ContiTech Force Transmission Data sheet and instruction of use ...

ContiTech Force Transmission Data sheet and instruction of use ...

ContiTech Force Transmission Data sheet and instruction of use ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

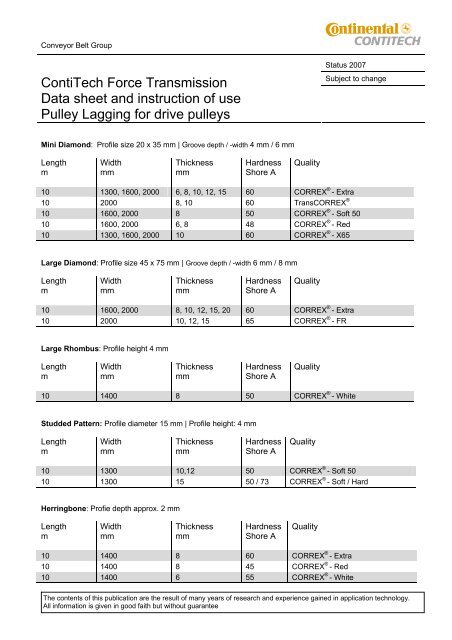

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong><strong>Data</strong> <strong>sheet</strong> <strong>and</strong> <strong>instruction</strong> <strong>of</strong> <strong>use</strong>Pulley Lagging for drive pulleysStatus 2007Subject to changeMini Diamond: Pr<strong>of</strong>ile size 20 x 35 mm | Groove depth / -width 4 mm / 6 mmLengthmWidthmmThicknessmmHardnessShore AQuality10 1300, 1600, 2000 6, 8, 10, 12, 15 60 CORREX ® - Extra10 2000 8, 10 60 TransCORREX ®10 1600, 2000 8 50 CORREX ® - S<strong>of</strong>t 5010 1600, 2000 6, 8 48 CORREX ® - Red10 1300, 1600, 2000 10 60 CORREX ® - X65Large Diamond: Pr<strong>of</strong>ile size 45 x 75 mm | Groove depth / -width 6 mm / 8 mmLengthmWidthmmThicknessmmHardnessShore AQuality10 1600, 2000 8, 10, 12, 15, 20 60 CORREX ® - Extra10 2000 10, 12, 15 65 CORREX ® - FRLarge Rhombus: Pr<strong>of</strong>ile height 4 mmLengthmWidthmmThicknessmmHardnessShore AQuality10 1400 8 50 CORREX ® - WhiteStudded Pattern: Pr<strong>of</strong>ile diameter 15 mm | Pr<strong>of</strong>ile height: 4 mmLengthmWidthmmThicknessmmHardnessShore AQuality10 1300 10,12 50 CORREX ® - S<strong>of</strong>t 5010 1300 15 50 / 73 CORREX ® - S<strong>of</strong>t / HardHerringbone: Pr<strong>of</strong>ie depth approx. 2 mmLengthmWidthmmThicknessmmHardnessShore AQuality10 1400 8 60 CORREX ® - Extra10 1400 8 45 CORREX ® - Red10 1400 6 55 CORREX ® - WhiteThe contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong><strong>Data</strong> <strong>sheet</strong> <strong>and</strong> <strong>instruction</strong> <strong>of</strong> <strong>use</strong>Pulley Lagging for drive pulleysStatus 2007Subject to changeCeramic pr<strong>of</strong>ile: frustum <strong>of</strong> pyramid Pr<strong>of</strong>ile height 1 mm | Total thickness 5 mmLengthmWidthmmThicknessmmHardnessShore AQuality6 500 9 1 mm Pr<strong>of</strong>ile 92% Al 2 O 34 mm Ceramic 92% Al 2 O 34 mm Rubber with tacky backProcessing:All the pulley lagging contains the tacky back. It`s not necessary to rough the rubber surface.The metal surface has to be s<strong>and</strong> blasted. Wipe the metal surface <strong>and</strong> the tacky back with a lint free cloth <strong>and</strong>RCE Cleaning Solution.Remove dust with h<strong>and</strong> brush <strong>and</strong>/or vacuum cleaner. Do not <strong>use</strong> compressed air, sincethe moisture/oil residues could influence the bonding strength.○○○One coat <strong>of</strong> CONTI PLUS ® to the metal surface.Drying time: min. 30 minutes by room temperature.1st coat CONTI SECUR ® BFA – with the activator RE onto the pulley surface.Drying time: at least 30 min. by room temperature. Max. drying time: 24 hours.2nd coat onto Pulley <strong>and</strong> lagging.Drying time: back <strong>of</strong> the h<strong>and</strong> test, max. 15 min.Attention:Using the cold bonding method the surfaces should have a minimum temperature <strong>of</strong> 10°C.Otherwise warm up the surfaces.The contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt Systems<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® - CeramicPulley LaggingStatus 2007Subject to changeDescription:Applications:Design:Pr<strong>of</strong>iled Ceramic lagging for drive – <strong>and</strong> tail pulleysPulley lagging for heavy duty <strong>and</strong> difficult applications like:- Sticky material- High abrasion- Wet condition3 types available. Width <strong>of</strong> the pulleys: 500 – 2100 mmAvailability:Thickness Available width Useable width <strong>of</strong> the pulleysapprox. mm 320 mmmm12 incl. Ceramic L 500 - 2100L = Stock item500 - 2100 mm320 mmSample „3“ Sample „4“Sample „5“The contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt