WJPRO Operating Guide - Hasler Inc.

WJPRO Operating Guide - Hasler Inc.

WJPRO Operating Guide - Hasler Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INTRODUCTIONCongratulations for choosing the <strong>Hasler</strong> WJ Pro mailing machine.The WJ Pro is the result of the expertise and innovative capabilitiesof the worldwide <strong>Hasler</strong> group and using ink jet technology, it willintegrate into your working environment to enhance your mailprocessing operation.The WJ Pro mailing system is dedicated to the productioninserter environment connected either mechanicaly orelectronically to high speed inserter up to 15K envelopes/hour.The WJ Pro is a unique communication tool for your company.Its high quality printing combined with its integrated library ofadvertisement messages, mail class texts and free format text willgive you extra tools to enhance your company’s image and theimpact of your mail.The WJ Pro has many capabilities that are important to yourbusiness:As well as being productive (up to 250 letters per minute), the WJPro is designed to be a user friendly machine that can fit into theproduction environment with its innovative and attractive design,simple user settings and very low noise level. The high volumecapacity ink system makes it easy and safe to handle, and theuser interface is particularly clear with a touch graphic display andpop up menus.The WJ Pro is adaptable and as such can handle many differenttypes of mail. The machine can be used to process, in a continuouscycle, items of different sizes (ranging from postcards to largeflats) and items of various thickness (up to 5/8 inch), with automaticimprint shift. For thicker mail items or packages, adhesive labelscan be automatically dispensed.It’s automatic thickness adjustment and inkjet printing ensurereliable processing and quality imprints including thick and unevenmaterial.You will very soon discover by yourself that the WJ Pro is theultimate in quality and productivity for mail processing equipment.14131935Y/C17/09/2008ORIG0077-1

WARNING!Do not remove any secured covers or attempt to repair the WJ Pro byyourself, there are no user serviceable parts contained and the WJPro product is licensed for use only under the conditions of the PostOffice rules. This license is issued subject to the product being secureat all times. Any removal of covers or dis-assembly of the product willresult in the license being revoked and may result in the Post Officerequesting <strong>Hasler</strong> to remove the product from use.The inking system used within the WJ Pro contains Post Officeapproved ink. This cartridge should not be tampered with in any wayor the use of non approved inks be attempted. This will breach anyPost Office licence agreement on the product and may result in thePost Office requesting <strong>Hasler</strong> to remove the product from use.FCC COMPLIANCE STATEMENTThis equipment has been tested and found to comply with the limitsfor a Class A digital device, pursuant to Part 15 of the FCC Rules.These limits are designed to provide reasonable protection againstharmful interference when the equipment is operated in a commercialenvironment. This equipment generates, uses, and can radiate radiofrequency energy and, if not installed and used in accordance with thisinstruction manual, may cause harmful interferences to radio communications.Operation of this equipment in a residential area is likelyto cause harmful interference, in which case the user will be requiredto correct the interferences at his own expense.The internal modem of this equipment complies with Part 68 of theFCC rules.INSTALLATIONThe power plug on this equipment is intended to serve as the devicefor isolation of the electrical supply. The equipment should be installedin close proximity to easily accessible electrical outlet and telephonewall connector.No part of this document may be reproduced or transmitted in anyform or by means, electronic or mechanical, for any purpose withoutthe express written permission of <strong>Hasler</strong>.Copyright© <strong>Hasler</strong> 200624131935Y/C17/09/2008ORIG0077-2

TABLE OF CONTENTSGETTING STARTED ............................................. 7SECTION A: BASIC FUNCTIONS ........................ 91. OVERALL PRESENTATION ................................................ 111.1 Overview ................................................................ 111.1.1 Overall view ................................................... 111.1.2 Overall inside view ......................................... 121.1.3 Touch screen and keyboard............................ 131.2 Installing the machine .............................................. 151.2.1 Prepare the mailing machine ......................... 151.2.2 Connections at the rear of the machine .......... 161.2.3 Ink reservoir and printhead ............................. 181.3 Connecting The Mailing Machine To An Inserter ........ 212. PROTECTING THE MACHINE BY AN ACCESS PIN CODE 223. ENTERING POSTAGE VALUE AND PROCESSING MAIL 233.1 Entering A Postage Value ....................................... 243.2 USING VALUES ..................................................... 273.2.1 Inserter NOT Connected to the Mailing Machine(NOT CONN.)................................................. 273.2.2 Inserter Connected to the Mailing Machine(ELECTRO or SERIAL).................................. 273.3 Processing Mail ..................................................... 283.3.1 Inserter NOT Connected to the Mailing Machine(NOT CONN.)................................................. 283.3.2 Inserter Connected To The Mailing Machine(ELECTRO or SERIAL).................................. 293.3.3 Pass through mode ........................................ 293.3.4 Autoclean process ......................................... 303.3.5 Date advance function .................................... 324. MODIFYING OF THE IMPRINT ..........................................3434131935Y/C17/09/2008ORIG0077-3

5. CONNECTING TO DEPARTMENTS .................................. 366. CONNECTION TO TELE METER SETTING® SERVER ..386.1 Adding Postage ..................................................... 386.2 Clearing a PO lockout ............................................ 396.3 Completing an interrupted add postage transaction 407. USING OPTIONAL STATUS LIGHTS TOWER ..................418. PC CONNECTION ...............................................................42SECTION B: ADVANCED FUNCTIONS .............431. ADDITIONAL OPERATIONS PERFORMED BY THE MA-CHINE ...................................................................................451.1 Printing on labels .................................................... 451.2 Date printing........................................................... 451.3 Message printing.................................................... 451.4 Report printing ........................................................ 462. MACHINE CONFIGURATION PRINTING (SUPERVISORMODE) .................................................................................. 552.1 Enabling The Supervisor Mode............................... 552.2 User setup (in supervisor mode) ............................. 592.3 Supervisor setup .................................................... 592.3.1 Security and high value alert ........................... 602.3.2 Low funds alert ............................................... 612.3.3 Time .............................................................. 622.3.4 Time-out ......................................................... 632.3.5 Touchscreen calibration.................................. 662.3.6 Serial Port Setup ........................................... 672.3.7 Ink spitting management ................................ 682.4 Display setup ......................................................... 692.5 Departments .......................................................... 692.6 Print alignment setup .............................................. 712.7 Reports .................................................................. 722.8 Ink information ........................................................ 732.9 Postal services ....................................................... 7444131935Y/C17/09/2008ORIG0077-4

2.10 Downloading an advertisement slogan ................... 762.11 Text modification..................................................... 782.12 Exiting the supervisor mode.................................... 79SECTION C: MACHINE CONFIGURATION .......811. MAILING MACHINE GENERAL CONFIGURATION ...........832. CONFIGURATION OF THE MAIN SCREEN DISPLAY ...... 842.1 Info Area ................................................................. 842.2 Batch configuration area ......................................... 86SECTION D: MAINTENANCE .............................871. TROUBLE SHOOTING ....................................................... 891.1 Misfeed in the mailing machine............................... 891.2 Machine problems .................................................. 912. GENERAL MAINTENANCE .................................................932.1 Roller cleaning ........................................................ 932.2 Printhead cleaning.................................................. 942.3 Removing the postage meter .................................. 952.4 Touchscreen precautions ........................................ 96SECTION E: MAINTAINING YOUR TELE METERSETTING® ACCOUNT ...................................971. ACCOUNT NUMBER ...........................................................992. ACCOUNT BALANCE .......................................................... 993. POST OFFICE REGULATIONS ..........................................994. POSTAGE NOW ................................................................. 1005. STANDARD TMS® BANK ACCOUNTS ............................ 1016. WHERE TO MAIL YOUR DEPOSIT: ................................. 10354131935Y/C17/09/2008ORIG0077-5

SPECIFICATIONS ............................................ 105ORDERING SUPPLIES..................................... 106CONTACT INFORMATION............................... 107INDEX ................................................................ 10864131935Y/C17/09/2008ORIG0077-6

GETTING STARTED1 Place envelopes in your inserter.2 Configure in supervisor mode the rates on the mailing systemby doing the following:- Log in using the Supervisor Pincode.- Press the «Batch Config» area to enter rates programmingsection.- Press the SETUP key to be able to modify the preset values.- Define a mail class and an amount for RATE 1, RATE 2...to RATE 10.- Validate your setting by pressing OK .- Logout from the Supervisor.3 Configure in user mode the postage to be used for the batch ofenvelopes by doing the following:- Press the «Batch Config» area to enter rates programmingsection.- Select «setting A», «setting B» and «setting C» (SettingsB and C are hidden if you have a mechanical connection)- For each setting, choose a rate class in the list.- Validate your setting by pressing OK .4 Start meteringEither press STARTSTOPwith mechanical connection, or send «startorder» from the inserter with electronic connection (assuming theconnection has been enabled when you have connected the cablebetween the inserter and the mailing machine).Congratulations! You have succeeded in metering your firstenvelope.Getting Started 74131935Y/C17/09/2008ORIG0077-7

