Projects & News - WSP Group

Projects & News - WSP Group

Projects & News - WSP Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

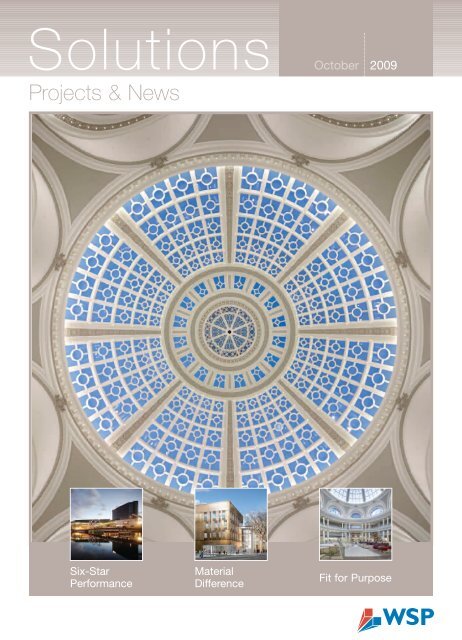

Solutions October<strong>Projects</strong> & <strong>News</strong>2009Six-StarPerformanceMaterialDifferenceFit for Purpose

Solutions October<strong>Projects</strong> & <strong>News</strong>200902Credit: Nicola Evans, <strong>WSP</strong> UKCONTENTS02 Six-Star Performance04 A level playing field05 Maintaining Access06 Going Wide08 Material Difference09 High Energy10 Fit for Purpose12 MilestonesFront Cover: The new WestfieldSan Francisco CentreEditor: Bridget Kennerley,<strong>WSP</strong> <strong>Group</strong> Communicationsbridget.kennerley@wspgroup.comDesigned and printed byrhc visual strategy www.rhc.uk.comOver the coming months youmay notice the appearanceof a new theme in ourcommunications from <strong>WSP</strong>.United by our Difference is a messagewe developed as part of a refresh of our brand,following a research exercise aimed at discoveringwhat <strong>WSP</strong> really meant to our staff, clients andinvestors. One overriding conclusion of thisresearch was that <strong>WSP</strong> was defined by thediversity of skills and backgrounds of <strong>WSP</strong>people, which generated tremendous dynamismand creativity, making for better solutions.The sentiments behind the United by our Differencemessage are implicit in every page of this issueof Solutions.Our difference is illustrated by our wide rangeof specialist expertise. Read, for example, howour green building experts from <strong>WSP</strong> LincolneScott have delivered the world’s first six-star GreenDesign Star rated Convention Centre in Melbourne;while across the globe our façade accessspecialists are designing and deliveringmaintenance strategies in buildings ranging fromhigh rise office blocks to historic art galleries.Our clients also benefit from the specialistknowledge of individuals, such as Meike Borcherwho, on P8, discusses the role of the structuralengineer in helping clients meet planningrequirements by focusing on choice of materialsand construction techniques to curb theirgreenhouse gas emissions.The diversity of our expertise is united through ourwork in different global markets, such as the roads,retail and sport sectors in the UK, Sweden and theUSA. Discover how our civil engineers are keepingtraffic moving through major road wideningprojects; how our building services engineers arereturning historic market halls and retail emporiumsto their former glory; and how <strong>WSP</strong> expertsof all disciplines are contributing to the enjoymentof sports enthusiasts in their design of high profilestadiums around the world.There’s nothing more satisfying than when oursolutions can be measured and proven withquantitative data. Consider this; one of ourcustomers spent £3,000 on installing our innovativeonline client product “Energy Bureau”, developedby <strong>WSP</strong> Environment & Energy to track andmanage the energy consumption of buildings. Forthat modest investment, the client saved £30,000,one tenth of its annual expenditure on energy. Thefigures speak for themselves – this is the sort ofresult we get by being United by our Difference.Chris Cole CEO, <strong>WSP</strong> <strong>Group</strong> plcSix-Star“Breaking new ground in environmentallysustainable design is a challengewe never shy away from, and we haveachieved it again at the MelbourneConvention Centre.” Ché Wall,Managing Director of <strong>WSP</strong> LincolneScott is justifiably proud of his team’ssignificant contribution in achievinga Six-Star Green Design Star rating withthe Convention Pilot tool developed bythe Green Building Council of Australiafor this iconic new Melbourne landmark.The largest convention centre in thesouthern hemisphere, it is also the firstconvention centre in the world to haveattained the highly sought afterenvironmental rating, which representsit world-leader status. Lincolne Scottand its specialist services AdvancedEnvironmental and Vision Design, providedall the engineering services to the project,with complete involvement from the bidphase to delivery, including all buildingservices, environmentally sustainable design(ESD) and architectural lighting.

