br />

QUICk ACTING VALVES<br />

Available with or without locking handles, brass construction for LP gas service only. All <strong>valves</strong> feature a replaceable bonnet assembly.<br />

NEE # alternate description Inlet Outlet repair Kits Sherwood / marshall Excelsior<br />

LV440<br />

440-50-KIT<br />

1/4” F NPT 1/4” F NPT<br />

LV440L w/ Locking Handle 440-50L-KIT<br />

LV440A 3/8” F NPT 3/8” F NPT 440-50-KIT<br />

LV440B ME791C<br />

440-50-KIT / ME791K<br />

1/2” F NPT 1/4” F NPT<br />

LV440BL ME792C w/ Locking Handle 440-50L-KIT / ME 792K<br />

LV440C ME791D<br />

440-50-KIT / ME791K<br />

1/2” F NPT 1/2” F NPT<br />

LV440CL ME792D w/ Locking Handle 440-50L-KIT / ME 792K<br />

lV440 lV440l<br />

Pneumatic Automatic Filling Guns<br />

Features:<br />

■ Filling is initiated as soon as the valve is connected.<br />

■ Air operated - Air-release and gas flow stoppage in one quick motion.<br />

■ Fits easily into any tank collar.<br />

■ Balanced for easy suspension.<br />

mE792d<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca<br />

mE791d<br />

NEE # Inlet Pneumatic Connection Fill Connection<br />

129A003<br />

POL<br />

129A006 1/4” F NPT 3/8” F NPT AIR 1 1/4” ACME Forklift<br />

129A009 QCC Type one ACME

Hose End Fill Nozzles & Adapters<br />

HOSE END NOZZLES & ADAPTERS<br />

Used in conjunction with ball, globe, angle, toggle or quick acting <strong>valves</strong> to adapt hoses to various container filling requirements. The<br />

adapers listed allow hose end <strong>valves</strong> designed for specific container <strong>valves</strong> to be adapted to various other valve styles allowing multiple<br />

valve configurations to be filled with single hose dispensing systems.<br />

NEE # Inlet Size Outlet Connection application Notes<br />

ME390 1/4” M NPT M POL POL Cyl. Fill nozzle, 6” OAL<br />

ME390S 1/4” M NPT M POL ME390 w/ steel nipple<br />

mE393<br />

mE516<br />

mE515<br />

Filler Hose Check Valve Adapters<br />

mE392<br />

mE635<br />

These adapters are intended to be attached to the LP gas delivery truck hose outlet. All have<br />

minimal flow restriction and a single back check valve that will allow the driver to leave it on the<br />

container valve in the event of a filler valve failure preventing the loss of product and allowing<br />

the driver to wait until the container is emptied before attempting valve repair.<br />

NEE # Inlet Outlet Notes<br />

ME568 F POL 1 3/4” F. ACME Swivel<br />

ME570<br />

ME572<br />

1 3/4” F. ACME Non-Swivel<br />

ME574 1 3/4” F. ACME Swivel<br />

With Bleeder Vent Valve<br />

ME578<br />

1 3/4”<br />

M ACME<br />

Full flow ball valve shut-off<br />

M570 1 3/4” F. ACME Non-Swivel Outer washer T13098 / Inner T13103<br />

PA901B<br />

1 3/4” F. ACME Swivel<br />

PA901BTM Easy Grip Handle<br />

mE790<br />

replacement O ring - 568-110-01<br />

replacement st. st. stem 390SWR-1<br />

ME515 1/4” M NPT F. 1-5/16” Type 1 ACME QCC Cyl. Fill nozzle, 7” OAL EZ Grip Handle<br />

ME516 1/4” M NPT F. 1-5/16” Type 1 ACME QCC Cyl. Fill nozzle, 6” OAL Standard Grip w/ Hand wheel<br />

ME388 1/4” M NPT M POL POL Cyl. Fill nozzle, 2 11/16” OAL<br />

ME392 F. POL F. 1-5/16” Type 1 ACME QCC Cyl. Fill adapter, 2 1/2” OAL<br />

ME393 M. 1-5/16” Type 1 ACME M POL QCC Cyl. Fill to POL adapter, 2 1/2” OAL Round Brass Handweel<br />

ME393HD M. 1-5/16” Type 1 ACME M POL QCC Cyl. Fill to POL adapter, 2 1/2” OAL Forged Brass Handwheel<br />

ME394 M. 1-5/16” Type 1 ACME F 1-1/4” ACME QCC fill to Forklift Adapter<br />

ME569 M. 1-5/16” Type 1 ACME F 1-3/4” ACME QCC fill to Auto valve Adapter<br />

ME393-1 M. 1-5/16” Type 1 ACME 1/4” F NPT QCC fill to your choice Adapter<br />

ME790 1/4” M NPT 1 1/4” M Lift truck Valve Forklift Cylinder Fill nozzle<br />

ME635-4 1/2” M NPT 1 3/4” F ACME 1 3/4” Extended ACME Coupling<br />

ME635-6 3/4” M NPT 1 3/4” F ACME 1 3/4” Extended ACME Coupling<br />

ME635-8 1” M NPT 1 3/4” F ACME 1 3/4” Extended ACME Coupling<br />

ME635-10 1-1/4” M NPT 1 3/4” F ACME 1 3/4” Extended ACME Coupling<br />

ME568 F. POL 1 3/4” F ACME Short Brass POL to ACME adapter With swivel ACME<br />

PA901H F. POL 1 3/4” F ACME Short Brass POL to ACME adapter<br />

mE388<br />

mE390<br />

mE568 mE570 Pa901B<br />

mE578<br />

m570 Pa901BTm<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 35<br />

PLANT, TRUCk & TANk EQUIPMENT

PLANT, TRUCk & TANk EQUIPMENT<br />

Female ACME Swivel Couplings<br />

36<br />

ACME SWIVEL COUPLINGS & ACME ADAPTERS<br />

Steel and brass ACME couplings for <strong>liquid</strong> valve connections. These adapters are used on the outlet side of globe or angle <strong>valves</strong> and<br />

quick acting <strong>valves</strong> as well as hose ends to allow various connections for <strong>liquid</strong> <strong>transfer</strong>. The new E-Z grip design used on the larger<br />

sized adapters are now available on the 1-3/4” ACME sizes to allow the <strong>valves</strong> to be operated with more ease when wearing gloves.<br />

Various materials of construction allow them to be used for LP (brass) or NH3 (steel) applications.<br />

