Final Sec. 7 BOQ-Crystal IT Park Balance Work - Madhya Pradesh ...

Final Sec. 7 BOQ-Crystal IT Park Balance Work - Madhya Pradesh ...

Final Sec. 7 BOQ-Crystal IT Park Balance Work - Madhya Pradesh ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

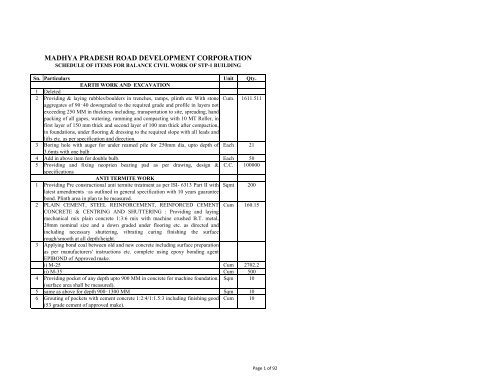

MADHYA PRADESH ROAD DEVELOPMENT CORPORATIONSCHEDULE OF <strong>IT</strong>EMS FOR BALANCE CIVIL WORK OF STP-1 BUILDINGSn. Particulars Unit Qty.EARTH WORK AND EXCAVATION1 Deleted2 Providing & laying rubbles/boulders in trenches, ramps, plinth etc With stone Cum. 1611.511aggregates of 90‐40 downgraded to the required grade and profile in layers notexceeding 250 MM in thickness including. transportation to site, spreading, handpacking of all gapes, watering, ramming and compacting with 10 MT Roller, infirst layer of 150 mm thick and second layer of 100 mm thick after compaction,in foundations, under flooring & dressing to the required slope with all leads andlifts etc. as per specification and direction.3 Boring hole with auger for under reamed pile for 250mm dia, upto depth of Each 213.6mts with one bulb4 Add in above item for double bulb. Each 505 Providing and fixing neoprien bearing pad as per drawing, design & C.C. 100000specificationsANTI TERM<strong>IT</strong>E WORK1 Providing Pre constructional anti termite treatment as per ISI- 6313 Part II with Sqmt 200latest amendments ‐as outlined in general specification with 10 years guaranteebond. Plinth area in plan to be measured.2 PLAIN CEMENT, STEEL REINFORCEMENT, REINFORCED CEMENTCONCRETE & CENTRING AND SHUTTERING : Providing and layingmechanical mix plain concrete 1:3:6 mix with machine crushed B.T. metal,20mm nominal size and a down graded under flooring etc. as directed andCum 160.15including necessary shuttering, vibrating curing finishing the surfacerough/smooth at all depth/height.3 Applying bond coal between old and new concrete including surface preparationas per manufacturers' instructions etc. complete using epoxy bonding agentEPIBOND of Approved make.i) M-25 Cum 2702.2ii) M-35 Cum 5004 Providing pocket of any depth upto 900 MM in concrete for machine foundation. Sqm 10(surface area shall be measured).5 same as above for depth 900‐1300 MM Sqm 106 Grouting of pockets with cement concrete 1:2:4/1:1.5:3 including finishing good Cum 10(53 grade cement of approved make).Page 1 of 92

Sn. Particulars Unit Qty.3 Providing and fixing in position 35mm thick single or double leaf solid core type Sqmt 40flush door shutters (Indian Manufacturing Co. Ltd., Indian Ply Woodcompany,.M/s Mysore Commercial Ltd., or approved equivalent) with solidblock board core internally lipped with well seasoned commercial hard woodtimber, bonded with' water proof, phenol formaldehyde synthetic resin hotpressed confirming to I.S. 2202‐1973,With one side veneered includingmelamine polish in two or more coats and other commercial side includingpainting with two coat synthetic enamel paints of approved make and shade andquality to give a smooth and even surface (appcolite paint of Asian paints orLuxol of Burger paint) over one coat of wood primer.4 Item same as above with both side teak veneered with vertical grains or cross Sqmt 12bands including malamine polish in two or more'coats on both the side.5 Deleted6 Same as Item above but all exposed surfaces shall be finished with approved Nos. 4epoxy paint.but each door shutter shall have central panel of 6mm thick clearglass of size 500 x 1000i) 900 x 2100 Single Shutter7 Doorframes and shutters to be primered in stoving grade epoxy zinc phosphateprimer and finished in aliphatic grade UV resistant polyurethane paint ofapproved shade. Door frames and shutters to have all hardware preparations,prepunched at the factory for flush fixing of hardware at site.i) 1800 x: 2100 Double Shutter Nos. 33ii) 1125 x 2100 Single Shutter Nos. 1148 Deleted1BRICK MASONARY WORK:Providing and constructing 20/30 Cm thick Brickwork built with chimney bricks Cum 178.702of approved quality in cement mortar 1:6 with crushing strength not less then50kg/sq. cm and water absorption by wt. not more then 15% in foundation,plinth and superstructure including scaffolding, racking and striking of joints,curing etc. at all Depths/Heights completePLASTER WORK:1 Providing 6mm thick cement plaster over Brickwork or Concrete surface incement mortar 1:3, including all necessary scaffolding, watering, curing etc.complete at all floors and heights as directed by Architect/Engg in charge.Sqmt 7083.4Page 4 of 92

Sn. Particulars Unit Qty.2 Providing and applying 20mm (two coats 12mm & 8 mm) water proof cement Sqmt 11.24plaster to brick masonry / concrete surface at all heights and depths using CM1:4 (1 part of cement : 2 parts of fine sand & 2parts of coarse sand) cementmortar including scaffolding, curing etc.. complete including groove bends, dripmolder wherever required as specified and directed. by site engineer. NOTE :The rate should also include the cost of water proof components and mixing withmortar etc as per manufacturer's specifications complete.3 Providing and fixing 24 gauge GI wire chicken mesh of ' 200 mm width on Sqmt 3602.454junction of RCC'and brick masonry before laying plaster including providingand fixing nails, making drill holes and repairing the same etc. complete at allheights and leads as per, drawing and as directed by Engineer.4 Providing and applying Readymade Acralic wall putty in two or more coats to Sqmt 56120give even finish to the satisfaction of EIC/Architect of approved makeAsian/equivalent approved i/c sand papering for making the surface smooth forapplying any paint and final coat with ready made approved branded putty.5 Providing and applying POP punning with minimum thickness of 10 mm in Sqmt 12124perfect line and level in both directions with first quality POP at any level andheight to wall surface. concrete surface, ceiling, grooves, chamfer, cleaning, etc.complete and as required and directed.6 Providing and applying ICI/approved equivalent as per Architect specifications Sqmt 12124make 'luster' paint on walls, other surfaces by scraping surface then applying'Patti" three times to make the surface perfectly leveled and smooth thenapplying roller finish three coats of paint of specified colours and shape,cleaning, etc. complete.7 Providing and applying Plastic Emulsion paint of two or more coats with Sqmt 14520approved quality paint of DULUX/approved equivalent make & shade over twocoats of primer including preparation of surfaces with sand papering, stoppingall holes and depressions as per specifications, scaffolding, primer, curing etccomplete for all heights and as directed by site engineer. Note: No extra paymentshall be made for the roughness of the plastered surface.8 Distempering on plastered surface (walls end ceilings) with synthetic oil boundwashable distemper of approved brand (Asian ‐Tractor or Burger Bison) andshade in two or more coats on new work including water based priming coat ofcement primer including cost of all material to give a smooth shade e.t.c.completeSqmt 41520Page 5 of 92

Sn. Particulars Unit Qty.9 Painting exterior walls, columns etc with Water proof cement paint of Sqmt 5811.535'SNOCEM PLUS /DUROCEM or EQUIVALENT make in two or more coats ofrequired shades on new work over and including priming coats of white cementto give even shade including preparing the surface, filling with putty whereverrequired, cost of all material and curing etc. complete at any height as directedby Architect/EIC.10 Providing and applying "Spectrum Perma Stone or approved equivalent a natural Sqmt 8400unpigmented permanent finish, cleaning the external plaster surface andapplying spectrum sealer primer with brush and spray apply "Spectrum PermaStone or approved equivalent average 3mm thick over primer finished with rolleror trovel as directed, cleaning etc. complete. Rate should be inclusive of M. S.scaffolding etc. and at any height or level.11 Providing and applying two coats of external grade acrylic paint of approved Sqmt 9450make over one coat of primer applied on external plaster on wall, ceiling andbeams by scraping the surface as directed, cleaning etc. complete as per theapproved colour and shade at any height and level. The rate should inclusive ofM.S. scaffolding etc.12 Finishing exterior wall, columns etc with water proof Santex matt paint( Sqmt 550Snowcem ) or weather coat (Berger paints) of required shade on new work intwo or more coats over one coat of white cement primer to give an even shadeincluding preparing the surface, filling With putty wherever required, cost of allmaterial scaffolding, curing etc complete at any height at directed byArchitect/EIC.1FLOORING WORK:Providing and fixing machine cut, pre polished, Kotah stone cladding, 600 x 600size in perfect line, level, and pattern, sorted out for uniform. green colour, avg.Sqmt 28820 mm thk. fixed over cm filling the joints With neat cement cleaning, polishingetc. completed at all levels and heights.2 Providing and fixing machine cut pre polished Kotah stone avg. 20 mm thk. Sqmt 632.576300/165 mm wide, 1500/1800 mm long single piece for staircase Landing, Riser& treads With cement mortar bedding fixed with cement in perfect line and levelkeeping the proper nosing as shown in drawing with polished edges etccompleteat all levels and heights.3 Providing and fixing machine cut, mirror polished, best quality approved kotahstone avg. 20mm thk. and 150 mm wide patta below railing resting on the floor,stair treads etc. fixed in neat cement in perfect line, level, closely jointed, fillingthe joints with white cement by adding matching collour pigment, includingcutting nitch for railing rods, mirror polishing the edges etc. complete.Rmt 900Page 6 of 92