PerformanceImages Courtesy of Peter BennettAdvanced Environmental drove theenvironmental outcomes. “We knew thatthe Melbourne Convention Centre wasgoing to be a benchmark project in termsof sustainable design. We set clearobjectives early and committedto a number of technically challenginginitiatives to get the most effective resultin terms of functionality and environmentalimpact,” said Matthew Jessup, Principalof <strong>WSP</strong> Lincolne Scott and AdvancedEnvironmental. “The sustainable featureswe implemented included a displacementventilation system; one of the largestbuildings-installed blackwater treatmentplants in Australia with water conservationfeatures in the design; and 8,500 squaremetres of sustainable harvested timberveneer board – that’s the largest use ofFSC certified timber in Australia. We alsomaximised the natural lighting capacityof the building with an 18 metre glassfaçade looking out onto the Yarra River.”The design team is particularly proud ofthe under floor air conditioning system forthe Plenary Hall, which seats 5,600 peoplewith a moveable seating component forover 2000 on retractable seating, that canalso be divided into three self-contained,acoustically separate theatres. Theirinnovative low energy displacementventilation solution enables the movabledesign, whilst providing high indoorenvironment quality.Other low energy solutions include:■■Innovative incorporation of chilledwater in heated slab system providingenergy efficient thermal comfort andreducing air conditioningSolar panels to provide hot waterfor 100% of public amenity and 40%of total hot water demand■ Building sensors to detect thenatural light and adjust lightingto conserve energyThe project was originally plannedto meet 4 star Green Star requirementsby the Victoria State Government.However, Advanced Environmental andthe team committed to achievingContact: Matthew Jessop, <strong>WSP</strong> Lincolne ScottTel: +61 2 8907 0900Email: matthew.jessup@lincolnescott.comBanksia EnvironmentalFoundation Awards 2009:Winner of theBuilt Environmental Awarda Six Star rating, which, accordingto Matthew Jessup, was a significant factorin winning the project for the integratedproject team put together by thePlenary <strong>Group</strong>. “It demonstrated the team’scommitments to ESD by considerablyexceeding the client’s brief,” he concluded.The Melbourne Convention Centre wasopened in June 09, and in August wasawarded the prestigious Built EnvironmentAward by the Banksia Foundation.Already 50 major international conventionsand a predicted 190 national conventions,meetings and large seminars will be heldin the centre between 2009 and 2015,bringing more than 270,000 delegatesto Melbourne, injecting hundreds of millionsof dollars into the Victorian State economy.03

