standard construction details - The Management System Parking Lot

standard construction details - The Management System Parking Lot

standard construction details - The Management System Parking Lot

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

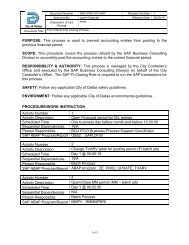

DEPARTMENT OF PUBLIC WORKSSTANDARD CONSTRUCTION DETAILSCITY OF DALLAS, TEXASRECOMMENDED FOR APPROVAL:THIS THE DAY OF , 1997.ASSISTANT DIRECTOROF PUBLIC WORKS& TRANSPORTATIONREVISED APRIL 1997UPDATED SEPT. 2002APPROVED:THIS THE DAY OF , 1997.DIRECTOR OF PUBLIC WORKS& TRANSPORTATION

TABLE OF CONTENTSPAVINGREVISIONSPAVING SECTIONS AND STREET LAYOUTS WITH MEDIAN DETAILS 1001MONOLITHIC MEDIAN NOSEPAVEMENT JOINTS AND BRIDGE APPROACH SLABDRIVEWAY TURNOUTSSPECIAL DRIVEWAY TURNOUT DETAILSPAVING DETAILS FOR DRIVEWAYS AND INTERSECTIONSPAVEMENT HALF SECTIONS AND CURB SECTIONSCBD MISCELLANEOUS DETAILS1002100310041004A100510061007REVISED DRIVEWAY DESIGNS TO INCLUDE TAS APPROVED WALK AREAS (7-99)REVISED DRIVEWAY DESIGNS TO INCLUDE TAS APPROVED WALK AREAS (7-99)STORM DRAINAGESTANDARD RECESSED INLETS & CURBS, "Y" TYPE INLETSDOUBLE & TRIPLE GRATE INLETSFOURTEEN FOOT INLETSTANDARD 36", 48", 60", 6’, 8’ AND 10’ INLETSSLOTTED DRAINSCONCRETE PIPE INSTALLATIONCONCRETE PIPE HEADWALLSMANHOLES AND FITTINGSLINED CHANNELSTWO, FOUR, SIX & EIGHT GRATE INLET, GRATE DETAILS2001200220032004200520062007200820092010STRUCTURESRETAINING WALL H.F.P.RETAINING WALL L.F.P.STANDARD RETAINING WALLS TYPES 6-8RETAINING WALLS; MISCELLANEOUS DETAILS3001300230033004ALLEYSTURNOUTS AND SLOPE PROTECTIONALLEY INTERSECTIONS40014002TRAFFIC CONTROLBARRICADE DETAILSTRAFFIC SIGNAL FOUNDATION DETAILSTYPICAL PAVEMENT MARKINGSTYPICAL PAVEMENT MARKINGS DETAILSINDIVIDUAL UNIT PAVEMENT MARKINGSARROWS AND LETTERS FOR PAVEMENT MARKINGSRAILROAD CROSSING PAVEMENT MARKINGSTRAFFIC SIGNAL DETAILSTRAFFIC SIGNAL DETAILSTRAFFIC SIGNAL DETAILSTRAFFIC SIGNAL DETAILSTRAFFIC SIGNAL DETAILS500150025003500450055006500750085009501050115012APPROVEDDIRECTOR OF PUBLIC WORKS & TRANSPORTATIONDATE:FILE 251D-1T.C. 1OF2

MISCELLANEOUSREVISIONSALUMINUM BRIDGE RAILING DETAILSMISCELLANEOUS CONSTRUCTION ITEMSMETAL BEAM GUARD RAILBICYCLE PATHSREINFORCED SIDEWALK AND BARRIER FREE RAMPSBARRIER FREE RAMPS PAVING DETAILSSTEPS AND HANDRAILCONCRETE MEDIAN BARRIER DETAILSTREET LIGHT EQUIPMENT DETAILSVANE TYPE CAST IRON GRATE9001900290039004900590069007900890099010APPROVEDDIRECTOR OF PUBLIC WORKS & TRANSPORTATIONDATE:FILE 251D-1T.C. 2OF2

12" 6"NOTES:107’-0"90’-0"1.ALL STEEL SHALL BE GRADE 40 DEFORMED REINFORCING BARS.2.GENERAL NOTES PROVIDED ON SHEET 1006 APPLY.10’-0"12’-0" 12’-0" 12’-0"PL 7’-6" 12’-0" 12’-0" 12’-0"NO 3 BARS ON 24"C LCTRS. BOTH WAYS 0" TO 7" MAX.FOR T < 9"NO. 4 BARS ON 24"REGULAR SECTIONCTRS. BOTH WAYSFOR 9 < T < 12"107’-0"10’-0" 36’-0"15’-0"36’-0"10’-0"2’-6"SAWED LONGITUDINAL DUMMY JOINTP L12’-0" 12’-0" 12’-0" 5’-0"10’-0" 12’-0" 12’-0" 12’-0"C L*36’-0" " : 1 " M I N " : 1 " M I NT/2T/215’-0" 36’-0"10’-0"SAWED LONGITUDINAL DUMMY JOINTT/2T/20 " T O** " : 1 " M I N . " : 1 " M IP LP LP LPL7’-6"30’-0"15’-0" 30’-0" 7’-6"SAWED LONGITUDINAL DUMMY JOINT10’-0" 10’-0" 10’-0"10’-0" 10’-0" 10’-0"0" TO 7" MAX.NO 3 BARS ON 24"CCTRS. BOTH WAYSL* " : 1 " M I N " : 1 " M I NT/2T/2T/20 " T OT.C. GRADET/2** " : 1 " M IFOR T < 9"NO.4 BARS ON 24"CTRS. BOTH WAYSREGULAR SECTIONFOR 9" < T < 12"90’-0"7’-6" 30’-0"15’-0"30’-0"7’-6"SAWED LONGITUDINAL DUMMY JOINT10’-0" 10’-0" 10’-0" 5’-0" 10’-0" 10’-0" 10’-0" 10’-0"C L7.6’ " : 1 " M IP LP L6"VARIES ACCORDING TO CLASSIFICATION AND SECTION OF STREET SPECIFIED12"ASPHALT SURFACE OF THICKNES SPECIFIEDT/2(BASE) " P E R F T M I NREINFORCED CONCRETE BASE W/ INTEGRAL CURBAND GUTTER & ASPHALT SURFACE COURSE( TO BE USED ONLY WHEN SPECIFICALLY SHOWN ON THE PLAN )EXCEPT AS INDICATED ABOVE ALL PLAN AND SECTION DETAILS SHALL BE IDENTICALTO THOSE SHOWN ELSEWHERE ON THIS SHEET FOR SECTIONS S-6-D, M-6-D(A), M-6-D(B),S-4-D FOR CURB AND GUTTER DETAILS. SEE PAGE 1006*SPECIAL PAVING SECTIONSCHEMATIC HALF-SECTION3. FOR SUBSTITUTING FOR #3 BAR REINFORCING, THE SIZE OF THEWIRE FABRIC SHALL BE 12 X 12 - W3.5 X W3.5 WITH A NOMINALDIAMETER OF 0.211 IN. AND NOMINAL WEIGHT OF 0.119 LBS PERLIN. FT.4. FOR SUBSTITUTION FOR #4 BAR REINFORCING, THE SIZE OF THEWIRE SHALL BE 12 x 12 - W6 X W6 WITH A NOMINAL DIAMETER OF0.276 INCHES AND A NOMINAL WEIGHT OF 0.204 LBS/LIN. FT.5. REDWOOD EXPANSION JOINTS SHALL BE PLACED AT OR NEARTHE RADIUS POINTS OF ALL INTERSECTIONS, AT ALL ABRUPTCHANGES IN ALIGNMENT OR WIDTH, OR AT MAX. DISTANCEOF 150 FT. REDWOOD EXPANSION JOINT WILL CONTINUE THROUGHMEDIAN PAVING AND SIDEWALK AND WALL WHEREVER APPLICABLE.TYPE S-6-D SECTIONTRANSITION MINIMUM CURVE CURVE LANECROSS STREETLENGTH ’A’ STORAGE ’B’ #1 RADIUS #2 RADIUS WIDTH(S)LOCAL109.09’ 90’ 400’ 200’ 10’COLLECTOR 109.09’ 100’ 400’ 200’ 10’MINOR ARTERIAL 133.79’ 150’ 600’ 300’ 10’PRINCIPAL ARTERIAL 133.79’ 200’ 600’ 300’ 10’SPECIAL MOVEMENTSSTANDARD DOUBLE197.78’ 150’ 600’ 300’ 2-11’LEFT TURNNOTE: (SEE PAGE 1002)LEFT TURN SECTIONLEFT TURN SECTIONMONOLITHIC MEDIAN NOSE IS STANDARD (ROUNDED NOSEIS TO BE USED ONLY AT DIRECTION OF ENGINEER TO MATCHMINIMUM DOUBLELEFT TURN188.68’150’600’300’2-10’EXISTING FACILITIES).RIGHT TURN109.09’90’400’200’10’107’53.5’53.5’10’ 36’ 15’ 36’ 10’CURVE #1CURVE #1=8^32’57"R=600.0’L=89.53’T=44.85’ABCURVE #2BARRIER BUTTONSON 30" CENTERSCURVE #2=8^32’57"R=300’L=44.76’ PLANT=22.42’46’ 36’5’TYPE S-6-D SECTION90’45’45’7.5’ 7.5’30’ 15’ 30’CURVE #1=8^32’57"R=600.0’L=89.53’T=44.85’ABCURVE #2CURVE #1BARRIER BUTTONSON 30" CENTERSCURVE #2=8^32’57"R=300’L=44.76’T=22.42’PLAN40’ 30’5’TYPE M-6-D(B) SECTIONNOTE: DUMMY JOINTS (SAWEDOR TOOLED) SHALL MATCHSTREET PAVEMENT JOINTS.RUN EXPANSION JOINTCONTINUOUS THROUGHCURB & MEDIAN PAVEMENTFACE OF CURB15’ " P R E M O L D E D E10’4" THICK MEDIAN PAVEMENTSIGNAL FOUNDATIONOR PULL BOXSTREET LIGHT FOUNDATION6 TYPE I- YELLOW BUTTONS ON 30" C-C (INSTALLED AND ORIENTED AS DIRECTED BY THEENGINEER).DETAIL OF 5’ MEDIAN PAVEMENTTYPE M-6-D(A) SECTIONTRANSITION MINIMUM CURVE CURVECROSS STREETLENGTH ’A’ STORAGE ’B’ #1 RADIUS #2 RADIUSLOCAL109.09’ 90’ 400’ 200’COLLECTOR 109.09’ 100’ 400’ 200’MINOR ARTERIAL 109.09’ 150’ 400’ 200’PRINCIPAL ARTERIAL 133.79’ 200’ 600’ 300’SPECIAL MOVEMENTSSTANDARD DOUBLE197.78’ 150’ 600’ 300’LEFT TURNMINIMUM DOUBLE188.68’ 150’ 600’ 300’LEFT TURNRIGHT TURN 109.09’ 90’ 400’ 200’LANEWIDTH(S)10’10’10’10’2-11’2-10’10’9’-6" 33’-0" 33’-0"15’-0"11’-0" 11’-0"11’-0"PL11’-0"11’-0" 11’-0"0" TO 7" MAXNO. 3 BARS ON 24"CTRS. BOTH WAYSC LFOR T < 9"NO.4 BARS ON 24"REGULAR SECTIONCTRS. BOTH WAYSFOR 9" < T < 12"100’-0"15’-0"9’-6"33’-0"2’-6"40’-6"5’SAWED LONGITUDINAL DUMMY JOINT11’-0"11’-0" 11’-0"10’-0" 11’-0" 11’-0" 11’-0"P L0 " T OMEDIAN GRADE SHOWNC L* " : 1 " M I N* " : 1 " M I NT/2T/2100’-0"SAWED LONGITUDINAL DUMMY JOINTT/2T/2** " : 1 " M I " : 1 " M I9’-6"9’-6"P LP LPLPL8’-6" 24’-0"15’-0"24’-0"*8’-6" 24’-0"5’-0" 10’-0"24’-0"*12’-0" " : 1 " M I NNO. 3 BARS ON 24"CTRS. BOTH WAYSFOR T < 9"NO. 4 BARS ON 24"CTRS. BOTH WAYSFOR 9" < T < 12"12’-0" " : 1 " M I NSAWED LONGITUDINAL DUMMY JOINT12’-0" 7’-6" 12’-0" 12’-0"12’-0"T/2SAWED LONGITUDINAL DUMMY JOINTT/280’-0"C LT/2REGULAR SECTION80’-0"2’-6"T/2*12’-0"* " : 1 " M I0" TO 7" MAX.12’-0" " : 1 " M I8’-6"8’-6"P LP L " P R E M O L DJOINT MATERIAL15’15’ MEDIAN4" CONCRETEMEDIAN PAVEMENTNON-REINFORCED MEDIAN PAVEMENT4"4"8"3"BACKFILL FOR MEDIAN SHALLCONSIST OF EXCESS EXCAVATION.THERE SHALL BE NO PAY ITEM FORANY FILL MATERIAL PLACEDWITHIN THE MEDIAN. MAX. FILLSHALL NOT EXCEED 12" AND SHALLBE CROWNED IN THE MIDDLE FORPROPER DRAINAGE.LOW CURB12"MAXCROSS STREETLOCALCOLLECTORMINOR ARTERIALPRINCIPAL ARTERIALSPECIAL MOVEMENTSSTANDARD DOUBLELEFT TURNMINIMUM DOUBLELEFT TURNRIGHT TURNCROSS STREETTYPE M-6-D(B) SECTIONTRANSITION MINIMUM CURVE CURVELENGTH ’A’ STORAGE ’B’ #1 RADIUS #2 RADIUS94.34’ 90’ 300’ 150’94.34’ 100’ 300’ 150’94.34’ 150’ 300’ 150’109.09’ 200’ 400’ 200’188.68’ 150’ 600’ 300’188.68’ 150’ 600’ 300’94.34’ 90’ 300’ 150’TYPE S-4-D SECTIONTRANSITION MINIMUM CURVE CURVELENGTH ’A’ STORAGE ’B’ #1 RADIUS #2 RADIUSLANEWIDTH(S)10’10’10’10’2-11’2-10’10’LANEWIDTH(S)*LEFT TURN SECTIONSEE PAGE 1006 FOR0 " T OLOCAL109.09’90’400’200’10’ALTERNATE DESIGN USINGNOTE: BUTTONS SHALLPARABOLIC SECTIONSC LLEFT TURN SECTIONBE INSTALLED & ORIENTEDAS DIRECTED BY THEENGINEER.TYPE I - YELLOW BUTTONS ON 30" C-CCOLLECTORMINOR ARTERIAL109.09’109.09’100’150’400’400’200’200’10’10’PRINCIPAL ARTERIAL133.79’150’600’300’10’FACE OF CURBSPECIAL MOVEMENTS100’50’50’9.5’ 9.5’33’ 15’ 33’ACURVE #2CURVE #1BARRIER BUTTONSON 30" CENTERSCURVE #1 CURVE #2=8^32’57" =8^32’57"R=600.0’R=300’L=89.57’L=44.76’T=44.85’T=22.42’B33’43’5’* " P E R F O O T80’40’ 40’24’ 24’8.5’15’ 8.5’ACURVE #2CURVE #1CURVE #1 CURVE #2=8^32’57" =8^32’57"R=600.0’ R=300’L=89.53’L=44.76’T=22.42’T=44.85’BBARRIER BUTTONSON 30" CENTERS.PLAN5’34’24’7’-6" 7’-6"R = 48’LIMIT OF 4" THICKMEDIAN PVMT.82.1 SQ.FT.R = 48’4" THICK MEDIANPAVEMENTMONOLITHICMEDIAN NOSE2’-6"RSTANDARD DOUBLE197.78’LEFT TURNMINIMUM DOUBLE188.68’LEFT TURNRIGHT TURN 109.09’APPROVED100’ 600’ 300’ 2-11’100’ 600’ 300’ 2-10’90’ 400’ 200’ 10’DIRECTOR OF PUBLIC WORKS & TRANSPORTATIONPLAN " P E R F O O T OHAVING GRADES OF 1.00% ORSEE PAGE 1002 FORBLOCKOUT FOR NOSE.DATE:TYPE M-6-D(A) PAVEMENTMORE.TYPE S-4-D DIVIDED SECTION23.24’12’=0"PAVING DETAILSTYPICAL SECTIONS-DIVIDED ARTERIAL STREETSDETAIL OF NOSE FOR 15’ WIDTH MEDIAN ISLANDPAVING SECTIONS AND STREETLAYOUTS WITH MEDIAN DETAILSDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119971001