Special iconsSignals an essential piece of information that cannot bemissed.Signals an important issue.Indicates an interesting idea or trickIllustrates through an example84131935Y/C17/09/2008ORIG0077-8

SECTION A: BASIC FUNCTIONS1. OVERALL PRESENTATION ............................................. 111.1 Overview 111.1.1 Overall view 111.1.2 Overall inside view 121.1.3 Touch screen and keyboard 131.2 Installing the machine 151.2.1 Prepare the mailing machine 151.2.2 Connections at the rear of the machine 161.2.3 Ink reservoir and printhead 181.3 Connecting mailing machine to an inserter 212. PROTECTING THE MACHINE BY AN ACCESS PIN CODE 223. ENTERING POSTAGE VALUE AND PROCESSING MAIL 233.1 Entering A Postage Value 243.2 USING VALUES 273.2.1 Inserter NOT Connected to the Mailing Machine(NOT CONN.) 273.2.2 Inserter Connected to the Mailing Machine(ELECTRO or SERIAL) 273.3 Processing Mail 283.3.1 Inserter NOT Connected to the Mailing Machine(NOT CONN.) 283.3.2 Inserter Connected To The Mailing Machine(ELECTRO or SERIAL) 293.3.3 Pass through mode 293.3.4 Autoclean process 303.3.5 Date advance function 324. MODIFYING OF THE IMPRINT ........................................ 345. CONNECTING TO DEPARTMENTS.................................. 366. CONNECTING TO POSTAGE-ON-CALL® SERVER ......... 386.1 Adding Postage 386.2 Clearing a PO lockout 396.3 Completing an interrupted add postage transaction 407. USING OPTIONAL STATUS LIGHTS TOWER ................. 418. PC CONNECTION ............................................................ 4294131935Y/C17/09/2008ORIG0077-9

104131935Y/C17/09/2008ORIG0077-10

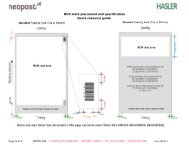

1. OVERALL PRESENTATION1.1 Overview1.1.1 Overall viewpre-cutlabeldispenserink reservoircoverON/OFFswitch(rear)modemconnector(rear)covertouchscreencontrolpanelpaperpathkeyboardmemorycardreaderOverall presentation 114131935Y/C17/09/2008ORIG0077-11

1.1.2 Overall inside viewinkreservoirprintheadpostagemeter12Overall presentation4131935Y/C17/09/2008ORIG0077-12

1.1.3 Touch screen and keyboardbatchconfigurationworkingmodesignal lightstatus whenconnectedpostagevalueuser definedlist ofparameterstextadvertisementdatewarningmessageTEXTABC 1MODELETTERBOXAD DIELIGHTBATCH CONFIGONDEPT 1 MARKETING1NEWPRESORTREPORTDEPTINFOTOI XXXXXX00.000LOW POSTAGEXX/XX/XXXXHOME LOGIN CLEANselection keyslinked totouch keys on the screenOverall presentation 134131935Y/C17/09/2008ORIG0077-13

locking and standby modeRESETreturn to main menu with default settingslabel mode selectionCSTARTSTOPinput value reset-clearswitching on/off envelope or label feed when noelectronic connection with the inserter.0 to 9 numeric entry keysOK or OK validating a selectionESCAPEreturn to previous menu with no validationHOMEreturn to main menu with no validation (excepttimeout)LOGINaccess to Supervisor mode and Service modeevery timeLOGOUTreturn to User modeindicates that there are other choices orselections in the next pageindicates that there are other choices orselections in the next and previous pagesindicates that there are other choices orselections in the previous page14Overall presentation4131935Y/C17/09/2008ORIG0077-14

1.2 Installing the machine1.2.1 Prepare the mailing machineThe mailing machine has to be installed on a flat, horizontalsurface. It is always near an inserter, connected or not electronically.Please allow sufficient free space as follows:- above the machine to enable the opening of the covers.- at the rear of the machine for cooling.With the O/I switch in the “ O ” position, connect the power cord tothe rear of the machine and to an 110V AC electrical outlet.Insert one end the telephone cable into the modem connector atthe rear of the machine and the other to an analog telephone walljack to enable Tele Meter Setting ® resetting connection.For security purposes, please ensure that all the items arecorrectly assembled prior to switch on the configuration.Overall presentation 154131935Y/C17/09/2008ORIG0077-15

1.2.2 Connections at the rear of the machineConnections at the rear of the mailing machineModemPrinterPort 2Port 4Port 3Inserterconnector(1)Port 1:Optional lightterminatorbe sure toinstall theblackterminatorplug here(1) Specific optional cable provided by the production folderinserter manufacturer.A connection error may generate a failure.16Overall presentation4131935Y/C17/09/2008ORIG0077-16

InserterconnectorAC power outletOverall presentation 174131935Y/C17/09/2008ORIG0077-17

1.2.3 Ink reservoir and printheadIt is possible to replace the reservoir when the machine is OFF orwhile machine is running until the final "ink out" message appears.To prevent unpriming of the system, this operation should last lessthan one minute. If it takes longer, the machine will stop automaticallyuntill the user completes the operation and restarts the machine.It is possible to replace the printhead when the machine isswitched on (no possibility when the machine is OFF).WHEN TO REPLACE INK RESERVOIR ORPRINTHEAD- When the message "ink low" is displayed, printing may continue;- When the message "ink very low" is displayed, printing maycontinue, but it is strongly recommended to replace the inkreservoir;- When the message “ink out” appears, ink reservoir must bereplaced before continuing operation.In the first and second cases, it is possible to replace theink reservoir while machine is running.INK RESERVOIR REPLACE-MENT PROCESS(1)If the machine is not running,switch machine OFF, then:- Open the reservoirdoor (1).- Press on the frontof the ink reservoir(2), then on the righthand side (3) inorder to remove it.(2)(3)18Overall presentation4131935Y/C17/09/2008ORIG0077-18

- Remove inkreservoir.- Insert the new inkreservoir .(2)(3)- Press on thefront of the inkreservoir (1),then on the lefthand side (2) inorder to lock it.(1)- Close thereservoir door(3).- Switch machineON.PRINTHEAD REPLACEMENTThe machine must be switched on.- Open the top cover and printheadcover: the printhead will move to the“replacement” position.Overall presentation 194131935Y/C17/09/2008ORIG0077-19

- Press on the front of the printhead in order toremove it.- Remove it.- Insert the new printhead.- Lock it in position by pinching the rear of theprinthead.- Close top cover (the printhead is automaticallyreset in the “protection” position).20Overall presentation4131935Y/C17/09/2008ORIG0077-20

1.3 Connecting The Mailing Machine To An InserterThree CONTROLLER modes are available:NOT CONN.: A physical connection between the mailing machineand inserter.- The mailing machine is positioned at the end of the inserter.- Mailing machine and inserter do not control each other.- Used for printing a single postage value (rate).ELECTRO : An electronic connection using a cable between themailing machine and inserter.- A cable is attached from the mailing machine's inserterconnection port to the inserter.- Inserter controls the mailing machine.- Used when a customer only requires three rates.SERIAL : A serial connection which requires a specific serialport setup by your service provider.- A cable is connected from the mailing machine's serial port tothe inserter.- Inserter controls the mailing machine.- Used when a customer requires more than three rates.Selecting CONTROLLER Mode:- From the main screen, press MENU and select USER SETUP.- Press OK . The following screen will be displayed:USER SETUP SUPER... DISPL...LANGUAGEBUZZERAMERICAN ENGLISHOFF ON ERR ON KEYCONTRAST-16 +CONTROLLERNOT CONN.ELECTROSERIALHOMELOGOUTDEFLTOK- Select NOT CONN., ELECTRO, or SERIAL.Overall presentation 214131935Y/C17/09/2008ORIG0077-21

2. PROTECTING THE MACHINE BY AN ACCESS PINCODEAt power-up or when pressing a key if the machine is in the sleepmode, the screen may prompt you to enter a 4-digit user pin code(when access to the machine has been protected by thesupervisor).PIN NUMBER ?****ESCAPEOK- If the department mode option is activated, the list of thedepartments available is displayed as follows:DEPARTMENTS1 DIRECTION2 MARKETING3 FINANCE4 RESEARCH5 FACTORYLOGINOK- Select the desired department using the up and downarrows.- Press OK .- If the department is protected by a code, enter the code (4digits), using the numeric keypad.The machine is ready and displays the main menu.22Protection by an access PIN code4131935Y/C17/09/2008ORIG0077-22