NEE # grip type Female acme<br />

ME100<br />

ME101<br />

ME110<br />

mE100<br />

mE121S<br />

mE111S<br />

mE646<br />

Male ACME by Male Pipe Thread Brass and Steel Adapters<br />

NEE # Type aCmE Size male Pipe Size Notes<br />

ME498-4/2<br />

1/2” M NPT & 1/4” F NPT Dual<br />

1 1/4” Male<br />

ME498-6/3 3/4” M NPT & 3/8” F NPT Threaded<br />

ME215<br />

3/4” M NPT<br />

ME216 1 3/4” Male 1” M NPT<br />

ME217<br />

ME233<br />

1 1/4” M NPT<br />

ME502-12/8<br />

ME502-16/10<br />

Brass<br />

2 1/4” Male<br />

1 1/2” M NPT & 1” F NPT<br />

2” M NPT & 1-1/4” F NPT<br />

ME502-16/12 2” M NPT & 1-1/2” F NPT<br />

ME503-16<br />

Brass, Knurled<br />

1 1/4”<br />

ME503-20 2 1/2” M NPT<br />

**<br />

Dual<br />

Threaded<br />

2” M NPT **<br />

ME262 3 1/4” Male 3” M NPT **<br />

ME503J-16 2” M NPT<br />

M504-24 4 1/4” Male 3” M NPT<br />

Pipe Thread<br />

Size<br />

3/8” MNPT<br />

1/2” MNPT<br />

ME110C Brass, Wing E-Z Grip<br />

ME111 Brass, Knurled<br />

ME111C<br />

ME111S<br />

Brass, Wing E-Z Grip<br />

Steel, Knurled<br />

3/4” MNPT<br />

ME111SC Steel, Wing E-Z Grip<br />

1 3/4”<br />

ME112 Brass, Knurled<br />

ME112C<br />

ME112S<br />

Brass, Wing E-Z Grip<br />

Steel, Knurled<br />

1” MNPT<br />

ME112SC Ductile Iron, Steel,<br />

ME113SC Wing E-Z Grip<br />

3/4” FNPT<br />

ME120<br />

ME120S<br />

ME121S<br />

Brass, Wing E-Z Grip<br />

Steel, Knurled<br />

2 1/4” - Brass Nipple<br />

2 1/4” - Steel Nipple<br />

1 1/4” MNPT<br />

ME130<br />

ME130B<br />

Brass, Wing E-Z Grip<br />

3 1/4” - Steel Nipple<br />

3 1/4” - Brass Nipple 2” MNPT<br />

ME130S Steel, Wing E-Z Grip 3 1/4” - Steel Nipple<br />

With 1/4” F<br />

NPT vent hole<br />

for bleeder<br />

Steel and brass ACME adapters for vapor equalizing<br />

applications. These adapters feature a protruding<br />

nose piece that opens the check valve to allow<br />

vapor equalizing through <strong>valves</strong> that incorporate<br />

an upper check valve mechanism.<br />

NEE # Type<br />

Female<br />

aCmE<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca<br />

Brass<br />

male Pipe<br />

Thread Size<br />

ME140<br />

3/8”<br />

1 1/4”<br />

ME141 1/2”<br />

ME150<br />

ME151<br />

ME141S<br />

ME646-4<br />

Steel<br />

1 3/4”<br />

3/4”<br />

1” (3 1/4”<br />

OAL)<br />

1 1/4” 1/2”<br />

1 3/4”<br />

1/2” (7”<br />

OAL)<br />

ME150S 3/4”<br />

ME646-6 3/4” (7” OAL)<br />

ME151S<br />

1” (3 1/4”<br />

OAL)<br />

ME646-8 1” (7” OAL)<br />

ME646-10<br />

** Also available with a strainer screen installed.<br />

ACME Adapters<br />

ME160S 2 1/4”<br />

mE233 mE503S-16 mE503J-16<br />

1” (7 1/4”<br />

OAL)<br />

1 1/4” (3<br />

3/8” OAL)<br />

NEE # Type aCmE Size male Pipe Size Notes<br />

ME520S-8<br />

ME521S-4<br />

1 1/4” Male 1” M NPT<br />

1/2” M NPT<br />

ME216S 1 3/4” Male 1” M NPT<br />

ME217S<br />

1 1/4” M NPT<br />

ME233S Steel 2 1/4” Male **<br />

ME503S-16<br />

2” M NPT **<br />

ME262S 3” M NPT **<br />

3 1/4” Male<br />

With 1/4” F<br />

ME503JS-16 2” M NPT NPT vent hole<br />

for bleeder

Male ACME by Female Pipe Thread Brass and Steel Adapters<br />

NEE # Type aCmE Size Female Pipe Size Notes<br />

ME498-4/2<br />

1/2” M NPT and 1/4” F NPT<br />

ME498-6/3 3/4” M NPT and 3/8” F NPT<br />

1 1/4” Male<br />

ME192 1/2” F NPT<br />

ME193 3/4” F NPT<br />

ME209<br />

3/8” F -16UNC<br />

ME210 1/4” F NPT<br />

ME211 1 3/4” Male<br />

3/8” F NPT<br />

ME212 1/2” F NPT<br />

ME213 3/4” F NPT<br />

ME214 Brass<br />

1” F NPT<br />

ME502-12/8<br />

1 1/2” M NPT and 1” F NPT<br />

ME502-16/10 2 1/4” Male<br />

2” M NPT and 1-1/4” F NPT<br />

ME502-16/12 2” M NPT and 1-1/2” F NPT<br />

ME250<br />

ME251 1 1/2” F NPT<br />

ME252-16<br />

ME252J-16<br />

ME508-24<br />

3 1/4” Male<br />

M509-24 4 1/4” Male<br />

ME209S<br />

Dual Threaded<br />

To Secure Hose End Valve<br />

to deck<br />

Dual Threaded<br />

1 1/4” F NPT **<br />

2” F NPT<br />

3” F NPT<br />

3/8” F -16UNC<br />

1 3/4” Male<br />

ME213S 3/4” F NPT<br />

ME214S 1” F NPT<br />

With 1/4” F NPT vent hole<br />

for bleeder<br />

ME502S-16/10 2 1/4” Male 2” M NPT and 1-1/4” F NPT Dual Threaded<br />

ME252S-16<br />

Steel<br />

ME252SJ-16<br />

ME508S-24<br />

3 1/4” Male<br />

M529-24 4 1/4” Male<br />

** Also available with a strainer screen installed.<br />

ACME ADAPTERS<br />

2” F NPT<br />

3” F NPT<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 37<br />

**<br />

To Secure Hose End Valve<br />

to deck<br />

With 1/4” F NPT vent hole<br />

for bleeder<br />

**<br />

mE192<br />

mE214S<br />

mE502-12/8<br />

mE252S-16<br />

PLANT, TRUCk & TANk EQUIPMENT

PLANT, TRUCk & TANk EQUIPMENT<br />

Male ACME by Male ACME Adapters<br />

NEE # Type aCmE Size<br />

ME270<br />

ME273 1-3/4” Male<br />

Brass<br />

ME275 2-1/4” Male<br />

38<br />

1-1/4” Male<br />

ME277 3-1/4” Male<br />

ACME Adapter Caps<br />

NEE # Type Size<br />

mE273<br />

ME611 Brass 2 1/4” F ACME X 1 3/4” M ACME<br />

ME612 Brass 3 1/4” F ACME x 1 3/4” M ACME<br />

ME442 Brass 3 1/4” F ACME X 1 1/4” F NPT<br />

ME614 Brass 3 1/4” F ACME x 2 1/4” M ACME<br />

ME611S Steel 2 1/4” F ACME X 1 3/4” F ACME<br />

ME612S Steel 3 1/4” F ACME x 1 3/4” M ACME<br />

ACME Dust Plugs<br />

NEE # description Size m aCmE<br />

ME178 Plastic 1 1/4”<br />

ME179 Plastic 1 3/4”<br />

ME180 Plastic 2 1/4”<br />

ME181 Plastic 3 1/4”<br />

ME178-1 Plastic w/Chain 1 1/4”<br />

ACME ADAPTERS<br />

NEE # Type aCmE Size<br />

ME273S<br />

mE611<br />

1-3/4” Male<br />

ME275S 2-1/4” Male<br />

Steel<br />

ME277S 3-1/4” Male<br />

M536-34 4-1/4” Male<br />

mE442<br />

NEE # description Size m aCmE<br />

ME179-1 Plastic w/Chain 1 3/4”<br />

ME180-1 Plastic w/Chain 2 1/4”<br />

ME181-1 Plastic w/Chain 3 1/4”<br />

M239 Aluminum 1 3/4”<br />

M535-34 Steel 4 1/4”<br />

mE273S<br />

mE612S<br />

mE178<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca

ACME Caps<br />

mE106<br />

Ring & Chain Assemblies<br />

mEP167<br />

mE109 mE108<br />

mE229 mE431F<br />

NEE # (Plastic) NEE # (Brass) NEE # (Steel) Size F aCmE Notes<br />

Plastic Brass Steel F aCmE<br />

ME108 - -<br />

1 1/4”<br />

ME108-1 - - w/ Chain<br />

ME109 1850-3 ME229 ME 229S<br />

1 3/4”<br />

ME109-1 1850-10 ME229-1 ME 229S-1 w/ Chain / Strap<br />

- ME431F ME431FS<br />

2 1/4”<br />

- ME431F-1 ME431FS-1 w/ Chain<br />

ME106 ME441F ME441FS<br />

3 1/4”<br />

ME106-1 ME441F-1 ME441FS-1 w/ Chain<br />

- M605-34 - 4 1/4”<br />

Wing E-Z Grip ACME Caps<br />

NEE # Type Size F aCmE Note<br />

mEP147<br />

mEP148<br />

ACME ADAPTERS<br />

ME229F Brass w/ knob for chain 1-3/4” Wing E-Z Grip<br />

ME229F-1 Brass w/ knob for chain 1-3/4” Wing E-Z Grip w/ Chain<br />

ME229FS Steel w/ knob for chain 1-3/4” Wing E-Z Grip<br />

ME229FS-1 Steel w/ knob for chain 1-3/4” Wing E-Z Grip w/ Chain<br />

mE441F-1<br />

NEE # NEE # (For Cap and Plug)<br />

MEP147 P147 1850-3, 1875-3A, ME178, 108.109<br />

MEP148 P148 ME179, 180<br />

MEP167 P167 ME443, 441, 535<br />

MEP183 P183 ME181<br />

mE229F mE229FS<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 39<br />

PLANT, TRUCk & TANk EQUIPMENT