Sn. Particulars Unit Qty.4 Providing and fixing best quality approved coloured machine cut mirror polished Sqmt 5020mm thk. Granite slab (Min. area 1 sqm) cladding on back coated plasteredwall in perfect line, level and plumb as per pattern, fixed with neat cement andcement slurry, brass pins, V groove at cornersetc. The joints shall be filled withcement by adding watching colour pigment, including, maintaining grooves,moulding, etc. as per drawing and as directed by Architect, scaffolding,cleaning, etc. complete at all levels. ( Refer basic rate)5 Providing and fixing best quality approved coloured machine cut, mirror Sqmt 1170polished 20mm thk. Granite slab (Min. area 1sqmt) cladding on back coatedplastered wall in perfect line, level and plumb as per pattern, fixed with neatcement and cement slurry, brass pins, V groove at corners etc. All the joints shallbe finished with 12mm wide brush ‐finish S.S strip including, maintaininggrooves. moulding, etc. as per drawing and as directed by Architect, scaffolding,cleaning, etc. complete at all levels. (Refer basic rate)6 Providing and fixing best quality approved colour, machine cut, mirror finish Sqmt 340Granite slab with minimum length of 1500 mm for sills, softs, jambs etc. forwindows, doors, etc. approx. 200 mm wide fixed over back coat platered surfacein perfect line, level, fixed in neat cement filling the joints with white cement byadding matching colour pigment, polishing the edges etc. complete at all levelsand heights.7 Providing and fixing 20 mm granite with both side mirror polish for urinal Nos. 100partition of 600mm x 1200mm size with shape as shown in drawing and roundedge moulding, fixed in the wall with chases, cleaning etc. complete at all leveland heights8 Providing and fixing approved colour best quality machine cut, 20 mm thk Sqmt 50Italian Marble slab(basic rate 900/sqft) with 300/165mm wide and 2100mmlong one piece for entrance step Risertreads with cement mortar bedding fixedwith neat cement in perfect line and level, keeping the proper nosing, includingmoulding and three grooves as antistid In perfect line, finishing the joints withwhite cement by adding matching colour pigment rounding and polishing theedges etc. complete at all levels and heights9 Making cut outs in granite / Italian Marble slab flooring to a perfect size andshape, making recess in flooring for floor spring, finishing the edges etc.complete. The breakage shall be to the Contractors accounts.Sqmt 600Page 7 of 92

Sn. Particulars Unit Qty.10 Providing and fixing sandwich type pantry counter 600 mm wide as per design Nos. 18and drawing with caddappa stone supporting structure as verticals and horizontalwith making provision for ready made stainless steel sink (to fixed by otheragency). Finishing the top, vertical surfaces and fascia 125 mm wide with 20mm thk best quality approved granite with mirror polish, machine cut ' slab,round edge moulding including making chases. providing shelves, filling thejoints with white cement by adding matching colour pigment, making the cutouts in caddappa and granite for drains and gas pipes etc. complete.i) 1600X2300 MM11 Providing and fixing 600 mm wide counter for wash basin as per drawing anddetails with avg. 20mm thk best quality approved colour, machine cut, mirrorfinish polished one piece Granite slab in perfect line, level including 125 mmwide fascia on front side and exposed edges with half round moulding as perdesign. fixed in to walls with making chases in the wall, cutting the granite inperfect size of wash basin with polished round edge moulding to fit the washbasing below the Granite, polishing the edges, filling the chases with cementmorter, providing brass pins, M. S. hidden brackets wherever necessary,finishing etc. complete at all levels and heights.i) 600 x 1700mm with two wash basins Nos. 10ii) 600 x 1500mm with two wash basins Nos. 1012 Providing and fixing approved colour, shade, pattern type of Bisazza/approved Sqmt 52vitrious tile up to beam bottom on R. C. columns in canteen area. The fixingshall be done as per manufacturers specifications and fixing material complete atall levels and heights, cleaning, etc. complete.13 Providing and fixing best quality Italian marble, mirror polished with top Sqmt 600protective chemical coating (Basic Rate Rs. 900/‐ per Sq. Ft.) approved byArchitect for flooring over white cement mortar bedding fixed with white cementin pattern as per drawing in perfect line and level with flush joints, applyingPOP over the marble flooring surface till final completion, cleaning aftercompletion etc. at all levels and heights.14 Providing and fixing best quality Italian marble, mirror polished (Basic Rate Rs.900/‐ per Sq. Ft.).approved b Architect cladding on back coated plastered wallin perfect line, level and plumb as per pattern, fixed with neat white cement andcement slurry, brass pins, V groove at corner etc. All the joints shall be finishedwith 12mm wide brush finish S.S strip including, maintaining grooves,moulding, etc. as per drawing and as directed by Architect, scaffolding cleaning,etc. complete at all levels.Sqmt 240Page 8 of 92

Sn. Particulars Unit Qty.15 Providing and laying machine cut, mirror polished, 20mm thick best quality Sqmt 1390Ruby Red Granite and Jet Black Granite slab(1sqmt min.) flooring in pattern asshown in the drawing on cement mortar bedding, closely joined in perfect lineand level as per pattern, joints filled with white cement by adding matchingcolour. pigment, cleaning, applying POP over the granite surface till finalcompletion, cleaning after completion etc. complete at all levels and heights.16 Providing and fixing 400mm x 400mm Boss/equivalent approved make and Sqmt 2010approved shade ceramic tile flooring as directed over cement mortar beddingfixed with neat cement slurry in perfect line, level, closely joined, filling thejoints with white cement by adding matching colour pigment, cleaning, etc.complete.17 Providing and fixing Boss/equivalent approved make 400mm x 400mm Sqmt 1970approved shade ceramic tile dado as directed over a back coat, fixing with neatcement in perfect line, level and plumb up to 8'‐0" or up to false ceiling or asdirected and as per pattern closely joined, filling joints with white cement.cleaning etc. complete at any heights or level.18 Providing and laying coloured Anti skid ceramic tiles of first quality in standard Sqmt 900size of 30cm x 30cm x 8mm for flooring of required Shade and design asapproved by Architect, (make kajaria/ equivalent approved) to required positionlaid down on bed of cement mortar 1:3 (1 cement : 3 coarse Narmada sand) bedthickness not exceeding 20mm and not less than 12mm at any place includingneat cement float filling joints with neat white cement slurry mixed with pigmentand cleaning etc. complete.19 Providing and laying 150mm thk. M‐20 grade concrete 'Trimix' flooring with Sqmt 12840nominal reinforcement 8 mm dia. or steel at 300 mm c/c both ways on wellcompleted P.C.C. subbase. The concrete shall consist of 325 kg. Of cement percubic meter of concrete and the water‐cement ratio shall be in the order of 0.53to 0.54. The concrete shall be poured in the panel (size not more than 25 Sq. Mt)and vibrated With poker vibrator, consolidated and levelled With triscreedvibrator and shall be vacuum De‐Watered to reduce final water cement ratio to0.42 to 0.43. After vacuume. De-Watering treatment. metallic dry shake ‐ at therate of 4.5 kg per Sq. Mt. shall be spread as per the guidelines detailed in B. S.8204 ‐ 1987 Part II, then the surface shall be trowelled with a power trowel andwithin 48 hrs of casting the construction joints shall be formed with mechanisedsaw cut to depth of 1/4th thickness of the Trimix floor and shall be 3 to 4mmwide filled with elastromatic sealant. The floor shall be cured for a period ofseven days etc. complete as specified and directed.20 DeletedPage 9 of 92

Sn. Particulars Unit Qty.ALUMINIUM WORK1A Providing fabricating and fixing in position in perfect line and level and plumb Sqmt 326top hung aluminium windows with approved colour, satin finish 20 micronsanodizing coated heavy duty sections of approved make, with EPDMgasket/imported PVC gaskets, sealing the joints with silicon based sealant andmaking the joints water tight etc. complete as per drawing and instructions.1B Providing and fixing in item No. 1A, 6 mm thick machine cut, machine polished Sqmt 326edges, heat reflective hard coated glass of 'Glaverbell' or equivalent, colour ofthe glass as approved by Architect. The breakage and wastage shall be to thecontractor's account.2A Providing, fabricating and installing 1200 mm high continuous strip/horizontal Sqmt 1179structural glazing system made with international design and collaboration forflat, curved a sloping surfaces with approved aluminium colour, satin finish 20microns anodizing coated heavy duty sections, for frame work including itsfittings, fixtures, aluminium alloy extrusions and accessories, rain waterdrainage, seven stage barrier for enchanted performance of air and water sealing(iun a manner that does not required a sealing the joints with sealant), makingthe joints water tight, fixing the structural glazing frame to the building withnecessary inserts, anchor fastners, brackets, etc. complete. The exposed surfaces,etc. shall be epoxy coated. The rate to include detail design calculations takinginto consideration the wind load, seismic forces, adequate factor of sagety, andthe relevant IS code and the international code. Contractor to furnish detailedworking of the weight of Aluminium per Sq.Mt. the rate should include forproviding 20% openable panels with S.S. heavy duty friction stay and multipointlatching and acremone handle.2B Providing and fixing in item No. 2A, 6 mm thick machine polished edges, heat Sqmt 1179reflective hard coated imported glass of 'Glaverbell' or equivalent, colour of theglass as approved by architect. The breakage and wastage shall be to thecontractor's account.3A Providing, fabricating and fixing in position in perfect line and level and plumb Sqmt 73double shutter aluminium framed openable windows with aprpoved colourpolyster powder coated heavy duty sections, with EPDM gasket/imported PVCgaskets, sealing the joints water tight etc. along with aluminium sub framecomplete as per drawing and instructions.3B Same as item No. 1B, but using 6 mm clear glass. Sqmt 1804A Same as item No. 2A with 2870 mm high fixed structural glazing. Sqmt 1834B Same as item No. 2B, but using 12 mm the glass. Sqmt 183Page 10 of 92