3. ENTERING POSTAGE VALUE AND PROCESSINGMAILThere are 2 modes to meter mail:- Letter Box Mode- Presorted ModeLetter Box ModeThis function is designed to allow the user to print in Letter Boxmode for non-presorted mail and adds the FIM MARK near theindicium as requested by the USPS.Presorted ModeThis function is used with presorted mail. No FIM D mark isrequired for automated presort mail.Entering Postage Value and Mail Processing 234131935Y/C17/09/2008ORIG0077-23

3.1 Entering A Postage ValueThere are 20 mail class allocations regardless of Letter Box orPresorted mode.5 are pre-defined and can be changed by the Supervisor:- Presorted First Class- First Class Auto- Standard- Presorted Standard- Nonprofit Org15 are empty and to be defined by the Supervisor.The first and last postage class screens are shown below:POSTAGE CLASSMAIL CLASSRATE 0 STANDARDRATE 1SUPAMOUNT08.05605.040 11002RATE 2RATE 3PRSRT STD00.000 1100200.000 11002ESCAPENEXTOK.../...POSTAGE CLASSMAIL CLASSRATE 16 STANDARDRATE 17SUPAMOUNT08.05605.040 11002RATE 18RATE 19PRSRT STD00.000 1100200.000 11002ESCAPENEXTPREVOK- The supervisor manually enters the 20 pre-default postage rates bypressing the MAIL CLASS and the AMOUNT for each rate.- After the rate selection is complete, press OK .It is up to the supervisor to check that mail classes andamounts are in line with USPS requirements.24Entering Postage Value and Mail Processing4131935Y/C17/09/2008ORIG0077-24

To configure postage class settings in Supervisor mode:- On the main screen, touch the BATCH CONFIG button.One setting is displayed on the BATCH CONFIGURATIONtab if the inserter is not connected (NOT CONN.).BATCH CONFIGURA...FRAC...MODESETTINGSETTINGAPRSRT FIRST-CLASS MAIL 00.123SETTINGLABELANOT ACTIVEHOMELOGINOK- Press SETTING SETTINGA to preset the SETTING A configurations.Three settings are displayed on the BATCH CONFIGURATIONtab if the inserter is connected (ELECTRO or SERIAL).BATCH CONFIGURA...FRAC...MODESETTINGSETTINGASETTINGSETTINGBASETTINGSETTINGCASETTINGLABELAPRSRT FIRST-CLASS MAIL 00.123NOT ACTIVENOT ACTIVENOT ACTIVEHOMELOGINOK- Press SETTINGSETTINGA to preset the SETTING A configurations.- Continue to preset the desired postage class configurations forSETTING A, SETTING B, and SETTING C.When the serial interface is activated, the label dispenseris automatically disabled.Entering Postage Value and Mail Processing 254131935Y/C17/09/2008ORIG0077-25

By touching MAIL CLASS key:RATE 1 : MAIL CL.RATE 1 : AMOUNT01 PRSRT FIRST-CLASS MAIL2 FRIST-CLASS AUTO3 STANDARD4 PRSRT STD5 NONPROFIT6ESCAPEMODIFYOKBy touching MODIFY key:MAIL CLASS24 CH. MAXPRSRT FIRST-CL_SUPQ W E R T Y U I OPA S D F G H J KLZ X C V B N MSPACEESCAPE 123 OKBy touching AMOUNT key:RATE 1 : AMOUNT5 DIGITSOLD VALUE :NEW VALUE :00.095_SUP0 123 4.5 6 78 9ESCAPEOK- Once the machine has been pre-set by the supervisor, either atthe installation or later, user can activate postage.- The user can set postage values once the supervisor has presetthem.26Entering Postage Value and Mail Processing4131935Y/C17/09/2008ORIG0077-26

3.2 USING VALUES3.2.1 Inserter NOT Connected to the Mailing Machine(NOT CONN.)A user can choose the postage amount to activate among the 20supervisor pre-set amounts.BATCH CONFIGURA...FRAC...MODESETTINGSETTINGAPRSRT FIRST-CLASS MAIL 00.123SETTINGLABELANOT ACTIVEHOMELOGINOK3.2.2 Inserter Connected to the Mailing Machine(ELECTRO or SERIAL)- A user can store 3 amounts among the20 pre-set by thesupervisor as references for the inserter.- The inserter can process mail with one of those 3 amounts in thesame batch.SETTING A SETTING B SETTING CMAIL CLASSAMOUNT0 NOT ACTIVE1 PRSRT FIRST-CLASS MAIL 00.1232 00.0003 FIRST-CLASS AUTO 01.6804 00.0005 00.0006 00.000ESCAPEOK- With a SERIAL connection, the value, date, and mail classmode are derived from the inserter.- Processing mail without a postage value (zero postage) canalso be chosen.Entering Postage Value and Mail Processing 274131935Y/C17/09/2008ORIG0077-27

3.3 Processing MailThe user needs to select the LETTER BOX or PRESORTEDmode before processing mail.- Touch the MODE button on the main screen.- The following screen is displayed:MAIL .. FRAC.. MODE0 NORMAL LETTER BOX1 PRESORTED2 PASS THROUGH3 MESSAGE4 DATERHOMELOGINOK- Select LETTER BOX or PRESORTED using the upand down- Touch OK .arrows.3.3.1 Inserter NOT Connected to the Mailing Machine(NOT CONN.)- Select postage by using the up and downarrows to highlight the desired mail class.- Touch OK .SETTING A SETTING B SETTING CMAIL CLASSAMOUNT0 NOT ACTIVE1 PRSRT FIRST-CLASS MAIL 00.1232 00.0003 FIRST-CLASS AUTO 01.6804 00.0005 00.0006 00.000ESCAPEOK28Entering Postage Value and Mail Processing4131935Y/C17/09/2008ORIG0077-28

3.3.2 Inserter Connected To The Mailing Machine(ELECTRO or SERIAL)- The inserter determines the postage amount for either theLETTERBOX or PRESORTED mode. The only exception islabels printed from the mailing system (see § 1.1 section B).- The inserter can switch from one postage amount to anotherbetween each envelope providing that the postage amount isone of the 3 pre-defined amounts.- To select the postage amount, touch SETTING A, B, or C.- Touch OK .BATCH CONFIGURA...FRAC...MODESETTING SETTING ASETTINGSETTINGBASETTING CSETTING ALABELSETTING AHOMEPRSRT FIRST-CLASS MAIL 00.123NOT ACTIVENOT ACTIVENOT ACTIVELOGINOK- When the serial interface is activated, the label dispenser isautomatically disabled.You cannot change the TEXT or mail class dynamically ina batch.3.3.3 Pass through modeThis function allows the envelope to go through the mailing systemwithout printing. This eliminates the need to remove the mailingsystem from the inserter when metering is not required.Entering Postage Value and Mail Processing 294131935Y/C17/09/2008ORIG0077-29

When this mode is activated, PASS THROUGH is displayed onthe screen, when activated (select PASS THROUGH mode asyou do for Letter Box or Presorted mode; see § 3.3).It is possible to use the batch registers counter to count itemsprocessed in this mode.In addition to the PASS TROUGH mode, when electronicallylinked to the inserter, an external command could be sent from theinserter to the mailing system to use a mode close to "passthrough" for a few envelopes which will not be metered (In thisspecific mode, number of envelopes passing through withoutfranking should be limited from the inserter to 20 envelopes toprevent the printhead from drying).3.3.4 Autoclean processIn order to ensure constant printing quality, the mailing machinewill automatically clean the printhead at regular intervals.In any case, the maximal interval between two cleaning cycles willnot exceed a 45 minutes (counter reset at the end of each cleaningcycle).When electronically connected to an inserter, WJ PRO will transmita signal to the inserter requesting to stop sending envelopeswhen the counter reaches the threshold. There is no time-outfeature. To minimize number of stops in the middle of a batch, themailing system will check the counter at each «Stop» from theinserter. If the counter is above 70% of the threshold, the machinewill execute the cleaning process.When not connected, WJ PRO will automatically proceed to thecleaning cycle when the counter reaches the threshold OR ontime-out (user settable). To minimize the number of stops in themiddle of a batch, the mailing system will check the counter at30Entering Postage Value and Mail Processing4131935Y/C17/09/2008ORIG0077-30

each «Stop» from the mailing system. If the counter is above 70%of the threshold, the machine will execute the cleaning process.The threshold (counter) set by default at 45 minutes may bedecreased by the supervisor through the following menu, selecting"HEADSET CLEANING":MENUS7 INK INFORMATION8 POSTAL SERVICES9 HEADSET CLEANING10 BMAU REPORT SETUPHOME LOGOUT CLEAN OKHEADSET CLEANINGSUPTHRESHOLD (SEC.)INACTIVITY TIMER(SEC.)-0015 2700+- 0015 30 +WARNING THRESH. (SEC.) - 0015 120 +HOME LOGOUT OKDuring the autoclean cycle, rollers and motors are stopped.The supervisor can change:- Threshold : time max between two headset cleaning (by default2700s / min=1 / max=9999) ; 0 inhibate this function.- Inactivity timer (only for system without inserter communication):time during the franking machine doesn’t detect document (bydefault 600s / min=20s / max=3600s)- Warning Thresh (only for system without inserter communication):time during the flashing light switched on before to launch anauto clean process (by default 120s / min=0s / max=240s).Entering Postage Value and Mail Processing 314131935Y/C17/09/2008ORIG0077-31