Stockholm Globe, White ArchitectsA level playing fieldNew Arena forStockholmStadiums are spaces of entertainment and theatreand their successful design contributes to theexcitement for both players and spectators.Their construction can also have a positive effecton urban development and regeneration in thewider community.Contact: Jonas Living, <strong>WSP</strong> SwedenTel: +46 8 688 78 28Email: jonas.living@wspgroup.seThe new Stockholm Arena willbe a multipurpose venue for yearrounduse, and is an important partin the plans to extend the existingEricsson Globe area.In addition to the new arena,approximately 45,000 square metresof commercial space and hotels and60,000 square metres of office spaceare planned in the vicinity. Demolitionand construction work is due to beginin January 2010 and will be completedby the end of 2012 at an estimated costof SEK 2.0 billion (200 million Euros).<strong>WSP</strong> is project manager and will alsobe providing an extensive suiteof services including Civils, Environmental,Fire & Risk and Acoustics. “It’s a uniquedesign that features a moving roofdesigned to take snow loads,” saysJonas Living of <strong>WSP</strong> Managementin Sweden. The heating system willprovide an indoor temperature of 22°Ceven in the depths of winter. Heatingwill come from underground pipes andventilation from fresh air circulation withminimal air-conditioning.The new arena will also meet UEFAstandards for a championship stadium,which require a seating capacityof no less than 30,000 and complieswith UEFA and FIFA regulations forseating, pitch measurements,safety arrangements, lighting andsound systems.New home for New York MetsIn the spring of 2009 a state-of-the-artvenue for the New York Mets baseballteam opened in Queens, NY.The architecture and design of theaward-winning $800 million Citi Field wasinspired by Ebbets Field, the home of theBrooklyn Dodgers until the 1950s.“The new field was given a turn of thecentury feel by reproducing Ebbets Fieldentrance porch, rotunda and façade,but the audiovisual systems and lightingare very much 21st century and there arebetter sight lines than at Shea Stadium,”says Allen Thompson, Senior Associateat <strong>WSP</strong> Cantor Seinuk, which providedthe structural engineering design servicesand concrete reinforcement inspectionservices for the project.It was like buildingon a bowl of Jello3D BIM modelling was used to createa model of the foundations andsuperstructure. The BIM model allowedthe architect to run clash detectionbetween the structural members andthe architectural finishes.Because of challenging soil conditionson the site, pile support of the stadium’sstructure was required. All theunderground utilities were hung from thepile supported slab using a special detailto avoid drag down forces. The soilconditions also drove the design of thelateral force resisting systems and sincethey were so poor, the design seismicforces were similar to thosein an earthquake zone, even thoughNew York City is not in a high seismiczone. “That was our biggest technicalchallenge,” admits Thompson.Contact: Allen Thompson, <strong>WSP</strong> Cantor SeinukTel: +1 212 687 9888Email: allen.thompson@wspcs.com“The ground the stadium was builton is so unstable that we had to designto high seismic loads. It was like buildingon a bowl of Jello.”The intimate and fan-friendly ballparkopened in March with a collegeexhibition game followed by two Metsexhibition games to mark the start of thebaseball season. By season’s end, morethan 3.2 million fans will visit Citi Fieldin its inaugural season.Mets Development Company, LLC04

Maintaining AccessWhat does it take to clean the windowsof a skyscraper, suspended high up inthe air against a tower of sheet glass?Apart from a very good head forheights, what’s required is a goodfaçade access system to get peopleup there safely and efficiently.This is the work of <strong>WSP</strong>’s newspecialist Façade Access service, ledby Paul Coleman and Colin Frederick,created in response to the increasinglychallenging business of maintainingand cleaning the exterior of buildings.Coleman and Frederick havean international reputation for theirfaçade access solutions, and <strong>WSP</strong>’sglobal portfolio is exposing the teamto an ever wider range of structuresand architecturally challenging façadesaround the world. Their experiencecovers every type of building project,including high-rise, retail, offices,residential, hotels & leisureand transportation.Within six months of joining <strong>WSP</strong>they are already appointed to projectsin UK, Russia, Libya, Abu Dhabi, Egyptand Lebanon. In Moscow they have thechallenge of developing a façade accesssolution for a project to extend the city’slargest museum of European art,the Pushkin Museum, workingwith architects Foster and Partners.“Our challenge was to delivera solution that suited both the originalhundred-year-old façade and themodern extension, balancingaesthetics, practicality and safety,”says Paul Coleman.Foster + PartnersContact: Paul Coleman, <strong>WSP</strong> UKTel: +44 (0)20 7406 7216Email: Paul.coleman@wspgroup.comThe team deliver bespoke solutionsand designs, providing adviceon codes and safety to the globalmarket in partnership with <strong>WSP</strong>’sFaçade Engineering team. They’ll alsobe providing a facade replacementservice, for which there’s a growingdemand. Another service providedby the team is carrying out inspectionsand surveys of existing equipment.The core activity is designing anddelivering cleaning and maintenancestrategies using the familiar BuildingMaintenance Units (BMU’s) anda variety of different hoists and jibs.Curved buildings, for example,require maintenance staff to be safelypositioned on the workface usingtelescopic and slewing jibs. They workon the tallest buildings in the world,but Paul Coleman explains: “It’s not theheight, but the increasingly complexgeometry of modern architecture thatposes the biggest challenge.”Their experience coversevery type of buildingproject, including high-rise,retail, offices, residential,hotels and leisure andtransportation.05