Sn. Particulars Unit Qty.5A Providing, fabricating and fixing in position, in perfect line, level and plumb Sqmt 39aluminium fixed windows with approved aluminium colour, satin finish 20micron anodizing heavy duty sections, with EPDM gaskets imported PVCgaskets, sealing the joints with silicon based sealant and making the joints watertight etc. complete as per drawing and instructions.5B Providing and fixing in item No.5 A, 6 mm thick machine cut, machine polished Sqmt 39edges, heat reflective hard coated glass of 'Glaverbell' or equivalent as approvedby Architect.6 Providing, fabricating and fixing 12 mm thick clear toughened glass with edge Sqmt 80polished and prepared for patch fittings with dimensions as shown in drawings,for entrance door and fixed glazing. The entrance glass door shall be fitted withover panel patch, top patch and bottom rail with locking system, the fixedglazing shall be supported by connecting profiles etc. all the patch panels,connectors and other accessories should be S.S. brush finish. All handles, florrssprings shall be of 'Dorma' or equivalent. All joints shall be sealed silicon basedseal and made water tight etc. complete as per drawign and instructions.7A Providing, fabricating and erecting in position framework for skylight withapproved colour, satin finish 20 micron anodized heavy duty aluminium section,with supporting structure, structurally supporting with building with necessaryinserts, fastners, etc. complete. The exposed M.S. surfaces, bracket,s etc. shallbe epoxy coated, making the joints water tight by silicon based as per drawingand design complete. Pyramid shape square base skylight as per design.Sqmt 237B Providing and fixing in Item No. 7A, 6 mm thick machine cut edges, heat Sqmt 23relective hard coated imported glass of 'Glaverbell' or equivalent as approved byarchitect, laminated with 4 mm thick clear float glass of required size and shape,with a minimum of a five years guarantee against delamination anddiscolouration of the materials used, imported PVC gaskets, angle clips, etc. thebreakage and wastage shall be to the contractor's account.8A Providing, fabricating and erecting in position semi-circular framework for Sqmt 50glass casing for capsule lift with approved colour, satin finish 20 micronanodized heavy duty aluminium section, with supporting structure, structurallysupporting with building with necessary inserts, fastners, etc. complete. Theexposed M.S. surfaces, brackets, etc. shall be epoxy coated, making the jointswater tight by silicon based as per drawing and design complete.8B Same as item No. 2B. Sqmt 50WATER PROOFINGPage 11 of 92

Sn. Particulars Unit Qty.A(a) Providing cement based water Proof treatment to the new terraces, Chajjas,cleaning the surfaces of concrete, giving injections to the terrace slab as requiredwith cement and approved slab as required with cement and approved waterproofing compound solution to fill up all inherent hole voids, honeycombs; etc inthe concrete slab, setting brick bat coba in water proof mortar with necessarygradient for easy flow of water and continue the treatment along with inner facesor parapet or other adjoining wall upto a height of 30 mm in the shape of vatasfinally treating the top surfaces an vatas with water proof plaster in 1:3 C.M.finished Smooth With trowel in approved colour shade with false making of 300mm square. (<strong>Balance</strong> rate)i) 110 mm thick (avg) for terrace Sqmt 1980.18ii) 50 mm thick (ayg) for chajjas Sqmt 350B DeletedC DeletedD Providing and laying integral cement based water proofing treatment on Vertical& *Horizantal surface by fixing kota stone slab 20mm th. With cement slurrymixed with water proofing compound confirming to IS 2645 In recommendedproportion with a gap of 20mm between stone slab and the reciving surface, fillthe gap with neat cement slurry mixed with water proofing compound andfinishing the exterior surface with CM 1:4 20mm with neat cement punningmixed with water proofing compound in recommended proportion complete atall levels and as directed by Architect. The waterproofing treatment is to beguaranteed for bone dry condition for a period of 10 years.Sqmt 8920E Providing and laying 225 MM wide x 8 MM thick PVC water stops(IS 5424) ofapproved make with bulb at center at construction joints of RCCNote for <strong>IT</strong>EM no. A(a)1) If due to location of rain water pipes the thickness of treatement exceeds110mm, for easy flow of water, no provision will be made for extra brick batcoba .2) The water proofing treatment shall be patented type of approved reputedcompany and guaranteed for absolute water tightness for a period of 10 yearsfrom the date completion3) The cement required for the treatment shall be arranged by the contractor.4) The measurement for payment shall be the entire area of terrace/chajjascovered by the treatment measured between brick/ concrete ‐ parapets withoutplaster and the area of vatas calculated by taking the length of vatas and theheight above the finished level of the terrace/chajjas.Note for <strong>IT</strong>EM no. BRmt 1538.4Page 12 of 92

Sn. Particulars Unit Qty.1. The waterproofing treatment is to be guaranteed for bone dry condition for aperiod of 10 years.2. The cement required for the treatment shall be arranged by the contractor.3. The measurement for payment shall be the actual area covered by thetreatment4. The waterproof brick bat coba filling coming over the waterproof plaster shallbe measured in Cum. seperately and the cost of the same is not included in thisitem.MISCELLANEOUS WORKSA Providing and laying offset made out in Brick masanory in C.M 1:3 ( 1 Cement:3 Fine SAND ) over Parapet wall and elsewhere as specified at all heightshaving one layer of 50 mm thick brick work which is projected 50 mm outsidethe outer edge of parapet wall and second layer of 50mm thick brickwork whichis again projected 50mm outside the lower layer Brickwork plastered in 20mmthick cement mortar 1:4 as per detail in drawing No . The cost shall include costof all material, centering, scaffolding reinforcement plastering in C.M. 1:4, andpainting external grade acrylic paint over one coat of primer in two or morecoats of required shade to give an even shade inclusive of cost of all materials.cleaning the surface before painting, curing, scaffolding julla etc complete.Cum 74BCFinishing Plaster 12 mm thick and 25 mm thick in C.M. 1:4 on concretecorbelling at different levels (Sill Level , Chajja level & Roof level as specifiedas per detail in drawing No . The cost shall include cost of all material.centering, scaffolding, reinforcement plastering in C.M. 1:4, and painting withexternal grade acrylic paint over one coat of primer in two or more coats ofrequired shadetogivean even shade inclusive of cost. of all materials, cleaningSqmt 220the surface before painting, curing, scaffolding julla etc complete.c) Roof levelProviding and laying Plain cement Mortar Raised Bands in 1:4 C.M. at anyheight The cost shall include cost of all material, centering, scaffolding,reinforcement plastering in C.M. 1:4, and painting with external grade acrylicpaint over one coat of primer in two or more coats of required shade to give aneven shade inclusive of cost of all materials, cleaning the surface beforepainting, curing, scaffolding Julla etc completei) 100 mm x 12 mm Rmt 100ii. 150 mrn x 25 mm Rmt 190Page 13 of 92

Sn. Particulars Unit Qty.D Providing and Fixing premoulded bituminous filler of 25mm thick (Shalitex or Sqmt 133.113other equivalent approved make) for expansion joints including cuttingpositioning, supporting, scaffolding and filling with approved sealing(polysulphide 25x40 mm) compound all compete as per specifications ofmanufacturer and as directed by EICE Providing and Fixing covering sheet of aluminium 3mm thick and 150mm wide Sqmt 500over expansion joints including screwing, colouring as required, cuttingpositioning, supporting, scaffolding all compete as per specifications ofmanufacturer and as directed by EICF Providing and fixing in position hand railing up to 900 mm high above finish Rmt 630floor level over stair and landing consisting of cast iron (max 8kg) decorativevertical, powder coated (basic rate 50/kg) one number on alternate stepembedded In floor and each grouted with cement mortar and bolted on top a M.S40mm pipe with all required bends, caps and other accessories decorative typehand rail including painting of two coats of primer and approved make , shadeenamel paint & all material. and labour, complete.G Providing and fixing in position hand railing over stair and landing consisting of Rmt 380M.S 40mm pipe grouted with cement mortar in wall and bolted on top a ith allrequired bends, decorative type hand rail including painting of two coats ofprimer and approved make , shade enamel paint & all material and labourcomplete.H Providing and laying 1200mm wide plinth protection all around the building as Sqmt 700per following sequence.a. Excavation and disposal of black cotton soil to a depth of 500mm, Supplying,filling and consolidating murrum to the required level.b. Providing and laying 100microns thick black HDPE film over murrum.c. Providing and laying 100 mm thick PCC 1:2:4 using 20mm nominal sizecoarse aggregate including edge shuttering, making wire mesh impression at thetop, curing etc. all complete as directed by Site Engineer.I Breaking/cutting/making chases/Grooves in of Plain / Reinforced CementConcrete using the following method and disposing the same as directed by siteEngineer.a) Manually by chisel Cum 15J Breaking/cutting/making chases/Grooves in of brick work and disposing thesame as directed by site Engineer.Cum 15Page 14 of 92

Sn. Particulars Unit Qty.K Providing and fixing in position Gypsum board false ceiling/panneling including Sqmt 3200patterns and different levels, suspended on G.I frame work as per dwg. theframing consisting of perimeter channel of 27mm x 0.5mm with. flange of20mm and 30mm screwed on wall and partition. intermediate channel of size45mm x 0.5mm with two flanges of 15mm each suspended from existing ceilingof 1200 mm center with steel hangers of width 25mm x 0.5mm thick/ angle 40 x40 x 5 fixed with hilti/approved make dash fasteners. ceiling section of 0.5mmthick having knurled edge of 51.5 mm and two flanges of 26mm each with lipsof 10.5 mm fixed to intermediate channel With the help of connecting clips andin the direction perpendicular to the intermediate channel at 450mm center tocenter and 12.6mm thick tapered edge gypsum plaster board(conforming toIS2095‐1985 "Gypboard) screw finally the tapered and square edges of theboard are to be jointed and finished with regular site filler, paper tape, finisherand primer suitable for gypsum plastic board to give smooth and even finishincludes all material labour making cutouts/openings for light fixtuers and withL Casting and fixing into place, plaster of paris moulding of sizes as per designitem complete with painting to give an even shade.i)40 mm x 40 mm Rmt 625ii) 40 mm x 75 mm Rmt 450iii) 75 mm x 150 mm Rmt 4607 a) Providing and fixing 32 mm dia'C' class GI pipe in chases including clamps Rm 100and necessary fittings to match 'C' class pipe and making good the classb) Providing and fixing 40 mm dia'C' class GI pipe in chases including clamps Rm 50and necessary fittings to match 'C' class pipe and making good the classc) Providing and fixing 50 mm dia'C' class GI pipe in chases including clamps Rm 80and necessary fittings to match 'C' class pipe and making good the class8 Providing and fixing 100 x 80mm Cl deep seal nahani traps upto 450 mm long No 108arm CP heavy grating with or without vent connection as required.9 Providing and fixing brass/Gl clean out plug with GI socket and lead caulkedjoint.i) 200 mm dia No 8ii) 150 mm dia No 10iii) 100 mm dia No 3iv) 80 mm dia No 6610 Providing and fixing GI to CI adaptor with GI reducer with lead caulked joint.i) 100 x 50 mm No 20ii) 80x40mm No 90iii) 80 x 32 mm No 72Page 15 of 92