It is also possible to manually execute a cleaning cycle by pressingthe CLEAN button in user mode (short cut in the mainscreen).TEXTABC 1MODELETTERBOXAD DIELIGHTONBATCH CONFIGDEPT 1 MARKETING1NEWPRESORTREPORTDEPTINFOTOI XXXXXX00.000LOW POSTAGEXX/XX/XXXXMENULOGINCLEAN3.3.5 Date advance functionPressing the date area in the main screen it is possible to printup to 30 days ahead schedule with WJ PRO.DATETEXTADVER...SUP200 DATE OFF100 DAY OFF0 NO DATE ADVANCE1 TODAY + 12 TODAY + 23 TODAY + 34 TODAY + 4HOMELOGOUTAUTOOKWJ PRO allows the meter to switch automatically from one dayto another at a certain time.32Entering Postage Value and Mail Processing4131935Y/C17/09/2008ORIG0077-32

AUTOMATIC DATE ADVANCE SETUPSUPAUTO DATE ADVANCE MODEOFFONACTIVATION TIME1100ESCAPEOKWhen activated the "date advance setting" remains active evenafter a stand by mode. Two cases:- When not connected electronically, the user is informed and hasto acknoledge at each start.- When connected electronically, the machine asks the user toconfirm date advance activation at the first start after the time ofshift to the next dayEntering Postage Value and Mail Processing 334131935Y/C17/09/2008ORIG0077-33

4. MODIFYING OF THE IMPRINTThe imprint may be modified by selecting:- date;- slogan;- text;advertisementslogantext dieyour zip code(updated if youmove)meterserialnumberdatepostageINKJET FRANKING MAILINGMACHINELETTER BOX MODETextSloganIBI IBI Lite Lite indicia indicia LIVE LIVEwith with FIM FIM mark mark(mail (rate class integrated in inthe indicia if if needed)PRESORTED MODETextSloganIBI IBI Lite Lite indicia indicia LIVE LIVEwith with FIM no mark mark(mail (rate class integrated in inthe indicia if if needed) needed)DATER MODETextSloganDateMESSAGE MODEText- In the main screen, select the area to be modified by using thetouchscreen: the available options are displayed.- Select an option using keys and or by pressingdirectly the numeric key corresponding to the selection.- To confirm and return to the previous screen, press on OK .34Modification of the imprint4131935Y/C17/09/2008ORIG0077-34

Whenever the machine is switched on or when resumingoperation following a standby period, the machinerestores the default values defined by the supervisor(advertisement, text, date).It is also the case when the user switches from one modeto another (Letter Box, Presorted...)Modification of the imprint 354131935Y/C17/09/2008ORIG0077-35

5. CONNECTING TO DEPARTMENTS- In order to use departments, the supervisor must firstactivate the department mode first (see section B,paragraph "Defining security").- The machine is defaulted with DEPT OFF. In order to usedepartments, select DEPT ON in supervisor mode.Total postage used and a number of pieces may be assigned toa department selected from a list, as described below.- In the main screen press on the tactile area under the DEPT tabto display Department MenuDEPARTMENTS1 NAME12CHARA2 DIRECTION3 DESIGN4 RESEARCH5 CE6 FACTORYLOGINOK- Select a department, using the arrows or by keying in directly thedepartment number via the numeric pad.- Validate your selection by pressing key OK .- If the department is protected by a code, enter the code to allowaccess to the department (a PIN can be up to 4 digits).36Connecting to departments4131935Y/C17/09/2008ORIG0077-36

- Departments sharing the same access pin code make upa group.When you have entered the access pin code once, youwill not be prompted to enter the pin code again withinthe same group.- The last department selected will be proposed by defaultwhen operation is resumed after a standby period orafter the machine power-up.Connecting to departments 374131935Y/C17/09/2008ORIG0077-37

6. CONNECTION TO TELE METER SETTING ® SERVER6.1 Adding PostagePostage may be purchased from the USPS, using the <strong>Hasler</strong> TeleMeter Setting ® (TMS) system.Connect one end of the telephone link cable to the Modem socket( ) at the rear of the machine and the other end to an adjacentanalog telephone jack. The meter only requires connection to thetelephone jack during the Add Postage or Clear Lockout transaction.If access to adding postage (resetting) has been protected by thesupervisor, the screen prompts to enter a 4-digit TMS code.- In the main screen press on key MENU , and select POSTALSERVICES, then CREDIT using keys and orby pressing directly the numeric key corresponding to theselection.- To confirm, press on OK :INFORECREDIT AMOUNTOLD VALUE: 1000NEW VALUE: _ESCAPEOK38Tele Meter Setting ® Connection4131935Y/C17/09/2008ORIG0077-38

- Enter the amount to be added and press OK .Press 1 0 0 0 for $1000.The machine will connect to the Tele Meter Setting ® System. Atthe end of the transaction, you should see displayed:INFOTRANSACTION SUCCESSFULCURRENT CREDIT : 1000OK6.2 Clearing a PO lockoutUSPS regulations require that your meter must be set at leastonce every three months. The WJ Pro meter has an internal timerthat tracks your reset activity. After three months without addingpostage, a PO LOCKOUT message is displayed and postageprinting is disabled.To clear the lockout:- Select the menu POSTAL SERVICES, then select AUDIT;- Press OK to confirm.When the Clear Lockout transaction is completed, postage printingis enabled.Tele Meter Setting ® Connection 394131935Y/C17/09/2008ORIG0077-39

6.3 Completing an interrupted add postage transactionIf an Add Postage transaction is accidentally interrupted beforethe transfer has been completed, you will receive the followingerror message: "x".- Select the menu POSTAL SERVICES, then select CREDIT;- Confirm with OK to automatically finish the incompletetransaction.40Tele Meter Setting ® Connection4131935Y/C17/09/2008ORIG0077-40

7. USING OPTIONAL STATUS LIGHTS TOWERA three light device may be connected tothe WJ PRO through its serial port #1(RS232 connection).WJ PRO will activate the lights based onthe following criteria:- Green light: Ready to print (as soon as therollers are running)- Yellow light: Warning alert. System isoperational but requires attention(Printhead, low ink level, etc.).- Red light: Machine not operational. WJ PROis in stand-by mode or there is an error;such as "cover open", "printhead empty", or "paper jam".Yellow flashing light: Approaching printhead cleaning cycle (basedon supervisor set-up)("WARNING THRESOLD" § 2.3.4)During the cleaning cycle :- For the electronic connection both GREEN and orange light(flashing) are activated.- For the mechanical connection both RED and orange light(flashing) are activatedAfter the cycle has completed the green light will return.Red flashing light: Low postage alert or the time out START/STOP is going to power off the motors soon (based on supervisordefined threshold).Optional lights 414131935Y/C17/09/2008ORIG0077-41

8. PC CONNECTIONWJ PRO supports a specific fusion PC accounting application.Please call your contact information for further details.42PC Connection4131935Y/C17/09/2008ORIG0077-42

SECTION B: ADVANCED FUNCTIONS1. ADDITIONAL OPERATIONS PERFORMED BY THE MA-CHINE............................................................................... 451.1 Printing on labels 451.2 Date printing 451.3 Message printing 451.4 Report printing 462. MACHINE CONFIGURATION PRINTING (SUPERVISORMODE) .............................................................................. 552.1 Enabling The Supervisor Mode 552.2 User setup (in supervisor mode) 592.3 Supervisor setup 592.3.1 Security and high value alert 602.3.2 Low funds alert 612.3.3 Time 622.3.4 Time-out 632.3.5 Touchscreen calibration 662.3.6 Serial Port Setup 672.3.7 Ink spitting management 682.4 Display setup 692.5 Departments 692.6 Print alignment setup 712.7 Reports 722.8 Ink information 732.9 Postal services 742.10 Downloading an advertisement slogan 762.11 Text modification 782.12 Exiting the supervisor mode 79434131935Y/C17/09/2008ORIG0077-43

