Powder Cooler - Christian Pfeiffer

Powder Cooler - Christian Pfeiffer

Powder Cooler - Christian Pfeiffer

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

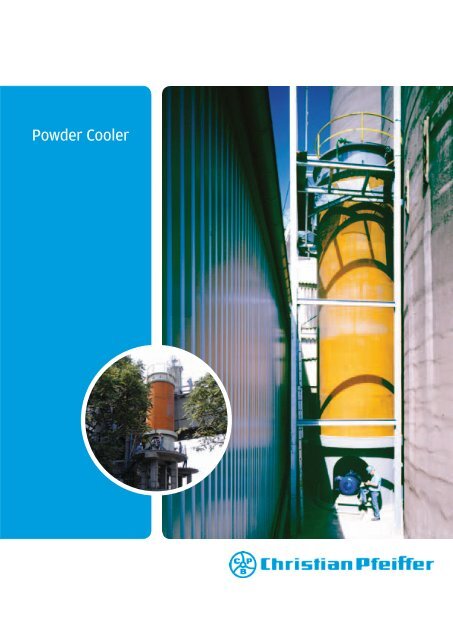

Cooling for allpowdered productsFor an overall or specific improvementof the product quality, itis often important to reduce thetemperature of the ground materialafter the comminution process.Direct cooling, like water injectionin the grinding system,often results in a reduced productquality. This is a reason indirectcooling processes are preferred.<strong>Christian</strong> <strong>Pfeiffer</strong> powder coolersare indirect heat transfer unitsused to provide an optimal coolingeffect for various material transportcapacities. The material beingcooled is not contaminated bythe cooling media so our coolersare suitable for all fine powders,coarse granules and most circulatingmaterials from grinding plantsor similar production processes.<strong>Christian</strong> <strong>Pfeiffer</strong>powder coolers areavailable in threesizes for a materialthroughputof up to 180 t/h.<strong>Cooler</strong> designsfor special conditionsand capacityrequirementsare also available.Outletcooled materialInlet hotmaterialIndirect cooling

Cool affair: temperaturereduction throughcounter flow heatexchangeprincipleWater supply at cooler topHeight of cooling cylinder [m]Temperature difference∆TCooling waterMaterial to becooled (cement)The <strong>Christian</strong> <strong>Pfeiffer</strong> powdercooler consists of a vertical cylindermade of steel and cooled by awater film. A rotor inside the cylindertransports the hot materialfrom the inlet at the bottom tothe outlet at the top of the cooler.A steady stream of cooling media(water) flows down the outsideto remove heat from the steel cylinderand thereby cooling the materialwhile being transported inside.Moving up the cooler on theadjustable spirals of the rotor, thematerial is constantly being turnedand pressed against the cooledouter wall. And depending on theinitial temperature of the feed materialand the cooling water, a reductionfrom 40 °C up to 70 °C canbe achieved. The complete driveunit is located in the cooler basewhere the components are easilyaccessible for maintenancework. In the lower area of the cylinder,the cooling agent flows intoa collection gutter. The water canthen be discharged completely, returnedto the water reservoir orpiped to a nearby water processingplant for re-cooling and re-use.Temperature [°C]

<strong>Cooler</strong> integration innew plants andexisting systemsAlternatively, some of the componentsof the cooler and connectingchutes can be made out of specialmaterials; abrasion or corrosion-resistantsteels wouldbe used to minimizewear from extremelyabrasive materialsand also when aggressivecoolingagents like saltwater are used.The compact constructionof the<strong>Christian</strong> <strong>Pfeiffer</strong>powder cooler makesthe installation into newgrinding circuits as well asintegration inside existing systemsfeasible.System integration

Water processingFresh water taken from streams,lakes and rainwater reservoirs isthe usual source for the coolingagent. But when fresh water isnot available in sufficient quantityor the efficient reuse of thisnatural resource is preferred, awater treatment and re-coolingplant should be installed. Thereare a variety of factors that affectthe design and construction ofa closed-circuit recooling plant.However, most important wouldbe the quality of the water andlocal atmospheric conditions.Additional measures must beconsidered for the inhibition ofmicro-organisms (bacteria, algae,etc.), scale prevention, corrosionand foreign materials control - toname a few. Further, the installationof a comprehensivehigh-level control for thecomplete grindingcircuit will allow forclose monitoringof each componentprovidingan integratedand efficientrunning of theentire system.Water circuit

Three construction sizes for all applications1110Type of cooler CPB 22-55 CPB 27-65 CPB 33-85Capacity t/h 70 120 180A 2450 2660 3000B 1350 1600 1950C 6950 7670 10040D 1350 1600 1950Ø E 2200 2700 3300Ø F 3300 3900 4500G 7400 8125 10530H 1350 1621 1985K 1020 874 1014Dimensions in mmDYou can count on ourcontinuous supportand services …Our partnership with you doesnot end when the plant is handedover to you. Our specialists pursueto make regular visits to supportyour operations, ensure the plantcontinues to perform to yoursatisfaction throughout its servicelife. We will bring to you the latestdevelopment and innovation to allowyou to continually improve theplant performance and productioncost advantage.45ϒOutletØ EGCØ FBInletAEmergencyoutletKSupportHService

<strong>Christian</strong> <strong>Pfeiffer</strong> worldwide= Offices/Production facilities= Agents/RepresentationsHead office Germany:<strong>Christian</strong> <strong>Pfeiffer</strong> Maschinenfabrik GmbHSudhoferweg 110-112 · 59269 BeckumPhone: +49 2521 849-00 · Fax: +49 2521 849-123Email: office@christianpfeiffer.dewww.christianpfeiffer.net