Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Efficient seedbed preparation

The soil is the most important resourcein productive agriculture. Choice of theprimary cultivation procedure, for theparticular location, and optimal use oftechnology, help retain the long-termprofitability of the soil. Another importantfactor for a successful harvest –irrespective of the cultivation procedure– is the preparation of seedbeds.The objective here is to prepare the soilso that the seeds can quickly germinateand efficiently grow. The prepared soilstructure should remain stable rightthrough to harvest.After primary soil cultivation the land isprepared for optimum plant developmentby the preparation of seedbeds.The seeds which have been sown andare germinating in the soil requirewater, heat and air to develop. The surfacesoil should be soft enough for theseedlings to grow through. The areaunder the seeds should be reconsolidatedto aid capillary action and watersupply to the plant. These factors areoptimised in a well prepared seedbed,thereby ensuring the basic requirementsfor a good growth rate.Seedbed preparation must also performthe following tasks:••The surface left by the primary soilcultivation must be levelled to createuniform conditions for sowing.••The tools on a machine used for thepreparation of seedbeds, e.g. powerharrow tines, must break up clods,lumps and crumbs. However, it is notjust a queston of generating the correctaggregate sizes. Even clod distributionin the seedbed and the longtermstructural stability of the soil arealso important for plantdevelopment.••The soil must be cultivated to a consistentworking depth.••An adequate reconsolidation of thesoil under the seeds is essential foroptimum soil compaction to ensurethat the seedlings are supplied withwater during the first growth phase.• • The pore volume, in the topsoil, mustbe large enough to ensure an adequatesupply of water and air to theplant roots.

<strong>Zirkon</strong> – perfection in many variationsIt is becoming ever more important toadjust the intensity of the seedbedpreparation to the prevailing field conditions.Practice shows that the powerharrow is a very versatile and efficientdevice and therefore best performs thispreparatory task.To ensure optimum seedbed preparation,the working parameters of the<strong>Zirkon</strong> power harrow from LEMKEN canbe perfectly adjusted. Whether shallow,quick and extensive, or deep andintensive – it is only neccesary to setthe specifications such as workingdepth, rotor speed, tine position andforward drive speed for the requiredsoil cultivation. The <strong>Zirkon</strong> power harrowproduces an intensive mixing andcrumbling action down to a workingdepth of approx. 15 cm. The active toolswill prepare an optimum seedbed inpractically all soil conditions, even incompacted, dry and hard or heavysoils. The use of the power harrow inagriculture is therefore acquiringgreater importance today. In combinationwith other machines many workprocesses can also be completed morequickly and economically.both in conventional and in conservationcultivation procedures and can beused both in a rear and front-mountedposition.The <strong>Zirkon</strong> power <strong>harrows</strong> are availablein different working widths anddesigns:••<strong>Zirkon</strong> 8: The mounted, entry-levelmodel in working widths from 2.5 to4 metres non-folding format.••<strong>Zirkon</strong> 10: The high-performancemounted, rigid power harrow with a3 or 4 metre working width.••<strong>Zirkon</strong> 10 K: At working widths from 4to 6 metres the mounted power harrowcan also be hydraulically foldedto a transport width of 3 metres evenin combination with the Solitair 9 Kseed drill.• • <strong>Zirkon</strong> 10 KA: The semi-mountedpower harrow in working widthsfrom 4 to 6 metres. When combinedwith the pneumatic Solitair seed drillfrom LEMKEN, is a powerful combinationfor demanding arable farming.The <strong>Zirkon</strong> power <strong>harrows</strong> fromLEMKEN best meet the high demandsof a modern arable farm. They are suitablefor very high continuous loads

