Download A PDF Of These Pages - ShopNotes

Download A PDF Of These Pages - ShopNotes

Download A PDF Of These Pages - ShopNotes

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

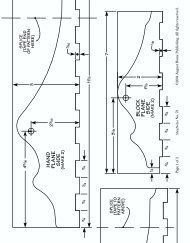

AdjustableTaper JigI recently needed to cut some tapersfor a project and didn’t want toinvest in a manufactured jig. So Ibuilt the simple jig you see above.This taper jig is accurate and canaccommodate a wide variety oflengths, widths, and thicknesses ofstock. It also works greatfor making straight rip cutson narrow pieces of stock.The jig’s base is a piece of 3 / 4"plywood with three long slots usedto attach an adjustable fence. Eachslot is recessed on the bottom for thehead of a carriage bolt (detail ‘a’).An adjustable 1 / 2" plywood fencesits on top of the base. It has slotscut to match the slots in the base foradjusting the angle of the taper.Four holes in the fence accept 1 / 4"carriage bolts for the hold-downs.I made four hold-downs from1"-thick hardwood, as in detail ‘b.’A slot at the top allows you toquickly position and then tightenthem down with a wing nut.To use the taper jig, adjust thefence to the desired taper and lockit in place. Then swing the holddownsover the workpiece andfirmly tighten the wing nuts.Finally, set the rip fence of thetable saw so the blade lines up withthe edge of the jig. Then simplypush the sled along the fence.That’s all it takes to cut perfecttapers every time.Frank PenickaMount Pearl, Nfld., Canadaa.b.6 www.<strong>ShopNotes</strong>.com

Shop-Made Set-Up GaugeLocating the depth of drill bit collars, determining thelength of dowels, or setting the cutting depth for toolsaccurately can be challenging. To make this task easier,I built the set-up gauge shown in the photo at right.The gauge frame is simply made of a piece of 1" x 1"aluminum angle. To this I added a second piece ofshorter aluminum angle with a wood stop blockattached, like you see illustrated in the drawing below.A threaded insert on the top of the wood blockaccepts a knurled knob that is used to set the tool.Adding a penny in the bottom fills in the space so theknob can be tightened firmly and accurately. Finally,stick a length of rule to the inside and you’re set to go.Len UrbanRancho Mirage, CaliforniaQuick Tips} To secure wood plugs, David Richards of Rochester,MN, uses the same finish he plans to use on the project.Just dip the plug into the finish and insert it in place. It’sfast and you won’t see any glue lines.< A vacuum extension mounted to the wall letsMike Oslund of San Antonio,TX, get rid of his dustpan. He just sweeps the dust to the nozzle.{ Gripping threaded hardware firmlywithout damaging the threads isalways a difficult task. So DavidJenkins of Phoenix, AZ, cuts smallpieces of hollow tubing and slips themover the jaws of the pliers to protect thethreads of the hardware.www.<strong>ShopNotes</strong>.com 7