18’-0"10’-0" 1’-0"#3 BARS ALIGNED WITHPAVEMENT REINFORCEMENT1’-0"A6 TYPE I-YELLOW BUTTONSBBON 30" C-C (TO BE INSTALLED& ORIENTED AS DIRECTED BYTHE ENGINEER).1’-0" 5’-0"1’-3"RPAY LINE & KEYEDCONSTRUCTION JOINTAMONOLITHIC MEDIAN NOSE#3 STIRRUP BARS6"3"PAY LINE & KEYEDCONSTRUCTION JOINTPAVEMENT REINF. BARSNOTE: MONOLITHIC MEDIAN NOSE & PAVEMENTWITHIN PAY LINES SHALL BE PAID FORPER EACH, COMPLETE IN PLACE.SECTION B-B1PAY LINE & KEYEDCONSTRUCTION JOINT33"1"RVARIABLE3" TO 6"12"SECTION A-AAPPROVEDDIRECTOR OF PUBLIC WORKS & TRANSPORTATIONDATE:PAVING DETAILSMONOLITHIC MEDIAN NOSEDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119971002

00EXPANSION JOINT20’-0"SAWED TRANSVERSE DUMMYJOINTS SPACED 15’-0" TYPICALSAWED DUMMY JOINTSAWED TRANSVERSEDUMMY JOINTSSAWED LONGITUDINAL DUMMY JOINTOR CONSTRUCTION JOINTSPACING DIAGRAM FOR JOINTSTCENTERLINE OF BRIDGE- NO JOINT15’-0"15’-0"TYP.(20’-0"MAX.,10’MIN)1/3 LANE WIDTHMAJOR TYPE STREETS1/2" PRE MOLDED EXPANSIONJOINT FILLER AT ABUTMENT2" CLEAR6"NO. 4 BARS ON 6" CTRS- -TOP & BOTTOMNO. 4 BARS ON 9" CTRS- -TOP & BOTTOM2" CLEAR2" CLEARVARIES ACCORDING TO ROADWAYWIDTH SPECIFIED ON PLANSSPACED 15’ TYPICALTRANSITION INTEGRAL CURB-FROM 7 1/2" TO 6" HEIGHT(20’ MAX)CONSTRUCTION JOINT ORSAWED LONGITUDINALDUMMY JOINT ALONG C.L.OF ALL SINGLE ROAD-WAY SECTIONS EXCEPTPAVEMENT LESS THAN14’ WIDE.IDENTICAL FOR STREETS (CONCRETE PAVEMENT OR BASE)AND ALLEYS EXCEPT THAT EXPANSION JOINTS FOR ALLEYSSHALL BE PLACED AT THE END OF THE RETURN INLINE WITH THE PROPERTY LINE.SPACING OF EXPANSION JOINTS SHALL NOT EXCEED 150 FEET.ALL EXPANSION JOINT DOWEL BARS SHALL BE HELD FIRMLY IN PLACE PARALLELWITH THE PAVEMENT SURFACE WITH WIRE BASKETS MODIFIED TO MOLD AROUND2" CLEAR2" CLEAR9" THKPLANNO. 4 BARS ON 6" CTRSPAVEMENTTHICKNESSTHE REDWOOD EXPANSION BOARD.ADDITIONAL SIMILARJOINT ON 10’-0" CENTERSEACH SIDE C.L. FORROADWAY SECTIONSWIDER THAN 30’.10’TYP.10’FOR ALL LONGITUDINAL CONSTRUCTION JOINTS PROVIDE TIE BARS AS FOLLOWS:#3 BARS ON 12"C-C FOR PAVEMENT THICKNESS < 9 IN.#4 BARS ON 12"C-C FOR PAVEMENT THICKNESS > 9 IN. AND < 12 IN.ALL TIE BARS SHALL BE 24" MIN. LENGTH AND CENTERED ON THE LONGITUDINAL JOINT.VERTICAL SAW-CUT3/16" TO 1/4" WIDEBACKER RODEZ-7 OR APPROVED EQUAL COLDPOUR JOINT SEALANTPAVINGBRACKET2" CLEARNO. 4 BARS ON 9" CTRSSECTION9"9"LOCAL & COLLECTORT/2T/4BRIDGE APPROACH SLAB17"TYPE STREETS24" NO. 6 SMOOTH DOWEL FOR T=6"24" NO. 8 SMOOTH DOWEL FOR 6" < T 12"NO. 3 BARS ON 24" CTRS. BOTH WAYS FOR T 9"16" DOWEL COATINGNO. 4 BARS ON 24" CTRS. BOTH WAYS FOR 9" T 12"2" MIN.1/2"1/2"EZ-7 OR EQUAL COLD POURJOINT SEALANT (APPLIED IN TWO COURSES)SAWED DUMMY JOINTIDENTICAL FOR STREETS AND ALLEYS EXCEPTWPAVEMENT SURFACE2"1 1/4" MIN. CLEARANCEALLEY LONGITUDINAL REINFORCEMENT BARSW TO 1.5 WT/26" 6" 5"MIN.BAR STOPEZ-7 OR APPROVED EQUAL JOINT SEALANT (MEDIUM VISCOSITY- 500 TO 700 SAYBOLT AT 77^F)TDOWEL SLEEVE TO FITDOWEL AND BE SECUREDCLOSED CELL BACKER ROD, POLYURETHANE COMPOSITION. DIAMETER = W+ 1/8 IN. (DELETE BACKER ROD FOR EXPANSION JOINTS)CLOSED ENDT/4NOTESREDWOOD EXPANSION JOINT FILLERDOWEL SUPPORT SHALL BE OF A METHODAPPROVED BY ENGINEERFORMED GROOVE-EDGESROUNDED TO 1/4" RADIUS3/8"1"EZ-7 OR APPROVEDEQUAL COLD POUR JOINT SEALANTVOIDSPACEW = JOINT WIDTHEXPANSION JOINT SHALL BE FILLED WITH SEALANT IN TWO APPLICATIONS. FIRST APPLICATIONSHALL BE MADE WITH HIGH VISCOSITY EZ-7-700 TO 1000 SAYBOLT AT 77 F. SECOND APPLICATIONSHALL BE MADE WITH MEDIUM VISCOSITY EZ-7-500 TO 700 SAYBOLT AT 77 F. ONE WEEKTRANSVERSE EXPANSION JOINTIDENTICAL FOR STREETS AND ALLEYS4"FIRST POUR1 -1/2"T/4SECOND POURBACKER RODCURE TIME REQUIRED BETWEEN APPLICATIONS.MINIMUM 48 HOUR CURE TIME REQUIRED BEFORE OPENING TO TRAFFIC (ALL SEALED JOINTS).FOR GRADE EXCEEDING 10%, HIGH VISCOSITY EZ-7 SHALL BE USED FOR SEALING ALL LONGITUDINAL JOINTS.EZ-7 JOINT SEALANT PRODUCED BY EZ SEAL, LLC, 408 N. BOWSER, SUITE 104, . (RICHARDSON, TX., 75081 (972-669-9178)8"JOINTS IN FACE OF CURB SHALL BE SEALED WITH EZ-7 JOINT SEALANT HIGH VISCOSITY, COLD POUR OR EQUAL.16"34’-0" B-B30 SPACES @ 1’-0"8"44’-0" B-B40 SPACES @ 1’-0"16"1"2"TYPICAL JOINT SEALING DETAIL8"16"16"8"FOR T < 9":NO. 3 BARS ON 24"CTRS. BOTH WAYSLAP BARS 30 DIA. & TIEFOR 9" < T < 12": NO. 4 BARS ON 24"10"8"31’-0" B-B28 SPACES @ 1’-0"10"8"10"41’-0" B-B38 SPACES @ 1’-0"10"8"CTRS. BOTH WAYSCONSTRUCTION JOINTFOR 8" THICKNESS PAVEMENT OR BASEMAJOR STREETS10"21’-0" B-B18 SPACES @ 1’-0"10"10"41’-0" B-B38 SPACES @ 1’-0"10"CHANGE BAR SPACING ACROSS JOINTS TO 12" CTRS.FOR LONGITUDINAL JOINTS8"8"8"8"10"8"27’-0" B-B 45’-0" B-B10 @ 1’-0" 6" 10 @ 1’-0" 10"10"42 SPACES @ 1’-0"18" 18"8"8"10"8"3"FORMED GROOVE-EDGESROUNDED TO 1/4" RADIUSFIRST POUR3/8"T/41"EZ-7 OR APPROVED EQUALCOLD POUR JOINT SEALANTSECOND POUR31’-0" B-B57’-0" B-B6"APPROVED10"8"12 @ 1’-0" 6" 12 @ 1’-0"18" 18"10"8"10"8"54 SPACES @ 1’-0"10"8"BACKER RODDATE:DIRECTOR OF PUBLIC WORKS & TRANSPORTATION37’-0" B-B 61’-0" B-BNO. 3 BARS ON 24"CTRS. BOTH WAYSLAP BARS 30 DIA. & TIEPAVING DETAILS10"8"34 SPACES @ 1’-0" 10" 10"58 SPACES @ 1’-0"8" 8"10"8"CONSTRUCTION JOINTPAVEMENT JOINTS AND BRIDGEFOR 6" MINIMUM THICKNESS PAVEMENT OR BASEAPPROACH SLABLOCAL & COLLECTOR STREETSSPACING DIAGRAM FOR DOWELS AT EXPANSION JOINTSIDENTICAL FOR STREETS AND ALLEYS EXCEPTALLEY LONGITUDINAL REINFORCEMENT BARSDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119971003

VARIESLFACE OF CURB4’ CONC. WALKPAVE DRIVEWAYS TO BACK OF WALKWHEN DRIVES INTERSECTPAVING LIMITPAVING LIMIT4576" REINF. CONC. NORMALLY.(8" REINF. CONC. FOR COMMERCIAL457OR INDUSTRIAL ACCESS)6" REINF. CONC. NORMALLY.432(8" REINF. CONC. FOR COMMERCIALOR INDUSTRIAL ACCESS) 4325’ CONC. WALKVARIESWALK ABUTTING CURBP LT/2 T/21"1-1/2"PAY LIMITS FOR PROP.PAVEMENT 463 & 456PAY LIMIT FOR PROP.DRIVE 457OR4321"ROUT AND SEAL 1" DEEPTHROUGH LIMITS OF KEYWAY.NO. 3 BARS14% MAX. SLOPE6"OR 8"DRIVEWALK AWAY FROM CURBPROPERTY LINE2"PL2’USUAL10’ MIN. WIDTH VARIES 10’ MIN. WIDTHMETALKEYWAY2’NO EXTRA PAY FORINCREASED THICKNESSPAVING LIMITS FORINTERSECTING DRIVEWAYS4’NORMAL(3’MINIMUM)WALK* 14% MAX. SLOPE2%* 14% MAX. SLOPESECTION A-ANOTES:* THE GRADE BREAK AT THE GUTTER LINE AND AT ANY POINTWITHIN 10 FEET OF THE GUTTER LINE MUST NOT EXCEED12 PERCENT UNLESS A VERTICAL CURVE IS PROVIDED.1. ALL SAWED DUMMY JOINTS SHALL BE SEALED WITH EZ-7 OR APPROVEDEQUAL COLD POUR JOINT SEALANT.2. TOOLED OR SAWED JOINT WILL BE REQUIRED AT CENTERLINEOF ALL DRIVEWAYS LESS THAN 24’ WIDE. ADDITIONAL JOINTSWILL BE REQUIRED AT EQUAL SPACINGS FOR DRIVEWAYSSECTION C-CWIDER THAN 24’.3. OFFSETS IN DRIVES TO MATCH PROPOSED WALKS WILL BE5’ MIN. TRANSITION5’ ARTERIALS10’ MIN. (VARIABLE WIDTH) 5’ ARTERIALS5’ MIN. TRANSITIONBUILT MONOLITHIC WITH THE DRIVE.2’ LOCAL/COLLECTORS2’ LOCAL/COLLECTORS4. PAVEMENT JOINTS WILL NOT EXTEND THROUGH DRIVE EXCEPT AS PROVIDEDFOR IN NOTES 9 AND 10 BELOW FOR CENTERLINE DRIVEWAY JOINTS.5. KEYWAY LIMITS WILL COINCIDE WITH LIMITS OF 1" CURB.6"A1"/1’ MAX. SLOPE6. REINFORCING STEEL WILL NOT EXTEND THROUGH KEYWAY.DRIVE WILL NOT BE TIED TO PAVEMENT.1"7. LENGTH OF TRANSITION FOR CURB AT EACH SIDE OF DRIVEMAY VARY DUE TO STREET GRADES AND REQUIREMENT TOHOLD MAXIMUM SLOPE OF 1"/1’.8. AN EXPANSION JOINT WILL BE REPLACED AT THE PROPERTY LINE.KEYWAYTMAX. 14%TO PLALONGITUDINAL SAWED OR TOOLED JOINT(SAWED DEPTH = T/4, TOOLED DEPTH = 1/2")9. TRANVERSE SAWED DUMMY JOINTS SHALL BE CONSTRUCTED ON15’ SPACINGS FOR DRIVEWAYS AS MEASURED FROM THE BACKOF CURB.10. LONGITUDINAL SAWED OR TOOLED DUMMY JOINTS SHALL BE CONSTRUCTEDFROM THE GUTTER EDGE TO THE PROPERTY LINE FOR ALL DRIVEWAYSPROPERTY LINEWIDER THAN 15’.4.5’ USUAL AND MAX.LESS IF P CLOSEREXPANSION MATERIALAND PAY LINE4’ NORMALMAX.2%2%MAX. 14%TO WALKCEXPANSION JOINTREQUIRED AT P L6" REINF. CONC. DRIVE NORMALLY-457(8" REINF. CONC. DRIVEFOR COMMERCIAL OR INDUSTRIALACCESS.- 432MAX. 14%TO WALK2%4’NORMAL(3’MINIMUM)WALKB2’ USUALEXPANSION MATERIAL AND PAY LINE4" CONC. SIDEWALKB4’ WALK2%MAX.11. STREET JOINTS SHALL BE ADJUSTED IN LOCATIONS TO LINE UP WITHDRIVEWAY CENTERLINES.EXPANSION MATERIAL6"-4000 REINF. CONC. DRIVE4"CONCRETE SIDEWALK5’ WALK2%MAX.B4" CONC. SIDEWALK2’TRANSITIONMAX. 14%BPAY LINE ATBACK OF CURBACENTERLINE OF DRIVEMAX, 14%ROUT AND SEAL 1" DEEPLENGTH OF KEYWAY4"4"NO. 3 BARS PARALLEL TO EDGE OF DRIVENO. 3 BARS ON 24" CENTERSBOTH WAYS.NO EXPANSION MATERIALSECTION B-B6"AKEYWAYFACE OF CURBAPPROVEDDIRECTOR OF PUBLIC WORKS & TRANSPORTATIONCDATE:24’ MINIMUM LOCAL/COLLECTORS (SERVING LOW TO MED. DENSITY RESIDENTIAL PROPERTY)30’ MINIMUM ARTERIALS AND LOCAL/COLLECTORS (SERVING HIGH DENSITY RESIDENTIAL/COMMERCIAL PROPERTY)32’ MINIMUM ALLEY TURNOUTSPOUR TRANSITION TO BOTTOM OF CONC. SLAB OF STREETPAVING DETAILSDRIVEWAY TURNOUTSDRIVEWAY TURNOUT DETAILALL STREETSDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119971004