Going WideRoad-widening schemes are oftencontroversial due to the disruptionthey cause, but <strong>WSP</strong> has been involvedin designing several successful projectsthat allow traffic to flow while workis underway.Concrete InnovationViaduct improvements<strong>WSP</strong> SELLS developed and testedan award-winning accelerated-cureconcrete, used for the first time on thisproject. The concrete’s setting timeof just 12-15 hours saved time andcosts by avoiding weekend closuresin stretches where alternative lanescouldn’t be re-allocated. This productwill be rolled out in other projects andoffered to new clients in the future.In New York, <strong>WSP</strong> SELLSis responsible for design improvementsto a 3.8 mile elevated GowanusViaduct, part of the GowanusExpressway in Brooklyn that connectswith the Verrazano Narrows Bridge.The six/eight lane structure was builtin the 1940s and has already beenwidened once during the 1960s. TheState of New York is currently evaluatingwhich long-term steps to take andpreparing an environmental impactreport. Meanwhile interim repairsare being carried out while maintaininga 200,000 annual average daily trafficand keeping the maximum numberof lanes open.The concrete deck has a multi-stringersuperstructure and is supported on steelpiers with pile foundations. The viaducthas three major interchanges –the Brooklyn Queens Expressway,the Prospect Expressway and theShore Parkway. The first two werewidened in 2006 and 2008 respectivelyas part of $150 million and $160 millioninterim deck replacement contracts.The third will be widened in 2010as part of a $220 million contract.Traffic will be shifted temporarily intoa new central lane, which will be usedas a High Occupancy Vehicle (HOV)lane once the process is completed.“The work won’t impact the overallwidth of the viaduct which reducesthe environmental impact of the work,”explains <strong>WSP</strong> SELLS’ Phil Bousader.“At the end of the process, no lanes willbe gained or lost but they will be bettermanaged using the HOV lane and newhard shoulders.”Contact: Philippe BousaderTel: +1 914 747 1120Email: phil.bousader@wspsells.com06

Maintaining Motorway traffic flowIn the UK, <strong>WSP</strong> has acted as designerto the contractors on the HighwaysAgency’s widening scheme for theM1 motorway around Nottingham.The contract was awarded in early 2007,with construction being fully underwayin January 2008 on a 24 km stretchof road divided into three sectionsbetween Junctions 25 and 28.The central section was substantiallycompleted in February 2009 bothnorthbound and southbound, and thebulk of the earthworks and drainage forthe other two sections is now complete.Traffic management is in place on allthree sections simultaneously, exceedingthe normal HA limit of a 10 km stretch.Instead of a contraflow there are threenarrow lanes in each direction,maintaining traffic flow and greatlyreducing traffic delays.“The initial costs were based on a designprovided by the Highways Agency,but the cost of the works would haveexceeded the available budget,” saysRoland Diffey, Senior Technical DirectorContact: Roland Diffey, Senior Technical Director, <strong>WSP</strong> CivilsTel: +44 (0)1256 318866Email: roland.diffey@wspgroup.comat <strong>WSP</strong>. “So we developed someinnovative solutions, making hugesavings on structures, pavements andearthworks, to reduce works coststo within budget.”The original design was basedon a standard 4-lane motorway.The <strong>WSP</strong> Civils Design and Supervisionteam proposed a reduced width crosssectionbased on reduced width trafficlanes, having demonstrated the abilityto achieve this safely in previous workon the M27. This solution reducedthe carriageway width by 2.7 metres,saving on bulk earthworks materials,and reducing the number of bridgesrequiring demolition and replacementfrom five to just one.A further contract has now beenawarded for a section from Junctions16-30 of the M25, starting on sitein July 2009. <strong>WSP</strong> are sub-consultantsresponsible for detail design andsupervision for approximately 25%of the works. Designs for the contractorstarted some nine months prior to thefinal contract being awarded, to allowfor the widening to be completed in timefor the 2012 Olympics. “We’ve addedvalue by taking lessons learned fromthe M27 and previous M25 work,applying them in the M1 widening andthen through continuous improvementreapplying to the latest M25 contract.”07