Sn. Particulars Unit Qty.12 Making nacessary holes in RCC slab and walls and making good the same using No 300an approved cement expanding compound in cover etc. to make good the holeafter laying pipes / traps etc.13 Providing and fixing CI ‐ LA class pipes of approved make including allnecessary fittings with lead caulked Joints complete with anchor fastners,clamps, cradles, MS brakets, etc as directed including two coats of approvedpaint over a primer as directed after testingi) 150 mm dia Rm 200ii) 100 mm dia Rm 50iii) 80 mm dia Rm 501(D) Sanitary FixturesProviding and fixing in position 575 mm Orissa type porcelain Chinaware Indian Sets 2WC pan with integrated foot steps in pestal colour, suitable, porcelainChinaware P or S trap as necessary with or without vent holes as requiredincluding: Supplying and Fixing 32 mm dia CP brass Open/concealed type flushvalve of approved make complete as directed Supplying and fixing 32 mm diaCP brass flush pipe with long bend at inlet to pan including making allconnection, bushing at Inlet etc. complete as directed. Providing necessarycement concrete reinforced seating around WC pan and trap in PCC 1:2:4 etc. asdirected.2 Providing and fixing In position European Type water closet of approved makecomprising. wall hung European type WC in pastel shade with CI brackets andchair & pan connector for vent pipe. 32mm dia CP brass flush valve of approvedopen /concealed type complete as directed 32 mm CP brass flush pipe with longbend and suitable bushing at inlet. deluxe black solid backelite WC cover & seatwith CP hinges and rubber buffers (ISI ‐ A Grade) of matching shade. FixingSets 76EWC to wall as directed.3 Supplying and fixing Counter type circular/oval porcelain ware china clay washbason in pestal shade central tap hole and overflow comprising. CI concealedtype brackets fixed to wall with GI rag bolt. 32 mm heavy quality CP brasswaste fitting with rubber plug and CP ball chain 32 mm heavy quality CP brassbottle trap with cleaning eye, extension piece & wall flange. 15 mm CP brassswan neck pillar tap of heavy quality of approved make Painting exposedsurfaces of brackets with two coats of white enamel paint over one coat ofapproved primer. 15 mm CP brass heavy grade flexible inlet connection with CPnuts (minimum length 450mm) made to measure. 15 mm CP brass heavy qualityangle stop cock with fancy head and ISI certified of approved make with wallflange etc. complete.Sets 76Page 16 of 92

Sn. Particulars Unit Qty.4 Supplying and fixing Porcelain China ware urinals comprising. Half stall flashback deluxe type large urinals in pastel shade and size 580 x 380 x 250 mmapprox. size with concealed type wall hanger or special brackets in wall andhinged type CP brass dome gratings. CP brass flush. pipes, spreaders and inletcaps as necessary made to measure Auto flush electronic sensing system forurinals for a range of 1 mt. and flushing period of 2 to 30 seconds of approvedshade and make complete with necessary electrical connection and SS plate withbrass screws for maintenance as directed Heavy quality CP brass bottle trap withcleaning eye for each urinal pan with CP brass extension piece and wall flange.Sets 935 Supplying and fixing 460 mm dia Commander or Flushlight circular mirror with No 74HDPE or PVC frame in white colour complete with concealed type screws forfixing.6 Supplying and fixing heavy quality stainless steel towel rod 750mm long with No 38approved type SS brackets concealed type screw of approved make (ESSESS orequivalent make)7 Providing and fixing approved type SS coat hooks with concealed screws. No 768 Providing and fixing CP brass liquid soap dispensers, of approved make with No 74nozzle and piston arrangement.9 Providing and fixing 15mm CP brass bib tap with fancy head ISI heavy quality No 10with wall flange of approved make (Jaguar or equivalent make)10 Providing and fixing vitreous China urinal partitions large size 680 x 380 mm or No 73near Size in white colour including fixing in wall with counter sunk CP brassscrews of sufficient length of rawl plug driven in wall to avoid wobbling.11 Providing and fixing races type toilet‐ paper holder in vitreous China to suit wall No 74tile size in pastel shade.12 Providing and fixing health faucet for ablution at toilets In heavy quality of No 74Jaquar or equivalent approved make.13 Providing and king standard size ISI certified electrical storage water heater ofapproved make complete with vaccum and pressure release device and ventvalve made in copper vessel and adequately insulated of approved make.i) 140 litre capacity No 1ii) 70 litre capacity No 2iii) 25 litre capacity No 2Providing and fixing in position 3 to 4.5 kw instantaneous geyser of non pressuretype14 Providing water supply and drain piping to water coolers as directed. (watercooler will be supplied by client)Sets 18Page 17 of 92

Sn. Particulars Unit Qty.15 Providing and fixing SS sink with integrated single drain board similar to No 18NIRALI or approved make of 1145 x 510 side basket strainer outlet Angle stopcock long body, pillar cock C.P. bottle trap, C.P. extension pipe, wall flange etc.complete.(E) Water Supply Distribution1 Supplying and laying 100 mm dia, G. I C‐Class pipes with necessary fittings Rm 100and pipes wrapping with hessian cloth over a coat of bitumastic paint includingnecessary excavation in earth or murum bailing & pumping out water fromtrenches with shoring wherever necessary, providing 1:3:6 150 mm thickconcrete bedding & pedestals benching. refilling, the trenches, removing awaythe surplus earth or dumping it on site as directed complete including hydraulictesting at 10.54 Kg pressure (depth upto, 1.00M).2 Supplying and laying 80 mm dia, G. I C‐Class pipes with necessary fittings and Rm 200pipes wrapping with hessian cloth over a coat of bitumastic paint includingnecessary excavation in earth or murum bailing & pumping out water fromtrenches with shoring wherever necessary, providing 1:3:6 150 mm thickconcrete bedding & pedestals benching. refilling, the trenches, removing awaythe surplus earth or dumping it on site as directed complete including hydraulictesting at 10.54 Kg pressure (depth upto, 1.00M).3 Supplying and laying 50 mm dia, G. I C‐Class pipes with necessary fittings andpipes wrapping with hessian cloth over a coat of bitumastic paint includingnecessary excavation in earth or murum bailing & pumping out water fromtrenches with shoring wherever necessary, providing 1:3:6 150 mm thickconcrete bedding & pedestals benching. refilling, the trenches, removing awaythe surplus earth or dumping it on site as directed complete including hydraulictesting at 10.54 Kg pressure (depth upto, 1.00M).Rm 1504 Supplying and laying 40 mm dia, G. I C‐Class pipes with necessary fittings andpipes wrapping with hessian cloth over a coat of bitumastic paint includingnecessary excavation in earth or murum bailing & pumping out water fromtrenches with shoring wherever necessary, providing 1:3:6 150 mm thickconcrete bedding & pedestals benching. refilling, the trenches, removing awaythe surplus earth or dumping it on site as directed complete including hydraulictesting at 10.54 Kg pressure (depth upto, 1.00M).Rm 125Page 18 of 92

Sn. Particulars Unit Qty.5 Supplying and laying 32 mm dia, G. I C‐Class pipes with necessary fittings and Rm 75pipes wrapping with hessian cloth over a coat of bitumastic paint includingnecessary excavation in earth or murum bailing & pumping out water fromtrenches with shoring wherever necessary, providing 1:3:6 150 mm thickconcrete bedding & pedestals benching. refilling, the trenches, removing awaythe surplus earth or dumping it on site as directed complete including hydraulictesting at 10.54 Kg pressure (depth upto, 1.00M).6 Supplying and laying 25 mm dia, G. I C‐Class pipes with necessary fittings and Rm 75pipes wrapping with hessian cloth over a coat of bitumastic paint includingnecessary excavation in earth or murum bailing & pumping out water fromtrenches with shoring wherever necessary, providing 1:3:6 150 mm thickconcrete bedding & pedestals benching. refilling, the trenches, removing awaythe surplus earth or dumping it on site as directed complete including hydraulictesting at 10.54 Kg pressure (depth upto, 1.00M).7 Supplying and laying 20 mm dia, G. I C‐Class pipes with necessary fittings and Rm 200pipes wrapping with hessian cloth over a coat of bitumastic paint includingnecessary excavation in earth or murum bailing & pumping out water fromtrenches with shoring wherever necessary, providing 1:3:6 150 mm thickconcrete bedding & pedestals benching. refilling, the trenches, removing awaythe surplus earth or dumping it on site as directed complete including hydraulictesting at 10.54 Kg pressure (depth upto, 1.00M).8 Supplying and laying 15 mm dia, G. I C‐Class pipes with necessary fittings and Rm 300pipes wrapping with hessian cloth over a coat of bitumastic paint includingnecessary excavation in earth or murum bailing & pumping out water fromtrenches with shoring wherever necessary, providing 1:3:6 150 mm thickconcrete bedding & pedestals benching. refilling, the trenches, removing awaythe surplus earth or dumping it on site as directed complete including hydraulictesting at 10.54 Kg pressure (depth upto, 1.00M).9 Deleted10 Providing and fixing 80 mm dia tested heavy duty 'C' class GI pipes including Rm 266necessary specials, clamps wall or ceiling as required and testing 10.54 kg/sqcm.hydraulic pressure including painting as above.i) do- 50 mm dia Rm 151.76ii) do-40 mm dia Rm 80iii) do-32 mm dia Rm 237.26iv) do-25 mm dia Rm 97v) do-15 mm dia Rm 253.68Page 19 of 92

