Linde in Solar. - Linde Gas

Linde in Solar. - Linde Gas

Linde in Solar. - Linde Gas

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

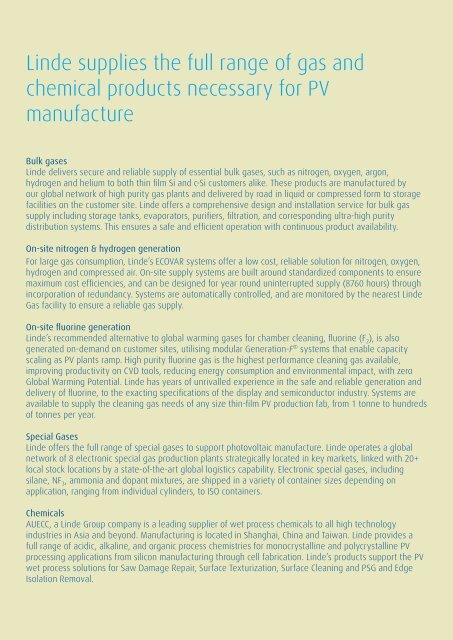

12 Column<strong>L<strong>in</strong>de</strong> supplies the full range of gas andchemical products necessary for PVmanufactureBulk gases<strong>L<strong>in</strong>de</strong> delivers secure and reliable supply of essential bulk gases, such as nitrogen, oxygen, argon,hydrogen and helium to both th<strong>in</strong> film Si and c-Si customers alike. These products are manufactured byour global network of high purity gas plants and delivered by road <strong>in</strong> liquid or compressed form to storagefacilities on the customer site. <strong>L<strong>in</strong>de</strong> offers a comprehensive design and <strong>in</strong>stallation service for bulk gassupply <strong>in</strong>clud<strong>in</strong>g storage tanks, evaporators, purifiers, filtration, and correspond<strong>in</strong>g ultra-high puritydistribution systems. This ensures a safe and efficient operation with cont<strong>in</strong>uous product availability.On-site nitrogen & hydrogen generationFor large gas consumption, <strong>L<strong>in</strong>de</strong>’s ECOVAR systems offer a low cost, reliable solution for nitrogen, oxygen,hydrogen and compressed air. On-site supply systems are built around standardized components to ensuremaximum cost efficiencies, and can be designed for year round un<strong>in</strong>terrupted supply (8760 hours) through<strong>in</strong>corporation of redundancy. Systems are automatically controlled, and are monitored by the nearest <strong>L<strong>in</strong>de</strong><strong>Gas</strong> facility to ensure a reliable gas supply.On-site fluor<strong>in</strong>e generation<strong>L<strong>in</strong>de</strong>’s recommended alternative to global warm<strong>in</strong>g gases for chamber clean<strong>in</strong>g, fluor<strong>in</strong>e (F 2 ), is alsogenerated on-demand on customer sites, utilis<strong>in</strong>g modular Generation-F ® systems that enable capacityscal<strong>in</strong>g as PV plants ramp. High purity fluor<strong>in</strong>e gas is the highest performance clean<strong>in</strong>g gas available,improv<strong>in</strong>g productivity on CVD tools, reduc<strong>in</strong>g energy consumption and environmental impact, with zeroGlobal Warm<strong>in</strong>g Potential. <strong>L<strong>in</strong>de</strong> has years of unrivalled experience <strong>in</strong> the safe and reliable generation anddelivery of fluor<strong>in</strong>e, to the exact<strong>in</strong>g specifications of the display and semiconductor <strong>in</strong>dustry. Systems areavailable to supply the clean<strong>in</strong>g gas needs of any size th<strong>in</strong>-film PV production fab, from 1 tonne to hundredsof tonnes per year.Special <strong>Gas</strong>es<strong>L<strong>in</strong>de</strong> offers the full range of special gases to support photovoltaic manufacture. <strong>L<strong>in</strong>de</strong> operates a globalnetwork of 8 electronic special gas production plants strategically located <strong>in</strong> key markets, l<strong>in</strong>ked with 20+local stock locations by a state-of-the-art global logistics capability. Electronic special gases, <strong>in</strong>clud<strong>in</strong>gsilane, NF 3 , ammonia and dopant mixtures, are shipped <strong>in</strong> a variety of conta<strong>in</strong>er sizes depend<strong>in</strong>g onapplication, rang<strong>in</strong>g from <strong>in</strong>dividual cyl<strong>in</strong>ders, to ISO conta<strong>in</strong>ers.ChemicalsAUECC, a <strong>L<strong>in</strong>de</strong> Group company is a lead<strong>in</strong>g supplier of wet process chemicals to all high technology<strong>in</strong>dustries <strong>in</strong> Asia and beyond. Manufactur<strong>in</strong>g is located <strong>in</strong> Shanghai, Ch<strong>in</strong>a and Taiwan. <strong>L<strong>in</strong>de</strong> provides afull range of acidic, alkal<strong>in</strong>e, and organic process chemistries for monocrystall<strong>in</strong>e and polycrystall<strong>in</strong>e PVprocess<strong>in</strong>g applications from silicon manufactur<strong>in</strong>g through cell fabrication. <strong>L<strong>in</strong>de</strong>’s products support the PVwet process solutions for Saw Damage Repair, Surface Texturization, Surface Clean<strong>in</strong>g and PSG and EdgeIsolation Removal.