Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

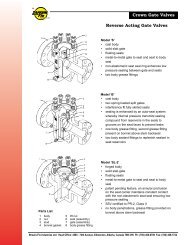

<strong>Crown</strong> Gate Valves<strong>Crown</strong> <strong>Model</strong> A Gate Valve89101112, 1320181920123, 456714151617Parts List1 nut2 handwheel3 bearing retainer lock nut4 bearing retainer nut5 thrust bearing6 stem packing7 stem8 bearing spacer sleeve9 bearing grease fitting10 packing retainer bushing11 packing injection fitting12 nut13 stud14 bonnet15 bonnet gasket16 seat17 gate guide18 gate assembly19 body20 body grease fittingThe <strong>Crown</strong> <strong>Model</strong> A gate valve utilizes an expanding gate to provide a positive mechanical seal ina wide variety of applications. This valve is available for 2000, 3000 or 5000 psi working pressuresand can be supplied in sizes up to 4 1 /16” flanged or threaded.Main Design and Construction Features:• Integral cast steel body and one-piece bonnet.• Non-rising stem design.• Parallel expanding gate provides a tight mechanical metal seal between the seats, protecting bodyand operating components from flow in both open and closed positions.• PTFE ring in each seat ensures an initial seal between seats and gate in addition to the metal‐to‐metalseal generated by full expansion of the gate.• Valve does not rely on line pressure for sealing.• Roller thrust bearings minimize valve operating torque.• External bearing grease fitting allows easy lubrication of stem bearings.• Packing injection fitting allows the stem packing to be energized under pressure.• Body cavity is filled with grease to allow easier operation, corrosion resistance and longer life. Twosafety-capped grease fittings are provided on the body so that grease may be added at any time.• Continuous full bore / thru conduit flow at sealing surfaces minimizes pressure drop and turbulence.<strong>Stream</strong>-<strong>Flo</strong> Industries Ltd. Head Office 4505-74 Avenue, Edmonton, Alberta, Canada T6B 2H5 Ph (780) 468-6789 Fax (780) 469-7724<strong>Stream</strong>-<strong>Flo</strong> <strong>USA</strong> LLC., 8726 Fallbrook Drive, Houston, Texas 77064 Ph (832) 912-1022 Fax (281) 653-1188

<strong>Crown</strong> Gate ValvesDimensional DataThreaded ValvesFlanged End Valvespsi (MPa)2000 (13.8)3000 (20.7)5000 (34.5)Size(mm)2 1 /16 (52)2 9 /16 (65)3 1 /8 (79)4 1 /16 (103)2 1 /16 (52)2 9 /16 (65)3 1 /8 (79)4 1 /16 (103)2 1 /16 (52)2 9 /16 (65)3 1 /8 (79)4 1 /16 (103)A2.062.563.194.122.062.563.194.122.062.563.194.12B23.6225.5629.2534.6224.2526.0030.0635.3124.2526.0030.0035.50C18.6919.9422.1225.6918.9419.8122.6226.1918.9419.8122.6226.19D11.012.512.516.012.512.516.020.012.512.516.020.0Ethreaded9.8311.6011.69-9.8312.2511.69-9.8312.2511.69-Eflanged11.6213.1214.1217.1214.6216.6217.1220.1214.6216.6218.6221.62N13.015.520.024.513.015.520.024.513.015.520.024.5Wtthreaded85125180-115145225-115145225-Wtflanged100140200390160220280490160220320600Dimensions in inchesN = number of turns required to openWt = lbsTrim ChartMatl Body & BonnetService Trim Class Bonnet Seal Gate Seat Stemgeneral oilfield oil and gas T-21 AA alloy steel CS alloy steel alloy steel alloy steelgeneral oilfield low temp -50 ºF T-36 AA alloy steel CS alloy steel alloy steel alloy steelgeneral with slight CO2 corrosion T-22 BB alloy steel SS 13 Cr SS 17-4 PH 17-4 PHcorrosive with high CO2 T-23 CC 13 Cr SS SS 13 Cr SS HF 17-4 PH 17-4 PHSOG low temp -50 ºF LD DD-NL alloy steel CS alloy steel SH alloy steel alloy steelSOG T-24 DD-NL alloy steel SS alloy steel HF 17-4 PH alloy steelSOG low temp -50 ºF T-37 DD-NL alloy steel SS alloy steel HF 17-4 PH alloy steelSOG low temp -50 ºF T-37N DD-NL alloy steel SS alloy steel HF 17-4 PH CRASOG low temp -50 ºF T-37Z DD-0.5/ZZ alloy steel SS alloy steel HF 17-4 PH 17-4 PHslight CO2 corrosion and SOG T-25 EE-0.5/ZZ alloy steel SS 13 Cr SS HF 17-4 PH 17-4 PHwaterflood T-27 EE-0.5/ZZ alloy steel (2) SS 316 SS HF 17-4 PH 17-4 PHslight CO2 corrosion and SOG T-25N EE-NL alloy steel SS 13 Cr SS HF 17-4 PH CRAwaterflood T-27N EE-15.0 alloy steel (2) SS 316 SS HF 17-4 PH CRAcorrosive with high CO2 and SOG T-26 FF-0.5/ZZ 13 Cr SS SS 13 Cr SS HF 17-4 PH 17-4 PHcorrosive with high CO2 and SOG T-26N FF-NL 13 Cr SS SS 13 Cr SS HF 17-4 PH CRAextremely corrosive T-78 HH-NL CRA (1) CRA CRA HF CRA CRASOG Sour Oil and Gas H2S NACE MR0175(1) or Alloy Steel Clad 625(2) PTFE base or ENC coatingMaterials subject to change without notice. Special trims available.<strong>Stream</strong>-<strong>Flo</strong> Industries Ltd. Head Office 4505-74 Avenue, Edmonton, Alberta, Canada T6B 2H5 Ph (780) 468-6789 Fax (780) 469-7724<strong>Stream</strong>-<strong>Flo</strong> <strong>USA</strong> LLC., 8726 Fallbrook Drive, Houston, Texas 77064 Ph (832) 912-1022 Fax (281) 653-1188