ASPIRE Summer 08 - Aspire - The Concrete Bridge Magazine

ASPIRE Summer 08 - Aspire - The Concrete Bridge Magazine ASPIRE Summer 08 - Aspire - The Concrete Bridge Magazine

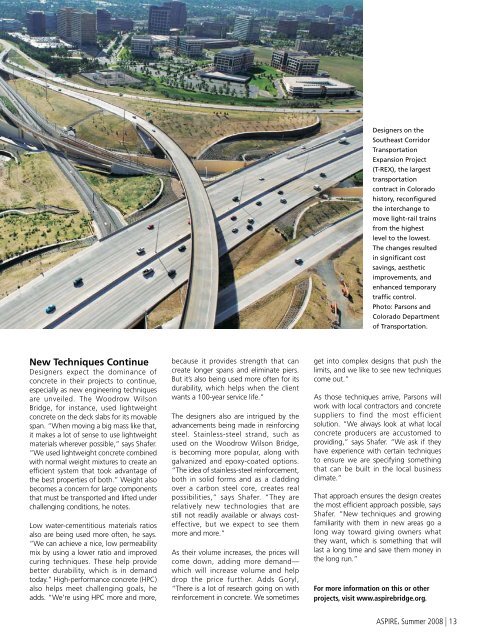

Designers on theSoutheast CorridorTransportationExpansion Project(T-REX), the largesttransportationcontract in Coloradohistory, reconfiguredthe interchange tomove light-rail trainsfrom the highestlevel to the lowest.The changes resultedin significant costsavings, aestheticimprovements, andenhanced temporarytraffic control.Photo: Parsons andColorado Departmentof Transportation.New Techniques ContinueDesigners expect the dominance ofconcrete in their projects to continue,especially as new engineering techniquesare unveiled. The Woodrow WilsonBridge, for instance, used lightweightconcrete on the deck slabs for its movablespan. “When moving a big mass like that,it makes a lot of sense to use lightweightmaterials wherever possible,” says Shafer.“We used lightweight concrete combinedwith normal weight mixtures to create anefficient system that took advantage ofthe best properties of both.” Weight alsobecomes a concern for large componentsthat must be transported and lifted underchallenging conditions, he notes.Low water-cementitious materials ratiosalso are being used more often, he says.“We can achieve a nice, low permeabilitymix by using a lower ratio and improvedcuring techniques. These help providebetter durability, which is in demandtoday.” High-performance concrete (HPC)also helps meet challenging goals, headds. “We’re using HPC more and more,because it provides strength that cancreate longer spans and eliminate piers.But it’s also being used more often for itsdurability, which helps when the clientwants a 100-year service life.”The designers also are intrigued by theadvancements being made in reinforcingsteel. Stainless-steel strand, such asused on the Woodrow Wilson Bridge,is becoming more popular, along withgalvanized and epoxy-coated options.“The idea of stainless-steel reinforcement,both in solid forms and as a claddingover a carbon steel core, creates realpossibilities,” says Shafer. “They arerelatively new technologies that arestill not readily available or always costeffective,but we expect to see themmore and more.”As their volume increases, the prices willcome down, adding more demand—which will increase volume and helpdrop the price further. Adds Goryl,“There is a lot of research going on withreinforcement in concrete. We sometimesget into complex designs that push thelimits, and we like to see new techniquescome out.”As those techniques arrive, Parsons willwork with local contractors and concretesuppliers to find the most efficientsolution. “We always look at what localconcrete producers are accustomed toproviding,” says Shafer. “We ask if theyhave experience with certain techniquesto ensure we are specifying somethingthat can be built in the local businessclimate.”That approach ensures the design createsthe most efficient approach possible, saysShafer. “New techniques and growingfamiliarity with them in new areas go along way toward giving owners whatthey want, which is something that willlast a long time and save them money inthe long run.”For more information on this or otherprojects, visit www.aspirebridge.org.ASPIRE, Summer 2008 | 13