PLANT, TRUCk & TANk EQUIPMENT<br />

Washers & O-Rings<br />

40<br />

mEW5<br />

1E8126<br />

a3184-8r<br />

B231<br />

1h2917<br />

mEW6<br />

1E8128<br />

a3194-8r<br />

ACME ADAPTERS<br />

NEE # NEE # (alternate) aprox. Size Style - Nominal Size application<br />

0015-0004 130122 51 mm OD Gasket Sr. Sr. Float Gauges<br />

0015-0007 130121 37 mm OD Gasket Jr. Jr. Float Gauges<br />

MEW4 1425BA-8 21 mm OD Gasket 1-1/4” 1 1/4” ACME Forklift valve connector<br />

MEW2 A2697-20R / 1E8124 35 mm OD Gasket 1-3/4”<br />

MEW3 1E812203022 23 mm OD Gasket 1-1/4”<br />

MEW5 1E8126 / A3184-8R 46 mm OD Gasket 2-1/4”<br />

MEW6 1E8128 / A3194-8R 73 mm OD Gasket 3-1/4”<br />

T1094803022 - - Gasket 4-1/4”<br />

G216B - 33 mm OD O Ring 1-3/4”<br />

B223 T12655T0012 47 mm OD O Ring 2-1/4”<br />

B231 1H291706562 71 mm OD O Ring 3-1/4”<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca<br />

ACME Fill, Vapor Valves<br />

and Adapters<br />

7193-1 T12945T0012 / 568-110-01 14 mm OD O Ring POL Nipple<br />

G114B 7513-25 20 mm OD O Ring Internal Forklift<br />

mEW4<br />

1425Ba-8<br />

g216B<br />

0015-0004<br />

130122<br />

g114B<br />

7513-25<br />

7193-1<br />

T12945T0012<br />

568-110-01<br />

B223<br />

T12655T0012<br />

mEW2<br />

a2697-20r<br />

1E8124<br />

0015-0007<br />

130121<br />

IMAGES REPRESENT ACTUAL SIZE

BREAk-AWAy & SAFETy COUPLINGS, CyLINDER FILLING VALVE<br />

Break-Away Couplings<br />

FloKill Break-Away Couplings for use with vapor or <strong>liquid</strong> lines to protect against<br />

separation and product spill during filling operations if a hose is pulled without<br />

being disconnected. Suitable for LP and NH3 , Buna soft seat provides positive<br />

shut-off upstream and downstream, 100 to 300 lb of force required for pull-away.<br />

Approx. 100 lb force required to reconnect. Available with bracket or laynard<br />

style cable. Large internal bore for increased flow. Steel construction for strength<br />

and durability.<br />

NEE # description O.a.l. Style<br />

ME860S-6 3/4” F NPT Break-away 6” Bracket<br />

ME861S-6 3/4” F NPT Break-away 6” Lanyard cable<br />

ME860S-8 1” F NPT Break-away 8” Bracket<br />

ME861S-8 1” F NPT Break-away 8” Lanyard cable<br />

ME860S-10 1-1/4” F NPT Break-away 9” Bracket<br />

ME861S-10 1-1/4” F NPT Break-away 9” Lanyard cable<br />

MEP128-6 Reassembly tool<br />

Squibb Taylor TriPod Safety Coupler<br />

Designed to prevent the escape of LPG at the filling riser area in the event of an<br />

accidental pull-away of the container being filled. Double back check permits<br />

closure in both sections of the coupler, minimizing LPG release at the riser and<br />

the filling tank hose. Ideal for loading arm applications.<br />

Features:<br />

■ Release mechanism unaffected by pull-away.<br />

■ Easily reconnected for years of continued service.<br />

■ Stainless steel construction, teflon back check seats for long dependable<br />

operation.<br />

■ Adapts to most existing risers without the need for piping changes.<br />

■ Independent protection of each hose, not sensitive to the direction of the<br />

pull-away.<br />

■ 5 year limited warranty.<br />

Automatic Cylinder Filling Valve<br />

N201<br />

mE860S-6<br />

NEE # Inlet / Outlet Flow Capacity<br />

TP-0-1000 3/4” M NPT 25 GPM<br />

TP-5-1001 1” M NPT 55 GPM<br />

TP-6-1001 1” M NPT 77 GPM<br />

TP-7-1001 1-1/4” M NPT 126 GPM<br />

TP-4-1000 3” M NPT / 2” F NPT 350 GPM<br />

mE861S-6<br />

The MEP128-6 tool is made from a solid 3/4” diameter steel rod, which has been formed into the shape of a large set<br />

of pliers. With the custom forks, you simply slide them over the end of the bracket and the inlet side of the valve then<br />

compress the two handles together. This action can be done with one hand, leaving the other free to insert the mating<br />

nipple back into the valve side of the coupling without straining yourself to do so. Once the nipple has been securely<br />

snapped back into place, simply release pressure on the handles of the tool allowing the retaining sleeve to slide back<br />

into a secured position. The valve is now whole once again.<br />

TP-5-1001<br />

TP-6-1001<br />

Type N201 fills DOT / TC cylinders by weight and stops the gas supply when specified fill weight is reached.<br />

Operated by air or propane vapor pressure, it is designed for beam type scales and requires no electrical<br />

or mechanical power. The assembly comes completely piped up and includes special parts that allow the<br />

slide weight on the scale to move to zero. A red button appears in the indicator on top of the N201 each<br />

time a cylinder is filled to the desired weight.<br />

NEE # description<br />

mEP128-6<br />

N201 Filling Valve, 1/2” inlet / Outlet<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 41<br />

PLANT, TRUCk & TANk EQUIPMENT

PLANT, TRUCk & TANk EQUIPMENT<br />

Rotary Gauges<br />

42<br />

ROTARy GAUGES & INTERNAL VALVES<br />

Fisher rotary gauges can be used on stationary or mobile tanks to visually indicate the amount of<br />

LP-Gas or NH3 in the container. They are also used in filling the tank to the proper <strong>liquid</strong> level. On<br />

mobile applications and some large stationary storage tanks, hangers are recommended to support the<br />

horizontal length of the dip tube.<br />

Type J31 consists of heavy duty gauges that minimize vibration effects (swaying,<br />

bouncing) by a long (68”, 1.73 meters) stem tube extension. Gauges fit 1” coupling<br />

container connections. All gauges have stem and dip tubes with an extra large inside<br />

diameter. This assures that the correct <strong>liquid</strong> level can be obtained quickly. A nylon<br />

packing sleeve and a friction ring for the pointer indicator gives smooth rotation and long<br />

service life. Steel and stainless steel materials resist rust or corrosion.<br />

NEE # description Note<br />

J31L-2 Gauge for 69-92” tanks With P323 Dial<br />

J31X-3L Gauge for 108 - 140” tanks No Dial<br />

J31L-3L Gauge for 108 - 140” tanks With P323 Dial<br />

P322 Replacement Dial LPG - Less than 1200 USWG<br />

P323 Replacement Dial LPG - More than 1200 USWG<br />

P324 Replacement Dial NH3 - More than 1200 USWG<br />

Threaded Internal Valves<br />

Internal <strong>valves</strong>, both threaded<br />

and flanged versions, are used<br />

as primary shutoff <strong>valves</strong>, excess<br />

flow <strong>valves</strong> and back check<br />

<strong>valves</strong>.<br />

The most frequent application<br />

is on mobile and transport truck<br />

tanks, they are also gaining<br />

popularity in stationary storage<br />

vessel use because of their<br />

inherent safety features.<br />

NEE # Type<br />

Tank<br />

Connection<br />

C421<br />

Outlet<br />

Connection<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca<br />

C402<br />

ul rated Closing Flow gPm<br />

Propane<br />

C427<br />

C407<br />

Vapor Capacity SCFh @ 100 PSIg Inlet<br />

C407-10-08<br />

Straight<br />

1 1/4” M NPT 1 1/4” F NPT 30, 50 or 80 13, 200 with 50 GPM spring<br />

C427-16-25 Through Body 2” M NPT 2” F NPT 100, 150 or 250 53, 600 with 150 GPM spring<br />