Systems<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® - CeramicPulley LaggingStatus 2007Subject to change1mm64 mm1 mm4mm20 mm 20 mm8mm328-331 mmCross – Section – Sample 3 / 429 mm10 mm20 mm4,5 mm20 mm8 mmCross – Section - Sample 5The contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® -ExtraMini Diamond / Large Diamond / HerringboneStatus 2007Subject to changeDescriptionApplication:Black SBR – compound with tacky backDiamond-, Mini- Diamond <strong>and</strong> Herringbone patternGroove depth: 6 – <strong>and</strong> 4mmLagging for driven pulleysParameters Measurement Physical Values(mean value)DIN St<strong>and</strong>ardSpecific weight* g / cm 3 1.15 53550Shore hardness Shore A 63 53505Tensile strength N / mm 2 18 53504Elongation at break % 450 53504Abrasion mm 3 120 53516*Material subject to wearAvailability: Mini DiamondThicknessmmAvailable widths1300 mmAvailable widths1600 mmMinimum ordermAvailable widths2000 mmMinimumorder m6 A A 50 L8 A A 50 A 5010 A A 50 A 5012 A A 50 A 5015 A A 50 A 50Availability: Large DiamondThicknessmmAvailable widths1600 mmMinimum ordermAvailable widths2000 mmMinimum orderm8 A 50 A 5010 A 50 L12 A 50 L15 A 50 L20 A 50 LThe contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® -ExtraMini Diamond / Large Diamond / HerringboneStatus 2007Subject to changeAvailability: HerringboneThicknessmmAvailable width1400 mm8 LA= Production to order, L = Stock itemThe contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt Systems<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® - Extra Stripe laggingStatus 2007Subject to changeDescription:Applications:Black SBR – compound with tacky backSt<strong>and</strong>ard qualityLagging for drive pulleys, wet <strong>and</strong> dry conditions.Parameters Measurement Physical Values(mean value)DIN St<strong>and</strong>ardSpecific weight* g / cm 3 1.16 53479Shore hardness Shore A 60 53505Tensile strength N / mm 2 15.0 53504Elongation at break % 450 53504Abrasion mm 3 110 53516* Material subject to wearAvailabilityThicknessmmAvailable width370 mmAvailable lengthmm12 L Up to 50.00020 L Up to 50.000L = Stock item370 mm345 mm40 mm 10 mmThe contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® - MSHA Stripe LaggingStatus 2007Subject to changeDescription:Application:Black SBR – compound with tacky back.Flame retardent quality.Pulley lagging for drive pulleys.Dry – <strong>and</strong> wet conditionsParameters Measurement Physical Values DIN St<strong>and</strong>ard(mean value)Specific weight* g / cm 3 1.16 53479Shore hardness Shore A 60 53505Tensile strength N / mm 2 15 53504Elongation at break % 450 53504Abrasion mm 3 110 53516* subject to wearAvailability:Thicknessapprox. mmAvailable Width370 mmAvailable Lengthmm12 L Up to 50.00020 L Up to 50.000L = Stock item370 mm355 mm40 mm10 mmThe contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® FR Large DiamondStatus 2007Subject to changeDescription:Application:Black SBR – compound with tacky back.Flame retardent; groove depth: 6 mmPulley laggingParameters Measurement Physical Values(mean value)DIN St<strong>and</strong>ardSpecific weight* g / cm 3 1,18 53550Shore hardness Shore A 65 53505Tensile strength N / mm 2 24 53504Elongation at break % 500 53504Abrasion mm 3 100 53516* Material subject to wearAvailability: Large DiamondThicknessmmWidth2000 mm10 A12 L15 AA – Production to order, L – Stock itemThe contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® - Wine-redSupercreppStatus 2007Subject to changeDescription:Wine-red NR – compound with tacky backParameters Measurement Physical Values(mean value)DIN St<strong>and</strong>ardSpecific weight* g / cm 3 0.98 53550Shore hardness Shore A 37 53505Tensile strength N / mm 2 16 53504Elongation at break % 700 53504Abrasion mm 3 250 53516* Material subject to wearAvailability: Supercrepp-Pr<strong>of</strong>ileThicknessmmWidth1350 mmMinimum Order (A)mm2,4 A 66A = Product to orderThe contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without gurantee