Sn. Particulars Unit Qty.11 Providing and fixing 'C' class GI pipes including specials as necessary in chasein walls clamping wrapping With superior make hessian cloth or FRP tape orequivalent treatment over 2 coats of bitumastic paint as per standard practicejoint teflon taped for concealed work including testing of pipes to 10.54kg/sqcm. before wrapping.i) 40 mm dia Rm 50ii) 32mm dia Rm 125iii) 25 mm dia Rm 50iv) 20 mm dia Rm 250v) 15 mm dia Rm 50012 Providing and fixing heavy quality GM valves (fullway valves) of approvedmake.i) 150 mm Nominal bore. No 6ii) 100 mm Nominal bore. No 8iii) 80 mm Nominal bore No 8iv) 65 mm Nominal bore No 8v) 50 mm Nominal bore No 6vi) 32 mm Nominal bore No 18vii) 25 mm Nominal bore No 20viii) 20 mm Nominal bore No 35ix) 15 mm Nominal bore No 6513 Providing and fixing 80 mm NB basket strainer and foot valve for suction tank No 4with brass moving parts.i) do-65 mm dia No 414 Providing and fixing 150 mm NB,CI double flanged ISI heavy quality tested No 2sluice valve of standard water works pattern tested to 160 mt. head with handwheel on top CI body phosphor bronze gate and spindle all certified by BMC.15 Providing and fixing 100 mm NB,CI double flanged ISI heavy quality tested Noi 2sluice valve of standard water works pattern tested to 160 mt. head with handwheel on top CI body phosphor bronze gate and spindle all certified by BMC.16 Providing and fixing 80 mm NB,CI double flanged ISI heavy quality tested No 4sluice valve of standard water works pattern tested to 160 mt.head with handwheel on top CI body phosphor bronze gate and spindle all certified by BMC.i) Same as above with 65 mm Dia. Size. No 417 Providing and fixing 65 mm NB, CI horizontal / vertical type non return valve, No 4with GM moving parts heavy pressure quality.18 Providing pump foundations as per structural engineers drawings in PCC 1:2:4. Cu.Mt. 20including shuttering.19 Providing and fixing 50 mm copper ball valve complete as per specifications. No 2Page 20 of 92

Sn. Particulars Unit Qty.20 Supplying and fixing 600 mm dia CI circular manhole cover and frame weighing No 1475 Kgs, fixed to RCC cover slab with handles and locking arrangement as permunicipal rules.21 Providing and fixing 40 mm inlet size high pressure tested ball valve with copper No 2float and brass moving parts, ISI certified make22 Providing and fixing brass mosquito proof coupling as per municipal No 4requirements for 100 mm overflow piper.23 Providing and fixing 50 mm NB GI vent pipe 600 to 750 mm high with double No 10GI bends mosquito proof coupling (brass) at free end, fixing to concrete coverslab etc. complete.24 Supplying and fixing air release valve of approved make.i) 15 mm dia No 13ii) 20 mm dia No 1325 Supplying & fixing pressure reducing valve of approved make.i) 50 mm dia No 12ii) 40 mm dia No 2iii) 32 mm dia No 12iv) 25 mm dia No 2v) 20 mm dia. No 226 Supplying & laying 10 to 15mm dia Asbestos rope hot water insuladon as perstandard practicei) 20mm dia pipe Rm 25ii) 15mm dia pipe Rm 251Municipal water connection to underground tanks ‐(F)Providing and fixing 80 mm dia G.I C‐Class municiple tested pipe withnecessary fittings and wrapping with hessian cloth over a coat of bitumasticRm 50paint as per standard practice and testing to 10.54 kg/sqcm. hydraulic pressureafter laying and jointing, including excavation in earth or murum with looseboulders, shoring, backfilling trenches in 16 layers, consolidating and rammingincluding disposing surplus earth & all incidental charges etc. as directed. (depthupto 1.0M)2 Providing and fixing 80 mm size municipal approved water meter with necessaryflanges, Cl pot strainer 80mm flanged cut off valve, all fixtures to be of ISIcertified quality municipal tested as per by ‐ laws.Sets 1Page 21 of 92

Sn. Particulars Unit Qty.3 Constructing water meter chamber 900 x 450 mm clear inside dimension with No 1230 mm thk.brick wall in CM 1:5, PCC bedding 230mm thick at bottom with1:2:4 conc., with I no. 900 x 450 air and water tight extra heavy duty CI manholecover and frame as directed, 20mm thk plaster, smooth finish inside and roughout side, brick pedestals 230 x 300mm height below meter and accessoriesincluding necessary, excavation In earth, murum & loose boulder, necessaryshoring, back filling in trenches in layers, consolidating and ramming includingdisposing surplus earth as directed and providing locking tie bar arrangement tomanhole covers.4 Making water connection on municipal main as per Instructions with necessary Job 1approvals & NOC from concerned local authorities including nacessary plug orvalve connections within owner's property as directed and all incidental expensesto avail of water supply facility.5 Constructing 600 x 600 mm size valve chambers in brick work masonry with No 15medium duty C.I. full size frame & cover etc ‐ same as item No. A‐4 above withdepth of 600 mm etC, complete.6 Constructing 450 x 450 mm size valve chambers in brick work masonry with No 12medium duty C.I. full size frame & cover etc ‐ same as item No. A‐4 above withdepth of 600 mm etc. complete.7 Providing and fixing in position GI pipe sleeves of required length, threadedoutside within loose socket coupling for jointing the flanged as directed, weldedto MS middle plate 5 mm thick and size as required, for tying to mainreinforcement.i) 200 mm dia No 6ii) DeletedBasement Drainage – (G)1 Supplying and fixing 100 mm dia GI 'C' class pipe of IS grade, laid to required Rm 75slope in trenches or clamped to ceiling including clamped fittings as perspecification including two coats of approved paint over a primer2 Supplying and fixing 80 mm‐dia GI 'C' class pipe of IS graft laid to required Rm 25slope in trenches or clame to ceiling including clamplet fittings as perspecification including two coats of approved paint over a primer3 Composite control panel (common for two pumps) of approved make DOL /stardelta starter with auxiliary contacts for indicator lamps, level switches,change over facility, selector switches for ON / OFF/ AUTO operation, High &Low level probs (Rombus, Pen) and control circuit fuses as per electricalconsultants's requirements for above sump pumps (all accessories should besuitable for damp and humid area) including suitable cabling from panel topump.Sets 2Page 22 of 92

Sn. Particulars Unit Qty.4 Providing and fixing 65 mm horizontal / vertical type GM non return valve Nos. 2tested to 21 kg/sq.cm. With flanged type connection5 Providing and fixing 65 mm GM valves, medium quality tested to 20 kgf/cm2 Nos. 5for control purpose.6 Providing and fixing CI slotted grating with frame of approved make over RM 220basement channel. 500 mm size(H) Hydropeneumatic System1 Supplying & fixing approved make 50mm. Dia cast iron double flanged vertical Nos. 4special design non‐return valves having bronze seated stem guided flep withsynthetic rubber disc type sealing washer and side bolted opening for easyremoval of internal parts for replacement without dismantling pipeline.2 Supplying & fixing about 500 ltrs. Capacity AFL series overall height MS Nos. 4fabricated imported approved make percharged diaphragm tank with 50mm. To80mm. Outlet complete with air inlet valves pressure switches and pressureguages.3 Supplying & fixing 80mm dia butterfly valves with G.M moving parts etc. Nos. 4complete.4 Supplying & fixing 80mm dia heavy duty G.M vertical/horizontal non‐retum Nos. 4valve etc. complete5 Supplying & fixing 80mm dia pot strainer etc. complete. Nos. 4Page 23 of 92

Sn. Particulars Unit Qty.ESTIMATE OF COST OF FIRE FIGHTING WORK OF PROPOSED STPSECTION – AWET RISER & FIRE HYDRANTSA-1 Supplying and fixing GI 'C' Class pipe flanged/welded as specified, includingnecessary excavation in earth or murum, bailing or pumping out water from thetrenches with shoring wherever necessary, refilling the trenches, removing awaythe surplus earth or dumping it on site as directed (depth upto 1000 mm)including short lengths and special as required, laying PCC pedestals, supports,and testing 13.5Kg/Sq.cm complete including necessary protective tape orhessian cloth over a coat of bitumastic paint for buried piping complete asspecified.i) 150 mm dia. ‐do‐ to IS:1239 Rm 50ii) 100 mm dia. ‐do‐ to IS:1239 Rm 33A-2 Supplying and fixing 200 mm dia. G.1 'C' Class pipes to IS: 3589 (wall min. Rm 945mm thick) screwed flanged/ welded as specified and with heavy clamps,hangers, brackets or pipe supports all with screwed /bofted / welded joints asrequired including standard specials as necessary, fixing supports into masonrywalls or RCC with anchor fasteners an painting two finishing coats of enamelpaint of ap colour over a coat of approved primer after hydraulic testing to 13.55Kg/sq.cm pressure, complete as specified.A-5 i) 80 mm dia Rm 40.2A-6 Supplying & fixing 150 x 80 mm dia tee tapping with necessary flanges for 2 Set 49Nos. of single landing valves on wet risers including providing flanges withholes for fixing landing valves including paintingA-7 Supplying and fixing C.I double‐flanged sluice valve with non rising spindle &as per IS:780‐PN‐1.6 of approved make with necessary nuts, bolts, flanges,rubber gasket etc. complete as specified.i) 200 mm Nominal Bore No 6ii) 150 mm Nominal Bore No 12iii) 100 mm Nominal Bore No 10iv) 80 mm Nominal Bore No 8A-8a Supplying and fixing 150mm dia flanged C.I. tested non return valve as per No. 3IS:5213 of approved make with necessary nuts, bolts, flanges, rubber gasket etc.complete as specified.i) 100 mm dia as above. No. 5A-9a Supplying and fixing 200 mm horizontal pot strainer assembly With brass or2phosphor bronze working parts, necessary flanges, rubber gasket etc complete asspecifiedi) 100 mm dia do as above No. 4Page 24 of 92