MaterialDifferenceMeike Borchers examinesthe emerging role of thestructural engineerin reducing greenhousegases (GHG) andconserving resources.The construction industry has a majorenvironmental responsibility for bothman-made climate change andresource depletion. In the UK, about50% of all CO 2 emissions are linkedto the construction and useof buildings. Construction materialsaccount for about one fifth of ourtotal national ecological footprint,and a quarter of the total nationalGHG emissions. Cement productionis responsible for over 5% of all GHGemissions worldwide, and steel usedin construction for another 3%.Traditionally, the design decisions thatstructural engineers take are drivenby giving the client value for money andresource efficiency. A change in planningrequirements and a heightened clientawareness has led to an increasedfocus on materials and constructiontechniques with low environmentalimpact. But the potential of structuralengineering in curbing GHG emissionshas been largely unrecognised until now.Energy savingpotentialThe UK has pledged to reduce nationalGHG emissions by 80% by 2050,an ambitious goal, which will requirehuge savings in all areas, from the builtenvironment, industry and in transport.Strategies for GHG reductionsin the built environment usually focuson emissions caused during thebuilding’s use. There’s huge potentialfor energy saving in existing buildingstock by improving the thermalperformance of the building envelope.For new buildings, the goal is to buildonly zero carbon homes from 2016 andit’s likely that zero carbon non-domesticbuildings will be a requirement from2019. The zero carbon definition relatesto operational energy demand only,but we believe that this approach leavesout another area with opportunities forsavings: GHG emissions resulting frombuilding design and construction.Carbon-negative cementContact: Meike Borchers, <strong>WSP</strong> UKTel: +44 (0)20 7314 5880Email: Meike.borchers@wspgroup.comResearch and development is ongoing into new typesof “green cement”. Currently <strong>WSP</strong>, Rio Tinto Materialsand Laing O’Rourke are supporting Novacem, basedat Imperial College in London, in the development ofa magnesium silicate based process which requires muchless heating than conventional cement and also absorbslarge amounts of CO 2 as it hardens making it a carbonnegative process. The company has started a £1.5mproject funded by the UK Government-backed TechnologyStrategy Board to build a pilot plant, which will bedesigned by <strong>WSP</strong>’s process engineering company, CEL.40% GHGin the structureTo date, little attention has been paidto energy embedded in the materials,or comparing their relative CO 2 emissions.The emerging field of lifecycle footprintingassesses a building over its lifespan,from planning and the extraction of rawmaterials over construction and operationto deconstruction, recycling and disposalof materials. This enables evaluationof the environmental consequencesof a development and supports decisionmakingduring the design process.Our recent lifecycle studies suggest thatthe building’s structure can account foras much as 40% of the life-time GHGemissions over an assumed lifespanof 60 years.Another area where the structural engineercan have an impact is material choice.For example, the use of high cementreplacement content in concrete mixescan achieve massive GHG savings.While concrete with high GGBS (groundgranulated blast furnace slag) content isfrequently used for certain applications, e.g.secant pile walls, CO 2 savings could beachieved in most other concrete elements.Energy efficiencyat London SouthBank University<strong>WSP</strong> is currently providing structuraldesign for the redevelopment of theLondon South Bank University.The concrete structure enhances energyefficiency by absorbing and storing heat.The thermal mass of the concrete actsas a “thermal flywheel” reducing thetemperature peak by 3° to 4°, anddelaying its onset by up to six hours.The slabs are cooled overnight, primingthem for the next day’s cycle. Troughedfloor slabs distributed over a large areamaximise the heat exchange area.Waste materials such as GGBS have beenused in the concrete mix to reduce theembodied energy by 40-70%.The structure is founded on 750mmdiameter 28m long, closed loopgeothermal piles, the number anddepth of which enable the transferand storage of geothermal energy.Closed polyethylene pipes are castinto the piles and contain a solutionof environmentally friendly anti-freezeand water.The concrete structureenhances energyefficiency by absorbingand storing heat.08