C427-24-25<br />

(1 Outlet)<br />

3” M NPT #” F NPT 150, 200, 250, 400 or 500 75, 400 with 200 GPM spring<br />

C421-16-25 Tee Body 2” M NPT 2” F NPT 100, 150 or 250 53, 600 with 150 GPM spring<br />

C421-24-25 (2 outlets) 3” M NPT #” F NPT 150, 200, 250, 400 or 500 75, 400 with 200 GPM spring<br />

C402-1625 Strainer Body 2” M NPT 2” F NPT 100, 150 or 250 53, 600 with 150 GPM spring<br />

C402-24-400 (3 outlets) 3” M NPT #” F NPT 150, 200, 250, 400 or 500 75, 400 with 200 GPM spring<br />

* All units have manual operating lever. The valve can be operated by cable or air cylinder.<br />

Tank<br />

Coupling<br />

Half

Flanged Internal Valves<br />

INTERNAL VALVES<br />

Flanged <strong>valves</strong> provide a sturdy and compact means of directly mounting a pump or piping connection.<br />

Special break-away stud bolts are furnished with the <strong>valves</strong> to permit the pump or piping to shear off in the<br />

event of an accident, leaving the valve intact.<br />

C404a32-60 C403-24-40 C404m32-60<br />

NEE # Tank Connection<br />

All flanged <strong>valves</strong> have an internal<br />

screen for pump protection that<br />

can be easily removed if the valve<br />

is used primarily for filling the<br />

tank.<br />

Outlet<br />

Connection<br />

ul rated Closing<br />

Flow* gPm Propane<br />

Vapor Capacity SCFh @<br />

100 PSIg Inlet<br />

C404-24-25<br />

means of actuation ** Type<br />

C404-32-40<br />

C404A32-40<br />

C404M32-60<br />

4” 300 lb ANSI RF Modified<br />

Flange (5 7/8” dia. bore)<br />

4” 300 lb ANSI<br />

RF Flange<br />

340, 400, 600 or 800<br />

108, 600 with 400 GPM<br />

spring<br />

Single Flange<br />

Body<br />

C404-24-25<br />

C403-24-40<br />

3” 300 lb ANSI RF Modified<br />

Flange (4 13/16” dia. bore)<br />

3” 300 lb ANSI<br />

RF Flange<br />

150, 200, 250 or 400<br />

64, 100 with 200 GPM<br />

spring<br />

Manual, Cable or Air<br />

Double Flange Body<br />

* Closing flow vertical down. Consult NEE for flows in alternative positions or with screen removed. ** Refer to following pages for control options.<br />

Internal Valve Accessories<br />

NEE # Size<br />

Primary Cable<br />

Control<br />

aux remote<br />

release<br />

Cable assembly<br />

C404-32-40<br />

latch release<br />

mechanism<br />

The FAST stroke and Power Stroke Actuators from Marshall Excelsior are available with Stainless Steel brackets and are designed for quick<br />

and easy installation on Fisher ISC <strong>valves</strong>. Rugged construction and repairable with common automotive parts.<br />

Pneumatic<br />

Cylinder actuator<br />

Pneumatic<br />

diaphragm actuator<br />

C407-10 1-1/4” P650, P651* P163A, P164A** Incl’d w/ P650 P341, P342*** P389 ME205 / P631<br />

C402/421/427-16 2” P650, P651* P163A, P164A** Incl’d w/ P650 P320 P326-6 ME206 / P639<br />

C402/421/427-24 3” P650, P651* P163A, P164A** Incl’d w/ P650 ME206 / P639<br />

C403-24 3” Double Flange P650, P651* P163A, P164A** Incl’d w/ P650 N/A P326-5 ME207 / P623<br />

C404-24 3” Single Flange P650, P651* P163A, P164A** Incl’d w/ P650 N/A P326-7 ME207 / P613<br />

C404-32 4” Single Flange<br />

Allegheney or<br />

Wheaton Control<br />

P315 P314 P313**** P312 ME207 / P614<br />

* P651 is primary control only, P650 includes 20’ cable, P134 fusible links, return spring and mounting hardware. ** Identical to P163A except untrimmed length is 50’ where the<br />

P163A is 25’. ***Bi-directional allows operation in two directions. **** Use with P315.<br />

P320 P650<br />

P326<br />

P341<br />

P315<br />

P389<br />

P313<br />

mE205<br />

mE206<br />

mE207<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 43<br />

P312<br />

PLANT, TRUCk & TANk EQUIPMENT

PLANT, TRUCk & TANk EQUIPMENT<br />

Replacement Parts & kits<br />

44<br />

INTERNAL VALVES<br />

Cable Controls and accessories can be furnished to remotely open and close all threaded or flanged internal <strong>valves</strong> up to 3”. A fusible link must be incorporated to allow the<br />

<strong>valves</strong> operating lever to return to the closed position in the case of exposure to a fire.<br />

Latch/Remote Release Mechanisms can be fitted to all Internal Valves, with the exception of the 3” flanged size. When the valve’s operating lever is moved to the open<br />

position, the lever can be latched in place. The lever can then be released from a remote location by pulling a cable attached to a pull ring, thus closing the internal valve. A<br />

built-in fusible element in the latch/release allows the <strong>valves</strong> operating lever to return to the closed position in the case of exposure to a fire.<br />

Pneumatic Operated Cylinders can be fitted on all Internal Valves that permits the valve to be opened and closed from a remote location using air, nitrogen, or carbon dioxide.<br />

When pressure is applied to the cylinder, it moves the cylinder rod and internal valve operating lever to the open position. Upon loss of pressure, the <strong>valves</strong> operating lever<br />

returns to the closed position.<br />

NEE # Type Size replacement Parts Kit Complete Parts Kit with Bonnet<br />

C407-10<br />

1 1/4” RC40710T012 -<br />

C402-16, C421-16, C427-16 2” RC40016T012 T20377000A2<br />

C402-24, C421-24, C427-24 3” RC40024T012 T20430000A2<br />

Internal Valve Type<br />

C403-24 3” Double Flange RC40324T012 -<br />

C404-24 3” Single Flange RC40424T012 -<br />

C204-43, C404-32 4” Single Flange RC20443T012 T11396000A2<br />

Replacement Gaskets & Studs for Flanged Internal Valves<br />

Included in the purchase of new <strong>valves</strong>.<br />

Valve<br />

model #<br />

Flange<br />

Size<br />

Top gasket<br />

Between Valve & Tank<br />

Bottom gasket<br />

Between Valve & Pump<br />

C404-24 3”<br />

1P877799152 (before 1990)<br />

1P877699152<br />

T1360370012 (after 1990)<br />

C403-24 3” T10561138992<br />

C404-32 4” 1P110799152 T1118299152<br />

Allegheny Universal Mechanical Operator<br />

NEE # Number of levers<br />

OP9001EY 1<br />

OP9002EY 2<br />

NEE # Number of levers<br />

OP9003EY 3<br />

20040A0001 Adjusting Bolt Assembly<br />

OP9003Ey<br />

Studs Nuts<br />

1P790832928<br />

(8 required)<br />

1N946228982<br />

(16 required)<br />

T1118131032<br />

(8 required)<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca<br />

1A368124112<br />

(16 required)

EMERGENCy SHUT-OFF VALVES<br />

Snappy Joe® Type N550 Emergency Shut-off Valves<br />

Snappy Joe® Type N550 Emergency Shutoff Valves (ESVs) are designed for in-line installations, usually near a bulkhead. The<br />

<strong>valves</strong> provide a means of shutting off gas in the event of a hose rupture or piping break at the <strong>transfer</strong> area to avoid a large<br />

scale loss of LP-Gas or NH3. The <strong>valves</strong> can be manually opened and closed at the installed location or closed remotely by either<br />

cable or air or nitrogen. A remote operating actuator is also available.<br />

Pneumatic Operation – Remote pneumatic closure is available with Type P327D release. Depending upon valve inlet pressure,<br />

a minimum supply pressure of 30 to 70 PSIG on the P327D allows the valve to be latched in the open position with manual<br />

closure possible at the valve. Loss of supply pressure to the cylinder permits the ESV to close. Air, nitrogen, or CO2 can be used<br />

for the cylinder supply source. Maximum inlet pressure to the cylinder is 125 PSIG (8, 6 bar). Operating Temperature Range =<br />

