Acro® 50A Filters - Pall Corporation (PLL)

Acro® 50A Filters - Pall Corporation (PLL)

Acro® 50A Filters - Pall Corporation (PLL)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

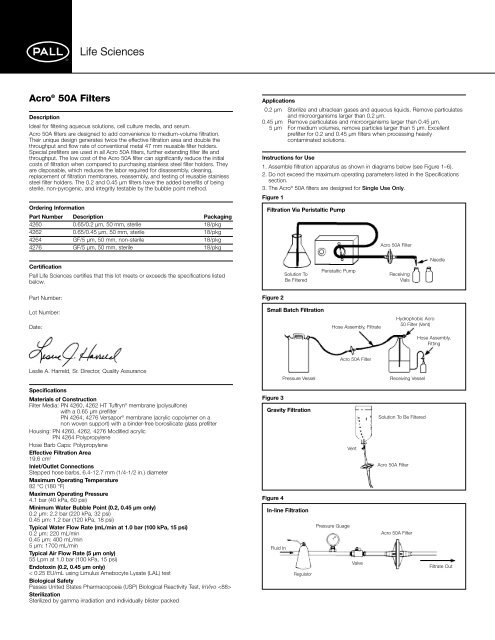

Acro ® <strong>50A</strong> <strong>Filters</strong>DescriptionIdeal for filtering aqueous solutions, cell culture media, and serum.Acro <strong>50A</strong> filters are designed to add convenience to medium-volume filtration.Their unique design generates twice the effective filtration area and double thethroughput and flow rate of conventional metal 47 mm reusable filter holders.Special prefilters are used in all Acro <strong>50A</strong> filters, further extending filter life andthroughput. The low cost of the Acro <strong>50A</strong> filter can significantly reduce the initialcosts of filtration when compared to purchasing stainless steel filter holders. Theyare disposable, which reduces the labor required for disassembly, cleaning,replacement of filtration membranes, reassembly, and testing of reusable stainlesssteel filter holders. The 0.2 and 0.45 µm filters have the added benefits of beingsterile, non-pyrogenic, and integrity testable by the bubble point method.Ordering InformationPart Number Description Packaging4260 0.65/0.2 µm, 50 mm, sterile 18/pkg4262 0.65/0.45 µm, 50 mm, sterile 18/pkg4264 GF/5 µm, 50 mm, non-sterile 18/pkg4276 GF/5 µm, 50 mm, sterile 18/pkgApplications0.2 µm Sterilize and ultraclean gases and aqueous liquids. Remove particulatesand microorganisms larger than 0.2 µm.0.45 µm Remove particulates and microorganisms larger than 0.45 µm.5 µm For medium volumes, remove particles larger than 5 µm. Excellentprefilter for 0.2 and 0.45 µm filters when processing heavilycontaminated solutions.Instructions for Use1. Assemble filtration apparatus as shown in diagrams below (see Figure 1–6).2. Do not exceed the maximum operating parameters listed in the Specificationssection.3. The Acro ® <strong>50A</strong> filters are designed for Single Use Only.Figure 1Filtration Via Peristaltic PumpAcro <strong>50A</strong> FilterCertification<strong>Pall</strong> Life Sciences certifies that this lot meets or exceeds the specifications listedbelow.Solution ToBe FilteredPeristaltic PumpReceivingVialsNeedlePart Number:Figure 2Lot Number:Date:Small Batch FiltrationHose Assembly, FiltrateHydrophobic Acro50 Filter (Vent)Hose Assembly,FittingAcro <strong>50A</strong> FilterLeslie A. Harreld, Sr. Director, Quality AssurancePressure VesselReceiving VesselSpecificationsMaterials of ConstructionFilter Media: PN 4260, 4262 HT Tuffryn ® membrane (polysulfone)with a 0.65 µm prefilterPN 4264, 4276 Versapor ® membrane (acrylic copolymer on anon woven support) with a binder-free borosilicate glass prefilterHousing: PN 4260, 4262, 4276 Modified acrylicPN 4264 PolypropyleneHose Barb Caps: PolypropyleneEffective Filtration Area19.6 cm 2Inlet/Outlet ConnectionsStepped hose barbs, 6.4-12.7 mm (1/4-1/2 in.) diameterMaximum Operating Temperature82 °C (180 °F)Maximum Operating Pressure4.1 bar (40 kPa, 60 psi)Minimum Water Bubble Point (0.2, 0.45 µm only)0.2 µm: 2.2 bar (220 kPa, 32 psi)0.45 µm: 1.2 bar (120 kPa, 18 psi)Typical Water Flow Rate (mL/min at 1.0 bar (100 kPa, 15 psi)0.2 µm: 220 mL/min0.45 µm: 400 mL/min5 µm: 1700 mL/minTypical Air Flow Rate (5 µm only)55 Lpm at 1.0 bar (100 kPa, 15 psi)Endotoxin (0.2, 0.45 µm only)< 0.25 EU/mL using Limulus Amebocyte Lysate (LAL) testBiological SafetyPasses United States Pharmacopoeia (USP) Biological Reactivity Test, InVivo SterilizationSterilized by gamma irradiation and individually blister packedFigure 3Gravity FiltrationVentFigure 4In-line FiltrationPressure GuageFluid InValveRegulatorSolution To Be FilteredAcro <strong>50A</strong> FilterAcro <strong>50A</strong> FilterFiltrate Out