HighEnergyIn the early summerof 2009, <strong>WSP</strong>Environment &Energy launchedthe Energy Bureau,a web-basedservice that canbe used anywherein the world by anykind of business.It works through the installationof remote data logging devices,which capture and analyse a client’sdata. On-site energy data is broughtback to a central web-based reportingservice. “The use of remote datacollection is now common in allsorts of business situations,”says Chris Stubbs, Director of <strong>WSP</strong>Environment & Energy. “We thoughtit was a good thing to be doingin the property business, and a lotof companies are interested.”A clear picture of client buildings’energy consumption and performanceis then built up, highlighting areas whereissues such as control logic failuresin heating or cooling are present.It’s the detail in these reports that allowsclients to see exactly where power andwater are being wasted, often during thenight or in off-peak periods. Email alertsare automatically sent to key personnelto alert them to such failures,and the data collected allows forboth monitoring and forecastingperformance and the setting of targets.The Energy Bureau also uses theinformation to analyse tariffs and utilitytenders, and allows better compliancewith carbon reduction and emissiontrading schemes. The savings canbe impressive. “Clients are payingfor their investment within a month,”says Stubbs. “For about £3000we identified and delivered savingsof £30,000 a year to a companyspending £300,000 per year on energy.It may sound too good to be true butgovernment research backs up ourclaims.” The UK Carbon Trust researchshows that companies who monitortheir consumption usually achieveat least a 10% energy savingfor a very small installation cost.Contact: Chris Stubbs, <strong>WSP</strong> Environment & EnergyTel: +44 (0)161 886 2400Email: Chris.stubbs@wspgroup.com“For about £3000 weidentified and deliveredsavings of £30,000a year to a companyspending £300,000 peryear on energy. It maysound too good to betrue but governmentresearch backsup our claims.”<strong>WSP</strong>’s offer extends beyond datacollectionand reporting. “The EnergyBureau opens the door to the deliveryof follow-up services,” confirms Stubbs,“We are going back and talking to clientsabout their needs as part of a long-termrelationship.”09

Fit for PurposeIn the final part of our serieson refurbishment, we look at howrevitalised retail spaces reflectthe needs of the modern shopperon both sides of the Atlantic.Flagships of San FranciscoIn San Francisco, two iconic retailnames have been the subjectsof striking renovations. The newWestfield San Francisco Centre hasbeen created from the much-lovedEmporium department store,a flagship of the city’s retail scenethat survived the 1906 earthquake.The 1.5 million square feet facilityprovides 250,000 square feet of officespace in addition to the retail space.Fronting on both Mission andMarket Streets, the Centre boastsBloomingdale’s as its most prominenttenant, along with other upscale storessuch as Juicy Couture, Tag Heuer andTommy Bahama, restaurants and foodcourts, office space and a 9-screencinema. While the whole buildingis constructed to current seismic code,the original Market Street façade hasbeen preserved, along with thedome and rotunda, which are visiblethroughout the mall and have becomethe building’s signature.“We preserved the best historic featuresinside the building, but a huge amountof structural re-working was neededto meet current codes,” says Todd See,Senior Vice President of <strong>WSP</strong>Flack + Kurtz. “An important partof the process was the quake-proofingof the building.” His team provided M&E,plumbing, fire protection and securityand telecoms services for both the basebuilding and tenants, and is still workingwith the client as new tenants jointhe facility. “Next up is an upgradeto building controls on an adjacentproperty, also owned by Westfield,so the two buildings can be operatedtogether and improve energy efficiency.”Contact: Marcus Keay and Todd See, <strong>WSP</strong> Flack + KurtzTel: +1 415 398 3833Email: marcus.keay@wspfk.com or todd.see@wspfk.comA few blocks away on O’Farrell Streetthe 1907 FAO Schwartz toy store hasbecome home to up market departmentstore, Barneys. Completed at the endof 2008 and covering 60,000 squarefeet, it has the luxury feel of all Barneysflagship stores. “The work requiredhigh end finishes and interior designwhich had to integrate buildingsservices,” observes <strong>WSP</strong> Flack + Kurtz’sMarcus Keay. “The existing store’s mainescalator has been taken out and thestreet corner entry has an ornatestairway ascending six floors. Localbuilding codes don’t allow more thantwo connecting floors without fire doors,so smoke protection doors have beenrecessed so they can’t be seen.”The original façade of single pane clearglass presented a significant designchallenge. Using energy modelling10

