OBD Operation Summary for 6.7L Diesel - MotorCraftService.com

OBD Operation Summary for 6.7L Diesel - MotorCraftService.com

OBD Operation Summary for 6.7L Diesel - MotorCraftService.com

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

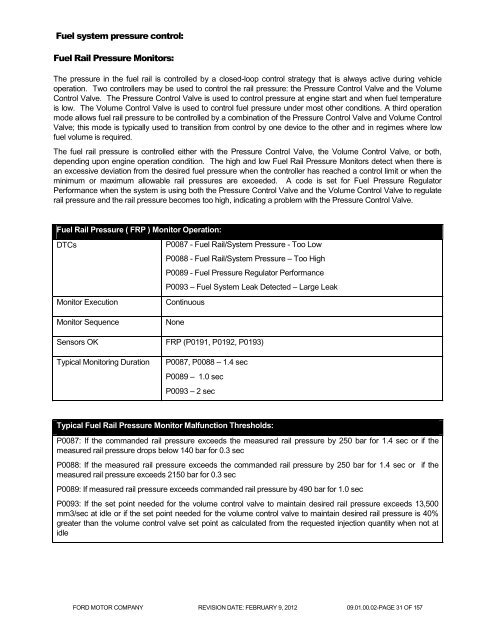

Fuel system pressure control:Fuel Rail Pressure Monitors:The pressure in the fuel rail is controlled by a closed-loop control strategy that is always active during vehicleoperation. Two controllers may be used to control the rail pressure: the Pressure Control Valve and the VolumeControl Valve. The Pressure Control Valve is used to control pressure at engine start and when fuel temperatureis low. The Volume Control Valve is used to control fuel pressure under most other conditions. A third operationmode allows fuel rail pressure to be controlled by a <strong>com</strong>bination of the Pressure Control Valve and Volume ControlValve; this mode is typically used to transition from control by one device to the other and in regimes where lowfuel volume is required.The fuel rail pressure is controlled either with the Pressure Control Valve, the Volume Control Valve, or both,depending upon engine operation condition. The high and low Fuel Rail Pressure Monitors detect when there isan excessive deviation from the desired fuel pressure when the controller has reached a control limit or when theminimum or maximum allowable rail pressures are exceeded. A code is set <strong>for</strong> Fuel Pressure RegulatorPer<strong>for</strong>mance when the system is using both the Pressure Control Valve and the Volume Control Valve to regulaterail pressure and the rail pressure be<strong>com</strong>es too high, indicating a problem with the Pressure Control Valve.Fuel Rail Pressure ( FRP ) Monitor <strong>Operation</strong>:DTCsP0087 - Fuel Rail/System Pressure - Too LowP0088 - Fuel Rail/System Pressure – Too HighP0089 - Fuel Pressure Regulator Per<strong>for</strong>manceP0093 – Fuel System Leak Detected – Large LeakMonitor ExecutionContinuousMonitor SequenceNoneSensors OK FRP (P0191, P0192, P0193)Typical Monitoring DurationP0087, P0088 – 1.4 secP0089 – 1.0 secP0093 – 2 secTypical Fuel Rail Pressure Monitor Malfunction Thresholds:P0087: If the <strong>com</strong>manded rail pressure exceeds the measured rail pressure by 250 bar <strong>for</strong> 1.4 sec or if themeasured rail pressure drops below 140 bar <strong>for</strong> 0.3 secP0088: If the measured rail pressure exceeds the <strong>com</strong>manded rail pressure by 250 bar <strong>for</strong> 1.4 sec or if themeasured rail pressure exceeds 2150 bar <strong>for</strong> 0.3 secP0089: If measured rail pressure exceeds <strong>com</strong>manded rail pressure by 490 bar <strong>for</strong> 1.0 secP0093: If the set point needed <strong>for</strong> the volume control valve to maintain desired rail pressure exceeds 13,500mm3/sec at idle or if the set point needed <strong>for</strong> the volume control valve to maintain desired rail pressure is 40%greater than the volume control valve set point as calculated from the requested injection quantity when not atidleFORD MOTOR COMPANY REVISION DATE: FEBRUARY 9, 2012 09.01.00.02-PAGE 31 OF 157