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® -RedMini Diamond / HerringboneStatus 2007Subject to changeDescription:Red SBR – compound with tacky back.Pr<strong>of</strong>ile depth: 4mm / 2mmParameters Measurement Physical Values(mean value)DIN St<strong>and</strong>ardSpecific weight* g / cm 3 1.10 53550Shore hardness Shore A 45 53505Tensile strength N / mm 2 28 53504Elongation at break % 700 53504Abrasion mm 3 175 53516* Material subject to wearAvailability: Mini DiamondThicknessmmWidth1600 mmWidth2000 mmMinimum Orderm6 A A 508 A A 50A = Product to orderAvailability: HerringboneThicknessmmWidth1400 mm8 LL = Stock itemThe contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® - S<strong>of</strong>t 50 Mini DiamondStatus 2007Subject to changeDescription:Application:Black NR – compound with tacky back.Abrasion- <strong>and</strong> low temperature resistant.Pr<strong>of</strong>ile depth: 4 mmPulley lagging against sliding problemsParameters Measurement Physical Values(mean value)DIN St<strong>and</strong>ardSpecific weight* g / cm 3 1,04 53550Shore hardness Shore A 50 53505Tensile strength N / mm 2 15 53504Elongation at break % 500 53504Abrasion mm 3 150 53516* Material subject to wearAvailability: Mini DiamondThicknessmmWidth1600 mmWidth2000 mmMinimum Orderm8 L A 50A = Production to order, L = Stock itemThe contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® - S<strong>of</strong>t / HardRound pr<strong>of</strong>ileStatus 2007Subject to changeDescription:Black SBR – compound with tacky back <strong>and</strong> reinforced fabric ply.S<strong>of</strong>t pr<strong>of</strong>ile with a hard underground.Pr<strong>of</strong>ile depth: 7mmParameters Measurement Physical ValuesS<strong>of</strong>t (mean value)Physical ValuesHard (mean value)DIN St<strong>and</strong>ardSpecific weight* g / cm 3 1.04 1,12 53550Shore hardness Shore A 50 73 53505Tensile strength N / mm 2 15 23 53504Elongation at break % 500 450 53504Abrasion mm 3 150 150 53516* Material subject to wearAvailability:ThicknessmmWidthmax. 1300 mmMinimum Orderm15 A 308 A 50A = Production to orderThe contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® - S<strong>of</strong>t 50 Round pr<strong>of</strong>ileStatus 2007Subject to changeBeschreibung:Anwendungen:Black NR – compound with tacky back.Pulley lagging against sliding problemsParameters Measurement Physical values(mean value)DIN St<strong>and</strong>ardSpecific weight* g / cm 3 1.04 53550Shore hardness Shore A 50 53505Tensile strength N / mm 2 15.0 53504Elongation at break % 500 53504Abrasion mm 3 150 53516* Material subject to wearAvailability: Round pr<strong>of</strong>ile (Pr<strong>of</strong>ile Ø 15 mm | Pr<strong>of</strong>ile height 4 mm)ThicknessmmWidthmax. 1300 mmMinimum orderm10 L12 LL = Stock itemThe contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee.