Sn. Particulars Unit Qty.A-10Supplying and fixing specially designed gun metal orifice plates on hydrantoutlets including distance pieces of suitable size. for adjustment of deliverypressure complete with necessary companion flanges, nuts, bolts, gaskets etc.No 56A-11A-12A-13A-14A-15A-16A-17complete as specified.Supplying and fixing 65 mm dia single hydrant outlet landing valve in gun metalwith C.I hand wheel & tested to 21 kg/cm 2 pressure (conforming to IS‐ 5290)with companion flanges, nuts, bolts, washers, gaskets, gun‐metal cap " & chain,etc; complete as specified.Supplying and fixing weather proof courtyard fire hydrant M.S. hose cabinet ofabout 750 mm x 600 mm x 250 m size made of 3mm M.S plate capable ofaccommodating two lengths of 65 mm dia. canvas hose of 15 Mtr. length withlocking arrangement and lever for opening the door after breaking glass. Eachhose box to be fitted with glass door in front, painted 'FIRE' in red luminouspaint Hinges should be sturdy to bear the weight of fully open door withoutsagging. Cabinet should be painted two coats of red enamel paint over a primersuitable for fixing to wall /floor with all necessary supports etc. complete asspecified.Supplying and fixing swinging type wall mounted fire hose reel to IS 884 withfire hose of braided rubber to IS 444 suitably reinforced, approved make 19 mmsize and 30 Mtrs. length, with 10 mm tapering branch nozzle in Brass male andfemale coupling with cut off valve attachment including fixing with approvedanchor fasteners and bolts, complete ‐ as specifiedFabricating and fixing M.S Air vessel (air cushion tank) on top of each 150 mmdia. wet riser 300 mm dia. and 1200 mm high with necessary cut off. air releasevalve to release water hammers and air locks as necessary, including two coatsof enamel paint of approved colour over a primer coat after testing. complete asspecified.Providing and fixing 65 x 19 mm G.M adaptor coupling for connection fromlanding valve to hose reel with heavy quality braided flexible rubber pipe ofabout 600 mm length with hose clips etc, complete as specified.Providing and fixing G.M single headed hydrant valve as per IS- 5290 with 80mm dia x 2 mt m.s stand post as a courtyard hydrant, painting / undergroundprotection , complete as specifiedSupplying and fixing 2 lengths of 63 mm dia canvas hose each 15 m long as perIS: 8423,2 nos instantantaneous couplings duly bound to the hose as per IS:903and 1 no. 65 mm dia copper branch pipe with nozzle as per I‐S 903 complete asspecifled.(Fire shaft door will be provided and fixed by Civil Contractor.No. 49No. 7Set 49No. 5No. 49No. 7Set 56Page 25 of 92

Sn. Particulars Unit Qty.A-18Supplying and fixing C.I butterfly valve with tamper proof arrangement, nuts,bolts, gaskets, flanges, coupler etc. complete as specified.i) 80 mm dia No. 23ii) 100 mm dia No. 10iii) 200 mm dia No. 1SECTION – BSIAMESE INLET & BREACH CONNECTIONSB-1 Supplying and fixing Fire Brigade 150 min size breach inlet connection with Set 1four connecting points .65 mm size fixed over 150 mm dia G.I. Pipe necessarycompanion flanges, nuts, bolts, gasket. washers, outlets, necessary bronzecoupling connection : B215 etc. as specified.B-2 Supplying and installing 150 mm C.I. Sluice valve of non rising Spindle type; No. 2approved make as per IS‐780 (PN‐1.6)B-3 Supplying and fixing 150 mm GI 'C' Class pipe including necessary excavation RM 50in earth or murum, bailing or pumping out water from the trenches with shoringwherever necessary, refilling the trenches, removing away the surplus earth ordumping it on site as directed (depth upto 1000 mm) including short lengths andspecials as required, fixing supports,. painting two coats of approved enamelpaint over a coat of approved primer after laying and testing to 13.SKg/Sq.cmcomplete including necessary protective tape or hessian cloth for buried pipingcomplete as specified.B-4 Providing and fixing Siamese in breaching assembly in brass with twin 63 mmbreaching gun metal male inlets with non return valve, blank caps & drain valve.inlet boxes, gates & air release valves conforming to BS‐5041 Part 3 completeas specified.Set 1Page 26 of 92

Sn. Particulars Unit Qty.SECTION – CFIRE PUMPS AND ACCESSORIESC-1 Supplying and installing multistage direct coupled centrifuglal pump or single Set 2stage pump as per manufactures pump characteristics data, cast iron casing andbronze/phosphor bronze internal parts, make approved by Tariff AdvisoryCommittee for fire duty, capable of discharging 47 Ltrs. per sec-against 75metrehead, against all losses, complete, with TEFC motor (H.P of motor to beconfirmed from the pump manufacturer to suit the pump characteristics ) ofapproved make motor winding with class F insulation suitable for starter as perFire Brigade / Supply Co. regulations, base plate. foundation bolts, suitablecable entry gland box. pressure gauges etc. and wired for gauges etc. and wiredfor automatic start on drop of pressure in the wet riser systemC-2 Providing and fixing automatic motor control centre for hydrant, sprinkler &Jockey & Booster pumps to suit the HP of motor for the rated capacity anddesired head of pumps. MCC shall be provided with suitable starters andcontrols fori) 1 No. ‐ Hydrant pump (Electrically operated)ii) 1 No. ‐Fire ' Fighting pump Diesel Engine operated (common stand‐by pumpfor Hydrant & sprinkler)iii) 1 No. ‐Sprinkler pump Electrically operatediv) 2 Nos. ‐ Jockey pumps2 Nos. ‐ Booster Pumps at terrace level (Electrical v) Driven)comprising of automatic switch unit isolators, pressure switches to set operatingpressure, switches rated 500 Volt AC 50 Hz supply for continuous maximumload and Supply Company's regulations, contacts of suitable size, internalisolating baffles, terminal boxes for cables suitably screwed standard 250 Volts.15 Waft bayonet cap, indicator lamps fo; the respective pumps behind rubydomes suitably protected against damage. interlocking arrangements as per FireBrigade stipulatms, auxilary switch/switches to provide warning by lighting of alamp and ftooters; for audible alarm both at pump room and main fire console,tripping a circuit breaker connecting the electric supply to leave ample power forFire Pump, if so required.Auxilary switch to be rated at 5 Amps. 250 Volts AC complete with C.T Set 1connected ammeters, volt meters and selector are to be provided on the panelsfor each starter and incoming switch fuse unit including necessary power &control cabling from panel to respective pumps complete as specified.Note:‐ Contractor should submit necessary shop drawing for approval ofconsultants before fabricating the panel.Page 27 of 92

Sn. Particulars Unit Qty.C-3 Providing and installing pump with discharge and head as in Item C‐I above butcoupled to approved make Diesel Engine mounted with 24 Volts DC startingmotor, push button for manual starting Tacho generator attachment for multiplekicks, electronic panel for automatic starting, fuel tank for eight hours full loadrun of the pump, set of 24 V required ampere‐ hour capacity. heavy duty leadSet 1cell. leak prool battery including interbattery connectors and terminalscomplete, automatic. two rate circuit battery charger suitable for either quick ortrickle rate, suitable for 200/250 V 50 Hz supply, single phase, fabricated baseplate for pump and engine, suitable MB type pressure switches complete. Allcontrol units and instruments to be mounted on MCC specified under Item C‐2.C-4 Supplying and fixing wrought steel or MS fabricated air vessel in pump room300 mm dia. and 1200 high on M.S stand with necessary arrangement andincluding the cut off, drain and air release and drain pipes to the channel inpump room.C-5 Providing and installing jockey pump of 40 gpm at 75 Mt.head against all lossescomplete. With suitable motor and base plate all as Rom No. C‐I Providing andinstallin boostei pump of 450 Ur. per minute against 50 ML head against alllosses complete with suitable motor and base plate all as Rem No. C‐1.Set 5Set 2C-6 Providing and installing booster pump of 450 Ltr. per minute against 50 Mt. Set 2head against all losses complete with suitable motor and base plate all as itemNo. C-1.SECTION‐ DSPRINKLER INSTALLATIOND-1 Providing and fixing G.I 'C' Class pipes with screwed – or welded joints withspecials as necessary clamped to wall, beams or ceilings as per specificationswith approved anchor fastners; MS brackets testing to 13.5 Kg/Sq.cm hydraulkpressure after installation, and painting two coats of enamel paint of approvedcolour over two coats of primer.i) 150 mm dia. ‐do ‐ ‐ do ‐ welded joints - Deleted RMii) 100 mm dia. ‐do ‐ ‐ do ‐ ‐ do ‐ RM 117iii) 80 mm dia. ‐do.‐ ‐ do ‐ ‐ do ‐ RM 350iv) 65 mm dia. ‐do‐ ‐do‐‐do- RM 100v) 50 mmdia. ‐do ‐ ‐ do ‐ serewed joints RM 165vi) 40 mm dia. ‐do ‐ ‐ do ‐ ‐ do ‐ RM 150vii) 32 mm dia. ‐do ‐ ‐ do ‐ ‐ do ‐ RM 1000viii) 25 mm dia. ‐do ‐ ‐ do ‐ do ‐ RM 2600Page 28 of 92

Sn. Particulars Unit Qty.D-2 Supplying and Installing 15 mm dia inlet sprinkler heads brass/ cp With No 1200quartzold bulb, of approved make and quality, to operate at 68 degree C.D-3 Providing and fixing special barrel nipple and 25 mm dia dropper pipes from Set 1200ceiling with necessary 25 x 10 mm / 25 x 15 reducer coupling( Dropper lengthupto 800 mm shall be included in this item. Additional length of dropper pipewhere required shall be paid under item D. 1. h)D-4 Providing and fixing approved make stainless steel bellow type flow switch No 95having a pair of No/Nc contact for alarm signal to apper in fire alarmannunciator on sprinkler branches for connecting to fire alarm annunciatoroperating at 24 V in main console.D-5 Supplying and fixing 150 mm installation valve with 24 V hooter, connection at Set 1pump room and fire console room: complete with drain pipe leading to drain,cabling, pressure & flow switches, Bell etc. complete. (For sprinkler system)D-6 Supplying and fixing 10 mm inlet, approved make side wall sprinkler heads No 25operated at 68 degree C do‐ as item D‐2D-7 Supplying & fixing 25 mm dia G.M. Peet valve for sprinkler draining No 70arrangement of standard approved make.D-8 Supplying and fixing approved flow switch annunciation panel with 50 nos. No 1windows in main console room including cable connections.SECTION – EFIRE EXTINGUISHER & BUCKETSE-1 Supplying and fixing hand held fire extinguisher 5 Kg. capacity dry chemical No 50powder with carbon dioxide cartridges complete with refill, full length backbracket hose and clip as per IS 2171.E-2 do ‐10 Kg. capacity ‐do- No 20E-3 Supplying and fixing hand held fire extinguisher 5 Kg. capacity Co2 with No 50complete with refill, full length back bracket, hose and dip as per IS 2171.E-4 ‐ do ‐10 Kg. capacity ‐do- No 20E-5 Supplying and fixing ISI grade approved 9 Ltrs. capa galvanised round bottomed No 60fire buckets painted Red and lettered 'FIRE' each with a bracket to hang thebucket on a wall or pillar as directed.SCHEDULE OF <strong>IT</strong>EMS FOR ELECTRICAL WORK OF PROPOSEDSTP BUILDINGA POINT WIRINGA.2 Supply, Installation. Testing and commissioning of light points in group controlsystem including 2x2.5 sq. mm coppei flexible 660 V/1.1KV grade insulatedwire, switch, switch board, conduit and material.3 4 Lights controlled by 16A switch. Nos. 43A-3 DeletedPage 29 of 92