Instructions for Use (cont.)Figure 5Syringe Volume FiltrationWARNINGEmployment of the products in applications not specified, or failure to followall instructions contained in this product information insert, may result inimproper functioning of the product, personal injury, or damage to propertyor the product. See Statement of Warranty in our most recent catalog.Acro ® <strong>50A</strong> FilterATTENTIONL’utilisation de nos produits dans des applications pour lesquelles ils nesont pas spécifiés ou le non-respect du mode d’emploi qui figure sur cedocument, peut entrainer un disfonctionnement du produit, endommager leproduit ou d’autres biens matériels ou représenter un risque pour l’utilisateur.Se référer à la clause de garantie de notre catalogue le plus récent.Figure 6Vacuum FiltrationAcro <strong>50A</strong> FilterACHTUNGDer Einsatz dieses Produktes in Anwendungen für die es nicht spezifiziertist, oder das Nichtbeachten einiger, in dieser Bedienungsanleitunggegebenen Hinweise kann zu einem schlechteren Ergebnis, oder Zerstörungdes Produktes oder anderer Dinge oder gar zu Verletzungen führen.Beachten Sie auch unsere Garantiebedingungen im aktuellen Katalog.Solution To Be FilteredTo Vacuum SourceADVERTENCIAEl uso de este producto en aplicaciones no especificadas o el no considerarlas instrucciones indicadas en la hoja de información del producto puedeocasionar un mal funcionamiento del producto, daños en las instalaciones oen el producto y riesgo para el personal del laboratorio. Consulte elapartado de Garantía en nuestro último catálogo.Integrity TestingFilter integrity confirmation is recommended before and after filtration usingstandard techniques. To ensure test validity, all membrane pores must be fullywetted with liquid prior to applying air test pressure. The flushing procedure belowis designed to ensure adequate wetting.Bubble Point Method1. Orient the filter with the outlet port pointed upwards.2. Starting with low pressure (< 0.3 bar, 30 kPa, 5 psi), carefully initiate liquid flow.Avoid introduction of air.3. Gradually increase liquid pressure to a minimum of 2.4 bar (240 kPa, 35 psi) andpass a minimum of 250 mL of wetting solution through the filter4. Release the liquid pressure and disconnect the flow source.5. Apply a compressed air source to the filter on the inlet side and increase thepressure to one psi below the recommended minimum bubble point listed in theSpecifications section.6. Wait 30 seconds and place the filter outlet under water (either directly or via aconnected length of tubing). Any evidence of airflow (rapid continuous bubbling)indicates a bubble point failure. Integral filters should show no visible bubbling.After the test, carefully relieve the pressure before disassembling the equipment.Alternate testing methodology may be used as determined appropriate by the filteruser.ATTENZIONEL’impiego dei prodotti in applicazioni non specificate, o il mancato rispettodi tutte le istruzioni contenute nel presente bollettino tecnico, potrebberoportare ad un utilizzo improprio del prodotto, ferire gli operatori, odanneggiare le caratteristiche del prodotto stesso. Consultare ladichiarazione di garanzia pubblicata nel nostro più recente catalogo.Chemical CompatibilityChemical compatibility data is listed in the current <strong>Pall</strong> Life Sciences catalog. Formore information, or to request a copy of the current literature, please contact yourlocal <strong>Pall</strong> Life Sciences office listed on the bottom of this page.Complementary ProductsHardware and AccessoriesPart Number Description Packaging12941 AcroPak 200 with Supor ® Membrane, 3/pkg200 cm 2 , 0.8/0.2 µm, sterile12069 AcroPak 200 with Fluorodyne ® II Membrane, 3/pkg200 cm 2 , 0.2 µm, sterile12158 Micro Culture Capsule with Filling Bell, HT Tuffryn ® 1/pkgMembrane, 300 cm 2 , 0.2/0.2 µm, sterile12122 Mini Capsule with HT Tuffryn Membrane, 1/pkg500 cm 2 , 0.45/0.2 µm, sterile12123 Mini Capsule with Versapor ® Membrane, 1/pkg500 cm 2 , 0.8/0.45 µm, sterile<strong>Pall</strong> Life Sciences600 South Wagner RoadAnn Arbor, MI 48103-9019 USAFor ordering or technical information:In USA and CanadaTel: 734-665-0651800-521-1520Fax: 734-913-6114Outside USA and Canada+800 PALL LIFE+800 7255 5433Visit <strong>Pall</strong> Life Sciences on theWeb at www.pall.com/Lab orE-mail us at Lab@pall.comOffices:Australia, Cheltenham, VIC, 03 8586 81<strong>50A</strong>ustria, Wien, 00 1 49 192 0Canada, Ontario, 905-542-0330Canada, Québec, 514-332-7255China, P.R., Beijing, 86-10-8458 4010France, St. Germain-en-Laye, 01 30 61 39 92Germany, Dreieich, 06103-307 333India, Mumbai, 91 (0) 22 55995555Italy, Milano, 02 47 79 61Japan, Tokyo, 03-6901-5800Korea, Seoul, 82-2-560-7834Malaysia, Selangor, +60 3 5569 4892New Zealand, Hamilton, +64 7 957 9510Poland, Warszawa, 22 510 2100Russia, Moscow, 5 01 787 76 14Singapore, (65) 389-6500South Africa, Johannesburg, +27-11-2662300Spain, Madrid, 91-657-9876Sweden, Lund, (0)46 158400Switzerland, Basel, 061-638 39 00Taiwan, Taipei, 886 2 2545 5991Thailand, Bangkok, 66 2937 1055United Kingdom, Farlington, 02392 302600<strong>Pall</strong>, , Acro, AcroPak, Fluorodyne, Supor, Tuffryn, and Versapor are trademarks of <strong>Pall</strong> <strong>Corporation</strong>.® indicates a registered trademark in the USA.© 2007, <strong>Pall</strong> <strong>Corporation</strong>, 11/07 PN 82276AA