Contemporary interventionsoftware eQuest and TAS, the solutionwas to apply a tinted film to the interiorof the glass rather than replacing withdouble glazing, which would havecompromised the historic appearance.This reduced both cost and energy load,which in turn reduced the weight of themechanical equipment on the roof.In the UK, Bolton’s Victorian markethall has been restored, and itsinterior updated to attract majorhigh street retail names.The original market hall had a distinctive19th century wrought ironwork anda glazed clerestory roof. Its market stallsfaced inwards and the Grade II listedstructure had fallen into disrepair overmany years.A sensitive refurbishment was carriedout by owner, Warner Estate Holdings,in partnership with English Heritage andlocal conservation officers, and theresulting structure has been short-listedfor a regeneration award. “Workingon a Grade II listed building youencounter many restraints thatultimately steer the design solution,”says Ian Standring, <strong>WSP</strong> BuildingsDirector. Alterations to the building’sfabric have been kept to an absoluteminimum, with the roof retiledin slate and the clerestory re-glazed.The clerestory windows are usedto create natural ventilation and theresult is a much greener building, usingthe same concept that ventilated theContact: Ian Standring, <strong>WSP</strong> UKTel: +44 (0)161 886 2400Email: Ian.standring@wspgroup.combuilding 150 years ago. This, and theambient water loop for retail tenants,has helped to achieve a credibleBREEAM score and significantlyimproved energy efficiency.<strong>WSP</strong> provided a suite of multidisciplinaryservices, including MEP, fire engineeringand travel planning. The major retail unitsnow face outwards, and their serviceshave been run down into the basementlevel to minimise intrusiveness and visualimpact. “The brief for this scheme wasto achieve a ‘contemporary intervention’,”says Standring. “In other wordseverything that you put in hasto be capable of being removed.All structures have to be independentand can’t be installed through the roofor the facades.” The result is a cleardistinction between old and new,with the walls of the new retail space setback from the original columns and yetintegrated with the Victorian streetscape.The building has also been kept at theheart of the local community, followinga series of community art initiatives thatWarner Estate commissioned to mark thestart of the newest chapter in the markethall’s history.Four roof mounted air-cooled DX units,using an outdoor air economiser,provide the building’s air-conditioning.San Francisco’s moderate climate allowsthe system to be operated by freecooling for approximately 3000 degreedays of the year when the outside airtemperature is below 65°F. “Given localbuilding codes and the existing interiordesign challenges, it was a successfuland rewarding project from our pointof view,” says Keay.11