Sn. Particulars Unit Qty.A-4 Supply, Installation, Testing and commissioning of Bell/Buzzer point including2x1.5 sq. mm copper 660 V/1.1 KV grade insulated, conduit, bell, buzzer andMaterial.1 Including CPL buzzer board Nos. 22 Including Alarm bell Nos. 1B CIRCU<strong>IT</strong> WIRING/MAINS WIRING,B-1 Supply, Installation, testing and commissioning of 16 gauge HGMS blackenameled ERW grade conduit of approved make with accessories.'1 DIA 32mm conduit ‐(Released part rate) Mtr 885.8B-2 Supply, Installation, Testing and commissioning of following size flexible Mtr 723.7copper wire 660 V/1.1 KV grade of approved make PVC Insulated including MSconduits , pull boxes hardware etc. 2 x 2.5 Sqmm1 2x1.5 sqmm(P&N)+1xl.O sqmm‐(E) Mtr 40002 2x4 sq.mm(P&N)+lx2.5 sq.mm (E) Mtr 15003 2x6 sq.mm(P&N)+lx2.5 sq.mm (E) Mtr 5004 4x2.5 sq.mm(P&N)+2xl.5 sq.mm (E) Mtr 2005 4x4 sq.mm(P&N)+2x2.5 sq.mm (E) Mtr 2006 4k6 sq.mm(P&N)+2x2.5 sq.mm (E) Mtr 200B-3 Supply. Installation, Testing and commissioning of 5A 5 pin switch and socketoutlet on separate board (including supply of all material like MS box, switch,socket and hardware etc).1 1 no. 5A switch and I no. SA socket on separate board. Nos. 75B-4 Supply. Installation, Testing and commissioning of 5A 5 A switch and socket Nos. 46outlet on switch board (including supply of all material like MS box, switch,socket and hardware etc) including wiring between switch and socket.B-5 DeletedB-6 Supply, Installation, Testing and commissioning of 20A industrial socket, 20A Nos. 45pin top and 20A SP MCB with box and the box shall be concealed in wall. Thebox also shall be of respective make of MCB. Including wiring between switchand socket.B-7 Supply, Installation, Testing and commissioning of 32A 3 phase industrial Nos. 5switch and socket complete with all accessories.C CABLING WORKPage 30 of 92

Sn. Particulars Unit Qty.Supply and laying of cables in excavated trenches, concrete trenches, alongwalls, through hume pipes, cable trays etc with testing & commissioning. Thecable shall be 1.1 KV grade, aluminium or copper armoured of approved makeas per following sizes. The scope includes supply & fixing of aluminium cabletags( at every 6 Mts distance).clamps/saddles for dressing of cable/cable routemarkers at every 7 Mtr. distance as ' per drawings, specifications & instructionsof consultant1 3.5c x 300 Sq mm AYFY Mtr 2402 3.5c x 240 Sq mm AYFY Mtr 1003 3.5c x 185 Sq mm AYFY Mtr 4204 Deletec Mtr5 3.5c x 120 Sq mm AYFY Mtr 406 3.5c x 95 Sq mm AYFY Mtr 2107 3.5c x 70 Sq mm AYFY Mtr 508 Deleted Mtr9 Deleted Mtr10 3.5cx25 Sq mm AYFY Mtr 8011 4c x 16 sqmm AYFY Mtr 64012 4c x 10 sqmm AYFY Mtr 200013 4c x 4 sqmm YFY Mtr 237514 4c x 2.5 sqmm YFY Mtr 1375C-2 Cable. termination of armoured cables 1.1 KV grade including supply,&installation of cableglands, cable lugs (copperdouble compression type), heatshrinkable sleeves on long ends, crimping paste etc. The work includes testing &commissioning of cables, meggaring values & submitting reports of tests. (Oneset includes termination of all cores of one end only)1 3.5c x 300 Sq mm AYFY Set 1642 3.5c x: 240 Sq mm AYFY Set 43 3.5c x: 185 Sq mm AYFY Set 124 Deleted Set5 3.5c x 120 Sq mm AYFY Set 146 3.5c x 95 Sq mm AYFY Set 47 3.5c x: 70 Sq mm AYFY Set 48 Deleted Set9 Deleted Set10 3.5cx25 Sq mm AYFY Set 611 4c x 16 sqmm AYFY Set 4012 4c x 10 sqmm AYFY Set 15013 4c x 4 sqmm YFY Set 296Page 31 of 92

Sn. Particulars Unit Qty.14 4cx2.5 sqmm YFY Set 120C-3 Excavation in all type of soil for preparation of cable trench (2M(W)X2M(D)) Cum 3803for power cable and (0.75M (W)x1M (D)) for street lighting including supplyand spreading of sand (Narmada river) and supply and laying of bricks.C-4 Supply and installation of GI perforated (return flange type) cable tray withcover and all accessories like perforated tee , 90 degree horizontal bend elbowhorizontal tee, plain cover, raised cover supports, hangers etc. of following sizes(depth ‐ 100mm)1 2000 mm Mtr 2502 1500 mm Mtr 503 1000 mm Mtr 2004 500 mm Mtr 3505 300 mm Mtr 250D LIGHTING FIXTURES AND FANSSupply , Installation, testing commissioning of lighting fixtures. All fixturesshould be complete with all accessories such as lamps, starters , low loss copperchokes, PF improvement capacitors etc. The fixtures should be completeD-1 Light fitting for parking area suitable for 2x26w cfl lamp fitting. Nos. 650SURFACE TYPE INVICIBLE CIVR 236 OF THORN OR EQUIVALENTFROM APPROVED MAKE LIST.D-2 Light fitting for entrance lobby area suitable for 2x36w CFL lamp fitting Nos. 30(Assymetric wall washer type)WIPRO WCP 90236 OF THORN OR EQUIVALENT FROM APPROVEDMAKE LIST.D-3 Light fitting suitable for 2 x 18w CFL lamp for ramp OD 7018 Nos. 30UNILAMP OR EQUIVALENT FROM APPROVED MAKE LISTD-4 outdoor surface down lights suitable for 2x9W CFL fitting (for outer staircase) Nos. 120NOVELLO CNVS 209 OF THORN MAKE OR EQUIVALENT FROMAPPROVED MAKE LIST.D-5 Light fitting suitable for 2x11w CFL lamp fitting for inner stair case. Nos. 100ORBIL<strong>IT</strong>E CORS 211 OF THORN MAKE OR EQUIVALENT FROMAPPROVED MAKE LIST.D-6 Light fitting suitable for 1 x1 8W CFL lamp for toilets Nos. 120WCP 15118 OF WIPRO OR 4069 OF GEMINI GLOABAL OF THORNMAKE OR EQUIVALENT FROM APPROVED MAKE LIST.D-7 Light fitting suitable for 2x11 W PL/CFL lamp fitting for was basins Nos. 403069 OF GEMINI GLOABAL ‐OR THORN MAKE REQUIVALENT FROMAPPROVED MAKE LIST.Page 32 of 92

Sn. Particulars Unit Qty.D-8 Step light fitting suitable for 1x13W CFL lamp for stairs terrace general area Nos. 30OD 6001 OF UNILAMP OR THORN MAKE OR EQUIVALENT FROMAPPROVED MAKE LIST.D-9 Down light fitting suitable for 2x26w CFLIamp fitting (for ebtrance lobby level Nos. 501 &2)DL 614 OF UNILAMP OR THORN MAKE OR EQUIVALENT FROMAPPROVED MAKE LIST.D- Spot light fitting suitable for 70w MH lamp fitting (for ebtranc lobby level 1 Nos. 1010 &2)WIPRO WCH 50070 OR THORN MAKE OR EQUIVALEN FROMAPPROVED MAKE LIST.D- Spot light fitting suitable for 150 w MH lamp fitting for ebtrarice lobby level 1 Nos. 1011 &2)WIPRO WCH 50150 OR THORN MAKE OR EQUIVALEW FROMAPPROVED MAKE LIST.D- Spot light fitting suitable for 50 w Halogen lamp fitting with transformer. (for Nos. 2012 entrance lobby level 1 &2)WIPRO WCO 12150 OR THORN MAKE OR EQUIVALENT FROMAPPROVED MAKE LIST.D- wall breacket suitable for 2x36W CFL lamp fitting (for ebtrance lobby level 1 Nos. 4013 &2)ATURA OF THORN MAKE OR EQUIVALENT FROM APPROVED MAKELIST.D- Wall recess luminaire suitable for 1x26W CFL lamp for level 1 entrance Nos. 1014SILKA OF UNILAMP OR THORN MAKE OR EQUIVALENT FROMAPPROVED MAKE LIST.D- Mirror Optic fitting Suitable for 2x36 w FTL for dining hall & service lobbies. Nos. 12515PHILIPS XTEND OR THORN MAKE OR EQUIVALENT FROMAPPROVED MAKE LIST.D- Fitting for 20.4 M high void 1X400W MH/SON Nos. 1216WIPRO, PANTASSY FFH 33400 ASSOMETRIC OR THORN MAKE OREQUIVALENT FROM APPROVED MAKE LIST.D- 2X9W surface mounted light fitting for service passages Nos. 5017DL 515 OF UNILAMP OR THORN MAKE OR EQUIVALENT FROMAPPROVED MAKE LIST.Page 33 of 92