444131935Y/C17/09/2008ORIG0077-44

1. ADDITIONAL OPERATIONS PERFORMED BY THEMACHINE1.1 Printing on labelsIt is possible to print labels when allowed by the supervisor andchosen by the user:- Press key ;- If required, enter the number (from 1 to 999) of labels to beprocessed at the same value (default value is 1).- Press on key STARTSTOP: The machine will automatically print therequired number of labels at the displayed value.For a single label, simply pressand then STARTSTOP .1.2 Date printingThis function is designed to print the date instead of a postage imprint.04-28-06It is possible to use the batch registers to count items processedin this mode.1.3 Message printingIt is possible to print TEXT only by selecting the message printingmode. This allows the user to print predefined text without meteringenvelopes.Additional operations performed by the machine 454131935Y/C17/09/2008ORIG0077-45

1.4 Report printingREPORT PRINTING IN USER MODEThe following reports (or statements) may be printed with a printeror on label in user mode:- General registers : Provides the main registers of the machine.These counters are not resettable.- Batch data : Provides the number of documents printed betweentwo reset of the counter in each mode (batch = letter box orpresorted ; pass through ; message ; dater). These counters areindependent and can be set to zero by the user.- This month report : Provides the number of items, total postagemetered per day, and the ascending register during the currentmonth.- Prev month report : Provides the number of items, total postagemetered per day, and the ascending register during the previousmonth.- Annual report : Provides the amount of postage used per monthand the ascending register during the year.- Postage set report : Provides the data of the last recredit.- Inserter batch report : It provided the data of the current Presorted/BMAU batch. This data is initialized at the beginning of eachnew Presorted batch setup by the user.REPORTSHEADS...1 GENERAL REGISTERS2 BATCH DATA3 THIS MONTH REPORT4 PREV MONTH REPORT5 ANNUAL REPORT6 POSTAGE SET REPORT7 INSERTER BATCH REGISTERHOME LOGIN OK46Additional operations performed by the machine4131935Y/C17/09/2008ORIG0077-46

REPORT PRINTING IN SUPERVISOR MODEThe following reports (or statements) may be printed with a printeror on label in supervisor mode:- Modules details : Provides the software version, serial numberand number of cycle of the different components of the mailingmachine (meter, mailing system, label dispenser).- Setup report : Provides specific technical setup data like stateof the meter; high value setting, time out setting.- Dept setup report : Provides the status of each department(name ; open, closed or locked, pin code).- Print value history : Provides the last 20 values printed in letterbox or presorted mode.- Postage set history : Provides the 10 th last postage refills.- General registers : Provides the main registers of the machine.These counters are not resettable.- Batch data : Provides the number of documents printed betweentwo reset of the counter in each mode (batch = letter box orpresorted ; pass through ; message ; dater). These counters areindependent and can be set to zero by the user.- This month report : Provides the number of items, total postagemetered per day, and the ascending register during the currentmonth.- Prev month report : Provides the number of items, total postagemetered per day, and the ascending register during the previousmonth.- Annual report : Provides the amount of postage used per monthand the ascending register during the year.- Postage set report : Provides the data of the last recredit.- Inserter batch report : Provides the data of the current Presorted/BMAU batch. This data is initialized at the beginning of eachnew Presorted batch setup by the user.Additional operations performed by the machine 474131935Y/C17/09/2008ORIG0077-47

POSTA...DEPAR...1 MODULES DETAILS2 SETUP REPORT3 DEPT SETUP REPORT4 PRINT VALUE HISTORY5 POSTAGE SET HISTORY6 GENERAL REGTRS7 BATCH DATAREPORTSSUPHOME LOGOUT OKPOSTA... DEPAR... REPORTSSUP8 THIS MONTH REPORT9 PREV MONTH REPORT10 ANNUAL REPORT11 POSTAGE SET REPORT12 INSERTER BATCH REGISTERHOME LOGOUT OK- From the main screen press on key MENU , and selectREPORTS using keys and or by pressingdirectly the numeric key corresponding to the selection.- To confirm, press on OK ; the below menu is displayed:REPORTSPOSTA..ONLIN..1 GENERAL REGTRS2 BATCH DATA3 THIS MONTH REPORT4 PREV MONTH REPORT5 ANNUAL REPORT6 POSTAGE SET REPORTHOME LOGIN OK48Additional operations performed by the machine4131935Y/C17/09/2008ORIG0077-48

- Select a report using keys and or by pressingdirectly the numeric key corresponding to the selection.- To confirm, press on OK . For example, by selecting"GENERAL REGISTERS", the below screen is displayed:GENERAL REGISTERSPRINTED ON :PRINTERDESC XXXXX NORM.ITEMS XXXXXXASC XXXXX HIGH ITEMS XXXXXXCTL XXXXX ZERO ITEMS XXXXXXTOTAL ITEMS XXXXXXESCAPEPRINT- Press PRINTER to select the label printer (if a printer isconnected to the machine):PRINTER LABELSPRINTERis displayed. Then, simply press LABELS orPRINTER.- Press PRINT : the report will be automatically printed out(press NEXT if there is more than one page).BATCH DATA1BATCHBATCH DATAREGTRS02 PASS THRU XXXXX3 MESSAGE XXXXX4 DATER XXXXXESCAPERESETAdditional operations performed by the machine 494131935Y/C17/09/2008ORIG0077-49

and selecting a batch register using keys and ;then, when pushing on RESET , the selected batch register isreset to zero.For Presorted/BMAU mode, the user decides to start a newreport and press the "PRESORT REPORT" button on the mainscreen:TEXTABC 1MODELETTERBOXAD DIELIGHTONBATCH CONFIGDEPT 1 MARKETING1NEWPRESORTREPORTDEPTINFOTOI XXXXXX00.000LOW POSTAGEXX/XX/XXXXMENULOGINCLEANThen, by pressing PRESORT REPORT:TEXTABC1AD DIE1INFO00.000MODEPRESORT BATCH / REPORTLOW POSTAGEXX/XX/XXXXLETTER START A NEW BATCHBOX PRESS « PRINT » TO PRINTYOUR REPORT BEFORE TO CLEAR ITBATCH CONFIG WITH THE « OKDEPT» BUTTON .TOI XXXXXXDEPT 1 MARKETINGCANCELPRINTOKTo print the report on the selected device (either label or printer),the user selects the «INSERTER BATCH REGISTER» item in thelist of reports:50Additional operations performed by the machine4131935Y/C17/09/2008ORIG0077-50

REPORTSPOSTA..ONLIN..1 GENERAL REGISTERS2 BATCH DATA3 THIS MONTH REPORT4 PREV MONTH REPORT5 ANNUAL REPORT6 POSTAGE SET REPORT7 INSERTER BATCH REGISTERHOME LOGIN OKBy selecting inserter batch register on the report screen, the usermay view the report information screens.INSERTER BATCH REGISTERPRINTED ON :PRINTERSTART OF BATCHDATE TIME TOTAL ITEMS04/28/06 10:06 163ASC DESC552.860 19447.140CTL20000.000(2/6)ESCAPERESETPRINTPREVNEXTINSERTER BATCH REGISTERSPRINTED ON :PRINTEREND OF BATCHDATE TIME TOTAL ITEMS04/28/06 10:07 166ASC DESC554.860 19445.140CTL20000.000(2/6)ESCAPERESETPRINTPREVNEXTAdditional operations performed by the machine 514131935Y/C17/09/2008ORIG0077-51

INSERTER BATCH REGISTERSPRINTED ON :AMOUNT ITEMS TOTAL1.000 1 1.0000.500 1 1.0000.000 00000 00000.0000.000 00000 00000.0000.000 00000 00000.0000.000 00000 00000.0000.000 00000 00000.000PRINTER(x/6)ESCAPERESETPRINTPREVNEXTINSERTER BATCH REGISTERSPRINTED ON :PRINTERTOTAL ITEMS 3TOTAL POSTAGE 2.000(6/6)ESCAPERESETPRINTPREVNEXTFor customers who do not want to use this kind of report, thesupervisor is able to disable this feature by going into the"PRESORT BATCH SETUP" item and selecting "NOT ACTIVE":MENUS7 INK INFORMATION8 HEADSET CLEANING9 PRESORT BATCH SETUPHOME LOGOUT CLEAN OK52Additional operations performed by the machine4131935Y/C17/09/2008ORIG0077-52

BMAU BATCH SETUPSUPBMAU BATCHACTIVENOT ACTIVEESCAPEOKIn this case, the BMAU BATCH button does not appear on themain screen."NOT ACTIVE" is the default mode.As the report is limited to 20 entries (20 different postage values),an alert is raised to the user when 15 different postages havebeen used from the beginning of the batch activation.TEXTABC 1AD DIE1INFO00.000LOW POSTAGEMODE ERRORXX/XX/XXXXLETTERBOX T150 YOUR REPORT IS ALMOST FULL.YOU HAVE TO START A NEW PRESORT BATCH.BATCH CONFIG DEPTTOI XXXXXXDEPT 1 MARKETINGBATCH RUNNINGOKPress OK to acknowledge the message and display mainscreen.When the report reachEs 20 different entries, the user shouldcreate a new batch, or ask the supervisor to deactivate thisfeature.Additional operations performed by the machine 534131935Y/C17/09/2008ORIG0077-53

