Technical overview - LMC-Couplings

Technical overview - LMC-Couplings

Technical overview - LMC-Couplings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

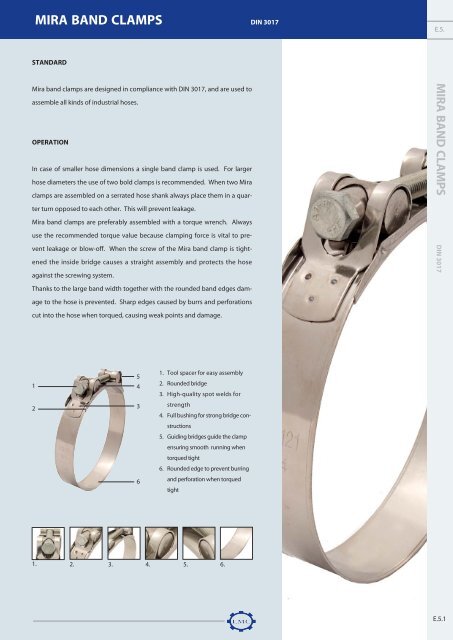

MIRA BAND CLAMPS DIN 3017APPLICATIONSealing and retaining suction and pressure hoses with steel or plastic reinforcement and high shore hardness.Torque moment - Nm for steel band clampsHOSE DIAMETER NM NMMIN - MAX STEEL CLAMP SS CLAMP17 - 19 4.5 25.020 - 22 4.5 25.023 - 25 4.5 25.026 - 28 4.5 25.029 - 31 8.0 25.032 - 35 8.0 25.036 - 39 8.0 25.040 - 43 8.0 50.044 - 47 16.0 50.048 - 51 16.0 50.052 - 55 16.0 50.056 - 59 16.0 50.060 - 63 16.0 50.064 - 67 16.0 50.068 - 73 25.0 50.074 - 79 25.0 50.080 - 85 25.0 50.0HOSE DIAMETER NM NMMIN - MAX STEEL CLAMP SS CLAMP86 - 91 25.0 50.092 - 97 25.0 50.098 - 103 25.0 50.0104 - 112 25.0 50.0113 - 121 25.0 50.0122 - 130 25.0 50.0131 - 139 50.0 50.0140 - 148 50.0 50.0149 - 162 50.0 50.0163 - 174 50.0 50.0174 - 187 50.0 50.0188 - 200 50.0 50.0210 - 213 50.0 50.0214 - 226 50.0 50.0227 - 239 50.0 50.0240 - 252 50.0 50.0Nm= maximum advised torque moment, we recommend working at 72% of the maximum valuesMATERIALMIRA CLAMPMIRAR CLAMPClamp W1, galvanised steel band W4, stainless steel AISI 304 - EN 1.4301Bushing Zinc-plated Q235LL W4, Stainless steel AISI 304 - EN 1.4301Screw 8.8 Stainless steel A2 - galvanizedBridge W1, galvanised steel plate Stainless steel AISI 304 - EN 1.4301W1 clamps are the most frequently used. W4 clamps are recommended where greater corrosion resistance is required.We recommend W5 for use in high-corrosion environments.E.5.2Chapter E: Assembly clamps & ferrules

MIRA BAND CLAMPS DIN 3017E.5.W 1W 2W 3W 4W 5Galvanised steel band. Low corrosion resistance.Application: Household and indoor plumbing applications.Chrome steel band and housing (AISI 430 – EN 1.4016). Zinc-plated mild steel screw. Low to average corrosion resistance,ensuring that corroded connections can be loosened.Application: Cars, trucks and mechanical engineering applications with low corrosion-resistance requirements.All components in chrome steel (AISI 430 – EN 1.4016). W3 is used exclusively in original equipment applications.Medium corrosion resistance.Application: Automotive industry.Nickel chrome steel band (AISI 304 – EN 1.4301, also known as V2A). High corrosion resistance and bright durable surface.Application: For critical automotive connections, such as fuel lines (SM 9 clamps made from W4), top-grade mechanicalengineering applications, agricultural machinery, motorcycles, outdoor signage and hose applications and stainless steel fluassembly.All components in nickel chrome molybdenum steel (AISI 316 – EN 1.4401, also known as V4A). W5 is saltwater-resistant andis very hard to magnetise. Maximum corrosion resistance. Used close to critical components and electronic circuits.Application: Ship building, defence, food , sewage treatment, chemical and high-specification mechanical engineeringapplications.MIRA BAND CLAMPS DIN 3017THREADSEN ISO 228-1, BSP metric sizeChapter E: Assembly clamps & ferrulesE.5.3

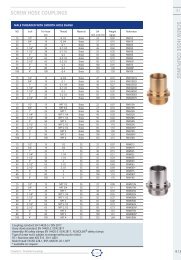

MIRA BAND CLAMPSMIRA BAND CLAMP: STAINLESS STEEL W4ND Band with Band thickness Screw Nm Referencemm +/- 1 mm mm17 - 19 18.0 0.6 M5 25.0 MIRAR01720 - 22 18.0 0.6 M5 25.0 MIRAR02023 - 25 18.0 0.6 M5 25.0 MIRAR02326 - 28 18.0 0.6 M5 25.0 MIRAR02629 - 31 20.0 0.6 M6 25.0 MIRAR02932 - 35 20.0 0.6 M6 25.0 MIRAR03236 - 39 20.0 0.6 M6 25.0 MIRAR03640 - 43 20.0 0.6 M6 50.0 MIRAR04044 - 47 22.0 0.8 M6 50.0 MIRAR04448 - 51 22.0 0.8 M6 50.0 MIRAR04852 - 55 22.0 0.8 M6 50.0 MIRAR05256 - 59 22.0 0.8 M6 50.0 MIRAR05660 - 63 22.0 0.8 M8 50.0 MIRAR06064 - 67 22.0 0.8 M8 50.0 MIRAR06468 - 73 24.0 0.8 M8 50.0 MIRAR06874 - 79 24.0 0.8 M8 50.0 MIRAR07480 - 85 24.0 0.8 M8 50.0 MIRAR08086 - 91 24.0 0.8 M8 50.0 MIRAR08692 - 97 24.0 0.8 M8 50.0 MIRAR09298 - 103 24.0 0.8 M8 50.0 MIRAR098104 - 112 24.0 0.8 M8 50.0 MIRAR104113 - 121 24.0 0.8 M8 50.0 MIRAR113122 - 130 24.0 0.8 M8 50.0 MIRAR122131 - 139 26.0 1.0 M10 50.0 MIRAR131140 - 148 26.0 1.0 M10 50.0 MIRAR140149 - 161 26.0 1.0 M10 50.0 MIRAR149162 - 174 26.0 1.0 M10 50.0 MIRAR162175 - 187 26.0 1.0 M10 50.0 MIRAR175188 - 200 26.0 1.0 M10 50.0 MIRAR188210 - 213 26.0 1.0 M10 50.0 MIRAR201214 - 226 26.0 1.0 M10 50.0 MIRAR214227 - 239 26.0 1.0 M10 50.0 MIRAR227240 - 252 26.0 1.0 M10 50.0 MIRAR240Material: W4, stainless steel AISI 304 - EN 1.4301Nm = torque momentE.5.6Chapter E: Assembly clamps & ferrules