XR1045 Operation Manual - Xtreme Manufacturing

XR1045 Operation Manual - Xtreme Manufacturing

XR1045 Operation Manual - Xtreme Manufacturing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

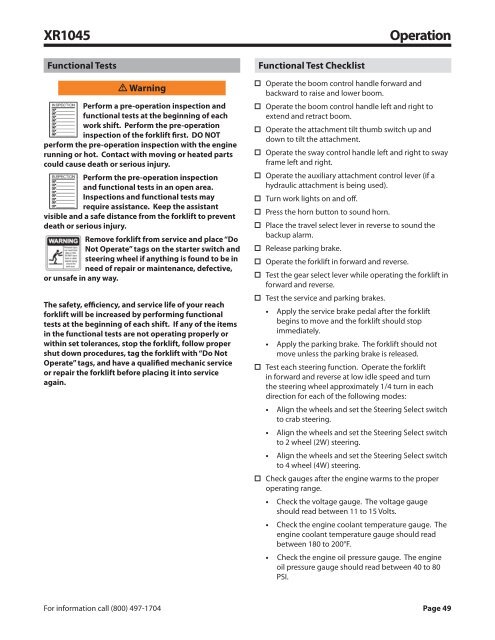

<strong>XR1045</strong><strong>Operation</strong>Functional Tests WarningPerform a pre-operation inspection andfunctional tests at the beginning of eachwork shift. Perform the pre-operationinspection of the forklift first. DO NOTperform the pre-operation inspection with the enginerunning or hot. Contact with moving or heated partscould cause death or serious injury.Perform the pre-operation inspectionand functional tests in an open area.Inspections and functional tests mayrequire assistance. Keep the assistantvisible and a safe distance from the forklift to preventdeath or serious injury.Remove forklift from service and place “DoNot Operate” tags on the starter switch andsteering wheel if anything is found to be inneed of repair or maintenance, defective,or unsafe in any way.The safety, efficiency, and service life of your reachforklift will be increased by performing functionaltests at the beginning of each shift. If any of the itemsin the functional tests are not operating properly orwithin set tolerances, stop the forklift, follow propershut down procedures, tag the forklift with “Do NotOperate” tags, and have a qualified mechanic serviceor repair the forklift before placing it into serviceagain.Functional Test ChecklistOperate the boom control handle forward andbackward to raise and lower boom.Operate the boom control handle left and right toextend and retract boom.Operate the attachment tilt thumb switch up anddown to tilt the attachment.Operate the sway control handle left and right to swayframe left and right.Operate the auxiliary attachment control lever (if ahydraulic attachment is being used).Turn work lights on and off.Press the horn button to sound horn.Place the travel select lever in reverse to sound thebackup alarm.Release parking brake.Operate the forklift in forward and reverse.Test the gear select lever while operating the forklift inforward and reverse.Test the service and parking brakes.• Apply the service brake pedal after the forkliftbegins to move and the forklift should stopimmediately.• Apply the parking brake. The forklift should notmove unless the parking brake is released.Test each steering function. Operate the forkliftin forward and reverse at low idle speed and turnthe steering wheel approximately 1/4 turn in eachdirection for each of the following modes:• Align the wheels and set the Steering Select switchto crab steering.• Align the wheels and set the Steering Select switchto 2 wheel (2W) steering.• Align the wheels and set the Steering Select switchto 4 wheel (4W) steering.Check gauges after the engine warms to the properoperating range.• Check the voltage gauge. The voltage gaugeshould read between 11 to 15 Volts.• Check the engine coolant temperature gauge. Theengine coolant temperature gauge should readbetween 180 to 200°F.• Check the engine oil pressure gauge. The engineoil pressure gauge should read between 40 to 80PSI.For information call (800) 497-1704 Page 49