TEXTABC 1AD DIE1INFO00.000MODE ERRORLOW POSTAGEXX/XX/XXXXLETTERBOXT151 YOUR REPORT IS FULL.YOU MUST TO START A NEW PRESORT BATCH.BATCH CONFIG DEPTTOI XXXXXXDEPT 1 MARKETINGBATCH RUNNINGOKPress OK to acknowledge the message and display mainscreen.The other registers and batch counters are not impacted by themanagement and the process related to the BMAU/presorteddata.54Additional operations performed by the machine4131935Y/C17/09/2008ORIG0077-54

2. MACHINE CONFIGURATION PRINTING(SUPERVISOR MODE)Under this mode, the Supervisor can access to all the machinefunctions, except postage printing. The scrolling procedure fromscreen to screen is the same as in the user mode, except that thesupervisor mode includes a number of extra configuration functionkeys. The supervisor has access to all the departments.Mail processing cannot be done in supervisor mode.2.1 Enabling The Supervisor Mode- The supervisor mode may be activated by pressing LOGIN .- The screen below will be displayed:TEXTABC 1MODELETTERBOXAD DIELIGHTONBATCH CONFIGDEPT 1 MARKETING1NEWPRESORTREPORTDEPTINFOTOI XXXXXX00.000LOW POSTAGEXX/XX/XXXXMENULOGINCLEANTEXTABC 1MODELETTERBOXAD DIELIGHTBATCH CONFIGONDEPT 1 MARKETING1PIN NUMBER NEW ?****DEPTINFOTOI XXXXXX00.000LOW POSTAGEXX/XX/XXXXESCAPEOK- Enter the supervisor code (4 digits) and press OK or OK key.Machine configuration printing (Supervisor mode) 554131935Y/C17/09/2008ORIG0077-55

- From the main screen, touch the MENU button. The mainmenu in supervisor mode is displayed.- SUP is displayed at the top right of the menu screen indicatingthat the user is in supervisor mode.MENUSSUP0 USERUSERSETUPSETUP1 SUPERVISOR SETUP2 DISPLAY SETUP3 DEPARTMENTS4 RATE5 PRINTING INKER SERVICING6 REPORTSHOME LOGOUT CLEAN OK- By touching the up and down arrows, thesupervisor can navigate through the Supervisor Menus.MENUSSUP7 INK INFORMATION8 HEADSET CLEANING9 PRESORT BATCH SETUP10 INK SPITTING MANAGEMENTHOME LOGOUT CLEAN OK56Machine configuration printing (Supervisor mode)4131935Y/C17/09/2008ORIG0077-56

GENERALITIESA number of menus or selection keys can only be accessed insupervisor mode:- The MODIFY function used to modify for instance names,departments, advertisement, etc.- The DEFLT function designed to select a default value.- The C key designed to do a backspace in the alphanumericentry screen.In supervisor mode, the complete lists are displayed on thescreen.On the screens, the default values are signaled by a checkmark"✔". To change a default value, select a new value and pressDEFLT key. The checkmark "✔" moves to indicate the newselection.Selecting a value as a DEFLT , means that it will be activewhen the mail machine is powered on or returns fromsleeping mode.In the "SLOGAN" menu, select "SLOGAN 3", using keysand or numeric key 3 for instance:DATETEXT0 NO AD DIE1 FLAG2 RECYCLE3 FIRST CLASS4 AIR MAIL5 SEASONS GREETINGS6 EMPTYADVERT DIESUPHOME LOGOUT MODIFY DEFLT OKMachine configuration printing (Supervisor mode) 574131935Y/C17/09/2008ORIG0077-57

When pressing DEFLT key, the following screen isdisplayed:DATETEXT0 NO AD DIE1 FLAG2 RECYCLE3 ✔FIRST CLASS4 AIR MAIL5 SEASONS GREETINGS6 EMPTYADVERT DIESUPHOME LOGOUT MODIFY DEFLT OKTo activate an advertisement slogan, select it in theprevious screen and press MODIFY . The following screenis displayed:ADVERT DIE MODIFSUPSTATUSNAMENOT ACTIVEMARKETING FLAGACTIVENUMBER 1EXIST YESESCAPELOADOKSelect ACTIVE by simply touching ACTIVE .Validate with OK .Method for making a mail class die or text message active is thesame as for advertisement slogan.58Machine configuration printing (Supervisor mode)4131935Y/C17/09/2008ORIG0077-58

2.2 User setup (in supervisor mode)When pressing "USER SETUP" the screen below appears:USER SETUP SUPER... DISPL...LANGUAGEBUZZERAMERICAN ✔ ENGLISHOFF ON ERR ✔ONKEYCONTRAST-16 +CONTROLLERNOT CONN.✔ELECTROSERIALHOMELOGOUTDEFLTOKSelect the language, the buzzer function and the contrast simplyby touching keys and press OK to validate all the selections.2.3 Supervisor setupWhen selecting "SUPERVISOR SETUP" (after entering insupervisor mode), the screen below appears:USER ...1 SECURITY2 TIME3 TIMEOUT8 SERIAL PORT SETUP9 LIGHT TESTSUPERV. SETUPDISPL...SUPHOME LOGOUT OKMachine configuration printing (Supervisor mode) 594131935Y/C17/09/2008ORIG0077-59

2.3.1 Security and high value alertAfter selecting “SECURITY” in the main supervisor menu, thebelow menu will be displayed:SECURITYSUPUSER PIN # 12345MACHINE STATUSHIGH VAL ALERTNORMAL12345LOCKEDESCAPEOK- USER PIN # : is used to define the user accesscode (4 digits). Note: '0000' = freeaccess by default. Can be changedby the supervisor.- MACHINE STATUS : becomes “LOCKED" when themaximum number of pin codeattempts is reached.Press OK to validate all the selections.60Machine configuration printing (Supervisor mode)4131935Y/C17/09/2008ORIG0077-60

DEFINING THE HIGH VALUE ALERTThe HIGH VALUE ALERT prevents inadvertent metering of a highpostage value.In the "SECURITY" screen, after selecting the "HIGH VAL ALERT"menu, the below screen will be displayed:HIGH VALUE ALERTSUPOLD VALUE :NEW VALUE :_12450 123 45 6 78 9ESCAPEOKSimply enter the new value, using the numeric keypad (with nodecimal point or comma, e.g.: 99000 corresponds to 99.000).2.3.2 Low funds alertAn alert is implemented to signal low funds in the meter in advanceto the user. This intends to prevent the user to be stopped withoutcredit in the meter in the middle of a batch, causing also paper jamfrom the inserter.This warning is indicated by a flashing red signal light when thelevel of money in the meter reaches a low funds threshold.This threshold is preset by the supervisor in the range from 0 to99999$ ; By default , it is set to 250$00.Machine configuration printing (Supervisor mode) 614131935Y/C17/09/2008ORIG0077-61

POSTAL CONNECTION SETUPSUPPREFIX 33 33TELEPHONE #LOW FUNDS THRESLD18662961331250 123POC PIN # 3321 0000 3354ESCAPEOK2.3.3 TimeAfter selecting "TIME" in the main supervisor menu, the screenbelow will be displayed:TIME SETUP (HHMM 0000 to 2400)SUPOLD VALUE :NEW VALUE :1455_0 123 45 6 78 9ESCAPEOKTo set the time, simply enter the new value, using the numeric keys(max + 3hours). Validate by pressing or touching OK .62Machine configuration printing (Supervisor mode)4131935Y/C17/09/2008ORIG0077-62

2.3.4 Time-outTime-out, standby and sleepAfter selecting "TIME OUT" in the main supervisor menu, thescreen below is displayed:TIMEOUT (SEC)SUPSTART (10 - 9999)-1800 0015+STOP (1 - 9999)-1800 0015+STANDBY (1 - 9999)-0060 0015+SLEEP (30 - 9999)-0240 0015+ESCAPENEXTTIMEOUT (SEC)SUPWARNING STOP (0 - 240)-0015 120 +ESCAPEPREVThe timeout delays, expressed in seconds, are determined by thesupervisor (between 0 and 3600 seconds, in one secondincrements). The maximum delay is 3600 seconds or 60 minutes:START : waiting time for the first document with the transportmotor in operation. After this time out the machine stops.STOP : time out before the machine stops after the last documentprocessing.These two time out will be inhibited if their value is 0.Machine configuration printing (Supervisor mode) 634131935Y/C17/09/2008ORIG0077-63