L6"PAY LIMITS FOR PROP.463 & 456PAVEMENTPAY LIMIT FOR PROP.457DRIVEROUT AND SEAL 1" DEEPTHROUGH LIMITS OF KEYWAY.2"14% MAX. SLOPE6" DR.NO. 3 BARST/2 T/21-1/2"2"1"METALKEYWAYNO EXTRA PAY FORINCREASED THICKNESS2’SECTION A-APROPERTYLINE2"NO. 3 BARS14% MAX. SLOPE2’SECTION C-C4’ MIN. TRANSITION 1’-0"10’ MIN. (VARIABLE WIDTH)1’-0"4’ MIN. TRANSITIONNOTES:1. OFFSETS IN DRIVES TO MATCH PROPOSED WALKS WILL BEBUILT MONOLITHIC WITH THE DRIVE.6"A1"/1’ MAX. SLOPE2. PAVEMENT JOINTS WILL NOT EXTEND THROUGH DRIVE.2"3. KEYWAY LIMITS WILL COINCIDE WITH LIMITS OF 2" CURB.4. REINFORCING STEEL WILL NOT EXTEND THROUGH KEYWAY.DRIVE WILL NOT BE TIED TO PAVEMENT.TKEYWAY5. MAXIMUM SLOPE ON DRIVE IN ANY DIRECTION SHOULD BETO RESPECT PRINCIPLES OF BARRIER FREE CONSTRUCTION.ALOT LINE6. LENGTH OF TRANSITION FOR CURB AT EACH SIDE OF DRIVEMAY VARY DUE TO STREET GRADES AND REQUIREMENT TO5’-0"HOLD MAXIMUM SLOPE OF 1"/1’.PROPERTY LINEC7. AN EXPANSION JOINT SHALL BE PLACED AT THE PROPERTY LINE.EXPANSION MATERIALAND PAY LINE4.5’ USUAL AND MAX.LESS IF P CLOSER2%MAX.4’ NORMALEXPANSION JOINT6" REINF. CONC. DRIVE4572%MAX.14% MAX.3’ MIN. WALK AREATO WALK4’ NORMALB2’ USUALEXPANSION MATERIAL AND PAY LINE8’ MINIMUM TRANSITION4" CONC.SIDEWALKB2%MAX.4’ WALK8. NOTES 1, 2, 4, 10, 11, AND 12 ON PAGE 1004 CONCERNING PAVEMENTJOINTS APPLY TO THIS PAGE ALSO.EXPANSION MATERIAL6" REINFORCED CONCRETE DRIVE4" CONCRETE SIDEWALK5’ WALK4" CONC.SIDEWALK2%MAX.MAX. SLOPE14.0%4"NO. 3 BARS PARALLEL TO EDGE OF DRIVESECTION B-BNO. 3 BARS ON 24" CENTERSBOTH WAYS.PAY LINE ATROUT AND SEAL 1" DEEP4"NO EXPANSION MATERIALBACK OF CURBLENGTH OF KEYWAY6"KEYWAYFACE OF CURBAPPROVEDC4’-0" 1’-0" 1’-0"4’-0"DATE:DIRECTOR OF PUBLIC WORKS & TRANSPORTATION20’ MINIMUMON LOCAL/COLLECTOR STREETSSPECIAL DRIVEWAY TURNOUT DETAILLOCAL STREETSNOTE:THIS DESIGN IS FOR USE ONLY FORDRIVES CONSTRUCTED 5’ OFF THELOT LINE WHEN APPROVED BYTHE CITY.SPECIAL DRIVEWAY TURNOUTSONLY FOR DRIVEWAYS CONSTRUCTED 5 FEETOFF THE LOT LINEDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119971004A

A. APPROVED WELDED WIRE FABRIC SHEETS MAY BE USED IN LIEU OF "6"6"3"6’- 0"2"6" 6"2’-0" 2’-0"#3 BARS ON 24" CTRS.VALLEY GUTTER6"NORMAL CROWN FORTHOROUGHFARES N O R M A L CFOR LOCAL &COLLECTOR STREETS6"MINOR ARTERIALS AND PRINCIPALCOUPLETS WILL MAINTAIN NORMALCROWN THROUGH INTERSECTIONS OFLOCAL AND COLLECTOR STREETSWITHOUT VARIATION.25’25’ N O R M A LTRANSITION NORMAL CROWNCROWN ADJUSTMENTSFOR LOCAL ANDVALLEY GUTTERCOLLECTOR STREETSVALLEY GUTTER20’ 25’USUALRADIUSPOINT N OCROWN25’GUTTER N O R M ANORMAL CROWNNORMAL CROWNVARIES14% MAX.6"P LP LSIDEWALK SLOPEM I N : M A X : 2’ USUAL 4’VARIABLESIDEWALK 6" DRIVEWAY S L O P E " T O 1 ’ M8% MAX SLOPE TO 1’ BEHIND S.W.8% MAXIMUM DESIRABLE TO PL14% MAXIMUM SLOPE FROM 1’ BEHIND SIDEWALK TO PL6" 6"GRADE BREAKS EXCEEDING 12% REQUIRE VERTICAL CURVE.T.C.SECTION THRU. PRIVATE DRIVE3’-9"2’-4"6"6"3’-0"6" 2’-4"TRANSVERSE BAR DIAGRAMPAY LIMIT OF DRIVEWAY6"3’-9"10’-0"MINIMUMPROPERTY LINECONCRETE WALKNO 3 BARS ON 24"CTRS BOTH WAYSREINF. CONC. PVMT.FACE OF CURBBLOCK-OUT LIMITIF NOT MONOLITHICPAVEMENT REINFORCEMENT LAPPED 30 DIA. ORWITH STREET PVMT.NO. 3 BAR DOWEL 2’-0" LONGDRIVEWAYS ON ARTERIAL STREETS SHALL HAVE 10’ FACE OF CURB RADII.USE ONLY TO MATCH EXISTING CONDITIONS AS DIRECTED BY THE ENGINEER. DETAIL ON PAGE 1004STANDARD.DRIVEWAY PAVING DETAILS4’-0"USUAL2’-0"USUAL4’-6" USUAL LOCAL STREET9’-6" USUAL ARTERIAL AND COLLECTORPAY LIMIT6"12" 6"6"4’-6" USUAL LOCAL STREETWALK AREA6"9’-6" USUAL ARTEIAL AND COLLECTORNO 3 BARS ON 24"CTRS. BOTH WAYS1’-0" 3’-0" MIN3’-0"9’-0" MIN6"6"3"3’-0" MIN1’-0"LAP 12"NO. 3 24" LONGBARS DOWELSEXPOSED 30DIAMETERSPVMT. BARSEXPOSED 30DIAMETERSPAY LIMITPARABOLIC CROWN( ADJUSTMENT AT VALLEY GUTTER )SIDE ELEVATION11’-0" MIN WHEN WITH DRIVEWAY WALLSECTION2’-0" 6"CONC. GUTTERREINF. CONC. PVMT.6"FACE OF CURBASPH. PVMT.DRIVEWAY WITH STEPS IN CENTERHALF PLAN ASPH. CONC. PVMT.WITH SEPARATE CONC. CURBAND GUTTERHALF PLAN REINF. CONC. PVMT.WITH INTEGRAL CONC. CURBDRIVEWAYS ON ARTERIAL STREETS SHALL HAVE 10’ FACE OF CURB RADII.PLANGRAVEL DRIVE24"ASPHALT TRANSITIONCONC. DRIVE APPROACH24"FINE GRADE SURFACE HOT MIX ASPHALTIC CONCRETE, ITEM 5044" THICK-RESIDENTIAL SINGLE FAMILY, DUPLEX OR AGRICULTURAL6" THICK-MULTIFAMILY, RETAIL OR OFFICE8" THICK-COMMERCIAL OR INDUSTRIALGENERAL NOTES1. NOTES 1-12 ON PAGE 1004 ALSO APPLY TO THIS PAGE.2. BAR LAPS SHALL BE 30 DIAMETERS.3. ALTERNATE REINFORCEMENT FOR #3 BARS ON 24"C-C :DEFORMED REINFORCING BARS.EXIT GRAVEL DRIVE6" OR 8" REINF. CONC. DRIVEB. THE WIRE FABRIC SHALL BE SUPPORTED ON 36" CENTERS BOTHWAYS BY APPROVED BAR CHAIRS.C. THE SIZE OF THE WIRE FABRIC SHALL BE 12X12-W3.5XW3.5 WITH ANOMINAL DIA. OF 0.211 IN. & NOMINAL WT. OF 0.119 LBS/LIN. FT.CONCRETE DRIVE APPROACH CONNECTIONTO GRAVEL DRIVEPAVING DETAILSPAVING DETAILS FOR DRIVEWAYSAND INTERSECTIONSAPPROVEDDATE:DIRECTOR OF PUBLIC WORKS & TRANSPORTATIONDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.1005APRILC.O.D. A.B.&A. 251D 11997

10’-6"13’-6"15’-6"18’-6"20’-6"6"2’-6" 2’-6" 2’-6" 2’-6"6"3’-3" 3’-3" 3’-3" 3’-3"6"3’-9" 3’-9" 3’-9" 3’-9"6"4’-6" 4’-6" 4’-6" 4’-6"6"5’-0"5’-0"5’-0"5’-0"TTTTTT/2T/2T/2T/2T/26"2’-0" 2’-0" 2’-0" 2’-0" 2’-0"6"2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0"1’-0"6"2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0"1’-0"6" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 1’-6" 6"6"2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0"1’-6"6"22’-6"28’-6"30’-6"6"5’-6" 5’-6" 5’-6" 5’-6"6"7’-0"7’-0"7’-0"7’-0"6"7’-6" 7’-6" 7’-6" 7’-6"TT/2T/2TTT/26" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 1’-6" 6"6" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 1’-6" 6"6" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 2’-0" 1’-6" 6"6" 1’-6"3/8" R5/8"HALF SECTIONS- REINFORCED CONCRETE PAVEMENT AND CURBS7 1/2"1" R2" RALL BARS FOR T < 9" TO BE NO. 3 TRANSVERSE BARS TO BE SPACED ON 2’-0" CENTERS.ALL BARS TO BE NO. 4 FOR 9" < T < 12"ALL CROWNS TO BE PARABOLIC IN SECTION AND SYMMETRICAL ABOUT CENTERLINE.VARIESPAY LIMIT1 1/2"(ALTERNATE DESIGN USING PARABOLIC SECTIONS)6"SPECIAL CURB & GUTTER6"VARIES ACCORDING TO ROADWAY WIDTH SPECIFIEDVARIES ACCORDING TO ROADWAY WIDTH SPECIFIED3/8" R3/8" RSPECIFIEDH.M.A.C.6" 12"ASPHALT SURFACE OF THICKNESS SPECIFIEDT/2TSCHEMATIC HALF SECTION OF REINFORCED CONCRETEBASE WITH INTEGRAL CURB & GUTTER AND ASPHALT SURFACEAS SPECIFIED6"SEPARATE1 1/2" THICK. FINE GRADED ASPHALT SURFACE COURSE( USUAL 24" )CONC. CURB& GUTTERFIRST POUR 4 1/2" COARSE GRADED ASPHALT BINDER2 1/2"SCHEMATIC HALF SECTION OF ASPHALT PAVEMENTWITH SEPARATE CONCRETE CURB & GUTTER2 1/2"PAYLIMIT3" R1:3 BATTER3" 1 1/2" RINTEGRAL CURB6"TPAYLIMIT3"3" R1:3 BATTER1 1/2"1’-6"6"THICKNESS3/8" RINTEGRAL CURB & GUTTERT AEXCEPT AS INDICATED ABOVE, ALL SECTION DETAILS SHALL BE IDENTICAL TO THOSESHOWN ELSEWHERE ON THIS SHEET FOR COLLECTOR AND LOCAL TYPE STREETS.TABLE OF CROWN HEIGHTS AND ORDINATESFOR VARIOUS PARABOLIC SECTIONSFULLCROWN* SEE NOTE 12.3/4 POINT MID POINT 1/4 POINTROADWAY TYPE TOTAL 3/4MID 1/4WIDTH SURFACE CROWN POINT POINT POINT20’ CONCRETE 3" 1-11/16" 3/4" 3/16"20’ ASPHALT 4" 2-1/4"1" 1/4"26’ CONCRETE 4" 2-1/4"1" 1/4"26’ ASPHALT 5" 2-13/16" 1-1/4" 5/16"33’ CONCRETE 6" 3-3/8" 1-1/2" 3/8"33’ ASPHALT 7" 3-15/16" 1-3/4" 7/16"36’ CONCRETE 6" 3-3/8" 1-1/2" 3/8"36’ ASPHALT 7" 3-15/16" 1-3/4" 7/16"40’ CONCRETE 6" 3-3/8" 1-1/2" 3/8"40’ ASPHALT 7" 3-15/16" 1-3/4" 7/16"44’ CONCRETE 6" 3-3/8" 1-1/2" 3/8"44’ ASPHALT 7" 3-15/16" 1-3/4" 7/16"56’ CONCRETE 8" 4-1/2" 2" 1/2"56’ ASPHALT 9" 5-1/16" 2-1/4" 9/16"60’ CONCRETE 8" 4-1/2" 2" 1/2"60’ ASPHALT 9" 5-1/16" 2-1/4" 9/16"STANDARD PAVEMENT THICKNESS(T) OF STREETS FOR VARIOUSSTREET CLASSIFICATIONS ANDTRAFFIC DESIGN LOADING AREAS FOLLOWS:CLASSIFICATIONT-LOCAL STREET, NOT ON 6"BUS ROUTE.-LOCAL STREET, ON BUS 6"ROUTE.-RESIDENTIAL COLLECTOR 8"-COMMUNITY COLLECTOR 9"NORMAL TRAFFICDESIGN LOADING.-COMMUNITY COLLECTOR 10"HEAVY TRAFFICDESIGN LOADING.-PRINCIPAL AND MINOR9"ARTERIALS, NORMALTRAFFIC DESIGNLOADING.-PRINCIPAL AND MINOR11"ARTERIALS, HEAVYTRAFFIC DESIGNLOADING.-CBD STREETS 10"ON 4" CTB-CBD STREETS 10"ON 8"CEMENT(ALTERNATE DESIGN) STABILIZEDSUBGRADE (10%)SEE PAVING DESIGN MANUAL, TABLEV-1 FOR DESIGN DETAILS6"ALL DETAILS RELATING TO CROWN HEIGHTS AND CONTOUR SHALL BE IDENTICAL TO THOSESHOWN FOR " REINFORCED CONCRETE BASE WITH ASPHALT SURFACE." ASPHALT SHALL BE3/8" RPLACED IN LIFTS OF NO MORE THAN 3 INCHES.1:3 BATTER3/8" RGENERAL NOTES FOR ALL TYPES OF REINFORCED CONCRETE3"3" 1 1/2" R3" 1 1/2" R1 1/2" RPAVEMENT OR BASE -- ARTERIAL, COLLECTOR, & LOCAL.6"6"6"1:3 BATTER3/8" R6"7"6"7"6"27 1/2"6"3"17 1/4"6"6"3"7"3" R1:3 BATTER3/8" R1. ALL SUBGRADE COMPACTION UNDER STREET PAVEMENT SHALL BE 98% STANDARD PROCTORDENSITY AT +2% OF OPTIMUM MOISTURE.6"6"6" 6"6"2. THE MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT 28 DAYS SHALL BE AS2’-6"2’-0"1’-6"INDICATED ON THE PLANS AND ON THE SPECIFICATIONS.3. BARS SHALL CONFORM TO CITY OF DALLAS STANDARD SPECIFICATIONS AND BE GRADE40 ksi DEFORMED REINFORCING BARS. SIZES AND SPACING SHALL BE AS INDICATEDSEPARATE CURB & GUTTERHEREIN EXCEPT SUCH ALTERNATES THAT MAY BE ALLOWED IN THE SPECIFICATIONS.REINFORCEMENT SHALL BE NO. 4 BARSNOTE: SEPARATE CURB WITH 12" AND4. ALL CURB AND CURB & GUTTER SHALL BE INTEGRAL WITH PAVEMENT OR BASE EX-CEPT THAT FOR ASPHALT PAVEMENT.18" GUTTER SHALL BE USED5. AS REFLECTED IN "TABLE OF CROWN HEIGHTS AND ORDINATES FOR VARIOUS PARA-BOLIC SECTIONS", TOTAL CROWN HEIGHTS FOR ASPHALT PAVEMENT AND CONCRETEMATCH EXISTING CONDITIONS.BASE WITH ASPHALT SURFACE SHALL BE UNIFORMLY ONE INCH GREATER THANTHOSE INDICATED FOR CONCRETE SURFACES, WIDTH FOR WIDTH OF ROADWAY.18"6. CROWNS FOR ALL DIVIDED ARTERIAL STREET TYPE SHALL BE STRAIGHT LINE SLOPES.5’-0"20 1/4"7. CROWNS FOR ALL UNDIVIDED ARTERIAL, LOCAL OR COLLECTOR STREET TYPES MAY BEPARABOLIC OR STRAIGHT IN SECTION.NO EXPANSION MATERIAL 3"8. DETAIL AND ARRANGEMENT OF JOINTS, ALL TYPES, SHALL BE AS SHOWN ON SHEET 1003.9. INTEGRAL CONCRETE CURB AND CURB & GUTTER SHALL BE OF THE SAME COM-PRESSIVE STRENGTH AS THE PAVEMENT OR BASE.4000 P.S.I. REINF. CONC.3" R3" RCURB AND CURB & GUTTERPAVING DETAILS6"3"ONLY AS REPLACEMENT TO10. SEPARATE CONCRETE CURB & GUTTER SHALL BE OF THE STRENGTH SPECIFIED ONLAYDOWN CURB & GUTTERTHE PLANS.11. SEPARATE CONCRETE CURB & GUTTER SHALL BE MARKED 3/8 " DEEP WITH AN AP-#4 BARPROVED TOOL IN 15 FOOT SECTIONS. EACH FOURTH JOINT SHALL BE AN EXPANSIONJOINT CONFORMING IN DETAILS TO THOSE SHOWN IN "PART C" FOR PAVEMENT EX-6" REINF. CONC. WALK.CEPT THAT THE FILLER SHALL BE OF 1/2 INCH PRE-MOLDED BITUMINOUS JOINT#3 BARS 24" O.C. BOTH WAYS ORMATERIAL SHAPED SIMILAR TO THE CROSS SECTION OF CURB & GUTTER. THREE DOWELS6"X6"-6GA. WIRE MESH.6"2’-3"3"SHALL BE EMPLOYED FOR EACH EXPANSION JOINT.12. BAR LAPS SHALL BE 30 DIAMETERS.3’-0"13. SIX INCHES OF LIME STABILIZED SUBGRADE REQUIRED WHEN THE SOIL P.I. IS GREATERTHAN 15 FOR LOCAL STREETS.NOTES: SUBGRADE UNDER WALK MUST2"BE COMPACTED TO 95% PROCTOR,-EIGHT INCHES OF LIME OR CEMENT TREATED SUBGRADE REQUIRED WHEN THE SOIL P.I.OR USE A SAND CUSHION OFAPPROVEDIS GREATER THAN 15 FOR COLLECTOR OR ARTERIAL STREETS, NORMAL TRAFFIC DESIGN LOADING.4" MIN. THICKNESS.DIRECTOR OF PUBLIC WORKS & TRANSPORTATION-EIGHT INCHES OF CEMENT MODIFIED SUBGRADE (AT 4% DRY WEIGHT OF SOIL) FOR ARTERIALDATE:STREETS WHEN SOIL P.I. IS LESS THAN OR EQUAL TO 15, NORMAL TRAFFIC DESIGN LOADING.MOUNTABLE CURB AND GUTTER DETAILS-EIGHT INCHES OF CEMENT STABILIZED SUBGRADE FOR COMMUNITY COLLECTOR AND ARTERIALSTREETS REGARDLESS OF SOIL P.I. FOR HEAVY TRAFFIC LOADING DESIGNS.REINF. CONC. WALK DETAILS(SEE PAVING DESIGN MANUAL, TABLE V-1)-CBD STREETS REQUIRE 4" CTB, 650 PSI COMPRESSIVE STRENGTH ON 6" COMPACTED SUBGRADE WITHPAVEMENT HALF SECTIONS10" THICK REINFORCED CONCRETE PAVEMENT, REGARDLESS OF SOIL P.I. OR, IN THE ALTERNATE,8 INCHES OF CEMENT STABILIZED SUBGRADE (AT 10% OF DRY WEIGHT OF SOIL) WITH 10" THICKAND CURB SECTIONSREINFORCED CONCRETE PAVEMENT. SEE PAVING DESIGN MANUAL, TABLE V-1 FOR DESIGN DETAILS.7"DEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119971006