The quietest andsmoothest runningmachine in its classSimple replacement oftines by the quickchangesystemChange of rotation direction –correct tine position simply &quicklyEach four tine carriers per metre workingwidth are arranged with a minimumoffset to each other so that thetines of the <strong>Zirkon</strong> power harrow canwork in succession to each other.••A constant force flow of the tines inthe soil is achieved even underextremely difficult conditions.••This arrangement creates verysmooth running characteristics and auniform load on the tractor PTO.The advantages of the quick-changesystem are offered as standard by the<strong>Zirkon</strong> 10, optionally by the <strong>Zirkon</strong> 8.The knife tines have sharpened cuttingedges on both sides.••Each pair of tines is attached to thetine carrier with a safety plug. Tinescan be changed simply and quickly.••The special hardening process makesthe knife tines particularly wearresistantwithout becoming brittle.••Hard facing in the main wear areassignificantly extends the service lifeof the knife tines.The DUAL shift gears from LEMKENfacilitate not only changing the speedof the rotors but also the direction ofrotation of the rotors.••The change in the direction of rotationenables the knife tines to be setto “grip” or “drag”.••When set to “drag”, the tines have abetter levelling effect and are particularlyusefull in stoney conditions, asstones are pushed into the ground.••In the “grip” position the tines aid soilpenetration and prove themselves inmulch sowing through the intensivemixing of soil and vegetation. Fineearth is conveyed into the area of theseed placement. Large crumbsremain on the surface and reducecapping and erosion.

<strong>Zirkon</strong> 8Strong, inclined box profile (all specificationsin mm)The versatile power harrowfor optimum seedbedpreparationThe <strong>Zirkon</strong> 8 from LEMKEN is the newpower harrow for the low to middle HPclass. A special feature is its modulardesign which offers options for componentssuch as gearbox and attachmentof tines. In this way the <strong>Zirkon</strong> 8 can beadjusted optimally to the particularrequirements and applicationconditions.••The large distance between theupper and the lower bearings supportsthe tine carrier and ensuresthat the bearings have a long servicelife.••Thanks to the innovative higher andinclined box profile, dirt can slide offmore easily.••In addition to the simple angulargears, which set the required rotorspeed by replacement of the gearwheels, the <strong>Zirkon</strong> 8 can be fittedwith the DUAL shift manual gearbox.In addition to changing the speedwith the shift lever, the direction ofrotation of the tines can be changedfrom “grip” to “drag” without replacingthe tines.••Bolt-on knife tines, which have alength of 300 mm, are part of thestandard equipment of the <strong>Zirkon</strong> 8with the change gear train (WG). The<strong>Zirkon</strong> 8 with DUAL shift manualgearbox (SG) features 320 mm longtines with a quick-change system asstandard.••Thanks to the equipment options,such as a heavy duty headstock, thecentrally adjustable levelling bar, anoptimum roller from the extensiverange of LEMKEN rollers and otheraccessories, the <strong>Zirkon</strong> 8 can beadjusted to suit every customerrequirement.Simple power transmission by the change gear trainReplacing a quick-change tine

<strong>Zirkon</strong> 10The power harrow for veryhigh continuous loads in allcultivation proceduresThe LEMKEN <strong>Zirkon</strong> 10 power harrow isdesigned for very high continuousloads both in conventional and in conservationtillage procedures. The intensityof cultivation can be changed specificallyby the working speed, thepower take-off speed and the gears ofthe power harrow.••The closed gearbox made of thickwalledmicro-alloyed quality steelensures that all gear wheels, shaftsand bearings run smoothly and quietlythanks to the exactly alignedbearing housings. This guarantees ahigh service life.••The mounted <strong>Zirkon</strong> 10 power harrowwith mounted Solitair or Saphirseed drill from LEMKEN is an efficientcombination for precise sowing.••The DUAL shift gears allow easyadjustment of the speed from 330 to440 rotor revolutions. The optionalgears for 230 and 330 rotor revolutionsextend the range of applicationsof the <strong>Zirkon</strong> 10.••The direction of rotation of the tinesfrom “grip” to “drag” for adjustmentto all application conditions can alsobe easily changed with the DUALshift gears.••The forged quick-change knife tinewith a tine length of 340 mm and athickness of 20 mm guarantees maximumservice lives. The quick-changesystem allows the tines to bechanged simply and without tools.••The “special tine” which is 380 mmlong ensures intensive loosening inpotato farming.DUAL shift gearboxGearbox made of thick-walled quality steel (allspecifications in mm)Quick-change tines

