Upac2000_mini:upac 2000mini.qxd - Michele Caroli Srl

Upac2000_mini:upac 2000mini.qxd - Michele Caroli Srl

Upac2000_mini:upac 2000mini.qxd - Michele Caroli Srl

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

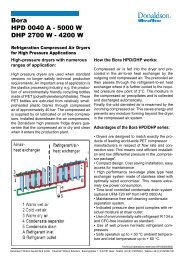

GBTechnical Data SheetPage 1 of 3Ultrapac 2000 Standard,Ultrapac 2000 Superplus,Mini (Typ 0005 to 0025)Complete purification package with heatless adsorption dryer,pre-, afterfilter and condensate drain.Compressed air is led through theinlet of the dryer (1) and across theprefilter (2).At this stage, the air is cleaned fromparticles and condensate.The condensate is removed via themembrane condensate drain (3).Via the lower shuttle valve (4), the airis led into desiccant cartridges (5), inwhich the air is dried down to therequired dewpoint.Via the upper shuttle valve (6), the airgets into an afterfilter (7), in whichparticles from the desiccant are retained.Via the outlet (8), the clean and dryair is lead into the compressed airnetwork to the point of use.While one vessel with desiccant cartridgeis in the drying phase (adsorption),the other cartridge is beingdried again (regeneration).A partial stream of dried air is expandedvia an orifice and lead accrossthe desiccant cartridge for regenerationand via a solenoid valve and asilencer system to the atmosphere.Ultrapac2000Volume flow inm 3 /h(1 bar, 20°C)** Related to 1 bar (abs) and 20 °C at inlet of compressor and 7 bar (g) and 35 °C inlet temperature5Ultrapac 2000StandardRegenerationair losses (average)m 3 /h(1 bar, 20°C)6Volume flow out(min.)m 3 /h(1 bar, 20°C)Pressurelossinitialmbar7PrefilterMFAfterfilterPEamountofcartridges0005 5 0.85 3.95 65 02/05 02/05 20010 10 1.70 7.90 95 03/05 03/05 40015 15 2.55 11.85 115 04/10 04/10 60025 25 4.25 19.75 250 06/10 06/10 108143 2Technical alterations reserved (R04/ 2007/04/24)Donaldson Filtration Deutschland GmbH · Industrial Filtration Solutions · Büssingstraße 1 · D-42781 Haan · Telefon +49/2129/569-0 · Telefax +49/2129/569-100

GBTechnical Data SheetPage 2 of 3Ultrapac 2000 Standard Mini / Superplus MiniFeatures Ultrapac 2000 series:Purification package complete withpre-, afterfilter and condensate drain.Desiccant in cartridgesCompact, space saving designComponent exchange displayUnique Multifunction BlockBenefits:Features Ultrapac 2000 Superplus: Benefits:Intermittent operationThrottle packageLoad controlSelf-Diagnosis-SystemTurnkey System, no additional installation cost; allcomponents from one hand, therefore perfect technicalmatchEasy storage, transport and installation; optimum fixationof desiccant; no risk of fluidizing of desiccantInstallation in smallest spaces, possible also as retrofitHigh operating safety, due to calculation of optimumexchange point for filter elements and desiccantcartridges.All moving parts and all electronic componentsintegrated in a function block, therefore easy andefficient maintenanceLink between dryer and compressor possible on centralapplications, therefore saving of regeneration airBy means of enclosed throttle package and automaticadaptation of the control at inputted operating conditions,an optimal regeneration air consumption and amaximally possible flow according to the correction factortable within the total range of 4-16 bar (g) and 25-50°C is reachedAdjustment of adsorption cycles to the actual inlet waterload, therefore saving of regeneration air and reductionof operating costSensor-controlled monitoring of regenerationair flow, therefore without-gap-monitoring of dryerfunctions and of system pressureProduct description:Ultrapac 2000 Standard andSuperplus:Complete purification package, consistingof heatless adsorption dryerwhich works on the basis of pressureswing adsorption, with integratedpre- and after filter and electroniccondensate drainMedium:Compressed air/ nitrogenPressure dewpoint–40 °C at 100% load, –70 °C at70% of rated flow and a maximuminlet temperature of 35 °COperation pressure:min. 4 bar (g), max. 16 bar (g)Medium temperature:min. 5 °C, max. 50 °CAmbient temperature:min. 4 °C, max. 50 °CCompressed air consumption:Text DisplayInfo-ChannelEconomizer-FunctionDisplay of all operating status, of fault indication andmaintenance intervals in clear text messagesSerial interface for transmission of alarm- and maintenancemessagesOnline calculation of optimum exchange point of filterelements by continuous evaluation of energy costversus cost of replacement filter element17% of the rated flow, in averagePower supply:230 V/50 -60 Hz AC;110 V/50 -60 Hz AC24 V DC; 24 V AC on requestSizing:Power consumption:.f4bar(g)5bar(g)6bar(g)7bar(g)8bar(g)9bar(g)10bar(g)11bar(g)12bar(g)13bar(g)14bar(g)15bar(g)16bar(g)25°C 0.69 0.82 0.96 1.10 1.24 1.38 1.50 1.50 1.50 1.50 1.50 1.50 1.5030°C 0.69 0.82 0.96 1.10 1.24 1.38 1.50 1.50 1.50 1.50 1.50 1.50 1.5035°C 0.63 0.75 0.88 1.00 1.13 1.26 1.38 1.50 1.50 1.50 1.50 1.50 1.5040°C 0.48 0.58 0.68 0.77 0.87 0.96 1.06 1.16 1.25 1.35 1.45 1.50 1.5045°C 0.38 0.45 0.53 0.60 0.68 0.75 0.83 0.90 0.98 1.05 1.13 1.20 1.2850°C 0.30 0.36 0.42 0.48 0.54 0.60 0.66 0.72 0.78 0.84 0.90 0.96 1.02V corr =.V nomfExample: V nom = 22 Nm 3 /h, Inlet temperature = 30°C, Operating pressure = 10 bar (g).V korr =.22 m 3 /h1.50= 14.66 m 3 /h.Calculated dryer size: Ultrapac 2000, type 0015approx. 4 WMaterials:ExtrudedProfilesAdsorber andFilter lidsDeclaration of conformity:acc. to 73/23/EC97/23/ECAnodizedAlu<strong>mini</strong>umGlass fiberenforced polyamide

GBTechnical Data SheetPage 3 of 3Ultrapac 2000 Standard MiniUltrapac 2000 Superplus MiniGGBDECAUltrapac 2000 MiniTypeGABCDE“mmmmmmmmmm0005 G 1 /2 300 121 343 84 2730010 G 1 /2 300 121 591 208 3970015 G 1 /2 300 121 853 339 5280025 G 1 /2 300 121 1377 601 789