.6"VARIABLE3/8"R3"6"1 1/2"R18"NOTE: GUTTER SLOPES 1"/12"3/8"R3"6"NOTE: GUTTER SLOPES 1"/12"1 1/2"R3/8"R3"6"18"1 1/2"RNOTE: GUTTER SLOPES 1"/12"H.M.A.C.3/8"R3"1"R12" USUALVARIABLE3"1:4 BATTER1 1/2"R6"3/8"R9"10 1/2"3"NO. 5PAY LIMITNO. 31:4 BATTER1 1/2"R6"10"3"NO. 5PAY LIMIT1:4 BATTER1 1/2"R6"3/8"R9" 1 1/2"1"RNO. 390^90^90^6" 6"6" 6"PAVEMENT FOLLOWSSTREET CONTOURPAVEMENT FOLLOWSSTREET CONTOURCBD SEPARATE CURB & GUTTERREINFORCEMENT SHALL BE NO. 5 BARS REINFORCEMENT SHALL BE AS NOTED REINFORCEMENT SHALL BE AS NOTEDFOR REPLACEMENT OF MID-BLOCKCBD SEPARATE CURB & GUTTERSCALE: 1 1/2" = 1’PROPERTY LINE OR BLDG. LINENO. 3 BARS ON 24" CENTERSBOTH WAYS6" SIDEWALKWIDTHBBAEXPANSION JOINT NO EXPANSION MAT’LASTREET4"WARP LINE4"EXPANSION JOINTNO. 3 BARS PARALLELTO EDGE OF DRIVECBD INTEGRAL CURBCBD INTEGRAL CURB & GUTTERSECTIONS TO MATCH EXISTINGSCALE: 1 1/2" = 1’ SCALE: 1 1/2" = 1’ NO SCALEMETALKEYWAYNOTES:T/2 T/21"1-1/2"PAY LIMITS FOR PROP.PAVEMENT 463 & 456PAY LIMIT FOR PROP.2"DRIVE1" NO. 3 BARSNO EXTRA PAY FORINCREASED THICKNESS2’SECTION A-ANO SCALEROUT AND SEAL 1" DEEPTHROUGH LIMITS OF KEYWAY.1. STANDARD PAVEMENT FOR CBD STREETS IS INTEGRALCURB WITH 10" THICK REINFORCED CONCRETE PAVEMENT ON 4" CTB650 PSI, NO ASPHALT SURFACES. ANY EXCEPTIONS MUST BE PROVIDEDFOR IN THE PLANS APPROVED FOR THE PROJECT.6" DR.* REMOVAL OF ASPHALT CONCRETEOVER CONCRETE BASE WHICHWILL REMAIN IN PLACE WILL BEPAID FOR AS 201REMOVEEXIST. CURB1’ USUAL& GUTTER6" 3000 P.S.I. CONCRETE ASPHALT CONCRETE FINEINTERGRAL CURBGRADED SURFACE COURSE604 SAWCUT202WITH 12" GUTTERVARIABLE THICKNESS201 *PROPOSED410 5043/4"/1’ Desirable Max.CURB0.1’/1’ Absolute Max.EXIST. ASPHALTICCONCRETE SURFACEPAY LINEEXIST. CONCRETEBASE TO REMAIN6"2. 9" BASE USED WITH STANDARD 4" CTB, 650 PSI DESIGN;9" BASE USED ON ALTERNATE 8" CEMENT STABILIZED SUBGRADE(@10%) DESIGN4000 P.S.I. R.C. ST. HEADER TO1"3. KEYWAY LIMITS WILL COINCIDE WITH LIMITS OF 1" CURB.4. REINFORCING STEEL WILL NOT EXTEND THROUGH KEYWAY.DRIVE WILL NOT BE TIED TO PAVEMENT.9" REINF. CONCRETE BASEREMOVE EXIST.CONCRETE BASEWITH ASPHALTPAY LINEBE USED WHERE EXIST. STEELCANNOT BE EXPOSED OR WHEREBASE IS DETERIORATED. PAY FORAS4605’ MIN20’ TYP 5’ MIN5. MAXIMUM SLOPE ON DRIVE IN ANY DIRECTION SHOULD BE 1" PER 1’.TO RESPECT PRINCIPLES OF BARRIER FREE CONSTRUCTION.427SURFACE2016. LENGTH OF TRANSITION FOR CURB AT EACH SIDE OF DRIVEMAY VARY DUE TO STREET GRADES AND REQUIREMENT TOCBD PAVEMENT REPLACEMENTHOLD MAXIMUM SLOPE OF 1" PER 1’.NO SCALECBD DRIVEWAY TURNOUT DETAILSCALE: 1" = 5’EXPANSION MATERIAL6"- REINFORCED CONCRETE DRIVE7-16-854" NON-REINFORCEDNOTE: BARRIER FREE RAMPSCONCRETE SIDEWALK ITEM 3574"SHALL HAVE A GROOVED RAKEFINISH 1/8" DEEP SPACED 1"APART. DRIVEWAY RAMPS NEEDNOT BE RAKED.PAY LINE6’ MIN. VARIABLE HEIGHTCURB 6" TO 5/8"SECTION B-BNO SCALE30"5 / 8T H R U B" C UWARPF. R .R B4"- REINFORCED RAMP WITH NO. 3 BARSAT 24" O.C.E.W. BACK OF WALK TO BACK OF CURB36"P.C.WARP6’ MIN. VARIABLE HEIGHTCURB 6" TO 5/8"2’-6" GRID ALONG CURB18"FACE OF CURB4"CBD BARRIER20’RP.C.10’7’-6"PAY LINEEXPANSION JOINT2’-6" GRID ALONG CURB10’ USUAL2" 71/2"13 1/2"R6"RFREE RAMP1/2" EXPANSION JOINT EVERY 40’SCALE: 1"=10’TOOLED JOINTSTYPICAL SIDEWALKCBD DETAIL FOR SHALLOW DEPRESSION INLETSSCALE: 1/2"=1’APPROVEDDATE:DIRECTOR OF PUBLIC WORKS & TRANSPORTATIONPROPERTY LINESCALE: 1"=10’NOTE: SEE PAGE 2004 FOR REINFORCEMENT DETAILSMISCELLANEOUS DETAILS4"-NON-REINFORCEDCONCRETE WALKNOTE: TOOLED JOINTS FOR SIDEWALKS AGAINST CURBMUST MATCH STREET PAVING JOINTS.EXPANSION JOINTS FOR SIDEWALKS AGAINST CURBMUST ALIGN WITH THE EXPANSION JOINTS IN STREET PAVEMENT.CBDSPECIAL DETAILSDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119971007

STANDARD RECESSED STORM DRAINAGE INLETS & CURBSSPECIAL "Y" INLETSTANDARD TYPE "Y" INLET4’-0"3’-6"AUSE 9" LONG NO. 3 BARS ON 24" CTRS. DRILLED3" INTO THE BACK OF INLET AND 6" INTO SIDEWALK6" 1’-6" 1’-6"6"6" 1’-3" 1’-3" 6"AND EPOXY GROUTEDVARIABLE13’ RADIUSCONC.WALK1/2" PREMOLDED EXPANSIONMATERIAL3/4" EXPANSION MATERIAL1’P L OF STREET13’ RADIUSCONC.WALKA1’-6"1’-6"6"A4’-0"A6" 1’-3"1’-3" 6"A3’-6"2’-0"WARP PAVE. SURF. TO THROAT OF INLET6"BENT BARSSTRAIGHT BARSNORMAL 6"INT. CURB1/2" EXPANSIONMATERIAL13’ RADIUSANORMAL FACE OF CURBPAY LIMIT LINENOTE: STREET SAWED DUMMYJOINT SHALL BE TOOLEDTHROUGH INLET THROAT.13’ RADIUSBLOCKOUTLINECONSTRUCT EXPANSIONJOINTS AT BLOCKOUT EDGESPROVIDE STREET SAWED DUMMYJOINT OR CONSTRUCTION JOINT INLINE WITH BLOCKOUT EDGES FORCONC. INTEGRAL PAVEMENT.ALL REINFORCING SHALL BE NO. 4 BARS."B" BAR "C" BAR "D" BARNOTES: DEPTH OF INLETS MAY VARY TO SUIT CONDITIONS IN THE FIELDOR AS SPECIFIED ON PLANS.USE CITY OF DALLAS STANDARD INLET FRAME & COVERPAGE 2004 (22 1/8 " FRAME)10’VARIABLE WITH SIZE OF INLET10’VARIABLE HEIGHT CURBVARIABLE HEIGHT CURB6"6"NORMAL 6"INT. CURB7 1/2"11 1/2"TOP OF INLETSECTION B-B6 1/2"GUTTER GRADE AT NORMAL FACE OF CURBGUTTER GRADE ALONG VARIABLEHEIGHT CURB.B6"6"6"4’-6""B" BAR"A" BAR1/2"2"12"C. TO C."E" BARS1’-6"WELDBB18"1/2"7"3’-6" USUAL5’-1" USUALBB4’-0" USUAL12"C. TO C."B" BARCONC. BUILD UP9"VARIABLECONC. BUILD UP6"2’-0"SLOPE 1/4" PER FOOT4"WALK1’-0"4"SLOPE 1/4" PER FOOT4"6"SECTION A-A71/2"6"PL71/2"13 1/2"R6"18"SECTION A-A2’-6" 3"4’-6" USUAL12"6"R6"4 7/8"2’-4" 6""A" BARS SHALL BE NO. 8 BARS PLACED AS SHOWN& WELDED AT EACH CORNER OF THE INLET.ALL OTHER BARS SHALL BE NO. 5 BARS PLACEDAS SHOWN."B" BARSB6" 2’-0" 6"3’-0"SECTION A-AFOR 36", 48" & 60" INLETS6"SECTION A-AFOR 6’, 8’ & 10’ INLETSNOTE:1. SEE PAGE 2004 FOR REINFORCING & BEAM DESIGN.2. PLASTIC OR NEOPRENE COATED STEEL STEPS SHALLBE PROVIDED FOR ALL EXTRA DEPTH INLETS GREATERTHAN 4.5’ AND SHALL BE EMBEDDED SECURELY INTOBACK OF INLET ON 15" CENTERS VERTICALLY ANDSTAGGERED ON 12" CENTERS HORIZONTALLY.3. SEE DETAIL ABOVE FOR PROPER INLET TIE-IN TO ADJACENT3’-0""A" BAR3" CLEARSECTION B-B3" 2’-6"SIDEWALK FOR ALL SIZE INLETS THAT ARE ADJACENT TOAPPROVEDSIDEWALKS.DIRECTOR OF PUBLIC WORKS & TRANSPORTATION4. GENERAL NOTES 1-10 ON SHEET 2003 ALSO APPLY TO THISDATE:SHEET.5. EXPANSION JOINTS SHALL BE CONSTRUCTED ALONG EDGES OFALL STREET INLET PAVEMENT BLOCKOUTS.3’-0"WELDDRAINAGE DETAILS6. CONCRETE FOR INLETS TOPS SHALL BE CLASS HAND FINISHSTANDARD INLETS & CURBSCONCRETE (4500 psi) WHEN USED IN STREETS AND ALLEYS.SECTION B-B"Y" TYPE INLETSDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119972001