-40°F to 212°F (-40° to 100°C). Opening and closing of Snappy Joe® ESVs from a remote location can be done by using Type<br />

P327C air cylinder. Depending upon valve inlet pressure, a minimum supply pressure of 30 to 70 PSIG to the cylinder opens the<br />

valve. Air, nitrogen, or CO2 can be used for the cylinder supply source. Using the MINI-1 with the P327C allows the valve to be<br />

opened or closed remotely.<br />

Snappy Joe® Type N562 Railroad Tank Car Emergency Shut-off Valves<br />

Designed for railcar protection, this pneumatically operated valve is opened and closed by means of a standard quick-disconnect<br />

coupling. Depending on pressure in the tank car, approximately 20 to 60 PSIG is required to open the valve. The N562 has<br />

a female coupling allowing application fl exibility as nipple lengths are fi eld selectable based on specifi c application<br />

requirements. Typically three of the <strong>valves</strong> are used, two on <strong>liquid</strong> lines and one on the vapor line.<br />

NEE # Size hose Connection<br />

N562-26 2” F NPT 3 1/4” ACME<br />

These Emergency Shut-off Valves can also be utilized in plant designs<br />

other than railway to provide additional safety shut-off control!<br />

Accessories for ESV Operation<br />

NEE # description<br />

P327D<br />

Air Release Assembly<br />

(closing)<br />

P327C<br />

Pneumatic Cylinder for<br />

N550 (opening and closing)<br />

P551A<br />

Retrofi t Closure kit for<br />

P327A<br />

Manual Cable release with<br />

P164B<br />

fuse link, 50 ft of cable,<br />

guides and adapter for<br />

N550.<br />

3-way pneumatic air control<br />

MINI-1<br />

valve, operates either<br />

P327C or D, Air tube not<br />

included<br />

SN-PUL-V<br />

Pull to Close sign - 10” x 12”<br />

rigid Vinyl<br />

SN-PUSH-V<br />

Push to Close sign - 10” x<br />

12” rigid Vinyl<br />

ME551 Airstroke fi restone actuator<br />

mINI-1<br />

SN-PuSh-V<br />

P164B<br />

P327d<br />

P327C<br />

NEE # Size Flow rate<br />

N550-10 1 1/4” 125 GPM<br />

N550-16 2” 150 GPM<br />

N550-24 3” 280 GPM<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 45<br />

N550<br />

Replacement Parts for ESV’s<br />

NEE # description<br />

P551A<br />

Retrofi t Closure Spring Kit for<br />

N550<br />

T13090T0012 Packing Kit for N550<br />

P134<br />

Fusible Link, 212º F for cable<br />

actuated <strong>valves</strong><br />

T20714T0012 Handle for N550<br />

mE551<br />

PLANT, TRUCk & TANk EQUIPMENT

PLANT, TRUCk & TANk EQUIPMENT<br />

Back Check Valves<br />

* Propane Flow<br />

** @ 1 PSIG differential<br />

46<br />

BACk CHECk VALVES<br />

Allows flow in only one direction and are normally closed. They are installed in <strong>liquid</strong> filling connections on stationary storage tanks, bobtail delivery trucks, and <strong>liquid</strong> <strong>transfer</strong><br />

lines. The <strong>valves</strong> are frequently used in conjunction with globe, angle and ball <strong>valves</strong>, as well as large single-check filler <strong>valves</strong>.<br />

Squibb Series<br />

NEE # application<br />

g100 Series<br />

Seat<br />

Construction<br />

Container<br />

or Inlet<br />

Connection<br />

g109<br />

Outlet<br />

Connection<br />

Flow Capacity<br />

@ 10 PSIg<br />

differential<br />

Pressure *<br />

Body<br />

Construction<br />

G100<br />

3/4” M NPT 3/4” F NPT 21 GPM Brass<br />

G101<br />

A1727<br />

Tanks<br />

1 1/4” M NPT<br />

1 1/4” M NPT<br />

1 1/4” F NPT<br />

1 1/4” F NPT<br />

55 GPM<br />

77 GPM<br />

Brass<br />

A1728 2” M NPT 2” F NPT 150 GPM<br />

A1733<br />

G112<br />

Tanks or<br />

In-Line<br />

Metal-to-<br />

Metal<br />

2” M NPT<br />

2” M NPT<br />

2” M NPT<br />

2” F NPT<br />

150 GPM<br />

150 GPM<br />

Steel<br />

G102<br />

G109<br />

Tanks<br />

In-Line<br />

2” M NPT<br />

2” F NPT<br />

2” F NPT<br />

2” F NPT<br />

150 GPM<br />

150 GPM<br />

Brass<br />

G104 Tanks 3” M NPT 3” F NPT 250 GPM<br />

G105<br />

2” F NPT<br />

2” M NPT and<br />

1 1/4” F NPT<br />

137.5 GPM<br />

G106<br />

Tanks or<br />

In-Line<br />

3” F NPT 2” M NPT 254 GPM<br />

Steel<br />

G107 3” M NPT<br />

3” M NPT and<br />

2” M NPT<br />

254 GPM<br />

G200-10<br />

1 1/4” F NPT 1 1/4” F NPT<br />

160 GPM (125<br />

GPM)**<br />

G200-16<br />

Soft Seat<br />

2” F NPT 2” F NPT<br />

250 GPM (200<br />

GPM)**<br />

G200-24<br />

G201-10<br />

In-Line<br />

3” F NPT<br />

1 1/4” F NPT<br />

3” F NPT<br />

1 1/4” F NPT<br />

750 GPM (300<br />

GPM)**<br />

160 GPM (125<br />

GPM)**<br />

Ductile Iron<br />

G201-16 2” F NPT 2” F NPT<br />

250 GPM (200<br />

GPM)**<br />

G201-24 3” F NPT 3” F NPT<br />

750 GPM (300<br />

GPM)**<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca<br />

g105<br />

Type<br />

Valve<br />

with Flow<br />

Indicator<br />

Fisher G200 Series<br />

Back Check Valves<br />

Specifically intended for heavy-duty inline<br />

service at the bulk plant’s <strong>transfer</strong><br />

area. Soft seat construction gives tight<br />

shutoff for maintenance, while body<br />

design reduces flow resistance improving<br />

flow capacity. The G201 has a built-in<br />

flow indicator, which can be used to<br />

replace sight flow indicators.<br />

g200 Series

BaCK CHeCK VaLVes & sigHt fLow indiCators<br />

marshall excelsior High flow Back Check Valves<br />

Marshall Excelsior High Flow Back Check Valves provide back flow protection to container openings or <strong>liquid</strong> lines where flow is<br />

intended for one direction. The valve is normally held closed until pressure activates the valve when flow is directed into the piping or<br />

container causing the back check to open. When flow stops or reverses, the check returns to the closed position. All Marshall Excelsior High<br />

Flow Back Check Valves are supplied with “O”-ring soft seats which can be removed to allow a metal-to-metal seat when required.<br />

Features:<br />

n Dual purpose - soft seat or Metal to Metal for wider applications with less inventory<br />

n Universal seat - Remove O-ring to create metal to metal seating surface<br />

n Maximum product flow achieved by full port and stem travel design<br />

n All models feature Stainless Steel Stem, Spring and Valve Guide for long durable performance life<br />

n Valve bodies and poppet assemblies available in brass, zinc plated, steel or stainless steel<br />

n Available from 3/4” to 3”<br />

n zinc plated and stainless steel models can be used with LP Gas or NH3<br />

Note: for Butane capacity - multiply LP flow rate by .94, for NH3 - multiply LP flow rate by .90<br />