- Page 2: ®Bentley®LEAPBridge. It’s all i

- Page 10: FOCUSPARSONS adapts to theMARKETby

- Page 17 and 18: Agency-Industry Collaboration Maxim

- Page 19 and 20: The pontoons are heavily reinforced

- Page 21 and 22: The final set of 10 anchors was tow

- Page 23 and 24: BRIDGESFORLIFE ®FEATURING HIGH-PER

- Page 25 and 26: 25, 2005, the design-build team had

- Page 27 and 28: HPC Bridge Views Is Now Electronic

- Page 29 and 30: upwards from the river for more tha

- Page 31 and 32: Protecting the EnvironmentThe proje

- Page 33 and 34: The bridge was widenedfrom three la

- Page 35 and 36: While preparation work was underway

- Page 37: A major consideration, especially f

- Page 40 and 41: The stay cables consist of 0.6-in.-

- Page 42 and 43: Bridge overSWINGLEY RIDGE ROADby Ke

- Page 44 and 45: The site geometry called for a brid

- Page 46 and 47: CONCRETE CONNECTIONSConcrete Connec

- Page 48 and 49: STATEConcrete Bridges inWashingtonS

- Page 50 and 51: girder that would be fabricated and

- Page 52 and 53: CITYIn the wake of tragedy,more fun

- Page 54: AASHTO LRFD2008Interim Changes Part

- Page 57 and 58: XHood canal Bridge / WASHINGTONNEW

- Page 59 and 60: I-10 Bridge Replacement / floridaPr

Designers on theSoutheast CorridorTransportationExpansion Project(T-REX), the largesttransportationcontract in Coloradohistory, reconfiguredthe interchange tomove light-rail trainsfrom the highestlevel to the lowest.<strong>The</strong> changes resultedin significant costsavings, aestheticimprovements, andenhanced temporarytraffic control.Photo: Parsons andColorado Departmentof Transportation.New Techniques ContinueDesigners expect the dominance ofconcrete in their projects to continue,especially as new engineering techniquesare unveiled. <strong>The</strong> Woodrow Wilson<strong>Bridge</strong>, for instance, used lightweightconcrete on the deck slabs for its movablespan. “When moving a big mass like that,it makes a lot of sense to use lightweightmaterials wherever possible,” says Shafer.“We used lightweight concrete combinedwith normal weight mixtures to create anefficient system that took advantage ofthe best properties of both.” Weight alsobecomes a concern for large componentsthat must be transported and lifted underchallenging conditions, he notes.Low water-cementitious materials ratiosalso are being used more often, he says.“We can achieve a nice, low permeabilitymix by using a lower ratio and improvedcuring techniques. <strong>The</strong>se help providebetter durability, which is in demandtoday.” High-performance concrete (HPC)also helps meet challenging goals, headds. “We’re using HPC more and more,because it provides strength that cancreate longer spans and eliminate piers.But it’s also being used more often for itsdurability, which helps when the clientwants a 100-year service life.”<strong>The</strong> designers also are intrigued by theadvancements being made in reinforcingsteel. Stainless-steel strand, such asused on the Woodrow Wilson <strong>Bridge</strong>,is becoming more popular, along withgalvanized and epoxy-coated options.“<strong>The</strong> idea of stainless-steel reinforcement,both in solid forms and as a claddingover a carbon steel core, creates realpossibilities,” says Shafer. “<strong>The</strong>y arerelatively new technologies that arestill not readily available or always costeffective,but we expect to see themmore and more.”As their volume increases, the prices willcome down, adding more demand—which will increase volume and helpdrop the price further. Adds Goryl,“<strong>The</strong>re is a lot of research going on withreinforcement in concrete. We sometimesget into complex designs that push thelimits, and we like to see new techniquescome out.”As those techniques arrive, Parsons willwork with local contractors and concretesuppliers to find the most efficientsolution. “We always look at what localconcrete producers are accustomed toproviding,” says Shafer. “We ask if theyhave experience with certain techniquesto ensure we are specifying somethingthat can be built in the local businessclimate.”That approach ensures the design createsthe most efficient approach possible, saysShafer. “New techniques and growingfamiliarity with them in new areas go along way toward giving owners whatthey want, which is something that willlast a long time and save them money inthe long run.”For more information on this or otherprojects, visit www.aspirebridge.org.<strong>ASPIRE</strong>, <strong>Summer</strong> 20<strong>08</strong> | 13