Sn. Particulars Unit Qty.D- 2x40W OPAL acrylic fitting for general areas Nos. 10018WRF 21136 OF WIPRO OR THORN MAKE OR EQUIVALENT FROMAPPROVED MAKE LIST.D- 2x40W industrial with reflector fitting for general areas Nos. 15019TKC 24 OF PHILIPS OR THORN MAKE OR EQUIVALENT FROMAPPROVED MAKE LIST.2-19 Sign Boards for toilets,public areas suitable for 1x9W CFL fittings Nos. 60(a)D-20SISZI FOR 2X9W W<strong>IT</strong>H APPROVED SIGNEGES OR THORN MAKE OREQUIVALENT FROM APPROVED MAKE LIST.Fresh air exhaust fan with louver size 200mm dia for toilets. Nos. 75KHA<strong>IT</strong>AN FRESHAIR DELUX OR EQUIVALENT FROM APPROVEDMAKE LIST.D- Industrial duty exhaust fan with louver size 300mm dia for kitchen panel room, Nos. 2021 dg room.KHA<strong>IT</strong>AN OR EQUIVALENT FROM APPROVED MAKE LIST.D- Wall fan sweep 400mm complete with all accessories. Nos. 1022D- Ceiling fan sweep1200mm complete with all accessories Nos. 5023CROPMTON HIGH SPEED OR EQUIVALENT FROM APPROVED MAKELIST.D- Decorative light fitting for outdoor lighting suitable for 1x70W MH lamp Nos. 5524 complete with all accessories for street lighting.NP‐3L‐ NORDICL<strong>IT</strong>E LARGE GEMINI OR SIMILAR PRODUCT FROMAPPROVED MAKE LIST.D- Gate light fitting for suitable for 1x70W MH lamp complete ,with allNos. 425 accessories.OD 7210 OF UNILAMP OR SIMILA RPRODUCT FROM APPROVEDMAKE LIST.D- Bollard fitting for suitable for 1x18wCFL lamp complete with all accessories. Nos. 3026OD 7123 OF UNILAMP OR SIMILA RPRODUCT FROM APPROVEDMAKE LIST.Page 34 of 92

Sn. Particulars Unit Qty.D- Flood light fitting suitable for 2X400w MH lamp for facade lighting Nos. 1027WFZ 554 ASSYMETERIC OF WIPRO OR SIMILA RPRODUCT FROMAPPROVED MAKE LIST.D- Flood light fitting suitable for 1x400w MH lamp for facade lighting Nos. 1028WFZ 330AK/400 OF PHILIPS OR SIMILA RPRODUCT FROM APPROVEDMAKE LIST.D- Neon Lights Nos. 229LED TYPE MIMIC MAKE OR QEUIVALENT FROM APPROVED MAKELIST.E INVERTERSupply installation testing & commissioning of 750va 1Hr back up invertar with12 volt Invagreen Exide or Farukawa make battery . The invertar is to beinstalled on every floor & connection shall be made ‐ with lighting D8 for flooremergency lighting Inverter shall be make MICROTECH/ LUMINIOUS/EXIDENos. 12TELEPHONE WIRING AND COMPUTER CABLINGF-2 Supply. Installation, Testing & commissioning of 0.5 with size tinned copper Mtr. 1600conductor , 2 pair PVC insulated telephone wire of approve make in existing MSconduits laid as per item F.1F-3 Supply, installation. Testing & commissioning of crone type tag block fortermination of telephone cables/conduits In MS sheet steel enclosures as perdrawing and specifications.Tag block 100 pair. Nos. 4Tag block 10 pair. Nos. 50F-4 Supply, Installation, Testing & commissioning of 0.5 mm size copper tinnedconductor armored PVC cable of make of following sizes10 pair. Nos. 150020 pair. Nos. 100100 pair. Nos. 750F-5 Supply, Installation, testing & commissioning of telephone outlet box with top Nos. 30plate.F-6 Supply , Installation testing and commissioning of EPABX with incoming 8 Nosof lines and extension up to 60 lines with operator console and battery bank.Nos. 1F-7 Supply . Installation testing and. commissioning of telephone instruments Nos. 30Page 35 of 92

Sn. Particulars Unit Qty.F-8 Supply , installation testing and commissioning of enhanced CAT E5 LAN cable Mtr. 500in previously laid MS conduits as per item no. F1 .F-9 Supply . installation testing and commissioning of RJ 45 connector type Nos. 20computer socket outlet with RJ 45 connector if approved make.G SLEEVESG-1 Supply, Installation of GI sleeves (hot dipped GI) of following izes made out ofclass '8' duty with bends long radius & accessories40 mm dia GI pipe Mtr. 50G-2 Supply, Installation of non metallic heavy duty PVC sleeves thickness 2 mm) offollowing sizes with bends long radius & accessories50 mm dia PVC pipe Mtr. 75100 mm dia PVC pipe Mtr. 63G-3 Supply, Installation of RCC HUME pipe sleeves in excavated trenches/floor offollowing sizes made with collar, bends long dius & accessories150 mm dia RCC Hume pipe Mtr. 100300 mm dia RCC Hume pipe Mtr. 44PDB level 2 Nos. 1INCOMER200A TPN MCCB ‐ 1 NO.CT RATIO 200/5A ‐6NOSRYB INDICATION W<strong>IT</strong>H CONTROL FUSE ‐ I SET.ECTRONIC METER TO MON<strong>IT</strong>OR VOLTAGE CURRENT, KWH, KW,KVA,PF,HZ ETC.‐ 1 NO.APFCR RELAY 6 STAGE‐ 1 NO.TPN ALUMINUM BUS BAR SU<strong>IT</strong>ABLE FOR 200AOUTGOING32A TPN MCB+7.5KW DOL+KWH METERCT OPERATED FOR ONEPHASE ONLY ‐1 SETS(AHU)40A TPN MCB+12KW FASD+KWH METERCT OPERATED FOR ONEPHASE ONLY ‐1 SETS(PEC) )10A SP MCB ‐ 25 NOS(COMP.)10A SP MCB ‐ 6 NOS(GEN POWER.)16A SP MCB ‐ 6 NOS(GEN POWER.)20ASP MCB ‐ 6 NOS(GEN POWER.)63A TPN MCB ‐ 4SET(SPARE)63 A TPN MCB ‐ 2SET(SUB UPS DB)100A TPN MCCB ‐ 1NO.(UPS)32A TPN SFU+25A HRC+CAPAC<strong>IT</strong>OR DUTY CONTACTOR ‐ 4 SET.32A TPN SFU+25A HRC+CAPAC<strong>IT</strong>OR DUTY CONTACTOR ‐ 2 SET.Page 36 of 92

Sn. Particulars Unit Qty.10 KVAR CAPAC<strong>IT</strong>ORS W<strong>IT</strong>H 7‐14 % DETUNED REACTORS ‐ 4 NOSH-16I4 KVAR CAPAC<strong>IT</strong>ORS W<strong>IT</strong>H 7‐14% DETUNED REACTORS ‐ 2 NOSNOTE : CAPAC<strong>IT</strong>ORS SHALL BE SU<strong>IT</strong>ABLE FOR 3 PHASE 525 VOLT2. EACH AHU FEEDER SHALL HAVEA. CONTROL TRANSFORMER OF 230V / 24V . 350 VA FORMODULATING VALVE SUPPLYB. CONTROL FUSE FOR SUPPLY OF CONTROL OF BMS DEVICESC. THERMOSTAT CONTROL FOR TEMP. RELATED MODULATINGVALVE.D. FEEDBACK AND DATALOGGING OF ALL PARAMETERS AS PERBMSSupply, installation, testing & commissioning energy management system torecord recordings from all energy analysis installed at various incommers &outgoings of It main & distribution panels (66nos.) for monitoring of allelectrical parameters including maximum demand on every feeder and complitdatalogging analysis facility with trend carves, billing facility & safty alarms &trip sets as per details ‐of building management system specried in technicalspecification of this dender. The scope includes supply & installation ofdatalogger for above number of units communication devices for computer ,printer , suitable hardware except energy analysers (which are part of panel andcabling (part of wiring)APPROVED MAKE ENERCON/TATA HONEYWELL/AS PER LIST OFAPPROVED MAKELT EARTHINGSupply, Installation, Testing & commissioning of earthing stations using600x600x6 mm GI plate/600x600x3.15 mm CU plate as earth electrodes buriedJob 1With 600x600x6 mm GI plate. Nos 4DeletedWith 600x600x3.1 5 mm CU plate Nos 17I-2 Supply & laying of hot dipped GI/pure copper earthing strip to connect to theDBS,Poles and equipments in outdoor yard and also in indoor portion ofsubstation25x5 mm GI strip Mtr 68050x5 mm GI strip Mtr 131.8525x5 mm CU strip Mtr 283.550x5 mm CU strip Mtr 21010 G GI wire Mtr 800Page 37 of 92

Sn. Particulars Unit Qty.10 G CU Solid wire Mtr 500J STREET LIGHTINGJ-1 DeletedJ-2 Supply, installation, Testing and commissioning of weather proof pole mounting Nos. 55control gear box with 5A English electric make HRC fuse, 2A approve makemake MCB, approve make 4 way x 30A lock type connector strip. gland plate toaccommodate up to 3 cables of 4C * 16 sq. mm. 'AL' armoured, Nipple for wireetc. & earth stud. The control gear shall be hinged door type and to have keylock system with rubber gas keting. Mounting damp arrangement shall beprovided as per dwg. & specifications.K FIRE ALARM SYSTEM / CCTV / PUBLIC ADDRESSK-2 Supply and installation, testing and commissioning approved make 1.1KV grade Mtr. 800PVC insulated wire copper conductor flexible (frls) in conduits laid for firealarm systema) 3 x 1.0 mm2K-3 Supply, installation, testing and commissioning of intelligent addressable double Nos 150ionization chamber type smoke detectors / heat detectors of approved make. Thework Includes all hardware, clamps and small materials required for installationof sensor.K-5 Supply, installation, testing and commissioning of approved make exit glow Nos 160signs with lamp 24V DC operated for route indications as required forinstallation of sensor.K-6 Supply , Installation, testing and commissioning of approved make manual breakglass type pill box with die cast aluminium body and LED indicator The switchshall give alarm and indication on fire alarm panel.Nos 50Page 38 of 92