ContiTech Force Transmission Data sheet and instruction of use ...

ContiTech Force Transmission Data sheet and instruction of use ... ContiTech Force Transmission Data sheet and instruction of use ...

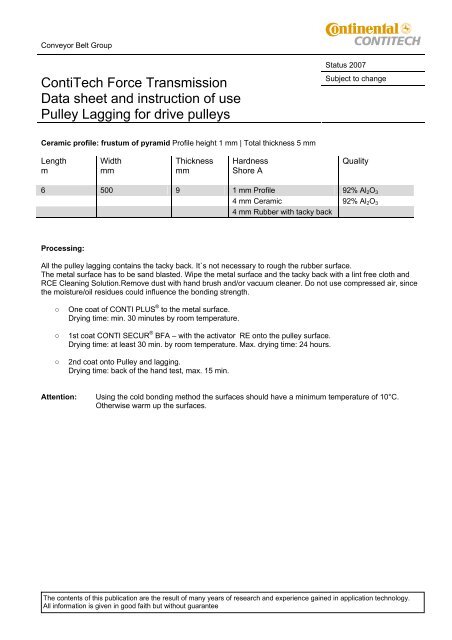

Conveyor Belt GroupContiTech Force TransmissionData sheet and instruction of usePulley Lagging for drive pulleysStatus 2007Subject to changeCeramic profile: frustum of pyramid Profile height 1 mm | Total thickness 5 mmLengthmWidthmmThicknessmmHardnessShore AQuality6 500 9 1 mm Profile 92% Al 2 O 34 mm Ceramic 92% Al 2 O 34 mm Rubber with tacky backProcessing:All the pulley lagging contains the tacky back. It`s not necessary to rough the rubber surface.The metal surface has to be sand blasted. Wipe the metal surface and the tacky back with a lint free cloth andRCE Cleaning Solution.Remove dust with hand brush and/or vacuum cleaner. Do not use compressed air, sincethe moisture/oil residues could influence the bonding strength.○○○One coat of CONTI PLUS ® to the metal surface.Drying time: min. 30 minutes by room temperature.1st coat CONTI SECUR ® BFA – with the activator RE onto the pulley surface.Drying time: at least 30 min. by room temperature. Max. drying time: 24 hours.2nd coat onto Pulley and lagging.Drying time: back of the hand test, max. 15 min.Attention:Using the cold bonding method the surfaces should have a minimum temperature of 10°C.Otherwise warm up the surfaces.The contents of this publication are the result of many years of research and experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt SystemsContiTech Force TransmissionCORREX ® - CeramicPulley LaggingStatus 2007Subject to changeDescription:Applications:Design:Profiled Ceramic lagging for drive – and tail pulleysPulley lagging for heavy duty and difficult applications like:- Sticky material- High abrasion- Wet condition3 types available. Width of the pulleys: 500 – 2100 mmAvailability:Thickness Available width Useable width of the pulleysapprox. mm 320 mmmm12 incl. Ceramic L 500 - 2100L = Stock item500 - 2100 mm320 mmSample „3“ Sample „4“Sample „5“The contents of this publication are the result of many years of research and experience gained in application technology.All information is given in good faith but without guarantee

- Page 1: Conveyor Belt GroupContiTech Force

- Page 5 and 6: Conveyor Belt GroupContiTech Force

- Page 7 and 8: Conveyor Belt SystemsContiTech Forc

- Page 9 and 10: Conveyor Belt GroupContiTech Force

- Page 11 and 12: Conveyor Belt GroupContiTech Force

- Page 13 and 14: Conveyor Belt GroupContiTech Force

- Page 15 and 16: Conveyor Belt GroupContiTech Force

- Page 17: Conveyor Belt GroupContiTech Force

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong><strong>Data</strong> <strong>sheet</strong> <strong>and</strong> <strong>instruction</strong> <strong>of</strong> <strong>use</strong>Pulley Lagging for drive pulleysStatus 2007Subject to changeCeramic pr<strong>of</strong>ile: frustum <strong>of</strong> pyramid Pr<strong>of</strong>ile height 1 mm | Total thickness 5 mmLengthmWidthmmThicknessmmHardnessShore AQuality6 500 9 1 mm Pr<strong>of</strong>ile 92% Al 2 O 34 mm Ceramic 92% Al 2 O 34 mm Rubber with tacky backProcessing:All the pulley lagging contains the tacky back. It`s not necessary to rough the rubber surface.The metal surface has to be s<strong>and</strong> blasted. Wipe the metal surface <strong>and</strong> the tacky back with a lint free cloth <strong>and</strong>RCE Cleaning Solution.Remove dust with h<strong>and</strong> brush <strong>and</strong>/or vacuum cleaner. Do not <strong>use</strong> compressed air, sincethe moisture/oil residues could influence the bonding strength.○○○One coat <strong>of</strong> CONTI PLUS ® to the metal surface.Drying time: min. 30 minutes by room temperature.1st coat CONTI SECUR ® BFA – with the activator RE onto the pulley surface.Drying time: at least 30 min. by room temperature. Max. drying time: 24 hours.2nd coat onto Pulley <strong>and</strong> lagging.Drying time: back <strong>of</strong> the h<strong>and</strong> test, max. 15 min.Attention:Using the cold bonding method the surfaces should have a minimum temperature <strong>of</strong> 10°C.Otherwise warm up the surfaces.The contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee