Acronal DS 6255 X - Basf

Acronal DS 6255 X - Basf Acronal DS 6255 X - Basf

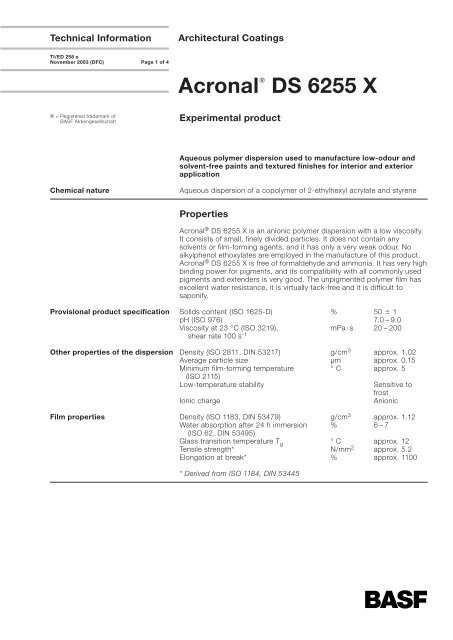

Technical InformationArchitectural CoatingsTI/ED 258 eNovember 2003 (DFC) Page 1 of 4Acronal DS 6255 X® = Registered trademark ofBASF AktiengesellschaftExperimental productAqueous polymer dispersion used to manufacture low-odour andsolvent-free paints and textured finishes for interior and exteriorapplicationChemical natureAqueous dispersion of a copolymer of 2-ethylhexyl acrylate and styrenePropertiesAcronal ® DS 6255 X is an anionic polymer dispersion with a low viscosity.It consists of small, finely divided particles. It does not contain anysolvents or film-forming agents, and it has only a very weak odour. Noalkylphenol ethoxylates are employed in the manufacture of this product.Acronal ® DS 6255 X is free of formaldehyde and ammonia. It has very highbinding power for pigments, and its compatibility with all commonly usedpigments and extenders is very good. The unpigmented polymer film hasexcellent water resistance, it is virtually tack-free and it is difficult tosaponify.Provisional product specification Solids content (ISO 1625-D) % 50 1pH (ISO 976) 7.0 – 9.0Viscosity at 23 °C (ISO 3219), mPa·s 20 – 200shear rate 100 s -1Other properties of the dispersion Density (ISO 2811, DIN 53217) g/cm 3 approx. 1.02Average particle size µm approx. 0.15Minimum film-forming temperature ° C approx. 5(ISO 2115)Low-temperature stabilitySensitive tofrostIonic chargeAnionicFilm properties Density (ISO 1183, DIN 53479) g/cm 3 approx. 1.12Water absorption after 24 h immersion % 6 – 7(ISO 62, DIN 53495)Glass transition temperature T g°C approx. 12Tensile strength* N/mm 2 approx. 5.2Elongation at break* % approx. 1100* Derived from ISO 1184, DIN 53445

- Page 2 and 3: TI/ED 258 e November 2003 Page 2 of

- Page 4: TI/ED 258 e November 2003 Page 4 of

Technical InformationArchitectural CoatingsTI/ED 258 eNovember 2003 (DFC) Page 1 of 4<strong>Acronal</strong> <strong>DS</strong> <strong>6255</strong> X® = Registered trademark ofBASF AktiengesellschaftExperimental productAqueous polymer dispersion used to manufacture low-odour andsolvent-free paints and textured finishes for interior and exteriorapplicationChemical natureAqueous dispersion of a copolymer of 2-ethylhexyl acrylate and styreneProperties<strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X is an anionic polymer dispersion with a low viscosity.It consists of small, finely divided particles. It does not contain anysolvents or film-forming agents, and it has only a very weak odour. Noalkylphenol ethoxylates are employed in the manufacture of this product.<strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X is free of formaldehyde and ammonia. It has very highbinding power for pigments, and its compatibility with all commonly usedpigments and extenders is very good. The unpigmented polymer film hasexcellent water resistance, it is virtually tack-free and it is difficult tosaponify.Provisional product specification Solids content (ISO 1625-D) % 50 1pH (ISO 976) 7.0 – 9.0Viscosity at 23 °C (ISO 3219), mPa·s 20 – 200shear rate 100 s -1Other properties of the dispersion Density (ISO 2811, DIN 53217) g/cm 3 approx. 1.02Average particle size µm approx. 0.15Minimum film-forming temperature ° C approx. 5(ISO 2115)Low-temperature stabilitySensitive tofrostIonic chargeAnionicFilm properties Density (ISO 1183, DIN 53479) g/cm 3 approx. 1.12Water absorption after 24 h immersion % 6 – 7(ISO 62, DIN 53495)Glass transition temperature T g°C approx. 12Tensile strength* N/mm 2 approx. 5.2Elongation at break* % approx. 1100* Derived from ISO 1184, DIN 53445