- STANDBY: time-out before the Printhead returns to the cappingstation (protection area that prevents the ink from drying in thePrinthead) after the motor has stopped (recommended standbytimeout: 150 sec.)- SLEEP: time-out before the machine goes into sleep modeafter the Printhead returns to the capping station in standby(recommended sleep time-out: 120 sec.)."Warning STOP"For mechanical connection, there is a message displayed beforethe motors stop."Franking machine will stop soon": this message will be signaledby a red flashing light and is displayed few seconds before to stopthe motor. These few seconds ("Warning STOP") are adjustablefrom 0 to 240s by the supervisor in the TIMEOUT menu (newpage named TIMEOUT : Warning) - by default 120s.If time out "Warning STOP" is higher than time outSTART and STOP, the light is red flashing from the startaction.For electronic connection, it is the inserter whichauthorizes the franking machine to stop its motor, at thesame process used for the function STOP from postagemeter.To modify the "SLEEP" time, enter the desired time (inseconds) using - and + keys, or touch 0240 toaccess to the numeric screen and enter the desired timeouttime. Confirm with ESCAPE .With inserter mode ON, the timeouts are maintained butare not taken into account when the motor is running.64Machine configuration printing (Supervisor mode)4131935Y/C17/09/2008ORIG0077-64

Timeout AUTO CLEANTo access the AUTOCLEAN TIME-OUT:- pressMENUCLEANING- press OK to confirm;from the main screen, and select HEADSETThe following screen will appear:HEADSET CLEANINGDISPL...SUPTHRESHOLD (SEC.)-0015 2700+TIME OUT (SEC.) - 0015 30 +WARNING THRESH. (SEC.) - 0015 120+HOME LOGOUT OKTHRESHOLD is used regardless of the inserter mode (connectedor not connected). This threshold is set to 45 minutes by default.It determines the timing between two headset cleaning. When thisthreshold is reached, headset cleaning is launched.This TIME OUT period is used in the inserter mode "Not connected".It is set to 600 seconds by default. This timeout period is used tolaunch a headset cleaning when the mailing machine does notdetect a document for the amount of time specified, and if thenumber of documents printed is higher than 70% of theTHRESHOLD value.The WARNING THRESHOLD is used to activate the flashingyellow light on the Status Light Tower (page 41) prior tocommencing the headset cleaning process.Machine configuration printing (Supervisor mode) 654131935Y/C17/09/2008ORIG0077-65

2.3.5 Touchscreen calibrationBy selecting "TOUCHSCREEN CALIBRATION" in supervisorsetup screen, the calibration input box is displayed:INFOTouchscreen CalibrationAim the targets with a fine penTouch the screen to beginTouch the screen; then four crosses will be displayed (one by one)like this:Touch the crosses; then the following is displayed (if not, tryagain):INFOCalibration was SuccessfulTouch the screen to continueTouch the screen to come back to the main supervisor menu.66Machine configuration printing (Supervisor mode)4131935Y/C17/09/2008ORIG0077-66

2.3.6 Serial Port SetupThis menu allows the user to define which peripheral is connectedto a port. When selecting SERIAL PORT SETUP, the followingis displayed:SERIAL PORT SETUPSUPPORT1PORT2PORT3PORT4LIGHTNOT LIGHT ACTIVENOT LIGHT ACTIVENOT LIGHT ACTIVEESCAPEOKWhen selecting a port, a list of the possible peripherals isdisplayed. In this example, port 2 has been selected.PORT 2 SETUP0 NOT ACTIVE1 SIGNAL LIGHT2 PC ACCOUNTING3 INSERTER 57K4 INSERTER 38K5 PC CONTROLLER 57K6 PC CONTROLLER 38KESCAPEOK- Select a peripheral using the up and downarrows or the numeric keypad.- Touch OK .- Repeat the operation with another port(s).- Touch OK .By default, port 1 is activated for light.Machine configuration printing (Supervisor mode) 674131935Y/C17/09/2008ORIG0077-67

SERIAL CONTROLLER SETUP- «INSERTER 57K»: Mailing machine connects to Inserter withbaud rate of 57.600- «INSERTER 38K»: Mailing machine connects to Inserter withbaud rate of 38.400- «PC CONTROLLER 57K»: Mailing machine connects to PCwith baud rate of 57.600- «PC CONTROLLER 38K»: Mailing machine connects to PCwith baud rate of 38.4002.3.7 Ink spitting managementMENUSSUP7 INK INFORMATION8 HEADSET CLEANING9 PRESORT BATCH SETUP10 INK SPITTING MANAGEMENTHOME LOGOUT CLEAN OKINK SPITTING MANAGEMENTSUPDENSITY (DROP.)FREQUENCY(SEC.)-0015 10+- 0015 6 +HOME LOGOUT OKDefault values are:- Density: 10- Frequency: 6Do not modify these values without your distributor approval.68Machine configuration printing (Supervisor mode)4131935Y/C17/09/2008ORIG0077-68

2.4 Display setupThis mode is accessible in User and Supervisor modes.See the paragraph "Configuration of the main screen display" inC section.2.5 DepartmentsDEPARTMENT: is used to enable the department mode. Thisfunctionality is proposed to allow the user to allocate the postagespending to the corresponding department. When this mode isactivated, the DEPARTMENT menu is displayed on the main screen.The machine default is DEPARTMENT OFF ; in orderto use the departments, select DEPARTMENTON(by touching it). Validate with OK . You should thenselect DEPARTMENT in the main supervisor menu toopen and define the departments you want to use (see onprevious page).The machine is configured by default as follows:- 0000 PIN code for all departments opened by the supervisor,- With names from D1 to D499 corresponding from 1 to 499.In the "no department" mode, all the values are assigned to amiscellaneous department (D0 MISCELLANEOUS) which cannotbe accessed by the user. This department will be reset with theother ones, when the registers are cleared. This departmentappears on the printed reports.After selecting "DEPARTMENT" in the main supervisor menu,the following menu is displayed:Machine configuration printing (Supervisor mode) 694131935Y/C17/09/2008ORIG0077-69

DEPARTMENTS REPOR... POSTA...DEPT MODE ONSUP1 MARKETING CLOSED2 DIRECTION OPEN3 DESIGN CLOSED OPEN4 RESEARCH OPEN5 D005 OPEN6 D12 CLOSED7 D07 LOCKEDHOME LOGOUT MODIFYSETUPOKAfter selecting a department using keys and (orby pressing directly the numeric key corresponding to theselection), when pressing key MODIFY from the above screen,the following menu is displayed:DEPARTMENT MODIFSUPSTATUS DEPTDEPT NAMEOPEN CLOSED LOCKEDMARKETING9012DEPT NUMBER 12345678DEPT PIN 1234ESCAPE RESET OKThen, simply by acting the specific area, the supervisor may:- create a department (OPEN),- close a department (CLOSED),- unlock an automatically locked department: lock out occurs ifmore than 8 attempts have been made to access this departmentwith a wrong pin code. The department name will disappear inuser mode from the menu selection when locked out.- select a name (12 characters max),- select a department number (8 digits only when a scale is notinterfaced, 4 digits with a scale),- select an access pin code (code 0000 = free access),- reset the current department register (key RESET ).70Machine configuration printing (Supervisor mode)4131935Y/C17/09/2008ORIG0077-70

To clear all the registers, select SETUP in the mainDEPARTMENT menu:DEPARTMENT SETUPSUPDEPARTMENTONOFFESCAPE RESET OKThen, press key RESET and press OK to confirm.2.6 Print alignment setup- From the main menu, select "PRINTING INKER SERVICING";the screen displays:PRINTING INKER SERVICINGSUPALIGN. A C E G I KB D F H JESCAPECLEANPRINTOK- Load labels and select PRINT ; the machine prints a testprinting:Machine configuration printing (Supervisor mode) 714131935Y/C17/09/2008ORIG0077-71

In order to adjust the alignment, select the letter corresponding tothe straightest vertical line (letter F in the above example), thenpress OK to confirm.Print alignment is required every time a new printhead isinstalled.2.7 ReportsAfter selecting "REPORTS" in the main supervisor menu, thefollowing menu is displayed, with the list of report types:DEPAR..RATE1 MODULES DETAILS2 SETUP REPORT3 DEPT SETUP REPORT4 PRINT VALUE HISTORY5 POSTAGE SET HISTORY6 GENERAL REGTRS7 BATCH DATAREPORTSSUPHOME LOGOUT OKSimilar to user mode, user can select the label or printer.72Machine configuration printing (Supervisor mode)4131935Y/C17/09/2008ORIG0077-72

Select "DEPT SETUP REPORT" and press OK :DEPT SETUP REPORTDATE 10-24-00 DIE N XXX YYYYYYNO NAME STATUS PIN CODE1 Accounting OPEN 06212 Marketing OPEN 69693 D03 OPEN 14454 D04 CLOSED 02215 Bookshop OPEN 00186 D06 CLOSED 02777 Car park CLOSED 20122.8 Ink informationSelect "INK INFORMATION" from the main supervisor menu listto see color, status and installation date:HEADSETCARTR..COLORSTATUS: BLACK: READYINSTALLATION DATE :01/01/2003MENUFrom the above menu, press INK RESERVOIR; the following isdisplayed:Machine configuration printing (Supervisor mode) 734131935Y/C17/09/2008ORIG0077-73