7 ’ - DOWNSTREAMUPSTREAM5 ’ DOWNSTREAMVARIES- 4’-0" TO 5’-0"VARIES - 6’-0" TO 10’-0"VARIES - 4’-0" TO 5’-0"4"614"615 ’6 ’UPSTREAMVARIES - 6’-0" TO 10’-0"TOP OF CURBTOP OF CURBGUTTER FLOW LINEGUTTER FLOW LINEDO NOT INCLUDE VARIABLE HEIGHT CURBIN UNIT PRICE BID FOR INLETDO NOT INCLUDEVARIABLE HEIGHTCURB IN UNIT PRICEBID FOR INLETAT CURB FACE.DO NOT INCLUDE VARIABLE HEIGHT CURBIN UNIT PRICE BID FOR INLETDO NOT INCLUDEVARIABLE HEIGHTCURB IN UNIT PRICEBID FOR INLETAT CURB FACE.LATERALLATERALSECTION C-C1 01 2SECTION F-F1 01 2SCALEFEETSCALEFEET8 ’ -6"7 ’ -6"6" 6"6"4"613 BARS A6"TOP OF CURB4"613 BARS ATOP OF CURBFLOWFLOWFLOWFLOW3/4" X 4" MCH. BOLTS3/4" X 4" MCH. BOLTS5’-0"4’-6"2’-6" WF 15.5-2’-8" LONG1/2" MORTAR FINISH, TROWEL TO ASMOOTH HARD SURFACE5’-0"4’-6"6" WF 15.5- 2’-8" LONG " M O R T A R FTO A SMOOTH HARD SURFACE1’-0"LATERAL1’-0"LATERAL6"SECTION B-BSECTION E-E1 01 2SCALEFEET6"1 01 2SCALEFEETDO NOT INCLUDE VARIABLE HEIGHT CURB8 ’ -DO NOT INCLUDEVARIABLE HEIGHTDO NOT INCLUDE VARIABLE HEIGHT CURBIN UNIT PRICE BID FOR INLET.6 ’DO NOT INCLUDEVARIABLE HEIGHTCURB IN UNIT PRICEBID FOR INLET.IN UNIT PRICE BID FOR INLET.CURB IN UNIT PRICEA8 BAR BBID FOR INLET.D6 BARS B3 BARS A3 BARS A6"6"6"CURB3’-0"1’-6" 6"BBCURBSTANDARD INLET GRATESAND FRAMES. SEE PAGE 2010.3’-0"1’-6"EE6"6"C5 BARS GAPLAN VIEWCPROVIDE ONE STREET OR ALLEY SAWED DUMMY ORCONSTRUCTION JOINT IN LINE WITH EDGE OF EACH INLET.PROVIDE ONE STREET OR ALLEY SAWED DUMMY ORCONSTRUCTION JOINT IN LINE WITH EDGE OF INLET FOREVERY TWO INLETS ADJACENT TO EACH OTHER .FDPLAN VIEW1 01 2F3 BARS G1 01 2SCALEFEETEXPANSION JOINT3 BARS ADEPRESSION OFGRATES TO SUITCONDITIONS.4"6" R.1’-0"1 /2" R.SCALECAST WITH CURB6 BARS BFEET6"STEEL DETAIL8’-8" - TRIPLE GRATE INLET5’-11" - DOUBLE GRATE INLET3 BARS ADEPRESSION OFGRATES TO SUITCONDITIONS.4"6" R.1’-0"1 /2" R.CAST WITH CURB6 BARS BGENERAL NOTES:1. PROVIDE EXPANSION JOINTS ALONG EDGES OF ALLSTREET PAVEMENT BLOCKOUTS.2. CONCRETE FOR INLET TOPS SHALL BE CLASS A HANDFINISH CONCRETE (4500 psi) WHEN USED IN STREETSAND ALLEYS.3. TYPE " L " GRATES SHALL BE USED AS SHOWN ONSHEET 9010.BARS A - #5 BAR, 9’-8" LONG ( TRIPLE GRATE INLET )6’-11" LONG ( DOUBLE GRATE INLET ),4. LATERAL MAY ENTER INLET AT ANY GRADE, ANGLE OR3 REQUIRED.LOCATION. INCLUDE IN UNIT PRICE BID FOR STANDARD5 BARS G3 BARS GSEE SHEET 2004 FOR#STEEL DETAILS FORWALLS & BOTTOMGRATE INLET COMPLETE IN PLACE ALL ITEMS, INCLUDINGEXCAVATION.5. REINFORCING STEEL AND CASTING SHALL CONFORM4’-6"5’-0"SEE SHEET 2004 FOR#STEEL DETAILS FORWALLS & BOTTOM2’-0"5"4’-6"5’-0"SEE SHEET 2010 FORTO THE SPECIFICATIONS.6. EXTRA DEPTH OF INLETS WILL BE DIMENSIONED ON PLANS.A SEPARATE BID ITEM PER FOOT OF EXTRA DEPTHWILL BE PROVIDED. STEPS WILL BE REQUIRED.2 STANDARD FRAME DETAIL7. PROVIDE STREET AND ALLEY JOINTS AS SHOWN FORAND SHEET 9010 FORINTEGRAL CONCRETE PAVEMENT.22GRATE DETAILS.BARS B - #5 BAR, 3’-9" LONG, 8 REQUIRED ( TRIPLESEE SHEET 2010 FORGRATE INLET ) ; 6 REQUIRED ( DOUBLESTANDARD FRAME DETAILGRATE INLET )AND SHEET 9010 FORAPPROVEDGRATE DETAILS.DIRECTOR OF PUBLIC WORKS & TRANSPORTATION1’-3"DATE:6"6"DRAINAGE DETAILS6" 2’-0"6"6"6" 2’-0"6"DOUBLE GRATE INLET3’-0"3’-0"TRIPLE GRATE INLETSECTION A-A1 01 2SCALEFEETBARS G - #3 BAR, 1’-3" LONG, 5 REQUIRED ( TRIPLEGRATE INLET ) ; 3 REQUIRED ( DOUBLEGRATE INLET )SECTION D-D1 01 2SCALEFEETDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119972002

1 STEEL SCHEDULE FOR 14-FOOT INLETSBARCODEABNO.REQ’D1210BARSIZE44LENGTH16’-1"11’-2"SPACE*2WEIGHT(LBS.)12979DESCRIPTION AND REMARKSSEE DETAILSSEE DETAILS**WALLS 13" CTR.BOTTOM 12" CTR.SEE SECTION "EE"ALTERNATE CONSTRUCTIONALTERNATE PRECAST INLET BOTTOMSMAY BE APPROVED ON A INDIVIDUAL BASISFOR INLETS IN STREETS AND ALLEYS ONLY.A15"15"MINCINLET COVERD15’-0"6’-8" 6’-8"6" 8" 6"6"ACD142444 ’1 4 ’18"8"4519SEE DETAILSSEE DETAILSSEE SECTION "BB"PRE-CAST INLETS SHALL BE OF EQUAL ORBETTER STRENGTH, MATERIAL AND WORK-MANSHIP, AND SHALL MEET THE STANDARDDESIGN CRITERIA OF THE CAST IN PLACEINLETS SHOWN IN THESE DETAILS.USUAL 10’-0"FRAME3’-6"USUAL 10’-0"FGHJK71541224343416’-1"3’-9"4’-7"3’-0"3’-0"**12"416"*752813144.00SEE DETAILSSEE DETAILSSEE DETAILSSEE DETAILSSTRAIGHT BARS****SEE SECTION "CC"SEE SECTION "BB"SEE SECTION "EE"SEE SECTION "BB" " E XMATERIALEXPANSIONJOINT " E X P A N S I4’-0"MIN. 50^12"MINCD " C HAROUND OPENINGPAY LINEPROVIDE STREET SAWED DUMMY ORCONSTRUCTION JOINTS IN LINE WITH12" 6" " E X P A N S I " E XMATERIALEXPANSIONJOINTU533’-9"98SEE DETAILSPLAN VIEWEDGE OF INLET WALLSPROVIDE STREET SAWED DUMMY ORCONSTRUCTION JOINTS IN LINE WITH BLOCKOUTTOTAL STEEL FOR 4’-6" STANDARD DEPTH INLET.415 LBS.EDGES FOR INTEGRAL CONCRETE PAVEMENTWEIGHT OF STEEL MAY VARY WITH INCREASED10’ MAX15’-0"10’ MAXDEPTH OF INLET BY AN AVERAGE OF 17.5 LBSP E R E A C H F O O TVARIABLE HEIGHT CURBVARIABLE HEIGHT CURB5.25 CUBIC YARDS OF 3000 P.S.I. CONCRETEREQUIRED PER STANDARD INLETB6’-8" 6’-8"6" 8" 6" " E X P A N S I " E X P A N S IC O N C R E T E F O R E A C HBARS "H"48BARS "A" 14’-8"OF DEPTH 0.32 CU. YD.84BARS "H"3’-9"BARS"B"4’-3"1BARS"C"CL4" 4"BARS"U"7’-6"6"4"INLET DEPTH MAY VARY AS SHOWN ONPLANS OR AS DIRECTED BY THE ENGINEER4’-6"STANDARD DEPTHBVARIABLE HEIGHT CURB NOT PART OF INLET,HOWEVER MAXIMUM LENGTH WILL BE USEDWHEN INLET IS LOCATED IN SAG.VARIABLE HEIGHT CURB LENGTH MAY VARY ASDIRECTED BY THE ENGINEER AND WILL BEGOVERNED BY STREET GRADE.BARS "F" 14’-8"BARS "H" 3’-2"3’-2"1CL1’-7"SECTION A-AFALSE BOTTOM WITH WARPED INVERTTROWELED TO A SMOOTH HARD SURFACE,S L O P E D F R O M "FIT CONDITIONS.1BARS"H"BARS BBARS U BARS A BARS B4"113’-5"BARS"D"3812"424"23"8"BARS"B"CONSTRUCTIONJOINT2"CLBARS KBARS CBARS DEE360^6"4BARS"C"6"173^45"*342BARS"G"2" 2"BARS"A"6"BARS GBARS F6R=5"2"CL5"BARS"U"BARS"J"14"SECTION E-E & HALF SECTION ELEVATIONBARS JBOTTOMBAR DETAILSUSUAL 4’-0"1’-6" 12"CTRBARS GTOPSECTION B-BPLANNO SCALEEXPANSIONJOINT " E XMATERIAL12"CORNER RADIUS 1"15"1’-6"4 3 4 2 21 CL8"82" CL4"12"15"1 CL2" CL4"PAVEMENTREINFORCEMENT9"PAY LINE2"CL6"BARS A6"2"CLR=12’1CL6" 5"BARS FBARS DBARS CBARS G1’-6"1 CONSTRUCTION JOINTBARS A1BARS JBARS BBARS B1CL8"6"1’-7"USUAL 5’-0"9"PAY LINE2"CLBARS A6"2"CLR=12’1CL6"BARS F1BARS JBARS BBARS DBARS CBARS GBARS UBARS HBARS ABARS B8"6"1’-7"USUAL 5’-0"GENERAL NOTES1. CONCRETE FOR INLET CONSTRUCTION SHALL BE CLASS HANDFINISH CONCRETE (4500 psi) WHEN USED IN STREETS AND ALLEYS.2. DIMENSIONS RELATING TO PLACEMENT OF REINFORCING BARSARE FROM CENTER TO CENTER OF BARS UNLESS OTHERWISENOTED. BAR SPLICES ARE PERMISSIBLE IF BARS ARE TIEDAND OVERLAPPED 30 DIAMETERS.3. PIPE LATERALS MAY ENTER INLET AT SIDES OR ENDS.4. STRUCTURAL EXCAVATION WILL NOT BE A SEPARATE PAYITEM.5 . C H A M F E R A L L E X P O S E D E D GAPPROVED6. INLET COVER & FRAME SHALL BE AT THE SAMEDIRECTOR OF PUBLIC WORKS & TRANSPORTATIONEND OF INLET AS PIPE LATERAL.DATE:7. SEE SHEET 2001 FOR SIDEWALK ADJACENT TO INLET DETAIL.8. PROVIDE STREET JOINTS AS SHOWN FOR INTEGRAL CONCRETEDRAINAGE DETAILSPAVEMENT."14-FOOT" CURB INLETPERMISSIBLE9. PROVIDE EXPANSION JOINTS ALONG EDGES OF ALL STREETPAVEMENT BLOCKOUTS.STANDARD DEPTH 4-FEET 6-INCHESCONSTRUCTIONJOINT2"CL6"2"CL6"10. EXTRA DEPTH INLETS WILL BE DIMENSIONED ON PLANS.DEPARTMENT OF PUBLIC WORKS & TRANSPORTATION6"2’-6"6"3’-6"6"2’-6"6"3’-6"A SEPARATE BID ITEM PER FOOT OF EXTRA DEPTH WILLBE PROVIDED. STEPS WILL BE REQUIRED IN THIS CASE.CITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.SECTION C-CSECTION D-DAPRILC.O.D. A.B.&A. 251D 119972003