TI/ED 258 e November 2003 Page 2 of 4 <strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> XApplicationAreas of application<strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X does not contain any ammonia, and it only containsvery small traces of volatile substances that are responsible for odour. Thepolymer forms a film without any coalescent solvents having to be added.Because of its high pigment-binding power, <strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X is mainlyemployed in low-odour products with a high filler content for interior application,such as emulsion paints, textured finishes, floor screeds andgrouts. Emulsion paints with a high pigment volume concentration formulatedwith <strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X are distinguished by their very high wetabrasion resistance.<strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X can also be used to manufacture exterior masonrypaints and textured finishes and, because of its excellent resistance toalkalis and its compatibility with all conventional grades of potassiumsilicate, it is very effective in silicate-based products.ProcessingIf emulsion paints and emulsion-type silicate paints are mixed in a highspeedimpeller mill such as a Dissolver, we would recommend dispersingthe pigments and fillers with sufficient amounts of dispersing agentsand/or wetting agents in advance before adding the polymer dispersion.<strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X should only be added along with the dispersingand wetting agents when products with a very high viscosity, such astextured finishes or grouts, are being mixed in low-speed mixers. Here, thepotassium silicate should always be mixed in after the polymer dispersion.Sodium polyacrylates, such as Pigment Disperser MD 20, N, NL or S, andsodium polyphosphates are particularly appropriate for use as dispersingagents in low-odour coatings.The nature and quantity of the pigments and fillers can be varied withinwide limits. This primarily depends on the application for which the coatingis intended, e.g. interior or exterior, factors such as the required gloss,flexibility and wet abrasion resistance, the type of substrate and theamount of binder required to disperse the pigments and fillers (i.e. their oilabsorption).Thickeners normally have to be added to coatings formulated with <strong>Acronal</strong>® <strong>DS</strong> <strong>6255</strong> X. Medium-viscosity and high-viscosity cellulose ethers,polyacrylates (Latekoll ® D), diurethanes (Collacral ® LR 8989 and Collacral® LR 8990) and bentonite can be employed as thickeners, and polysaccharidesare particularly effective in emulsion-type silicate paints. Thechoice of thickeners depends on the body of the coating, i.e. whether itneeds to be free-flowing or more thixotropic.Solvents do not need to be added to highly pigmented interior paints andsilicate paints formulated with <strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X to promote film formation,but they can be added in order to improve the wet abrasion resistanceeven further.Coatings based on <strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X can be tinted with pigment preparationssuch as BASF’s Luconyl ® grades or with ready-mixed, solventfreeformulations based on <strong>Acronal</strong> ® S 610 or <strong>Acronal</strong> ® S 559. Somecolorants can cause the phases to separate and the pigments to flocculate,and so it is very advisable to perform compatibility and storage tests.Problems can also be alleviated by adding a nonionic surfactant such asLumiten ® N-OC or Lumiten ® N-OG.Like all finely divided polymer dispersions, <strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X has atendency to foam. It is therefore necessary to add a commercial defoamerat the rate specified by the manufacturer. Trials should be performed totest the suitability of the defoamer.

TI/ED 258 e November 2003 Page 3 of 4 <strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> XAlthough <strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X itself is resistant to being broken down bymicroorganisms in the form in which it is supplied, preservatives need tobe added to products formulated with <strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X to protectthem from being attacked by microorganisms over long periods in storage.Trials should always be carried out to test the compatibility and efficacy ofthe preservatives.Customers have to carry out their own trials when developing and processingproducts based on <strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X. The compatibility of<strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X with other ingredients of formulations, its effect onmixing processes and its adhesion on different substrates etc., areaffected by a variety of factors which are too numerous for us to take intoaccount in our own trials. This includes testing its stability by storing it atca. 50 °C to confirm that its viscosity remains constant.SafetyGeneralSafety Data SheetLabellingThe usual safety precautions when handling chemicals must be observed.In particular, the place of work must be well ventilated if large quantitiesare being processed, the skin should be protected, and safety glassesshould be worn at all times.A Safety Data Sheet is available for <strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X which containsup-to-date information on all questions relevant to safety.According to all the data at our disposal, <strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X does notneed to be labelled as a dangerous substance or preparation as defined inthe relevant European Union directives (substances directive 1967/548/ECand preparations directive 1999/45/EC), according to their current status.Storage<strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X must not be allowed to come into contact duringstorage with metals or alloys that are susceptible to corrosion. It is importantto ensure that containers are kept tightly sealed, and the headspaceof bulk storage tanks must be kept saturated with water vapour. Thisproduct must not be exposed to high temperatures, and it must beprotected from frost.<strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> X has a shelf life of six months at 10 – 30 °C, provideddue attention is paid to the hygiene of tanks and storage facilities.We would recommend treating this product with a biocide in order to preventproblems with microorganisms from occurring during storage andprocessing. Further details are given in our leaflet on “The handling andstorage of polymer dispersions”.NoteThe information submitted in this publication is based on our currentknowledge and experience. In view of the many factors that may affectprocessing and application, these data do not relieve processors from theresponsibility of carrying out their own tests and experiments; neither dothey imply any legally binding assurance of certain properties or of suitabilityfor a specific purpose. It is the responsibility of those to whom wesupply our products to ensure that any proprietary rights and existing lawsand legislation are observed.

TI/ED 258 e November 2003 Page 4 of 4 <strong>Acronal</strong> ® <strong>DS</strong> <strong>6255</strong> XBASF AktiengesellschaftPerformance Polymers EDK/B67056 Ludwigshafen, Germanywww.basf.de/en/dispersionenarchitectural.coatings@basf-ag.dePrinted in Germany