NEE # Application Seat Construction Inlet / Outlet Connection<br />

ME870-6<br />

Flow Capacity @ 10 PSIG<br />

Differential Pressure<br />

Construction<br />

ME870S-6 3/4” FNPT x 3/4” MNPT 24 GPM<br />

Steel<br />

ME870SS-6 Stainless<br />

ME870-10<br />

ME870S-10 Soft Seat or<br />

1-1/4” FNPT x 1-1/4” MNPT 61 GPM<br />

Steel<br />

Tanks or In-line<br />

ME870SS-10 Metal to Metal<br />

Stainless<br />

ME870-16<br />

ME870S-16 2” FNPT x 2” MNPT 187 GPM<br />

Steel<br />

ME870SS-16 Stainless<br />

ME870S-24 3” FNPT x 3” MNPT 449 GPM Steel<br />

sight flow indicators<br />

Inspect in line back checks and excess flow <strong>valves</strong> while product is flowing. Same flow rate as a<br />

standard coupling - minimal presure loss. Field replaceable sight glass with protective cover - UL<br />

approved to 400 psi. Tempered lime glass for maximum strength. Spring return sight glass cover,<br />

always covers the sight glass when released. Allows insertion of corresponding size of back check<br />

or excess flow valve.<br />

NEE # Description<br />

A1742 2” F.NPT inlet & outlet<br />

A1743 3” F.NPT inlet & outlet<br />

ME875S-16 2” Sight Flow Back Check FNPT Ductile Iron<br />

ME875S-24 3” Sight Flow Back Check FNPT Ductile Iron<br />

Shown with<br />

O-Ring<br />

Shown Metal to Metal<br />

with O-Ring removed<br />

Canada’s Leader in energy ProduCts equiPment 47<br />

Brass<br />

Brass<br />

Brass<br />

A1742 / A1743<br />

PLant, truCK & tanK equiPment

PLANT, TRUCk & TANk EQUIPMENT<br />

Squibb Taylor Excess Flow Valves<br />

* at 100 PSIG inlet discharging to atmosphere<br />

48<br />

EXCESS FLOW VALVES<br />

Intended to prevent large discharges of LPG vapor or <strong>liquid</strong> to the atmosphere due to a break in the hose or<br />

piping system.<br />

WARNING! A break or leak downstream of an excess flow valve that does not allow a flow equal to the valve flow rating will not actuate the<br />

valve and could cause a hazardous condition. For this reason, system operators should be familiar with the shutoff <strong>valves</strong> in the system so<br />

that necessary precautions can be taken in an emergency.<br />

NEE # application and Style<br />

A1702-50<br />

Inlet<br />

Connection<br />

Outlet<br />

Connection<br />

Closing<br />

Flow rate<br />

Closing Flow<br />

differential Pressure *<br />

1 1/4” M NPT 3/4” F NPT 50 GPM 6 PSIG<br />

A1705-50 1 1/4” M NPT 1 1/4” F NPT 50 GPM 6 PSIG<br />

A1710 Tanks Style A 2” M NPT 2” F NPT 95 GPM 6.5 PSIG<br />

A1715-165 3” M NPT 2” F NPT 165 GPM 6 PSIG<br />

A1714-225 3” M NPT 2” F NPT 225 GPM 6 PSIG<br />

A1706-50<br />

1 1/4” M NPT 1 1/4” M NPT 50 GPM 6 PSIG<br />

A1708-95 Tanks or In-Line 2” M NPT 1 1/4” M NPT 95 GPM 14 PSIG<br />

A1715-165 Style B<br />

3” M NPT 2” M NPT 165 GPM 5 PSIG<br />

A1715-225 3” M NPT 2” M NPT 225 GPM 7 PSIG<br />

A1711-95<br />

2” M NPT<br />

Tanks or In-Line<br />

A1713-165 2” M NPT<br />

Style C<br />

A1713 2” M NPT<br />

Excess Flow Manifold Adapter<br />

2” M NPT and<br />

1 1/4” F NPT<br />

3” M NPT and<br />

2” F NPT<br />

3” M NPT and<br />

2” F NPT<br />

Allows the manifolding of ASME or DOT cylinders while providing<br />

excess flow protection for the container vapor outlet <strong>valves</strong>.<br />

mE353EX<br />

95 GPM 6.5 PSIG<br />

165 GPM 6 PSIG<br />

225 GPM 6 PSIG<br />

Care must be taken to be sure the valve’s closing rate is less than<br />

the capacity of the LPG system in which the valve is installed!<br />

NEE # description Closing Flow uS gPm<br />

ME353EX9 M POL x 3/8” Male flare 0.9<br />

ME353EX18 M POL x 3/8” Male flare 1.8<br />

ME354EX9 M POL x 1/2” Male NPT 0.9<br />

ME354EX18 M POL x 1/2” Male NPT 1.8<br />

ME355EX9 M POL x 1/2” Male flare 0.9<br />

ME355EX18 M POL x 1/2” Male flare 1.8<br />

ME356EX9 M POL x 5/8” Male flare 0.9<br />

ME356EX18 M POL x 5/8” Male flare 1.8<br />

Style a<br />

Style B<br />

Style C<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca

Excess Flow Valves<br />

Intended to prevent large discharges of LPG<br />

vapor or <strong>liquid</strong> to the atmosphere due to a<br />

break in the hose or piping system. When<br />

fl ow exceeds the valve’s setting, the valve<br />

closes and remains closed until the system<br />

equalizes. A built-in equalizing passage<br />

automatically opens the valve once pressure<br />

on both sides of the poppet is equal.<br />

* Closing fl ow rate propane in horizontal position.<br />

EXCESS FLOW VALVES<br />

NEE # application and Style Inlet Connection Outlet Connection material <strong>liquid</strong> gPm<br />

ul rated Closing Flow rate¹<br />

Vapor SCFm<br />

25 psig Inlet<br />

Vapor SCFm<br />

100 psig Inlet<br />

F110 Portable Service Male POL 9/16” - 18” UNF LH Brass 0.7 120 204 7.4<br />

F183 Portable Service Male POL 9/16” - 18” UNF LH Brass 1.5 335 570 9.7<br />

F173 Portable Service Male POL 1/4” MNPT Brass 0.7 120 204 2.4<br />

F181 Portable Service Male POL 1/4” MNPT Brass 1.5 335 570 9.7<br />

F110A Portable Service Soft Nose Male POL 9/16” - 18” UNFLH Brass 0.7 120 204 7.4<br />

F173A Portable Service Soft Nose Male POL 1/4” MNPT Brass 0.7 120 204 7.4<br />

F138 In-Line 1/4” MNPT 1/4” FNPT Brass 1.8 377 641 1.4<br />

F202 In-Line Male POL 1/2” SAE Flare Brass 1.9 634 1100 2.6<br />

F170 Tanks (Full or Half Coupling) 3/4” MNPT 3/4” FNPT Brass 6.6 1184 2012 1.2<br />

F100 Tanks (Full or Half Coupling) 3/4” MNPT 3/4” FNPT Brass 8.4 2010 3417 2.4<br />

F101 Tanks (Full or Half Coupling) 3/4” MNPT 3/4” FNPT Brass 20 3459 5880 8.5<br />

F102 Tanks (Full or Half Coupling) 1 1/4” MNPT 1 1/4” FNPT Brass 33 6300 10630 10.7<br />

F105 Tanks (Full or Half Coupling) 1 1/4” MNPT 1 1/4” FNPT Brass 55 9982 16967 10.7<br />

F106 Tanks (Full or Half Coupling) 2” MNPT 2” FNPT Brass 85 18513 31467 2.6<br />

F107 Tanks (Full or Half Coupling) 2” MNPT 2” FNPT Brass 100 20796 35349 3.6<br />

F130 In-Line 1” FNPT 1” FNPT Brass 25 5287 8986 3.3<br />

F131 In-Line 1 1/2” FNPT 1 1/2” FNPT Brass 60 11694 19877 4.7<br />

F132 In-Line 2” FNPT 2” FNPT Brass 95 19874 33877 2.1<br />

F133 In-Line 2” FNPT 2” FNPT Brass 155 29202 49718 4.2<br />

F134 Tanks (Full or Half Coupling) 1 1/2” MNPT & 1” FNPT 1” FNPT Brass 28 5181 8806 2.7<br />

F135 Tanks (Full or Half Coupling)<br />

F110a<br />

F110<br />

2 1/2” MNPT & 1 1/2”<br />

FNPT<br />

F100<br />

F138<br />

1 1/2” FNPT Brass 60 12000 20290 5.2<br />

F190 Tanks (Full or Half Coupling) 2” MNPT 2” MNPT & 1 1/4” FNPT Steel 80 15400 26250 3.7<br />

F191 Tanks (Full or Half Coupling) 2” MNPT 2” MNPT & 1 1/4” FNPT Steel 105 18800 32000 8.9<br />

F194 Tanks (Full or Half Coupling) 3” MNPT 2” MNPT Steel 165 32800 55950 3.1<br />