1 1 C L A T 1 "USUAL 4’-6" - MAX. 5’-0"6"VARIABLE6"73 ’ - 1 ’ -BARS B6"BAR AINLET OPENING L IN INCHESW A R P T O S U I TMORTAR FINISH TROWELED TO ASMOOTH HARD SURFACESECTION B-BC18"BAR CPIPE4"7BARS AUSUAL 4’-6" - MAX. 5’-0"VARIABLE6"NORMAL SLOPE " /CONFORMS TOPARKWAY SLOPEPIPEBARS C5"76" 2’-0" 6"12"74"8"12"1" RBAR GPAVING3’-0" 36, 48 & 60SECTION C-CPAY LINEINCH INLET8"A1" LETTERINGR A I SKEY HOLE1" LETTERSR A I SPICK HOLE& "DRAINPLAN OF COVERSTORM9A! " D I A .1 1" 1"A-A21BRONZE BOLT W/ BRASS SPRING8’ INLET10’ INLET9"BCURBCD6’ INLET7’-0"12"GUTTERPIPEPROVIDE EXPANSION JOINTSALONG BLOCKOUT EDGES FORCONCRETE STREETS9’-0"11 ’-0"6" 6"9"CDCORRECTIONS IN PAVING VARY FOR EACH INLET.THE LIMITS OF REMOVING AND REPLACING OFPAVING WILL BE DETERMINED BY THE ENGINEERAND WILL BE MEASURED AND PAID FOR AT THE2’-4"6" 6"3’-4"12" " E XMATERIALGUTTERB4"A1" LETTERSR A I SKEY HOLEA1" LETTERSR A I S7& "PICK HOLEDRAINSTORMPLAN OF COVERA! " D I A .1"1"1A-ASCALE IN INCHES0 3 611BRONZE BOLT W/ BRASS SPRING4’-0"36" INLETCONTRACT PRICE BID PER SQUARE YARD.6"5’-0"6’-0"INLET OPENING L IN INCHES6" 6"48" INLET60" INLETSCALE IN INCHES0 3 6PLANPROVIDE STREET JOINTS TO LINE UP WITH EDGES AS SHOWNINLET OPENING L IN FEETBARS BBARS B6’ INLET7’-O"3’-0"2’-0"BBARS AB8’ INLET10’ INLET6"9"9’-O"11’-O"INLET OPENING L IN FEET6"212"MIN.6"BAR G3"BARS C3"2 64"1" R7 4"7TOP OF CURBFLOW LINE OF GUTTER1SECTION OF FRAME4"CINLET FRAME AND COVERREINFORCING PLANC4’-0"5’-0"6’-0"INLET OPENING L IN INCHES6" 6"36" INLET48" INLET60" INLETSECTION OF FRAMEINLET FRAME AND COVER26"UP GRADEUSUAL 10’ UP GRADEDO NOT INCLUDE SPECIALCURB & GUTTER IN THISWING IN UNIT PRICE BIDFOR INLETUSUAL 4’-6"MAX. 5’-0"VARIABLE6"DOWN GRADEUSUAL 10’ DOWN GRADEDO NOT INCLUDE SPECIALCURB & GUTTER IN THISWING IN UNIT PRICE BIDFOR INLETABUSUAL 10’-0"12" GUTTER3’-0"2’-0"6" 6"18"INLET OPENING L IN INCHES12" 12"PIPEBCURBUSUAL 10’-0"A2’-6"2’-6"2’-6"#5 BARS A2’-9"2’-9"2’-9"36" INLET - 4 REQD.#5 BARS B6" 6"48" INLET - 4 REQD.60" INLET - 4 REQD.36" INLET - 4 REQD.48" INLET - 6 REQD.60" INLET - 8 REQD.521 ’ -32"7#3 BARS H6’ INLET 3 REQ’D.8’ INLET 4 REQ’D.10’ INLET 4 REQ’D.SECTION A-A1" R1"4"7BAR GBAR C16"11’-4"3 3" 3"14112’-4"3BAR H #3DIAM. @18" C-C6" 4"18"BARS DBARS ABAR BBAR D BAR D BAR CBAR DBAR ABAR HBAR CPROVIDE EXPANSION JOINTS " E XALONG BLOCKOUT EDGES FORCMATERIALCONCRETE STREETSCORRECTION IN PAVING VARY FOR EACH INLET. THE LIMITS OF REMOVING AND REPLACINGPAVEMENT WILL BE DETERMINED BY THE ENGINEER, AND WILL BE MEASURED AND PAIDFOR AT THE CONTRACT UNIT PRICE PER SQUARE YARD.PLANPROVIDE STREET JOINTS TO LINE UP WITH EDGES AS SHOWNONE EDGE OFINLET ONLY4’3’-9"4’-9"5’-9"#5 BARS C3’-0"#3 BARS G36" INLET - 2 REQD. 4’-9" LONG48" INLET - 2 REQD. 5’-9" LONG60" INLET - 2 REQD. 6’-9" LONG36", 48" & 60"& " 0REINFORCING STEEL DETAILS NOT TO SCALE3’-0"3"3’-0"3’-0"3’-0"6’ INLET - 10 REQ’D 3’-3" LONG8’ INLET - 13 REQ’D. 3’-3"LONG10’ INLET - 16 REQ’D. 3’-3"LONG#3 BARS A6’ INLET - 1 REQ’D. 4’-10" LONG8’ INLET - 1 REQ’D. 6’-10" LONG10’ INLET - 1 REQ’D. 8’-10" LONG#3 BARS B6’-8"8’-8"10’-8"SCALE IN INCHES0 4 8 126’ INLET - 15 REQ’D. 7’-8" LONG8’ INLET - 15 REQ’D. 9’-8" LONG10’ INLET - 15 REQ’D. 11’-8" LONG1" RBARS F @ C BARS D @ CORS.LALTERNATESECTION D-D( SEE STD. SEC. D-D BELOW )N O R M A LSLOPEBARS C4"BAR D2"2"2"2"BAR F1’-8"1’-8"1’-8"2’-2" 2’-2"2’-8" 2’-8"REINFORCING PLANALTERNATE9"BARS A SPACED 9" CTRS.BAR D1’-8"2"BAR B6’ INLET2"8’ INLET2"10’ INLET2"4"77UP GRADEUSUAL 10’ UP GRADEDO NOT INCLUDE SPECIALCURB & GUTTER IN THISWING IN UNIT PRICE BID FOR INLET4"6"4’-036" INLET5’-0"48" INLET6’-0"60" INLETINLET OPENING L IN INCHES6" 6"18"1" R 1" R TOP OF CURBFLOW LINE OF GUTTER7USUAL 4’-6"MAX. 5’-0"VARIABLE6"DOWN GRADESPECIAL CURB & GUTTERUSUAL 10’ DOWN GRADEIN THIS DISTANCE IS ADO NOT INCLUDEPART OF THE INLETSPECIAL CURB &GUTTER IN THIS WINGIN UNIT PRICE BID FORINLETSECTION A-A36, 48 AND 60 INCH INLETS2"STANDARDCURB & GUTTER71’-6"6"6"FACE OF CURB#4 BARS C6’ INLET - 5 REQ’D. 4’-8" LONG8’ INLET - 5 REQ’D. 4’-8" LONG13.5" R6" RDETAIL FOR SHALLOWDEPRESSION INLETSNOTES APPLICABLE TO ALL INLETS:1. LATERAL PIPE MAY ENTER INLET AT ANY LOCATION.REINFORCEMENT, STRUCTURAL STEEL AND CASTINGS SHALL CONFORM TOTHE SPECIFICATIONS.2. GENERAL NOTES 1-10 ON SHEET 2003 ALSO APPLY3. T O P O F I N L E T S L O P E S H A L L C O N F O R M T O4. CONCRETE FOR INLET TOPS SHALL BE CLASS HAND FINISH CONCRETE (4500 psi) WHENUSED IN STREETS AND ALLEYS.5. ALTERNATE CONSTRUCTION .10’ INLET - 5 REQ’D. 4’-8" LONG#4 BARS D3’-6" 1 REQ’D.6’,8’, & 10’ INLETSNO SCALE#4 BARS F3’-0"6’, 8’ &10’ INLETS& " 0#3 BARS G1" RALTERNATE PRECAST INLETS MAY BE APPROVED ON AN INDIVIDUAL BASIS PRECAST INLETSSHALL BE OF EQUAL OR BETTER STRENGTH MATERIAL, AND WORKMANSHIP AND SHALL MEETTHE STANDARD DESIGN CRITERIA OF THE CAST-IN-PLACE INLETS SHOWN IN THESE DETAILS.6. THE INLET FRAME & COVER SHALL BE AT THE SAME END OF INLET AS101PIPE LATERAL.SCALEFEET7. PROVIDE SHEET JOINTS IN INTEGRAL CONCRETE STREET PAVEMENT AS SHOWN.9" OR 12"P A Y L IN E34" 4"BAR G1BAR C1 331 ’BAR G6" R93744"BARS C3"212’-4"25"1 36" RPIPEBAR H18"2’-4"6" 6"3’-4" 6’, 8’ & 10’ INLETSSECTION C-CS5x101 6"BARS F @ C- BARS D @ COR’S.LSECTION D-DFOR STANDARD INLETSVARIABLE6"BAR DUSUAL 4’-6" - MAX. 5’-0"BAR DBARS C110"PIPE1BAR D REAR WALLBAR F FRONT WALL @ C LWARP TO SUIT CONDITIONS " M O R T A R F I6,8 & 10 FT. INLETSCALE IN FEET0 1 2 3TO A SMOOTH HARD SURFACEINLET OPENING L IN FEETSECTION B-BAPPROVEDDATE:DRAINAGE DETAILS36, 48, AND 60 INCH INLETS12"12"12"6"6, 8 AND 10 FOOT INLETSDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 11997BARS C12"DIRECTOR OF PUBLIC WORKS & TRANSPORTATIONVARIABLE6"USUAL 4’-6"-MAX. 5’-0"2004

WOREINFORCED CONCRETEPAVEMENT WITHINTEGRAL CURBASPHALTICCONCRETEPAVEMENTVARIABLEDETERMINED BY PIPEDIAMETER ( D ) AND BYPAVEMENT THICKNESS( T )1’-3"3"ASPHALTIC3’CONCRETEPAVEMENT6" CURBNO. 3 BARS3" 24" C-C MAX. 3"R=3"QT45^D/2R =D/4 6" 5 " E X P A N S IREINFORCED CONCRETESEPARATE CURB/GUTTERFACE OF CURBWARP FLOW LINE OFGUTTER TO MEETSLOTTED DRAINREINFORCED CONCRETEPAVEMENTSLOTTED DRAIN1’-3"Q = GUTTER CAPACITY = Q O + Q WYY W Y OQZ8/3Q = 0.56 ( - ) - S -Y OR USE TRIANGULAR CHANNEL FLOW NOMOGRAPHNZ = RECIPROCAL OF CROSS SLOPENO. 3 BARN = ROUGHNESS COEFFICIENT IN MANNING FORMULA ( USE N = O.0175 )Y = DEPTH OF FLOW. MAX. = HEIGHT OF CURB ( USUALLY 6" )DSTABILIZED BASE( USUAL ) 6" TRENCH BACKFILLSEE NOTE NO. 5BACK OF CURB6" HT. CURBVARIABLEHEIGHT CURBINTEGRAL CURBS = GRADE OF GUTTER IN FT./ FT.Q W = PORTION OF WATER DRAINED BY WEIR FLOWZ8/3Q = W0.56- ( - ) - S - Y WNSECTION WITH ASPHALTIC CONCRETE PAVEMENTASPHALTIC CONCRETE PAVEMENTPAVEMENT TRANSITION AT END OF SLOTTED DRAINVARIABLE1’-3"BLOCKOUTLINEHAND FINISH3"CONSTRUCTIONJOINTNO. 3 BARS24" C.-C. MAX.3"5D/46"D/2DNO. 3 BAR6"TRENCH BACKFILLSEE NOTE NO. 5SECTION WITH REINFORCED CONCRETE PAVEMENT3" 9" 3"21"NO. 3 BARS24" C.-C. MAX.D/45 " HY = DEPTH OF W WATER CONSIDERED AS WEIR FLOW /< 0.2’Q O = PORTION OF WATER DRAINED BY ORIFICE FLOW = Q - Q WY = DEPTH OF O WATER CONSIDER AS ORIFICE FLOW > 0.2’L W = LENGTH OF SLOTTED DRAIN NECESSARY TO PICK UP WEIR FLOW ( Q W )Q WQ WL = ---------- W = ------ = 9.7 Q ( WY = W 0.2’ )3/2 0.103C W H WPROVIDE JOINT IN STREET PAVEMENTC = WEIR COEFFICIENT W= 3.26TO LINE UP WITH BLOCKOUT LINEH = AVERAGE W DEPTH OF FLOW IN FEET = 0.1’3’L O = LENGTH OF SLOTTED DRAIN NECESSARY TO PICK UP ORIFICE FLOW ( Q O )REINFORCED CONCRETE PAVEMENTQ OQ OL = ---------------- O= ------- = 2.5 Q ( OFOR Y= 6" )C 0.399O A O 2gH OC = ORIFICE O COEFFICIENT = 0.60 " E XMATERIALHAND FINISHA = AREA O OF ORIFICE = 0.14 SQ. FT. / LN. FT.g = ACCELERATION OF GRAVITY = 32.2 FT. / SEC. / SEC.H = AVERAGE O DEPTH OF FLOW IN FEET = 0.35’ FOR Y = 6"BLOCKOUT LINE ANDCONSTRUCTION JOINTWARP FLOW LINE OFGUTTER TO MEETSLOTTED DRAINREINFORCED CCONCRETEPAVEMENTSLOTTED DRAINL = ADJUSTED LENGTH OF SLOTTED DRAIN DUE TO GUTTER GRADES/< 1% : NO ADJUSTMENTL O + L WS > 1% : L = -------1 - 4SFACE OF CURB1’-3"45^BACK OF CURB6" HT. CURBVARIABLEHEIGHT CURBINTEGRAL CURBGENERAL NOTES :5 " H1. ECONOMICAL INSTALLATION ON GRADE SHOULD BE DESIGNED TO PICK UP ORIFICE FLOWONLY AND BYPASS WEIR FLOW. FOR Y=6", USE Q 0 = 0.9Q.REINFORCED CONCRETE PAVEMENT2. SLOTTED DRAIN IS MANUFACTURED IN 20’ LENGTHS. INSTALLATIONS SHOULD BEMULTIPLES OF 20’ OR HALF-LENGTH SECTIONS OF 10’.PAVEMENT TRANSITION AT END OF SLOTTED DRAIN3. SPECIAL PERMISSION IS REQUIRED FOR SLOTTED DRAIN INSTALLATION IN SAGS.4. SLOTTED DRAINS WILL BE CONNECTED TO MAIN STORM DRAIN BY STANDARD BENDS,CONNECTING BANDS AND THE REQUIRED LENGTH AND SIZE OF CORRUGATED METAL PIPE.5. TRENCH BACKFILL MUST BE TAMPED TO 95% OF MAXIMUM DENSITY, OR ACEMENT - SAND CONCRETE SLURRY OR LEAN GROUT MAY BE USED.6. THE EXTRA CONCRETE FOR THE THICKENED PAVEMENT WILL BE INCLUDED IN THE COSTOF THE DRAIN.7. SLOTTED DRAIN PIPE WILL HAVE A MINIMUM DIAMETER OF 15" AND A MAXIMUM OF 24".8. PAVING DETAILS SHOWN ARE FOR USE WITH 6" DEEP GRATE ON SLOTTED DRAIN.S P E C I A L D E S I G N M U S T B E A P P R9. HEEL PLATE WILL BE INSTALLED ACCORDING TO MANUFACTURER’S RECOMMENDATIONS WHERESPECIFIED IN PEDESTRIAN AREAS. DESIGN LENGTH MUST BE ADJUSTED ACCORDINGLY.WATER MUST NOTOVERFLOW ON TO8% MAX. GRADEPRIVATE PROPERTYTNOTE: Z=- FOR SHALLOWYV- SHAPED CHANNELSC L3"TY6" MAX. DESIGN WATERDEPTHDTRENCH BACKFILLSEE NOTE NO. 5ADD 2- NO. 3 BARSEXTEND 2’ BEYONDEND OF SLOTTED DRAINDUSUAL ALLEYREINFORCEMENTAPPROVEDDIRECTOR OF PUBLIC WORKS & TRANSPORTATIONDATE:TRENCH BACKFILLSEE NOTE NO. 5WHERE SLOTTED DRAIN MAY BESUBJECT TO WHEEL LOADS, THICKENEDPAVEMENT WILL BE REQUIREDDRAINAGE DETAILSSECTION THROUGH DRIVESECTION THROUGH VALLEYALLEYS, PARKING LOTS, ETC.SLOTTED DRAINSIN STREETS AND ALLEYSDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119972005

NO FE NCING OR CO NST RUNOTE:TRENCH WIDTHS BASED ON1.25 Bc+1.0 WHERE Bc ISPIPEDIAMETER(INCHES)TRENCHWIDTH(FEET)24"COMPACTED BACKFILL TO95% MIN. DENSITYTHE OUTSIDE DIAMETER OFTHE PIPE IN FEET.1518213.03.43.8244.1COMPACTED BACKFILL 90%PROCTOR MINIMUM DENSITYNATURAL GROUNDOR ROCK27334.55.236425.66.348 7.054 7.860 8.566 9.2SELECT BACKFILL SALVAGED FROM TRENCH 72 10.0EXCAVATION MUST BE CLEAN AND FREE78 10.7OF LARGE ROCKS. IT MUST BE APPROVED8411.4BY THE ENGINEER AND STOCKPILED FORUSE WHEN NEEDED. IF ACCEPTABLE MAT-9012.1ERIAL IS NOT AVAILABLE, FLOWABLE BACKFILL96 12.9PER NCTCOG ITEM 2.15 (e) & (f) WILL BEREQUIRED.EMBEDMENT MATERIALDEPTH OF BEDDINGCRUSHED ROCKMATERIAL BELOWGRADATION: 0 RETAINED ON 1 1/4"PIPE95%-100% RETAINEDON NO. 10D (Inside Diameter) d (Min)27" OR SMALLER 3"30" TO 60" 4"66" & LARGER 6"d=DEPTH OF BEDDING MATERIAL BELOW PIPE.TRENCH WIDTHS SHOWN ARE MINIMUM FOR PROPERPLACEMENT AND COMPACTION OF EMBEDMENT ANDH=BACKFILL COVER ABOVE TOP OF PIPE.BACKFILL.TRENCH WIDTHS SHOWN WILL BE USED FOR CALCU-LATION OF ROCK EXCAVATION WHEN DESIGNATEDAS A PAY ITEM.6" 6"VARIESVARIES6"MIN.PREFAB. INLET BOX INSTALLATION6"MIN.dTOP OF SUBGRADEHConcreteGroundNO SCALE2’-0" 1’-0"Formed3000 psiD OF LO OD WAY3 1/4"+N O T DCT ION BE Y ON D T H IS P O IN TMAR KE R5/8" DIAM.REINF. RODBERNTSEN ModelROD 5325 ORIS T U R B3 1/4"24" 1/4"BACKFILL AROUND PIPEFLOWABLE FILL OR COMPACTEDSELECT MATERIAL FROMTRENCH EXCAVATION.90% PROCTOR MIN. DENSITYNOTE:Where Street or Alley iscrossed by the Storm Sewera 95% Proctor Min. DensityBc/2 1/8 H6" MINBcEQUALwill be required up to bottomof proposed subgrade.FLOOD MANAGEMENT MONUMENTIN NATURAL GROUNDREINFORCED CONCRETE CLASS IIIPIPE INSTALLATIONNOTE:FOR H>10’ DESIGN MUST BE CHECKED. UNLIMITED TRENCHWIDTH WILL NOT BE PERMITTED FOR CLASS III PIPE ANDHIGHER TYPE PIPE EMBEDMENT MAY BE REQUIRED.INSTALLATION WILL BE AS SHOWN OR AS DESCRIBEDIN THE GENERAL SPECIFICATIONS FOR CONSTRUCTIONTOP 24" OF BACKFILL MUST BE COMPACTEDTO 95% DENSITYUNDER PAVEMENT. SUBGRADE STABILIZATION UNDER STREETPAVEMENT SHALL BE COMPACTED TO 98% STANDARD PROCTORDENSITY AT +-2% OF OPTIMUM MOISTURE TO THE DEPTH SHOWNON THE PLANS AND IN ACCORDANCE WITH THE SPECIFICATIONS.MAXIMUM4:1 SLOPECAST IN PLACE INLET TOPAND TRANSITION REQUIRED6" 6"DETAIL OF CONCRETE COLLARFOR END TO END EXTENSIONS6" 6"6" FOR BACKFILL WITHFLOWABLE FILL TO FILL VOIDSOR COMPACT WITH SELECT SURPLUSEXCAVATION COMPACTED IN 8" LIFTSTO 95% STANDARD PROCTOR DENSITY.ROCK 3"ROCK FOUNDATION3" UNDERCUT FOR PLACEMENT OF PIPE BEDDINGAPPROVEDDATE:DIRECTOR OF PUBLIC WORKS & TRANSPORTATIONDRAINAGE DETAILSCONCRETE PIPE INSTALLATIONDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119972006

