General Specification - Gantrex

General Specification - Gantrex

General Specification - Gantrex

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

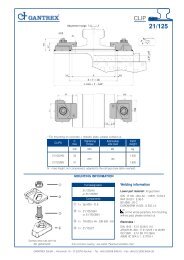

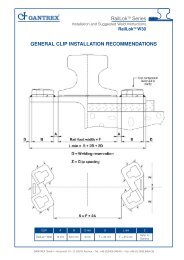

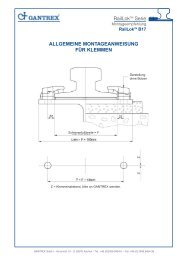

RailLok TM SeriesBOLTABLE CLIP<strong>General</strong> <strong>Specification</strong>This general specification describes the RailLok series of boltable rail clips :• RailLok B10, B15 & B20 incorporate the special “helical rotating washer ” feature.• RailLok B17 incorporates two pieces interacting through a “double slope system ”.• RailLok B30 is a “compact double bolted ” clip which provides a very high lateral resistance.The GANTREX ® crane rail soft-mounting boltable system consists of a range of crane rail clips with increased lateralresistances and the new patent pending RailLok steel reinforced rubber pads specifically designed to address theproblems created by today’s heavy wheel load and high duty cycle cranes. Individual data sheets on the variousGANTREX ® clips and pad profiles provide details of the unique characteristics and dimensions of these new products.GENERAL CHARACTERISTICSAll RailLok series clips are specifically designed for the mounting of crane rails, with or without pad. A full rangeof boltable clips is available to the designer, offering both cost efficiency and the very best technical solution for theinstallation.All RailLok clips consist of two interacting components which permit easy lateral rail adjustment and, once correctlyinstalled, are self-locking and self-tightening. A controlled vertical force is applied to the rail foot through a syntheticrubber “nose” which is vulcanize-bonded to the clip.The special “helical rotating washer ” feature prohibits an improper installation; the “double slope system” allowsdesigning narrow clips to fit 300 mm wide girders; the double bolted clip provides high strength while remaining themost compact size, possible through reductions in size and weight.SPECIFICATIONS OF THE PRODUCT RANGECLIPSERIESMaximum resistanceto lateral forces (*)LateraladjustmentMinimum supportwidthRail Foot +MaximumestimatedweightRailLok B10 50 kN 10 mm 106 mm 0.35 kgRailLok B15 100 kN 15 mm 145 mm 0.63 kgRailLok B17 100 kN 10 mm 100 mm 1.10 kgRailLok B20 140 kN 15 mm 145mm 0.68 kgRailLok B30 300 kN 10 mm 140 mm 2.50 kg(*) Contact GANTREX for application conditionsSee data sheet for specific clip series for details. All GANTREX ® clips are available in various heights, with optional“nose” thicknesses to accommodate all rail sizes with or without pad.Please contact GANTREX for more information on any GANTREX ® product or for clip specification if your rail sizedoes not appear on the data sheet tables.COMPONENT MATERIALClip Main Component Special washer Corrosion protectionLowerComponentPressure Block(Nose)RailLokB10, B15, B20RailLok B30RailLok B17Ductile Cast IronGJS 500-7according toEN1563Ductile CastIronNoneHot Dip Galvanizedaccording toISO 1461On requestNoneForged SteelSynthetic Rubbervulcanized on themain componentContact GANTREX for other protective coatings.GANTREX GmbH – Hirzenrott 10 – D 52076 Aachen – Tel. +49 (0)2408 9454-0 – Fax +49 (0) 2408 9454-28

RailLok TM SeriesBOLTABLE CLIP<strong>General</strong> <strong>Specification</strong>TECHNICAL ADVANTAGES OF THE RailLok TM BOLTABLE CLIPS “NEW VERSION ”New features• Higher grade bolts can be used in order to achieve clip assembly lateral resistance.All old features have been preserved• Simple and positive lateral rail adjustment of up to 15mm depending on type of clip.• Self-locking and self-tightening features through wedging action.• High resistance to lateral loads through careful selection of clip component materials.• Controlled vertical force applied to rail through synthetic rubber “nose”:• Minimized crane runway maintenance and down time compared to other rail fixing methods.CLIP SELECTIONThe following information is needed in order to select the correct GANTREX ® clip for your installation :• Rail designation (e.g. 175 CR, A 120).• Thickness of pad or wear plate if used between the rail and support.• Maximum side thrust per wheel.• Width of support plate or girder top flange.• Lateral adjustment required.• Vertical clearance tolerances when side rollers are used.Please consult GANTREX on any questions regarding selection.INSTALLATION INSTRUCTIONSChoose the adequate bolt grade to achieve the required resistance (10.9 grade bolts can be used). Componentsare positioned on the bolt and the main component is adjusted against the rail by a hammer hit once the nut ishand tightened.Electrical and pneumatic torque wrenches can be used as long as the torque is lower than 2/3 of the final torque.The final torque is achieved by using a calibrated torque wrench.See the individual product data sheet for details on the specific clip being used. For most applications, use screwsor bolts that are compliant with ISO 4014 (DIN 931), ISO 4017 (DIN 933), along with corresponding nuts and washers.Refer to “Installation Instructions” for detailed information on use.An available option on all GANTREX ® clips is protection against corrosion in the form of electro orhot-dip galvanizing. RailLok B10, B15 & B20 clips are hot dip galvanized as a standard. The clip bolt assembliesshould also be galvanized.If painting is required, please consult GANTREX before using mineral-based solvents, as they may adversely affectthe coefficient of friction between components.Do not use cleaning fluids or protective coatings which contain ketones or similar chemicals, as they may seriouslydamage the rubber nose.We reserve the right to discontinue or change specifications or design at any time without prior noticeand whithout incurring any obligation whatsoever.GANTREX GmbHHirzenrott 10 – D 52076 Aachen • Tel. +49 (0)2408 9454-0 • Fax +49 (0) 2408 9454-28E-mail : info@de.gantry.com • http://www.gantrex.de11/2012 Rev.0