Manual for Refrigeration Servicing Technicians - UNEP - Division of ...

Manual for Refrigeration Servicing Technicians - UNEP - Division of ...

Manual for Refrigeration Servicing Technicians - UNEP - Division of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2<br />

Refrigerants<br />

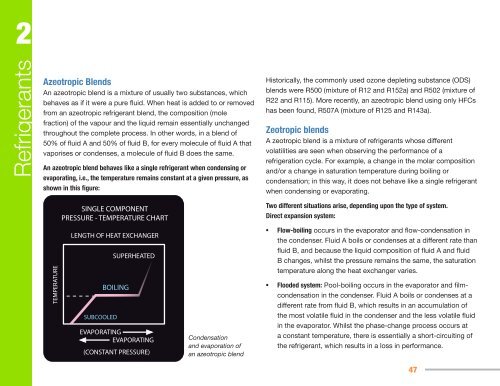

Azeotropic Blends<br />

An azeotropic blend is a mixture <strong>of</strong> usually two substances, which<br />

behaves as if it were a pure fluid. When heat is added to or removed<br />

from an azeotropic refrigerant blend, the composition (mole<br />

fraction) <strong>of</strong> the vapour and the liquid remain essentially unchanged<br />

throughout the complete process. In other words, in a blend <strong>of</strong><br />

50% <strong>of</strong> fluid A and 50% <strong>of</strong> fluid B, <strong>for</strong> every molecule <strong>of</strong> fluid A that<br />

vaporises or condenses, a molecule <strong>of</strong> fluid B does the same.<br />

An azeotropic blend behaves like a single refrigerant when condensing or<br />

evaporating, i.e., the temperature remains constant at a given pressure, as<br />

shown in this figure:<br />

TEMPERATURE<br />

SINGLE COMPONENT<br />

PRESSURE - TEMPERATURE CHART<br />

LENGTH OF HEAT EXCHANGER<br />

SUBCOOLED<br />

SUPERHEATED<br />

BOILING<br />

EVAPORATING<br />

EVAPORATING<br />

(CONSTANT PRESSURE)<br />

Condensation<br />

and evaporation <strong>of</strong><br />

an azeotropic blend<br />

Historically, the commonly used ozone depleting substance (ODS)<br />

blends were R500 (mixture <strong>of</strong> R12 and R152a) and R502 (mixture <strong>of</strong><br />

R22 and R115). More recently, an azeotropic blend using only HFCs<br />

has been found, R507A (mixture <strong>of</strong> R125 and R143a).<br />

Zeotropic blends<br />

A zeotropic blend is a mixture <strong>of</strong> refrigerants whose different<br />

volatilities are seen when observing the per<strong>for</strong>mance <strong>of</strong> a<br />

refrigeration cycle. For example, a change in the molar composition<br />

and/or a change in saturation temperature during boiling or<br />

condensation; in this way, it does not behave like a single refrigerant<br />

when condensing or evaporating.<br />

Two different situations arise, depending upon the type <strong>of</strong> system.<br />

Direct expansion system:<br />

• Flow-boiling occurs in the evaporator and flow-condensation in<br />

the condenser. Fluid A boils or condenses at a different rate than<br />

fluid B, and because the liquid composition <strong>of</strong> fluid A and fluid<br />

B changes, whilst the pressure remains the same, the saturation<br />

temperature along the heat exchanger varies.<br />

• Flooded system: Pool-boiling occurs in the evaporator and filmcondensation<br />

in the condenser. Fluid A boils or condenses at a<br />

different rate from fluid B, which results in an accumulation <strong>of</strong><br />

the most volatile fluid in the condenser and the less volatile fluid<br />

in the evaporator. Whilst the phase-change process occurs at<br />

a constant temperature, there is essentially a short-circuiting <strong>of</strong><br />

the refrigerant, which results in a loss in per<strong>for</strong>mance.<br />

47