1TABLE OF DIMENSIONS AND QUANTITIES FOR TWO TYPE A HEADWALLSTABLE OF DIMENSIONS AND QUANTITIES FOR TWO TYPE B HEADWALLSNO. OFPIPESDIAM.OF PIPESTABLEREINF. STEEL FOR TWO HEADWALLSOFBARS A 1 BARS A 2 BARS E BARS F 1BARS F 2DIMENSIONS4 ~ #3 #3 @ 18" - + 4 ~ #5@ 12" +@-12" -+G K T E HW Lgth. Wt. No. Lgth. Wt. Lgth. Wt. No. Size Lgth. Wt. No. Size Lgth. Wt.TOTALQUANTITIESSTEEL CONC.LBS. C.Y.NO. OFPIPESDIAM.OF PIPESTABLEOFDIMENSIONSG K X H Y WNo.BARS A 1#4 @ 12" + -- A XAv. Lgth.Wt.REINFORCING STEEL AND QUANTITIES FOR TWO HEADWALLSBARS B BARS B 1 - B X C = 2’-0" BARS D 1 - D X BARS EBARS F#3 @ 18" - + #3 @ 18" - + #4 @ 12" #3 @ 12" - + 8 ~ #5No. Lgth. Wt. No. Av. Lgth. Wt. No. Wt. No. Av. Lgth. Wt. Lgth. Wt. No. Size Lgth. Wt.BARS G4 ~ #3Lgth. Wt.BARS S12 ~ #4Lgth. Wt.No.BARS V 1#4 @ 12" + -- V XAv. Lgth.Wt.BARS W4 ~ #5Lgth. Wt.*TOTALQUANTITIESSTEEL CONC.LBS. C.Y.112"~12"9"1’-9"2’-6"7’-0"6’-8"1082’-6"86’-8"2812#42’-11"2312#43’-8"29981.48112"~12"2’-4"2’-0"1’-0"2’-4"22’-8"462’-6"6~~~45~~~2’-0"178#42’-2"122’-8"48"542’-11"81’-8"768.522"10"""""8’-10"8’-6"13"""8’-6"3514""2714""341171.812"10""4’-2"""4’-2""4’-6"68"8~~~""~~~3’-10"3212""174’-6"7"""""""95.823""""""10’-8"10’-4"16"""10’-4"4316""3116""391372.153"""6’-0"""6’-0""6’-4"810"9~~~""~~~5’-8"4716""236’-4"10"""""""122 1.114""""""12’-6"12’-2"18"""12’-2"5118""3518""441562.484"""7’-10"""7’-10""8’-2"1112"11~~~""~~~7’-6"6320""298’-2"12"""""""151 1.40115"~12"9"1’-9"2’-9"8’-3"7’-11"1283’-0"97’-11"3312#43’-2"2512#43’-11"311101.82115"~12"2 ’2’-3"1’-6"3 ’43’-0"863’-0"741’-10"3811~~2’-3"198#42’-5"133’-7"51’-3"1083’-0"162’-3"9101.752"1’-0"""""10’-6"10’-2"15"""10’-2"4214""3014""371332.242"1’-0""4 ’ -""5 ’"5’-3"148"9"""""~~4’-6"3812""195’-10"9"""""""1381.163""""""12’-9"12’-5"19"""12’-5"5216""3416""421562.663"""7 ’""7 ’"7’-6"2010"11"""""~~6’-9"5616""268’-1"12"""""""1741.574""""""15’-0"14’-8"22"""14’-8"6118""3818""471773.094"""9 ’""9 ’ -"9’-9"2614"16"""""~~9’-0"7520""3210’-4"16"""""""2141.98118"~12"9"1’-9"3’-0"9’-6"9’-2"1483’-6"119’-2"3820#43’-5"4620#44’-2"561652.19118"~12"2’-11"2’-6"2’-0"4 ’43’-10"1063’-6"841’-10"381141’-0"22’-7"228#42’-8"144’-5"71’-10"15123’-2"252’-11"121291.002"1’-2"""""12’-2"11’-10"18"""11’-10"4922""5022""611892.702"1’-2""5’-7"""6 ’"6’-6"178"11""""""""5’-3"4412""217’-1"11"""""""1721.553""""""14’-10"14’-6"22"""14’-6"6024""5524""672153.213"""8’-3"""9 ’"9’-2"2512"16""""""""7’-11"6616""299’-9"15"""""""2192.114""""""17’-6"17’-2"26"""17’-2"7226""5926""722403.734"""10’-11"""1 2 ’"11’-10"3216"21""""""""10’-7"8820""3612’-5"19"""""""2642.65124"~12"9"2’-0"3’-6"12’-0"11’-8"1884’-6"1411’-8"4924#43’-11"6324#44’-11"792233.17124"~12"3’-6"3’-0"3’-0"5 ’65’-0"2064’-6"1041’-10"381141’-0"23’-2"268#43’-2"176’-2"93’-0"24163’-5"374’-2"171761.622"1’-5"""""15’-5"15’-1"23"""15’-1"6326""6826""852533.892"1’-5""6’-11"""9 ’"8’-5"3410"17""""""""6’-7"5512""259’-7"14"""""""2392.463""""""18’-10"18’-6"28"""18’-6"7728""7328""922844.623"""10’-4"""1 2 ’"11’-10"4716"27""""""""9’-10"8216""3413’-0"20"""""""3043.324""""""22’-3"21’-11"33"""21’-11"9130""7930""993165.354"""13’-9"""1 6 ’"15’-3"6120"34""""""""13’-5"11220""4216’-5"25"""""""3684.18130"~12"9"2’-3"4’-0"14’-6"14’-2"21165’-6"3314’-2"5928#44’-5"8328#45’-8"1063024.31130"~12"4’-1"3’-6"4’-0"7 ’86’-2"3365’-6"1283’-1"9121682’-2"73’-9"318#43’-8"207’-11"124’-2"33203’-8"495’-5"232452.342"1’-8"""""18’-8"18’-4"28"""18’-4"7632""9432""1213525.282"1’-8""8’-3"""1 1 ’"10’-4"5512"25""""""""7’-11"6616""3912’-1"18"""""""3403.583""""""22’-10"22’-6"34"""22’-6"9436""10636""1364036.263"""12’-5"""1 5 ’"14’-6"7718"37""""""""12’-1"10124""5916’-3"24"""""""4354.804""""""27’-0"26’-8"40"""26’-8"11140""11840""1524547.244"""16’-7"""2 0 ’"18’-8"10024"50""""""""16’-3"13632""7820’-5"31"""""""5326.04136"~12"12"2’-6"4’-6"17’-0"16’-8"25166’-6"3916’-8"7032#45’-2"11132#46’-8"1433886.40136"~12"4’-8"4’-0"5’-0"9 ’107’-4"4986’-6"2083’-1"9121682’-2"74’-4"368#44’-2"229’-8"155’-4"43243’-11"636’-8"283083.232"1’-11"""""21’-11"21’-7"32"""21’-7"9036""12436""1604457.892"1’-11""9’-7"""1 4 ’"12’-3"8214"34""""""""9’-3"7716""4514’-7"22"""""""4264.893""""""26’-10"26’-6"40"""26’-6"11140""13840""1785069.373"""14’-6"""1 9 ’"17’-2"11520"49""""""""14’-2"11824""6719’-6"29"""""""5446.554""""""31’-9"31’-5"47"""31’-5"13144""15244""19656510.854"""19’-5"""2 4 ’"22’-1"14728"68""""""""19’-1"15932""8924’-5"37"""""""6668.22142"~12"12"2’-9"5’-0"19’-6"19’-2"29167’-6"4519’-2"8036#45’-8"13636#47’-5"1784688.10142"~12"5’-3"4’-6"6’-0"1 1 ’128’-6"6887’-6"23124’-5"201621123’-3"154’-11"418#44’-8"2511’-5"176’-5"51284’-2"787’-11"333924.232"2’-2"""""25’-2"24’-10"37"""24’-10"10440""15240""1985369.962"2’-2""10’-11"""1 6 ’"14’-2"11416"45""""""""10’-7"8816""5017’-1"26"""""""5416.403""""""30’-10"30’-6"46"""30’-6"12744""16744""21860311.803"""16’-7"""2 2 ’"19’-10"15924"68""""""""16’-3"13624""7522’-9"34"""""""6908.564""""""36’-6"36’-2"54"""36’-2"15148""18248""23867013.684"""22’-3"""2 8 ’"25’-6"20432"90""""""""21’-11"18332""10028’-5"43"""""""83810.74148"~15"12"3’-0"5’-9"23’-0"22’-8"34248’-9"7922’-8"9540#56’-5"26840#58’-5"35182710.74148"~15"5’-10"5’-3"7’-0"1 2 ’149’-8"90108’-6"32124’-5"201621123’-4"155’-6"468#55’-5"4513’-2"207’-7"61324’-5"949’-3"394835.432"2’-5"""""29’-5"29’-1"44"""29’-1"12144""29544""38692513.082"2’-5""12’-3"""1 9 ’"16’-1"15018"58""""""""11’-11"9916""9019’-7"29"""""""6768.253""""""35’-10"35’-6"53"""35’-6"14848""32148""422102315.433"""18’-8"""2 5 ’"22’-6"21026"83""""""""18’-4"15324""13626’-0"39"""""""87111.074""""""42’-3"41’-11"63"""41’-11"17552""34852""457112217.774"""25’-1"""3 2 ’"28’-11"27036"115""""""""24’-9"20732""18132’-5"49"""""""107213.89154"~15"12"3’-3"6’-3"25’-6"25’-2"38249’-9"8825’-2"10544#56’-11"31844#59’-2"42197012.87154"~15"6’-5"5’-9"8’-0"14’-6"1610’-10"116109’-6"36124’-5"202027164’-5"276’-1"518#55’-11"4914’-10"228’-9"70404’-8"12510’-5"435866.712"2’-10"""""32’-10"32’-6"49"""32’-6"13650""36150""478111215.772"2’-10""13’-9"""21’-10""18’-2"19420"71""""""""13’-5"11220""12322’-2"33"""""""84510.283""""""40’-2"39’-10"60"""39’-10"16656""40456""536125418.663"""21’-1"""29’-2""25’-6"27330"107""""""""20’-9"17332""19829’-6"44"""""""110713.844""""""47’-6"47’-2"71"""47’-2"19762""44762""593139621.554"""28’-5"""36’-6""32’-10"35140"143""""""""28’-1"23444""27236’-10"55"""""""136717.42160"~15"12"3’-6"6’-9"28’-0"27’-8"422410’-9"9727’-8"11548#57’-5"37148#59’-11"497112215.20160"~15"7’-0"6’-3"9’-0"1 6 ’1812’-0"1441010’-6"39165’-9"352027164’-5"276’-8"568#56’-5"5416’-7"259’-11"80444’-11"14511’-8"496818.112"3’-0"""""36’-0"35’-8"54"""35’-8"14954""41854""559122718.552"3’-0""15’-0"""2 4 ’"20’-0"24022"87""""""""14’-8"12220""13425’-7"38"""""""98412.343""""""44’-0"43’-8"66"""43’-8"18260""46460""621143021.893"""23’-0"""3 2 ’"28’-0"33732"126""""""""22’-8"18932""21432’-7"49"""""""127816.574""""""52’-0"51’-8"78"""51’-8"21666""51166""683158525.244"""31’-0"""4 0 ’"36’-5"43844"174""""""""30’-8"25644""29540’-8"61"""""""158720.82166"~15"12"3’-9"7’-3"30’-6"30’-2"453211’-9"14130’-2"12652#57’-11"43052#510’-8"579132117.72166"~15"7’-7"6’-9"10’-0"1 7 ’2013’-2"1761211’-6"52165’-9"352432205’-7"427’-3"608#56’-11"5818’-4"2811’-1"89485’-2"16613’-0"547929.652"3’-1"""""39’-1"38’-9"58"""38’-9"16258""47958""645148521.492"3’-1""16’-2"""2 6 ’"21’-9"29124"104""""""""15’-10"13220""14426’-11"40"""""""112914.543""""""47’-8"47’-4"78"""47’-4"19864""52964""712165125.273"""24’-9"""3 5 ’"30’-4"40534"147""""""""24’-5"20432""23135’-6"53"""""""145819.424""""""56’-3"55’-11"84"""55’-11"23370""57870""779181529.054"""33’-4"""4 3 ’"39’-8"53046"199""""""""33’-0"27544""31844’-2"67"""""""180724.31172"~15"12"4’-0"7’-9"33’-0"32’-8"493212’-9"15332’-8"13656#58’-5"49256#511’-5"667149720.42172"~15"8’-2"7’-3"11’-0"1 9 ’2214’-4"2111212’-6"56165’-9"352432205’-7"427’-10"658#57’-5"6220’-1"3012’-3"98525’-5"18814’-3"5987811.322"3’-2"""""42’-2"41’-10"63"""41’-10"17562""54462""738167324.662"3’-2""17’-4"""2 8 ’"23’-6"34524"113""""""""17’-0"14220""15529’-3"44"""""""125316.913""""""51’-4"51’-0"77"""51’-0"21368""59768""810185028.893"""26’-6"""3 8 ’"32’-10"48238"179""""""""26’-2"21832""24838’-5"58"""""""163922.524""""""60’-6""60’-2"90"""60’-2"25174""65074""881202533.124"""35’-8"""4 7 ’"41’-10"61550"235""""""""35’-4"29544""34147’-8"72"""""""201728.1121DBars EELEVATION TYPE ABarsA21Bars FBarsA216"Bars EDELEVATION MULTIPLE TYPE AGC LHTBars EBars F 1Bars ABars F 26"BarsA 128"E9"KC SECTIONL6"DELEVATION TYPE B1’-0" 6" 1’-0"H6"DC LBars FGBars ABars BBars GELEVATION MULTIPLE TYPE B8"Bars EBars EConforms to 2: 1 SlopeBars CBar WDBars V1Bars D 1Bars B 1- V X- D XBars S- B X2’-6"1’-6" 1’-0"Bars D- D XBars V 1- VXBars WBars SBars A 1’-0"Bars BBars CBars FBars GProvide a 12"6"footing asshown whereKH6"4" Min.Bars Erequired to maintain 4" Min. coverfor pipes. Concrete for footing shall1A =2A = B 1 = 8"This dimensionreduced 1’-1 7/8" foreach successive bar.GENERAL NOTES:B = Y+4"This dimensionincreased 2’- 7" foreach successive bar.BARS A 1 - A X BARS B & B 1 - B X BARS CAll exposed corners shall be chamfered 3/4".Reinforcing steel shall be placed with the center of the outsidelayer of bars 2" from the surface of the concrete. Total Quantitiesinclude one 20 diameter lap for all bars over 60’-0" in length.1’-2"8"3"11"7"12be added to total quantities shownXXBars EBars ABars FW W/2Bars EE-12"BARS F2H + T- 4"30^8"Y8"30^Bars EBars GBars FBar WA ABars CBars FBars D 1Bars STYPICAL WING ELEVATION6"- DXBars B 1- BXBars VBars SBars BConst. Jt.APPROVEDDATE:DIRECTOR OF PUBLIC WORKS & TRANSPORTATIONDRAINAGE DETAILSCONCRETE HEADWALLSFOR PIPE CULVERTSPLAN TYPE APLAN MULTIPLE TYPE A6"W6"WBars VXBars A 1- V 1- AX6"Bars A 1 - A XDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXAS* Concrete quanitties increase slighty for metal pipe installationsPLAN TYPE BPLAN MULTIPLE TYPE BSEC. A-ADESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119972007

