HALOX® 520

HALOX® 520

HALOX® 520

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

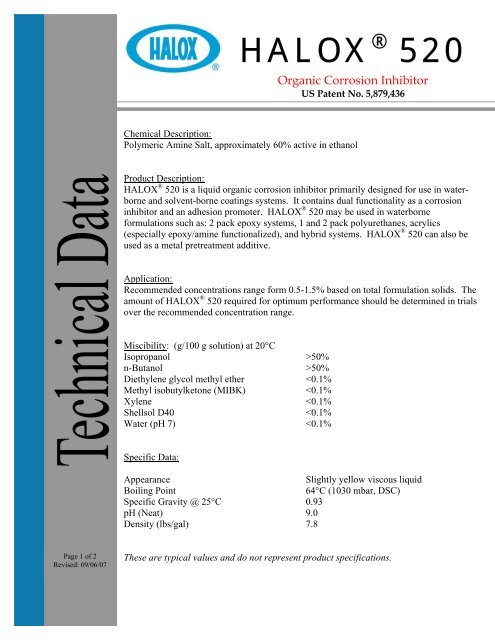

HALOX ® <strong>520</strong>Organic Corrosion InhibitorUS Patent No. 5,879,436Chemical Description:Polymeric Amine Salt, approximately 60% active in ethanolProduct Description:HALOX ® <strong>520</strong> is a liquid organic corrosion inhibitor primarily designed for use in waterborneand solvent-borne coatings systems. It contains dual functionality as a corrosioninhibitor and an adhesion promoter. HALOX ® <strong>520</strong> may be used in waterborneformulations such as: 2 pack epoxy systems, 1 and 2 pack polyurethanes, acrylics(especially epoxy/amine functionalized), and hybrid systems. HALOX ® <strong>520</strong> can also beused as a metal pretreatment additive.Application:Recommended concentrations range form 0.5-1.5% based on total formulation solids. Theamount of HALOX ® <strong>520</strong> required for optimum performance should be determined in trialsover the recommended concentration range.Miscibility: (g/100 g solution) at 20°CIsopropanol >50%n-Butanol >50%Diethylene glycol methyl ether

Incorporation:Although liquid, the product is best incorporated if added to a pigment grind, especially inthe polyol portion of 2 pack polyurethane systems, and amine/amide part of 2 pack epoxysystems. If possible, avoid systems with acetic acid, use surfactant stabilized hardenersinstead.If you are removing a heavy metal based anti-corrosive pigment, compensate for itsremoval with an extender (filler) so that the ratio PVC:CPVC remains constant. However,HALOX ® <strong>520</strong> can be used in conjunction with anti-corrosive pigments, preferably basedon compounds defined as non-toxic or reportable under applicable regulations. Checkcompatibility, shelf life (e.g. accelerated at high temperature), cure and pot-life, ifapplicable. Other formulation variables may also be optimized, for example, dispersants,surfactants, and PVC:CPVC ratio.Issued: 08/01/03Page 2 of 2Revised: 09/06/07A Division of Hammond Group, Inc.1326 Summer StreetHammond, IN 46320 USAtel: 219-933-1560fax: 219-933-1570e-mail: techservice@halox.comOur Quality System is ISO 9001:2000 CertifiedThe information contained within is believed to be reliable, but is presented without warranties, express or implied, including, but notlimited to, any implied warranty of merchantability or fitness for a particular purpose. User is responsible for determining whether theHALOX product is fit for a particular purpose and suitable for user's method of application.