<strong>Zirkon</strong> 10 KAlways efficient, whetherstand-alone or together withother machineryThe compact design and good positionof the centre of gravity make the foldable<strong>Zirkon</strong> 10 K power harrow and theLEMKEN Solitair seed drill a powerfulcombination.••The optimised efficiency of the drivetrain ensures maximum power transmissionto the rotors of the powerharrow.••To achieve optimum adjustment tothe soil surface, at working widthsfrom 4 metres, folding <strong>Zirkon</strong> power<strong>harrows</strong> consist of two separateunits. Each unit is attached to a centralpendulum axle and adjusts itselfto the soil independently of the otherunits.••As the pendulum axles are arrangedcentrally in relation to each workingunit, the <strong>Zirkon</strong> power harrow followsground contours accurately,guided by the roller. Despite thelarge working widths from 4 metres,the <strong>Zirkon</strong> 10 K power harrow can befolded to a transport width of lessthan 3 metres.••The <strong>Zirkon</strong> power harrow can bequickly folded and unfolded, makingit immediately ready for work ortransportation.• • A unique feature is that the seed tankof the Solitair 9 K seed drill is housedbetween the folded power harrowunits. This keeps weight as close aspossible to the tractor.Optimum adjustment to soil by central pendulum axle

<strong>Zirkon</strong> 10 KA<strong>Zirkon</strong> 10 KA folding,semi-mounted machine -always safe on the roadThe semi-mounted <strong>Zirkon</strong> 10 KA powerharrow from LEMKEN can be usedalone or in combination with seeddrills. In stand-alone operation the axleis raised during work keeping thewheels away from the soil.••Large tyres reduce soil damage duringheadland turns, as well as providingstable transport between fields.••The <strong>Zirkon</strong> can be used togetherwith LEMKEN‘s pneumatic Solitairseed drill. Mounting points abovethe axle of the power harrow, makethe total combination compact andeasy to connect or disconnect thedrill when required.••The standard weight transfer systemensures even weight distribution ofthe mounted machinery. The workingdepth of the power harrow is preciselymaintained no matter what thelevel of seed in the seed drill.••The semi-mounted <strong>Zirkon</strong> powerharrow can be fitted with a compressedair braking system if this isrequired or if the power harrow isused in combination with a seed drill.••A hydraulic rear linkage is also availableto allow other seed drills, or precisiondrills, to be coupled to the<strong>Zirkon</strong> power harrow.••The <strong>Zirkon</strong> power harrow can bemounted in the LEMKEN Compact-Solitair, if required, to provide alarger tank volume and full-widthtyre packer roller.Easily accessible coupling pointsEven weight distribution

Perfected down to thelast detailRobust three-point headstockThe <strong>Zirkon</strong> power harrow features arobust headstock with integrated toolbox.••The spring steel, cross-shaft betweenthe lower link arms absorbs shocksand protects tractor and device duringtransportation and work.••The movable lower link connectionpoints enable the distance betweentractor and power harrow to beadjusted to suit the tractor.

1Side plates prevent ridges atthe sideStone protection fortrouble-free workLevelling bar for regulatingthe flow of soilThe height-adjustable and springloadedside plates on each side preventthe outer tines from creating ridges.••The side plates can move sidewaysand upwards.••On machines with a 3-metre workingwidth, they can be simply folded infor transport.••Optionally the side plates can be fittedwith an extension.To ensure trouble-fee work in soilswhich have a high stone content, stoneprotection (1) is available for all <strong>Zirkon</strong>power <strong>harrows</strong> and is attached to theunderside of the gearbox in front of therotors.••The stone protection prevents stonesbecoming caught and causing damageas a result.Levelling bars are available as optionalequipment for all <strong>Zirkon</strong> power<strong>harrows</strong>.••The levelling bar can be attachedeither in front of, or behind, the knifetines. The levelling bar regulates theflow of soil and optimizes the work ofthe knife tines.••The height is adjusted centrally witha spanner on the side of the power<strong>harrows</strong>.

