Mitsubishi Graphic Operation Terminal GOT1000 ... - Omni Ray AG

Mitsubishi Graphic Operation Terminal GOT1000 ... - Omni Ray AG

Mitsubishi Graphic Operation Terminal GOT1000 ... - Omni Ray AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

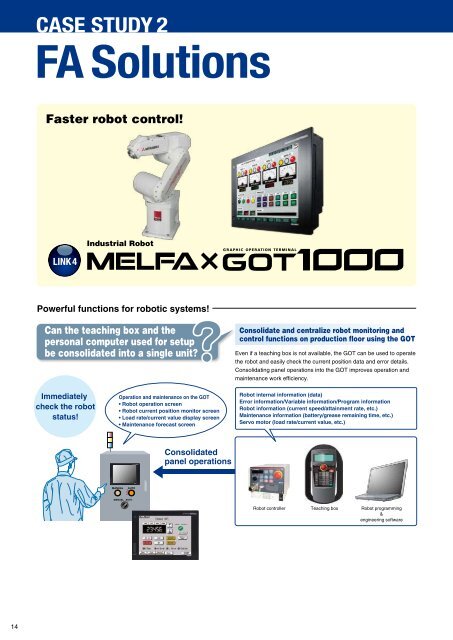

Q25HCPUMODERUNERRUSERBATBOOTUSBPULLQ25HCPU QX10 QX41QX41QJ71BR110123456789ABCDEFQJ71BR11CASE STUDY 2FA SolutionsFaster robot control!LINK 4Industrial RobotIdeal for robot programming!Can the robot programbe easily accessed?Robot operation panel screenRobot jog/hand operation screenReady-to-use sample screensSample screen data is available for robot operation, current positionmonitoring, and other purposes. There is no need to create robotprograms from scratch.Robot current position monitor screenOpens a video ofoperation examplesGOT Solutions FA SolutionsPowerful functions for robotic systems!Can the teaching box and thepersonal computer used for setupbe consolidated into a single unit?Immediatelycheck the robotstatus!<strong>Operation</strong> and maintenance on the GOT• Robot operation screen• Robot current position monitor screen• Load rate/current value display screen• Maintenance forecast screenConsolidatedpanel operationsConsolidate and centralize robot monitoring andcontrol functions on production floor using the GOTEven if a teaching box is not available, the GOT can be used to operatethe robot and easily check the current position data and error details.Consolidating panel operations into the GOT improves operation andmaintenance work efficiency.Robot internal information (data)Error information/Variable information/Program informationRobot information (current speed/attainment rate, etc.)Maintenance information (battery/grease remaining time, etc.)Servo motor (load rate/current value, etc.)Robot load rate/current value monitor screenCan the program be debuggedwithout opening the cabinet?FA transparent functionConnected with a personal computer, theGOT acts as a transparent gateway toenable start up and adjustment ofequipment using RT ToolBox2. Users donot have to bother with opening the cabinetor changing cable connections.RT ToolBox2Robot maintenance forecast screenFor details,see P.39Robot manual menu screenSystem monitor functionManual displayCan devices in the robotcontroller be validated?For details,see P.46Embedded monitoring utilities are available enabling users to view andchange device values.MANUAL AUTOMANUAL AUTOIn the event of trouble!Robot controller Teaching box Robot programming&engineering softwareCan robot profiles be recoveredafter controller failures?CF card,etc.If data is backed upReplace CPUBackup/restoration functionFor details,see P.42RestoreRobot controller data can be backed up to the CF card or USB memoryin the GOT. Users can perform batch operation to restore the data tothe robot controller.Robot data,etc.14 15