Installation Operation Maintenance

Installation Operation Maintenance

Installation Operation Maintenance

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

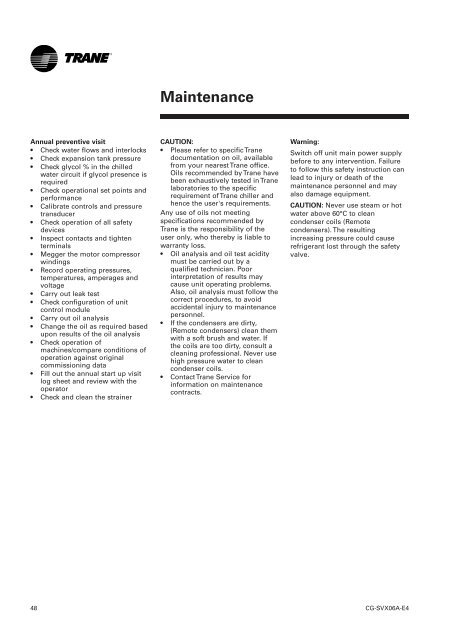

<strong>Maintenance</strong>Annual preventive visit• Check water flows and interlocks• Check expansion tank pressure• Check glycol % in the chilledwater circuit if glycol presence isrequired• Check operational set points andperformance• Calibrate controls and pressuretransducer• Check operation of all safetydevices• Inspect contacts and tightenterminals• Megger the motor compressorwindings• Record operating pressures,temperatures, amperages andvoltage• Carry out leak test• Check configuration of unitcontrol module• Carry out oil analysis• Change the oil as required basedupon results of the oil analysis• Check operation ofmachines/compare conditions ofoperation against originalcommissioning data• Fill out the annual start up visitlog sheet and review with theoperator• Check and clean the strainerCAUTION:• Please refer to specific Tranedocumentation on oil, availablefrom your nearest Trane office.Oils recommended by Trane havebeen exhaustively tested in Tranelaboratories to the specificrequirement of Trane chiller andhence the user's requirements.Any use of oils not meetingspecifications recommended byTrane is the responsibility of theuser only, who thereby is liable towarranty loss.• Oil analysis and oil test aciditymust be carried out by aqualified technician. Poorinterpretation of results maycause unit operating problems.Also, oil analysis must follow thecorrect procedures, to avoidaccidental injury to maintenancepersonnel.• If the condensers are dirty,(Remote condensers) clean themwith a soft brush and water. Ifthe coils are too dirty, consult acleaning professional. Never usehigh pressure water to cleancondenser coils.• Contact Trane Service forinformation on maintenancecontracts.Warning:Switch off unit main power supplybefore to any intervention. Failureto follow this safety instruction canlead to injury or death of themaintenance personnel and mayalso damage equipment.CAUTION: Never use steam or hotwater above 60°C to cleancondenser coils (Remotecondensers). The resultingincreasing pressure could causerefrigerant lost through the safetyvalve.48CG-SVX06A-E4