MILEST NES■ Crossrail has awarded <strong>WSP</strong> thecontract to design Bond Streetstation as part of Europe’s largestconstruction project. As leadconsultant, <strong>WSP</strong> will undertakethe detail design, providing structuraland M&E design, environmentalmanagement and planning.■ In Saudi Arabia <strong>WSP</strong> has beenappointed by Al-Mal InvestmentCompany to supply programmemanagement services for Ha’ilEconomic City. This appointmentgives <strong>WSP</strong> Middle East theopportunity to establish itselfas a major player in the projectmanagement and infrastructureplanning markets.■ Following a scoping study in thefirst quarter of 2009, <strong>WSP</strong> hasbeen appointed by BSG Resources(Guinea) to begin feasibility studiesfor the construction of a new rail linkto transport iron ore from theSimandou mining concession areain South Eastern Guinea to thecoast and for upgrading the Portof Buchanan.Crossrail has awarded<strong>WSP</strong> the contract todesign Bond Streetstation as part ofEurope’s largestconstruction project■ <strong>WSP</strong> is a key player in the CityLegacy team, named by GlasgowCity Council as the preferred bidderto build the £245m athletes’ villagefor the 2014 Commonwealth Gamesin Glasgow. <strong>WSP</strong> will providethe full range of engineering andenvironmental services to support thedelivery of one of Scotland’s mostsignificant regeneration projects.■ <strong>WSP</strong>imc has been awarded a twoyear Technical Assistance Projectto the Ethiopian Roads Authority,funded by the World Bank.The project involves establishinga system for monitoring theperformance of contractors andconsultants, as well as establishinga project cost and unit rate database.■ <strong>WSP</strong> Environment & Energy hasdeveloped a carbon accreditationscheme for Airports CouncilInternational in Europe. The schemewill provide the benchmark for carbonmanagement across Europe’s airportsand will be launched later in 2009.■ The Isle of Wight Council hascommissioned <strong>WSP</strong> to provideassistance in developing its HighwaysPFI project in support of the localeconomy. We have also beenappointed by Hertfordshire CountyCouncil to develop an urbanTransport Plan for Hertford and Ware.■ <strong>WSP</strong> continues to win hotel projectsin Africa, the latest being thestructural engineering consultancycontract for the Pivot, a four-starSouthern Sun hotel in Johannesburg.<strong>WSP</strong> has also been awardeda multi disciplinary appointmenton the prestigious 200-key four-starLe Coco Beach Resort underdevelopment in Mauritius.■ CEL International is currentlyundertaking the front end design fora new flu vaccine manufacturing facilityfor Medimmune, the biotechnologyarm of AstraZeneca, for Speke, UK.CEL is also implementing a projectfor Reckitt Benckiser’s Hull, UK facilityfor the manufacture of liquidconsumer healthcare products.■ In Hong Kong <strong>WSP</strong> has beenappointed as Building ServicesEngineer for another Shangri-LaHotel. With a floor area of over68,000 sq m, the five-star hotelis located in China’s famous historicaland cultural city, Yangzhou.■ Innovative design proposals forthe redevelopment of the centreof Sepänkylä in Mustasaari, Finland,have resulted in a <strong>WSP</strong>-led designteam being awarded joint first price inan international invitation competition.■ <strong>WSP</strong>’s Romanian business has beenawarded the design contract for theSmart Park in Straulesti, Romania byITD SRL, the Bucharest subsidiaryHead Office<strong>WSP</strong> House 70 Chancery LaneLondon WC2A 1AF United Kingdom<strong>WSP</strong> Environment& Energy hasdeveloped a carbonaccreditation schemefor Airports CouncilInternational in Europeof Rafael de La-Hoz (Madrid).<strong>WSP</strong> Environment &Energy haswon a BREEAM contract on samedevelopment.■ <strong>WSP</strong> has been retained for a studyto restructure the Jordan Nationalinter city Bus Network. <strong>WSP</strong> willdevelop a comprehensive publictransport Master Plan for bus andcoach services and coach stationfacilities in the 12 main citiesof Jordan. This contract waswon as a result of current workon developing the transportstrategy for Greater Amman.■ The Swedish Government hasapproved the new SEK 27.6bnmega highway bypass projectaround Stockholm. <strong>WSP</strong> is providingpreliminary design, all siteinvestigations and EIA. Constructionwork will commence in 2010 withcompletion in 2018.■ Through <strong>WSP</strong> Edunova we havebeen appointed by ictQatar to deliverfurther e-learning consultancyto 37 schools in the Knowledge-Netprogramme. The £600k, one-yearproject follows on from previous workcarried out by <strong>WSP</strong> for ictQataras subcontractor to IT firm ITWorx.■ <strong>WSP</strong> has signed a contract with theRussian design and constructionconsultancy, GT Morstroy, to deliverconsulting services for onshoreconstruction work for the first phaseof the Shtokman gas field in theBarents Sea, one of the world’slargest gas condensate resources.■ Pelli Clarke Pelli Architects haveappointed <strong>WSP</strong> Lincolne Scottto provide MEP services for a majornew office building project in Ho ChiMin City, Vietnam, which will be theheadquarters for Vietcombank.