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® -X 65Mini DiamondStatus 2007Subject to changeDescription:Example:Black NBR rubber compound with tacky back.Oil - & grease resistant.Pr<strong>of</strong>ile depth: 4 mmRecycling-industryParameters Measurement Physical Values(mean value)DIN St<strong>and</strong>ardSpecific weight* g / cm 3 1.19 53550Shore hardness Shore A 60 53505Tensile strength N / mm 2 17 53504Elongation at break % 600 53504Abrasion mm 3 170 53516* Material subject to wearAvailability: Mini DiamondThicknessmmAvailable width1300 mmAvailable width2000 mmMinimum Order (A)m10 L A 50A = Production to order, L = Stock itemThe contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>CORREX ® -WhiteLarge RhombusStatus 2007Subject to changeDescription:White NBR - compound. Oil - & grease resistant.Pr<strong>of</strong>ildepth: 2 to 4 mm.Parameters Measurement Physical Values(mean value)DIN St<strong>and</strong>ardSpecific weight* g / cm 3 1.20 53550Shore hardness Shore A 55 53505Tensile strength N / mm 2 10 53504Elongation at break % 620 53504Abrasion mm 3 300 53516* Material subject to wearAvailability: Large RhombusThicknessmmWidth1400 mm8 LL = Stock itemThe contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without gurantee

Conveyor Belt Group<strong>ContiTech</strong> <strong>Force</strong> <strong>Transmission</strong>Rubber-Metal-Bonding(Tacky Back Material)Status 2007Subject to changePreparationooWipe the metal surface <strong>and</strong> the tacky back with a lint free cloth <strong>and</strong> RCE Cleaning Solution.The metal surface has to be prepared with an angle grinder <strong>and</strong>/or preferably s<strong>and</strong>- <strong>and</strong>/or grit blasted. Grit16 <strong>and</strong>/or 24. Remove dust with h<strong>and</strong> brush <strong>and</strong>/or vacuum cleaner. Do not <strong>use</strong> compressed air, since themoisture/oil residues could influence the bonding strength.Cold BondingooStir CONTI PLUS ® , <strong>and</strong> apply one coat.Drying time: min. 30 minutes; h<strong>and</strong>ling period max. 3 weeks at room temperatureMix CONTI SECUR ® BFA <strong>and</strong> 5% RE Activator(1x 0,8 l tin CONTI SECUR ® BFA with 1 bottle RE Activator 40g)Apply one thin coat <strong>of</strong> CONTI SECUR ® BFA on metalDrying time: min. 30 min. at room temperatureRemark: do not <strong>use</strong> a short bristled brush, otherwise the already applied CONTI PLUS ® might bedesolved. I.e. <strong>use</strong> a normal brush.o Cut rubber <strong>sheet</strong> to size.o Apply second coat <strong>of</strong> CONTI SECUR ® BFA on metal, <strong>and</strong> one coat on tacky back <strong>of</strong> rubber <strong>sheet</strong>.Drying time: back <strong>of</strong> the h<strong>and</strong> test, max. 15 minuteso Join the rubber <strong>sheet</strong> <strong>and</strong> the metal surface, <strong>and</strong> apply pressure with a h<strong>and</strong> stitcher <strong>and</strong>/or a mallet, startingat the centre.Attention: the pressure need to be applied only briefly.The final bonding strength will be achieved after 24 hours.Coatings overview:Coating withDrying time at room temperature1 CONTI PLUS ® min. 30 minutes max. 3 weeks1 CONTI SECUR ® BFA min. 30 minutes2 CONTI SECUR ® BFA Back <strong>of</strong> the h<strong>and</strong> test, max. 15 minutesAttention:Using the cold bonding method the surfaces should have a minimum temperature <strong>of</strong> 10°C.Otherwise warm up the surfaces.The contents <strong>of</strong> this publication are the result <strong>of</strong> many years <strong>of</strong> research <strong>and</strong> experience gained in application technology.All information is given in good faith but without guarantee