NOTES: APPLICABLE TO ALL MANHOLESASTD. M.H. FRAME & COVER6" 3’-0"6"FINISHED GRADE OF M.H.6" 3’-0"6"BARS "A"6"BARS "A"BARS "A"BARS "A"#3 AT 8" C-CBARS "B"1"2 " F R! " P I C KLL1"211" LETTERSBARS "B"R A IBARS "E"#3 AT 12" C-CBARS "B"#3 AT 12" C-C2STORM1"43’-0"DIAMETER OFSTORM DRAINT THEIGHT VARIESDIAMETER18"-30"C!2 "MACHINING2HALF PLAN OF FRAME31"2 !1" 21"14 2MACHINE THIS SURFACESECTION C-F14F2221"6"! " P I C K L2 " F RDRAINCPLAN OF COVER1" LETTERSR A I1"1"1"3"2 " A F T E R1 71"24"SECTION C-LMACHINED1’-0"1’-0"CAST IRON MANHOLE FRAME AND COVERBARS "C"BARS "D"#3 AT 8" C-CBARS "C"#3 AT 12" C-CBARS "D"AELEVATIONSECTION A-ATYPE A STORM SEWER MANHOLE( FOR PIPE 18" TO 30" IN DIAMETER )NOTE:FRAME AND COVER SHALL BE BASS & HAYESPATTERN NO. 380-24 OR EQUAL AND SHALL BEOF GRAY CAST IRON CONFORMING TOA.S.T.M. SPEC. A-48 FOR CLASS 30 CAST IRON.BARS "A" - #3SPACED AS SHOWNABARS "J" - #3STD. M.H. FRAME & COVERSPACED AS SHOWN1.PREFABRICATED MANHOLES OF EQUIVALENT STRENGTH AND DESIGN MAY BESUBSTITUTED WITH THE APPROVAL OF AN ENGINEER.6" 3’-0"6"FINISHED GRADE OF M.H.6" 3’-0"6"FINISHED GRADE OF M.H.P R O V I D E " P R E MJOINT BETWEEN MANHOLE AND CONCRETEPAVEMENT AND SEAL WITH HOT POURED RUBBER.2.CONCRETE SHALL HAVE A MINIMUM COMPRESSIVE STRENGTH OF 4000 LBS.PER SQUARE INCH AT 28 DAYS.BARS "J"6"BARS "J"3.MANHOLES SHALL BE BUILT ON THE MAIN SEWER LINE, LATERAL PIPES MAYENTER MANHOLES AT ANY LOCATION.BARS "A"BARS "A"BARS "A"#3 ATBARS "A"#3 AT 8" C-C4.MANHOLES WILL BE MEASURED AND PAID FOR AT THE CONTRACT UNIT PRICEPER EACH REGARDLESS OF MANHOLE DEPTH.BARS "I"#3 AT12" C-CBARS "I"VARIES8" C-CBARS "B"#3 AT12" C-CVAR.BARS "B"#3 AT 12" C-CTOP PLANTYPE A & TYPE BSTORM SEWER MANHOLENOTE: MAX. PIPE SIZE 78"5.6.CYLINDRICAL SHAPED MANHOLES MAY BE USED AS DIRECTED BY ENGINEER INLIEU OF MANHOLE DESIGN SHOWN ON THIS PAGE.CONCRETE FOR PAVEMENT BLOCKOUTS SHALL BE CLASS HAND FINISH CONCRETE( 4500 P.S.I. ).6" 6"CONST. JOINT1CONST. JOINTCONST. JOINTBARS "D"1.5"BARS "D"1’-1"BARS "C"SPACED ASSHOWNBARS "D"4- #6’sEACH SIDE1’-1"NOTE:BASS & HAYES PLASTIC COATED STEEL,NEOPRENE COATED STEEL STEPS OR EQUALSHALL BE PLACED SECURELY INTO MANHOLEWALLS ON 15" CENTERS VERTICALLY ANDDIAMETER OFSTORM DRAINLENGTH4’-0" MINT DTBARS "E"BARS "F"BARS "C"CONST. JOINT3’-0"3"TDIAMETER33"-78"1D+TBARS "E" #3AT 8" C-CBARS "F"#5 AT8" C-CBARS "C"#3 AT12" C-CSTAGGERED ON 12" CENTERS HORIZONTALLY.1’-0"1’-0"210"10"BARS "G"#3 AT 6" C-CBARS "H"#3 AT 12" C-C7"BARS "H"BARS "G"7"WIDTHAPPROVEDDIRECTOR OF PUBLIC WORKS & TRANSPORTATIONA4’-0" MINMANHOLE STEP DETAILDATE:ELEVATIONSECTION A-ABASS & HAYES FOUNDRY# MA ( PLASTIC )DRAINAGE DETAILSTYPE B STORM SEWER MANHOLEMANHOLES AND( FOR PIPE 33" TO 78" IN DIAMETER )FITTINGSDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDRAWNDESIGN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119972008

FLOODWAYEASEMENTFLOODWAYEASEMENT3’ MIN.NATURAL GROUND ELEVATIONC OF SYMMETRYLHYDROMULCHING3’ MIN.NATURAL GROUND ELEVATIONC OF SYMMETRYLHYDROMULCHING3-112"MIN.9"3-13-112"MIN.9"3-1( COMPACTED FILLWHERE FILL REQUIRED)#4 BARS AT 12" C. TO C.2-1 SLOPE6"3"WATER SURFACE2’ MIN.LAP 15"1" TO 1’ SLOPE12"WATER DEPTHMIN.MAX. LINED DEPTH-8’W/O SPECIAL DESIGN2-1 MAXIMUM SLOPE12"12"#4 BARS AT 15" C. TO C.#4 BARS AT 12" C. TO C.SEE DETAIL "A"10 MIL. FILM2-1 SLOPE6"3"2’ MIN.LAP 15"MAX. LINED DEPTH-8"12"WATER DEPTHMIN.WATER SURFACE2-1 MAXIMUM SLOPE12"12"( COMPACTED FILLWHERE FILL REQUIRED)(90% DENSITY)#4 BARS AT 12" C. TO C.6"3"BOTTOM WIDTH18"3" WEEPHOLES AT 15’ C. TO C. & 18" X 12"CONTINUOUS GRAVEL TRENCHES ALONG EACHSIDE OF THE CHANNEL.6" 12"6"3"BOTTOM WIDTH10’ MINIMUM8"18"NORMAL CHANNEL SECTIONPAVED ALLEY SECTIONNORMAL CHANNEL SECTION MAY BE USED IN ROCK1 " B EWATER SURFACE13:124"VARIESNOTE: WEEPHOLE SPACING 15’ O. C. LONGITUDINAL3" WEEPHOLESHYDROMULCHING3:121 3 " B2"(COMPACTED FILLWHERE FILL REQUIRED)12"12"3"(90 % DENSITY)3"2"11CONSTRUCTION JOINTFOR NORMAL CHANNEL3" WEEPHOLES6" ROCK FOUNDATION6"3"6"#4 BARS AT 12" O. C.#4 BARS AT 15" O. C.10 MIL. FILMBOTTOM WIDTH6" 6"10’ MINIMUM18"CONSTRUCTION JOINTFOR PAVED ALLEY SECTIONPARTIAL CHANNEL LINING SECTION " D I A . B A R S S PSLEEVE FOR DOWEL SHALL HAVEA N I N S I D E D I A MSHALL BE 5" LONGSHALL SERVE AS DOWELS. DOWELS TO BEASPHALT COATED FOR 12" ON THE FREE END.SPACE 12" C. TO C.9"1 " B EJOINT FILLER5"3" 12"3"NOTES:1.ALL CONSTRUCTION SHALL BE IN CONFORMITY WITH CURRENT CITY OFDALLAS GENERAL SPECIFICATIONS.2. CONSTRUCTION JOINT SHOWN FOR CONVENIENCE ONLY - MONOLITHIC6"DETAIL "A"3"CONSTRUCTION MAY BE USED3.ALL REINFORCING STEEL SHALL BE #4 AND SPACED 12" C. TO C. BOTHWAYS UNLESS OTHERWISE SPECIFIED.3" 9" 2"4. CONCRETE SHALL HAVE A COMPRESSIVE STRENGTH OF 3000# AT 28DAYS AND SHALL CONTAIN A MINIMUM OF 5 SACKS OF CEMENTPER CUBIC YARD. " E X P A N S I O N J O I N T A12"5. SIDE SLOPES SHALL BE NO STEEPER THAN 2-1.APPROVEDDIRECTOR OF PUBLIC WORKS & TRANSPORTATIONTRANSVERSE EXPANSION JOINT6. TOP OF CURB OF ADJACENT ALLEY OR STREET IS MINIMUM OF 2’ ABOVE100 YEAR W. S.DATE:7. USE A SMOOTH TROWEL FINISH ON BOTTOM AND SLOPED SURFACES.USE ORDINARYSURFACE FINISH ON VERTICAL SURFACES.8. WHEN SOLID ROCK IS ENCOUNTERED BY NORMAL CHANNEL SECTION, REMOVE6" DEPTH OF SOLID ROCK AND REPLACE WITH 6" DEPTH OF CRUSHED ROCKFOUNDATION BELOW PROPOSED CHANNEL STRUCTURE.DRAINAGE DETAILSLINED CHANNELSDEPARTMENT OF PUBLIC WORKS & TRANSPORTATIONCITY OF DALLAS, TEXASDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119972009

3’-6"6’-2 1/4"8’-10 1/2"BA3’-2 1/4" 6"4’-2 1/4"AAB C C D D E3’-2 1/4" 6"4’-2 1/4"3’-2 1/4" 6"4’-2 1/4"10’-6 3/4"A6"3’-2 1/4"4’-2 1/4"E6"6"6"PLAN VIEW PLAN VIEW PLAN VIEW PLAN VIEWTWO GRATE INLET FOUR GRATE INLET SIX GRATE INLET EIGHT GRATE INLET6" 6"2’-6" 6" 6"7’-10 1/2"5’-2 1/4" 6" 6"60 LB. RAIL 3’-4" LONG60 LB. RAIL 11’-5" LONG3/4" X 4" MCH. BOLTS3/4" X 4" MCH. BOLTS4’-2" MIN.3’-8" MIN.12"4’-2" MIN.3’-8" MIN.60 LB. RAIL 6’-0" LONG1/2" MORTAR FINISH, TROWEL TO ASMOOTH HARD SURFACE60 LB. RAIL 8’-8" LONG1/2" MORTAR FINISH, TROWEL TO ASMOOTH HARD SURFACE3/4" X 4" MCH. BOLTS6"6"6"6"AAAANO SCALENO SCALENO SCALENO SCALE3’-6"6’-2 1/4"8’-10 1/2"11’-6 3/4"1/2" MORTARFINISHTROWEL TO ASMOOTH HARDSURFACEVARIABLE12"VARIABLE4’-2" MIN.3’-8" MIN.12"VARIABLE4’-2" MIN.3’-8" MIN.12"6" 10’-6 3/4"6"1/2" MORTAR FINISH, TROWEL TO ASMOOTH HARD SURFACEVARIABLE6"SECTION B-BSECTION C-CSECTION D-DSECTION E-E3/16" CLEARANCE AROUND GRATES2 1/2"G1/8"2 7/8"4’-2" MIN.3’-8" MIN.6"60 LB. RAIL6" 3’-2 1/4"6"4’-2 1/4"DEPRESSION OF GRATESTO SUIT CONDITIONSSIDE LUGS - TOP 5/8" X 1 1/8"BOTTOM 1" X 1 1/8"RFCORNER LUGS 1-1/8" X 1"LHLHRHLHRBL 5/8" BR5/8"FRL2’-8"2’-6 1/4"7/8"7/8"2’-5 3/4"1/4" 1/4"1/8" 1 1/8"1/8"LUGS2’-6"1 1/8"2 7/8"4"4"3’-2"SEE SHEET 9010FOR GRATE DETAILSEE SHEET #2004FOR STEEL DETAILSFOR WALLS ANDBOTTOM1. LATERAL MAY ENTER INLET AT ANY GRADE,ANGLE OR LOCATION.2. EXCAVATION, FRAMES, GRATES AND COVERS SHALLBE INCLUDED IN UNIT PRICE.3. EXTRA DEPTH INLETS WILL BE DIMENSIONED ONPLANS. A SEPARATE BID ITEM PER FOOT OFEXTRA DEPTH MAY BE PROVIDED.4. TYPE "L" GRATES SHALL BE USED AS SHOWN ONSHEET 9010.5. PROVIDE EXPANSION JOINTS AT EDGE OF ALL BLOCKOUTSFOR STREETS AND ALLEYSSECTION A-AGPLAN VIEW1 3/8"3"5"5/8"20"7/8"18 1/4"17 3/4"7/8"SECTION G-GTYPE "L" GRATE R-30762 1/2"1/8"1/4" 1/4"1 3/8"LUGMODIFICATIONS FOR DOUBLE AND TRIPLE GRATE INLETS (PAGE 2002)FOR STANDARD DOUBLE GRATE INLETS; ON RIGHT FRAME OMIT FLANGE ON LINE"L/L" AND ADD BRACKET "BL" AND CORE HOLES "HL", ON LEFT FRAME OMITFLANGE ON LINE "R/R" AND ADD BRACKET "BR" AND CORE HOLES "HR". FOR STANDARDAPPROVEDDATE:DIRECTOR OF PUBLIC WORKS & TRANSPORTATION2 5/8"5/8"1 1/4"3"5/8"5"TRIPLE GRATE INLETS; USE ONE RIGHT FRAME AND ONE LEFT FRAME AND ONE FRAMEOMITTING BOTH END FLANGES, ADD BRACKETS "BR" AND "BL" AND CORE HOLES "HR"AND "HL".THE AVERAGE WEIGHT OF ALL GRATE INLETS SHALL NOT BE LESS THAN 153 LBS.DRAINAGE DETAILSTWO, FOUR, SIX & EIGHT1 1/8"CORE FOR 3/4" BOLT18"1 1/8"THE AVERAGE WEIGHT OF SINGLE GRATE INLET FRAME SHALL NOT BE LESS THAN185 LBS., THE DOUBLE GRATE INLET FRAMES SHALL NOT BE LESS THAN 177 LBS.EACH, AND THE CENTER FRAMES SHALL NOT BE LESS THAN 170 LBS. EACH.GRATE INLETS, GRATE DETAILSDEPARTMENT OF PUBLIC WORKS & TRANSPORTATION20-1/4"2 7/8"CITY OF DALLAS, TEXASSECTION F-FTYPE "L" GRATE R-3076FRAME DETAILNO SCALEDESIGN DRAWN DATE FILE NO. PAGE NO.APRILC.O.D. A.B.&A. 251D 119972010