Suitable for allapplication areasOptimum loosening and levelling of the tractor tracksTractor tracks are best loosened andlevelled by using a narrow share trackeradicator instead of the wing sharetrack eradicator.••Both tools can be easily attached tothe standard carrier and simplyadjusted to any tractor track width.••The working depth can be adjustedwithout tools.••To prevent damage, the track eradicatorsare fitted as standard with anauto-reset safety device.

Tooth packer roller for mediumand heavy soil conditionsTrapeze roller for light andmedium soil conditionsSuitable forall seed drillsEven sticky soil does not stick to thetooth packer roller. This makes it universallysitable even in medium andheavy soil conditions.••The hardened scrapers are attachedto stable holders. They can be easilyadjusted with a spanner to ensurethat the rollers are thoroughlycleaned.••Optional hard facing or hard metalplates ensure that the scrapers havemaximum service lives.The key advantage of the trapeze rolleris reconsolidation of the soil, in strips,by the trapeze rings which are directlyin line with the following drill rows.••Soil between the rows, retains arough surface with a great deal offine soil and is therefore less inclinedto capping.••An especially regular seed placementdepth, and a seedbed with an optimalcapillary effect for the seed, isobtained.••All closed trapeze rollers are distinguishedby a good load-bearingcapacity on light to medium soils andto a large extent prevent earth fromsticking.Thanks to an adjustable couplingframe, the hydraulic three-point linkagecan be adapted to all known seeddrills.••The variable vertical and longitudinaldistances, of the coupling points,ensure the best possible adaptationof the power harrow to all seed drills.••All articulated joints are fitted withsleeves to protect against wear.

Always well equippedClearly marked path by trackmarkersFeed discs for preciselyharrowed pathsFoldable track markers are recommendedif a drill is to be fitted to thepower harrow. The markers produce aclear line in the soil to ensure boutwidths are accurate.••The 360° adjustment of the discensures an optimum mark is left in allconditions.••The shearbolt prevents the trackmarker from being damaged if itcomes into contact with obstacles.To ensure a precisely harrowed pathwithout any ridge build-up, the effectof the side plates can be furtherimproved by the use of feed discs.••The 450 mm large, curved, andheight-adjustable feed discs are fittedto the outside of the powerharrow.••As the feed discs convey the earthinwards, an absolutely level seedbedis obtained.

In all cases: the front-mountedpositionEach PTO shaft with overloadsafety deviceOf course: Safety and lightingAll mounted <strong>Zirkon</strong> power <strong>harrows</strong> canalso be used in a front-mounted position,by using the optional pushlinkage.••This also provides a combination forparticularly difficult conditions or foruse by specialised crop companies.••A tube bar roller in front of the powerharrow ensures that the depth of theworking tools is controlled exactly.The drive of the <strong>Zirkon</strong> power <strong>harrows</strong>is designed to run up to a PTO speed of1,000 revolutions per minute.••All relevant PTO shafts are fitted witha cam shifting clutch as an overloadsafety device.••To drive other machines, all power<strong>harrows</strong> are fitted with a PTOthrough shaft.Lighting and braking systems of the<strong>Zirkon</strong> power <strong>harrows</strong> conform withthe current road traffic laws.••Furthermore, bumpers are includedin the basic equipment of the foldable<strong>harrows</strong>.