F195 Tanks (Full or Half Coupling) 3” MNPT 2” MNPT Steel 260 50650 86350 6.9<br />

F198 Tanks (Full or Half Coupling) 3” MNPT 3” MNPT & 2” FNPT Steel 165 33000 56250 3.1<br />

F199 Tanks (Full or Half Coupling) 3” MNPT 3” MNPT & 2” FNPT Steel 260 49500 84350 7.1<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 49<br />

F130<br />

F134<br />

F190 Series<br />

PSId<br />

PLANT, TRUCk & TANk EQUIPMENT

PLANT, TRUCk & TANk EQUIPMENT<br />

Excess Flow Valves<br />

50<br />

EXCESS FLOW VALVES<br />

Marshall Excelsior Excess Flow Valves are intended for use in <strong>liquid</strong> or vapor, LP or NH3 systems. Excess flow <strong>valves</strong> can be used for filling, <strong>withdrawal</strong>, and vapor<br />

equalization in containers or line applications - specifically long lines or branch piping. This product protects against excessive discharge as a result of a break in the line or<br />

hose. The excess flow feature is designed to remain closed after activation until the system pressure equalizes on both sides of the shutoff poppet. Excess flow <strong>valves</strong> should<br />

generally be sized for 1.5 times the nominal flow of the system they are installed in to prevent premature closing and still adequately protect the piping system. All models<br />

feature Stainless Steel Stem, Spring, and Valve Guide for long life. Available in a wide range of closing flows and sizes in Brass, Zinc Plated Steel and Stainless Steel.<br />

NEE #<br />

ME880-6/4.6<br />

Size<br />

Inlet x Outlet<br />

Construction<br />

Closing Flow<br />

rate<br />

4.6 GPM<br />

ME880-6/14 14 GPM<br />

ME880-6/17 Brass<br />

17 GPM<br />

ME880-6/22 22 GPM<br />

ME880-6/28 28 GPM<br />

ME880S-6/4.6<br />

4.6 GPM<br />

ME880S-6/14 14 GPM<br />

ME880S-6/17<br />

3/4” MNPT<br />

x 3/4” FNPT<br />

Zinc Plated Steel 17 GPM<br />

ME880S-6/22 22 GPM<br />

ME880S-6/28 28 GPM<br />

ME880SS-6/4.6<br />

4.6 GPM<br />

ME880SS-6/14 14 GPM<br />

ME880SS-6/17 Stainless Steel 17 GPM<br />

ME880SS-6/22 22 GPM<br />

ME880SS-6/28 28 GPM<br />

ME880-10/32<br />

32 GPM<br />

Brass<br />

ME880-10/42 42 GPM<br />

ME880S-10/32 1-1/4” MNPT<br />

32 GPM<br />

Zinc Plated Steel<br />

ME880S-10/42 x 1-1/4” FNPT<br />

42 GPM<br />

ME880SS-10/32<br />

32 GPM<br />

Stainless Steel<br />

ME880SS-10/42 42 GPM<br />

ME880-16/80<br />

80 GPM<br />

ME880-16/105 Brass<br />

105 GPM<br />

ME880-16/114 114 GPM<br />

ME880S-16/80<br />

80 GPM<br />

ME880S-16/105<br />

2” MNPT<br />

x 2” FNPT<br />

Zinc Plated Steel 105 GPM<br />

ME880S-16/114 114 GPM<br />

ME880SS-16/80<br />

80 GPM<br />

ME880SS-16/105 Stainless Steel 105 GPM<br />

ME880SS-16/114 114 GPM<br />

ME880S-24/265 3” MNPT<br />

265 GPM<br />

Zinc Plated Steel<br />

ME880S-24/350 x 3” FNPT<br />

350 GPM<br />

mE880-10/42<br />

mE880S-24/350<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca

Strainers<br />

NOZZLES & STRAINERS<br />

All strainers are suitable for use with LPG or NH3. Ductile Iron Bodies, Stainless Steel 40 mesh perforated screens are standard.<br />

Optional mesh sizes are available. Clean-out plugs are not included. Contact NEE for sizes not listed.<br />

NEE # description PSI dimensions / Size<br />

ME650S 40 Mesh Stainless Steel Screen - threaded clean-out 600 1/2” NPT<br />

ME651S 40 Mesh Stainless Steel Screen - threaded clean-out 600 3/4” NPT<br />

ME652S 40 Mesh Stainless Steel Screen - threaded clean-out 600 1” FNPT x 1” FNPT<br />

ME653S 40 Mesh Stainless Steel Screen - threaded clean-out 600 1 1/4” NPT<br />

ME655S 40 Mesh Stainless Steel Screen - threaded clean-out 600 2“ FNPT x 2” FNPT<br />

SC0150B112AD-40 40 Mesh Stainless Steel Screen - threaded clean-out 600 1 1/2” NPT<br />

SC0150B112AD-60 60 Mesh Stainless Steel Screen - threaded clean-out 600 1 1/2”<br />

PAG 3” FLANGED STRAINER 60 Mesh Stainless Steel Screen - bolted clean-out 600 3” Flanged 300 # ANSI<br />

SC0400A105AD-40 40 Mesh Stainless Steel Screen - bolted clean-out 600 4” Flanged 300 # ANSI<br />

Gasguard 1 3/4” ACME Nozzles<br />

Threaded<br />

Clean-Out<br />

Bolted<br />

Clean-Out<br />

The LG1E Gasguard Nozzle is for attended Autogas and Industrial filling applications. Both the LG1E and LG20 are used in filling mobile and stationary LPG Tanks, where a<br />

1¾” Acme Adapter is used. The LG20 Gasguard Nozzle is designed to reach deeper positioned filler adapters, such as storage cylinders, forklift truck cylinders and recreational<br />

vehicles. It has a 164mm reach as compared to the 129mm on the LG1 Series Gasguard Nozzle.<br />

lg1E<br />

lg20<br />

Common Repair Parts for Gasguard Nozzles<br />

NEE # description<br />

LG8 Latch Sub-Assembly, LG1E, LG10<br />

10-0703-804 Body Sub-Assembly, LG1E, LG10<br />

L.G.3 Repair Kit (valve disc, o-rings & lip seals), LG1E, LG10<br />

L.G.3SW Inlet Swivel seal kit, LG1E, LG10<br />

Standard Features for both the LG1E and LG20 Series:<br />

■ The LG5SL lever reduces wear and improves long term flow performance of the nozzle, they cannot discharge LPG to the<br />

atmosphere, and must be connected to a filler valve to allow product to flow.<br />

■ Low finger presssure on the lever is required to operate their nozzles, and they cannot be disconnected from their filler<br />

<strong>valves</strong> while their levers are held in the open position, thereby avoiding accidental gas discharge.<br />

■ Only 1.9cc of product is discharged, with a standard nose piece , and 2.66cc with a high-flow nose piece, on release of the<br />

lever after filling operations are complete.<br />

■ They are lightweight and well balanced for ease of operation, and are available with 3/4” internal NPT threads on inlet<br />

swivel to nozzle.<br />

■ They feature a unique plastic O ring, securely housed in the nose piece, which positively seals to its mating filler valve even<br />

if the adapter gasket is missing and also have an optional lever hold-open latching assembly if required.<br />

The lg1E series features a high strength brass swivel nut to ensure long wear and resistance to distortion if the nozzle is<br />

accidentally dropped. A high strength aluminum alloy swivel nut, with a stainless steel ACME thread insert, provides long term<br />

stability with low wear on threads. The insert is chemically bonded to the swivel nut and is radially pinned with three stainless<br />

steel spring pins.<br />

NEE # description Weight PSI<br />

LG1E Standard Nozzle 4.84 Lbs, 2.2 Kg 350<br />

LG1EL Standard Nozzle, W/ Latch Assembly Only 4.84 Lbs, 2.2 Kg 350<br />

LG20LX3/4 Long Nose Piece Nozzle, W/ Latch Assembly Only 4.72 Lbs, 2.1 Kg 350<br />

Note: Material for all the above listed models is Aluminum Alloy to AS701 (Nozzle Body)<br />

NEE # description<br />

10-0759-803 Valve Body Sub-Assembly, LG1E<br />

LG2X3/4 Inlet Swivel Body Sub-Assembly,LG1E, LG10<br />

L.G.5 Lever Sub-Assembly, LG1E, LG10<br />

L.G.6N Nose piece Sub-Assembly, LG1E, LG10<br />

L.G.7 Swivel Nut Sub-Assembly, LG1E<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 51<br />