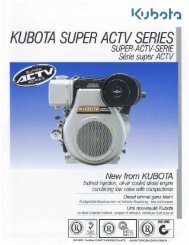

Technical dataModelWorking width(cm)Number of rotorsWeight withoutroller (approx. kg)For power take-offspeed up to (min-1)Rotor speed (min-1) at 1,000min-1kWTractor outputHPMounted, rigid<strong>Zirkon</strong> 8/250 WG1 / SG2 250 10 701 1,000 300/400 44-103 60-140<strong>Zirkon</strong> 8/300 WG1 / SG2 300 12 785 1,000 300/400 55-118 75-160<strong>Zirkon</strong> 8/350 WG1 / SG2 350 14 946 1,000 300/400 63-125 85-170<strong>Zirkon</strong> 8/400 WG1 / SG2 400 16 1,015 1,000 300/400 66-129 90-175Mounted, rigid<strong>Zirkon</strong> 10/300 300 12 922 1,000 330/440 66-154 90-210<strong>Zirkon</strong> 10/400 400 16 1,149 1,000 330/440 88-177 120-240Mounted, hydraulic folding<strong>Zirkon</strong> 10/400 K 400 16 1,792 1,000 330/440 88-177 120-240<strong>Zirkon</strong> 10/450 K 450 18 1,926 1,000 330/440 88-199 140-285<strong>Zirkon</strong> 10/500 K 500 20 2,096 1,000 330/440 121-221 165-300<strong>Zirkon</strong> 10/600 K 600 24 2,482 1,000 330/440 132-235 180-320Semi-mounted, hydraulic folding<strong>Zirkon</strong> 10/400 KA 400 16 3,561 1,000 330/440 88-199 120-270<strong>Zirkon</strong> 10/450 KA 450 18 3,764 1,000 330/440 88-199 140-285<strong>Zirkon</strong> 10/500 KA 500 20 3,953 1,000 330/440 121-221 165-300<strong>Zirkon</strong> 10/600 KA 600 24 4,477 1,000 330/440 123-235 180-320(1)Change gear train(2)Manual gearbox<strong>Zirkon</strong> 8 <strong>Zirkon</strong> 10<strong>Power</strong> harrow tines for different applications. Hard facing available if required for maximum service lives (marked in red on picture)All specifications, dimensions and weights are subject to continuous technical development and are therefore not binding. Theweight specifications always refer to the basic equipment. Subject to change.

Service decidesWhen you have bought a machine from LEMKEN, the wellknown,almost proverbial LEMKEN service starts. 16 customer-orientedfactory branches and outdoor storage areasin Germany as well as our own sales companies and importersin more than 40 countries, and a strong dealer network,ensure that machines and spare parts are supplied quickly.If a part is not in stock, it can be delivered to the customerwithin 24 hours via the LEMKEN logistics centre which ismanned round-the-clock 365 days a year.Knowledge from the LEMKEN specialistWell trained customer service technicians are available tofarmers, contractors and trade, who are using machinery forthe first time, as well as for professional maintenance andrepairs. Thanks to regular training courses, LEMKEN customerservice is always up to date with the latest LEMKENtechnology.Original spare parts for maximumservice livesLEMKEN wearing parts are designed for a maximum servicelife. High-quality steels, the latest production methods, andan intensive quality control ensure a long service life.Therefore, all original spare parts bear a unique identificationwith the registered LEMKEN trademark. Original spare partscan be ordered at any time online on the Internet via theLEMKEN information and ordering system.

As professional crop production specialists,LEMKEN is one of the leading companies inEurope, with over 850 employees worldwide,achieving sales revenues of more thanEUR 215 m. Originally founded in 1780 as ablacksmith’s forge, the family company produceshigh-quality and high-performancefarm machinery for soil cultivation, sowingand plant protection at its German headquartersin Alpen and at its two other productionsites in Hetzerath and Meppen. 70 percent ofthe approximately 11,000 machines per year areexported.Mounted ploughs Hybrid ploughs Semi-mounted ploughs Furrow presses Front pressesCompact combinations Seedbed combinations <strong>Power</strong> <strong>harrows</strong> Compact disc <strong>harrows</strong> CultivatorsSubsoilers Seed drills Drill combinations Mounted field sprayers Trailed field sprayersLEMKEN GmbH & Co. KGWeseler Straße 546519 AlpenTelefon +49 2802 81 0Telefax +49 2802 81 220lemken@lemken.comwww.lemken.comYour LEMKEN dealer:LEMKEN 05/10 . 175 0185/en