PLANT, TRUCk & TANk EQUIPMENT

PLANT, TRUCk & TANk EQUIPMENT<br />

Full Circle Swivels<br />

52<br />

Straight Through Type<br />

STRAIGHT-THROUGH & 90° TyPE SWIVELS<br />

Typically used on hose ends, loading arms and hose reels and are available in<br />

various sizes and configurations and are compatible with a wide assortment of<br />

chemicals.<br />

Features:<br />

■ Non-lube design, no maintenance.<br />

■ Hi load rated bearing design to minimize misalignment.<br />

■ Pre-drilled port for relief valve or pressure gauge mounting on some models.<br />

■ Static O-Rings, no U-cups or lip seals to wear out due to swivel motion.<br />

Marshall Excelsior E-Z Turn Hose End Swivels<br />

mE850SS<br />

NATIONAL TOLL FREE DIRECTORY 1-866-574-5100 I ON THE WEB www.nee.ca<br />

U.L. Listed for LP-Gas<br />

90° Type<br />

Allow hose end <strong>valves</strong> to rotate 360° for ease of connect and disconnect to tank filler <strong>valves</strong> while under tank<br />

pressure. They also extend hose life by preventing twisting and kinking during reeling and unreeling from the<br />

hose reel.<br />

Features:<br />

■ Non-Lube design, no maintenance.<br />

■ Hi load rated bearing design to minimize misalignment.<br />

■ All Stainless Steel construction for corrosion resistance and maximum durability.<br />

■ Straight through bore for unobstructed flow characteristics.<br />

■ Available pre-installed with Marshall Excelsior minimum bleed hose end <strong>valves</strong>.<br />

NEE # description Thread Size Weight Fuel Type<br />

SMAC-112 90° Type Swivel 1-1/2”F X 1-1/2”F 13 1/8 lb LPG<br />

SMAC-112ST Straight Through Type Swivel 1-1/2”F X 1-1/2”F 11 3/4 lb LPG<br />

SMAC-114LN 90° Type Swivel 1-1/4”F X 1-1/4”F 6 3/4 lb LPG and NG<br />

SMAC-114STLN Straight Through Type Swivel 1-1/4”F X 1-1/4”F 4 1/2 lb LPG and NH3<br />

SMAC-190LN 90° Type Swivel 1”F X 1”F 6 3/4 lb LPG and NH3<br />

SMAC-1STLN Straight Through Type Swivel 1”F X 1”F 4 1/2 lb LPG and NH3<br />

SMAC-200 90° Type Swivel 2”F X 2”F 13 1/8 lb LPG<br />

SMAC-200STLN Straight Through Type Swivel 2”F X 2”F 11 3/4 lb LPG and NH3<br />

SMAC-JO-1 Straight Through Swivel Hose End, Filler Valve Type 3/4 1”F X 1”M 1 1/2 lb LPG<br />

SMAC-JO-34 Straight Through Swivel Hose End, Filler Valve Type 3/4 3/4”F X 3/4”M 1 1/2 lb LPG<br />

ME850SS-8 Straight Through Swivel Hose End Valve, 1” 1” F x 1” M 1 1/4 lb LPG and NH3<br />

ME850SS-6 Straight Through Swivel Hose End Valve, 3/4” 3/4” F x 3/4” M 1 1/4 lb LPG and NH3<br />

ME850SS-6/8 Straight Through Swivel Hose End Valve, 3/4” x 1” 3/4” F x 1” M 1 1/4 lb LPG and NH3<br />

ME850SS-8/6 Straight Through Swivel Hose End Valve, 1” x 3/4” 1” F x 3/4” M 1 1/4 lb LPG and NH3<br />

Swivel Repair kits<br />

NEE # description<br />

JO-1SK Repair Kit For SMAC-JO-1<br />

SMAC-112LNSK Repair Kit For SMAC-112<br />

SMAC-1SK Repair Kit For SMAC-1<br />

NEE # description<br />

SMAC-200LNSK Repair Kit For SMAC-200<br />

SMAC-3490LNSK Repair Kit For SMAC-34<br />

ME850SS-K Repair Kit For Marshall Excelsior Hose End Swivels

VALVE REPAIR kITS & PARTS<br />

Repair kits for Squibb Taylor & Fisher Valves<br />

For Item Number Size<br />

NEE # (repair<br />

Parts Kit)<br />

rebuild Kit with Bonnet<br />

AL308, AL309, A1570, A1571, A1572, A1574, A1578 3/4” 308-22 308-25, 308-26<br />

AL310, AL311, AL477, A1587, A1590, A1591, A1592,<br />

A1596, A1597, A1598, A1599P<br />

1” 310-22 310-25, 310-26<br />

AL312, AL313 1 1/4” 312-22 312-25, 312-26<br />

AL314, AL315 1 1/2” 314-22 314-25, 314-26<br />

AL316, AL316F, AL317, AL317F 2” 316-22 316-25, 316-26<br />

AL320, AL320F, AL321, AL321F 3” 320-22 320-25, 320-26<br />

AL407,AL409, A1556 1/2” 407-21 407-25, 407-23<br />

AL410, AL411, AL412, AL413 3/4” 410-21 410-25, 410-23<br />

N301-04, N401-04 1/2” RN30008T012 T12690T0012<br />

N301-06, N401-06 3/4” RN30008T012 T12690T0012<br />

N301-08, N401-08 1” RN30008T012 T12690T0012<br />

N310-10, N410-10 1 1/4” RN30012T012 T20838T0012<br />

N310-12, N410-12 1 1/2” RN30012T012 T20838T0012<br />

N310-16, N410-16 2” RN30016T012 T20818T0012<br />

N310-24, N310F-24, N410-24, N410F-24 3” RN30024T012 T40259T0012<br />

N350-04, N450-04 1/2” RN350T00012 N/A<br />

N350-06, N450-06 3/4” RN350T00012 N/A<br />

Replacement kits/Parts for<br />

Sherwood Valves<br />

2341-100-KIT<br />

2035-100-KIT<br />

2033-100-KIT<br />

440-50(l)<br />

623a-100<br />

2030-100-KIT<br />

3349-100<br />

1855-100<br />

Kits Include:<br />

■ Packing<br />

■ Male Adapter<br />

■ Seat Disc<br />

■ Body Gasket<br />

■ Gasket<br />

■ Packing Spring<br />

■ O-Ring<br />

NEE # Valve Type description Valve model<br />

440-50-KIT Quick Acting Bonnet Assy Kit 440 Series<br />

440-50L-KIT Valves Bonnet Assy Kit 440L<br />

6775-60-KIT Dual Bonnet Replac. Bonnet 2033CLDB15.0 Only<br />

2341-100-KIT Transfer Valve Replac. Kit 2341 Series<br />

2030-100-KIT Multi Valve 2030BC Filler Section Replac. Kit 2030BC<br />

U701-19 Multi Valve 2030BC Protective Cap 2030BC Relief<br />

1850-3 Multi Valve 2030BC 1 3/4” ACME Cap 2030BC Filler<br />

2033-100-KIT ASME Tank Valve Repair Kit 2033 Series<br />

1875-3A ASME Tank Valve 1 1/4” ACME Cap 2035 Relief<br />

2035-100-KIT Multi Valve 2035 Filler Section Replac. Kit 2035 Series<br />

UT12X Multi Valve 2035 Protective Cap 2035 Relief<br />

1850-3 Multi Valve 2035 1 3/4” ACME Cap 2035 Filler<br />

1855-100-KIT Filler Valve 1855 Repair Kit 1855 Series<br />

1850-3 Filler Valve 1855 1 3/4” ACME Cap 1855 Filler<br />

623B-100-KIT Filler Valve 623 Repair Kit 623 Series<br />

1850-3 Filler Valve 623 1 3/4” ACME Cap 623 Filler<br />

3349-100-KIT Type 1 Valve Kit Incl: (1) TL126 (5) 3349-20 3349 Series<br />

3349-20 Type 1 Valve Backcheck Module 3349<br />

CANADA’S LEADER IN ENERGy PRODUCTS EQUIPMENT 53<br />

PLANT, TRUCk & TANk EQUIPMENT

PLANT, TRUCk & TANk EQUIPMENT<br />