HEADS..CARTRIDGECONSUMED : 80%COLOR: BLACKSTATUS: READY100%INSTALLATION DATE :01/01/2003MENUSee "Ordering Supplies" section for information on replacementInk Reservoirs or Printheads.2.9 Postal servicesThe telephone number for the modem connection to the TeleMeter Setting ® (TMS) credit re-setting center is stored in themailing machine. This is used when you want to refill the meter.Modification of the telephone number can be activated by selecting"POSTAL SERVICES" in the supervisor main menu:POSTAL SERVICES1 RECREDIT2 AUDIT3 UPDATE REGISTERSDEPAR...REPOR...SUPHOMELOGOUTSETUPOKThen select SETUP . Such a setting may be necessary in case ofmodification of your telephone network (for example a new prefixfor an external line), or if you are advised that this number haschanged. It must be entered as detailed below.74Machine configuration printing (Supervisor mode)4131935Y/C17/09/2008ORIG0077-74

POSTAL CONNECTION SETUPSUPPREFIX 33 933TELEPHONE #LOW FUNDS THRESLD180044660291234561000 123POC PIN # 3321 3354ESCAPEOKTo add or to modify a number, touch the correspondingarea and enter a number using the numeric keys. Confirmwith OK .POC PIN #: is used to define the recredit access (4 digits)"0000" = free access.LOW FUNDS THRESHOLDAfter selecting the "LOW FUNDS THRESHOLD", the belowscreen will be displayed:LOW FUNDS THRESHOLDSUPOLD VALUE :NEW VALUE :_10000 123 45 6 78 9ESCAPEOKDefault value is 0Machine configuration printing (Supervisor mode) 754131935Y/C17/09/2008ORIG0077-75

Simply enter the new value, using the numeric keypad (with nopoint or comma, e.g.:99000 corresponds to 99.000).When the postage is below the low postage threshold value, amessage will be prompted in the main menu.2.10 Downloading an advertisement slogan- From the main menu, select "SLOGAN"; the following isdisplayed:DATETEXT0 NO AD DIE1 FLAG2 RECYCLE3 FIRST CLASS4 AIR MAIL5 SEASONS GREETINGS6 EMPTYADVERT DIESUPHOME LOGOUT MODIFY DEFLT OK- Select a slogan, using keys and or numeric key.- Press MODIFY ; the following will be displayed on the screen:ADVERT DIE MODIFSUPSTATUSNAMENOT ACTIVEMARKETINGACTIVENUMBER 1ESCAPELOADOK76Machine configuration printing (Supervisor mode)4131935Y/C17/09/2008ORIG0077-76

- Modify NAME, or insert the memory card into the reader, on theright side of the machine and press LOAD to initiate thedownloading operation.INFOLOADING IN PROGRESSthen:INFOLOADING SUCCESSFULOK- Press OK .- The downloaded slogan is now accessible in SLOGAN menu inuser mode.Machine configuration printing (Supervisor mode) 774131935Y/C17/09/2008ORIG0077-77

2.11 Text modification- From a menu where there is text to modify, type the text area:ENTER NAME AND PRESS OK12 CHARS MAXMARKETI_SUPQ W E R T Y U I OPA S D F G H J KLZ X C V B N MSPACEESCAPE 123 OK- 123 allows to access to the following screen:ENTER NAME AND PRESS OK12 CHARS MAXMARKETI_10_SUP0748 95 6- #:@ /\SPACE.12 3ESCAPE ABC SUP OK- ABC allows to access to the previous screen.- To select a character, simply touch the desired character.- Key C is used to backspace (with deletion).- Validate completed name with OK .You can use the "two lines." character to print your text within78Machine configuration printing (Supervisor mode)4131935Y/C17/09/2008ORIG0077-78

2.12 Exiting the supervisor modeTo exit the supervisor mode, select the LOGOUT key from thesupervisor menu (return to the main menu) or press keywill set the machine to the sleep mode.whichMachine configuration printing (Supervisor mode) 794131935Y/C17/09/2008ORIG0077-79

804131935Y/C17/09/2008ORIG0077-80

SECTION C: MACHINE CONFIGURATION1. MAILING MACHINE GENERAL CONFIGURATION .......... 832. CONFIGURATION OF THE MAIN SCREEN DISPLAY ...... 842.1 Info Area 842.2 Batch configuration area 86814131935Y/C17/09/2008ORIG0077-81

824131935Y/C17/09/2008ORIG0077-82

1. MAILING MACHINE GENERAL CONFIGURATIONThe following parameters can be set up:- LANGUAGE- BUZZER - Activated in case of error and/or when pressing a key- CONTRAST - Display screen contrast- CONTROLLER - Whether the inserter is connected with amailing machine (electronic or serial connection) or NOTconnected with a mailing machine (physical connection).- On the main screen, touch the MENU button.- Select the USER SETUP tab.- Touch OK .USER SETUP SUPER... DISPL...LANGUAGEBUZZERAMERICAN ENGLISHOFF ON ERR ON KEYCONTRAST-16 +CONTROLLERNOT CONN.ELECTROSERIALHOMELOGOUTDEFLTOK- Select the desired LANGUAGE, BUZZER, CONTRAST, andCONTROLLER options.- Touch OK .Mailing machine general configuration 834131935Y/C17/09/2008ORIG0077-83

2. CONFIGURATION OF THE MAIN SCREEN DISPLAYThis mode is accessible in both User and Supervisormodes.2.1 Info AreaIn the main screen, the "INFO" area may display from 3 to 5 itemswith a dynamic update.TEXTABC 1MODELETTERBOXAD DIE1LIGHTONBATCH CONFIGDEPT 1 MARKETINGNEWPRESORTREPORTDEPTINFOTOI XXXXXX00.000LOW POSTAGEXX/XX/XXXXMENULOGINFrom the main screen, touch INFO, the following is displayed:LINE1POILINE2TOILINE3BTOUSER...HighLabelHighLabelDISPLAY SETUP1 ASCENDING2 TOTAL ITEMS3 POSTAL ITEMS4 DEPT NAME DEPT NAME5 DEPT TOTE6 DEPT ITEMS7 BATCH ASCENDINGREPORT...SUPHOME LOGOUT NEXT OK- Select the register using keys and or bypressing directly the numeric key corresponding to the selection.- Select the line simply by touching it (for example, to select theline 2, touchLINE2TOI).- Then touch .- If necessary, touch NEXT to go to the next lines.- To suppress an item, select the line concerned and touch .- To confirm, press on OK .84Configuration of the main screen display4131935Y/C17/09/2008ORIG0077-84

Abbreviations tableASCENDING ............. TOT .... Total money spentTOTAL ITEMS............ TOI ..... Total of items printedPOSTAL ITEMS ......... POI ..... Total number of mail metered(except 0 values)DEPT NAME ............. DEPT . Department name usedDEPT TOTE .............. DTO ... Amount of money spent in theactive departmentDEPT ITEMS ............. DIT ..... Number of pieces printed in theactive departmentBATCH TOTE ............ BTO ... Amount of money spent in letterbox mode or presorted modesince the last reset of the counterBATCH ITEMS ........... BIT...... Number of mail printed in letterbox or presorted mode since thelast reset of the counterPASS THRU ITEMS... PTH .... Number of mail proceeded inpassthrough mode since the lastreset of the counterMESSAGE ITEMS ..... MES ... Number of mail proceeded inmessage mode since the lastreset of the counterDATER ITEMS ........... DAT ... Number of mail proceeded indater mode since the last resetof the counterDESCENDING .......... DES ... Money available in the meter formailingCONTROL TOTAL ..... CTL .... Control counter equal to«Ascending + descending»FOLDER INSERTER . FI ........ Inserter connection status:CONNECTED (electronicconnection) or NOTCONNECTED (mechanicalconnection)Configuration of the main screen display 854131935Y/C17/09/2008ORIG0077-85

It is useful to select DESCENDING so that the amount ofpostage available in your meter is always displayed onthe main menu.2.2 Batch configuration areaPostage class (mail class + amount) are indicated on the mainscreen, before and during the printing process:- one postage for inserter without electronic communication isdisplayed- one to three postages depending on the batch configuration isdisplayed in case of inserter connected and using thecommunication protocol.- For the label the postage is not displayed.These values are displayed in the "batch configuration" area.TEXTABC 1MODELETTERBOXBATCH CONFIG DEPTA:PRSRT 0.042B:FIRST-CLASS MA 0.510C:STANDARD 0.325DEPT 1 MARKETINGLOGIN CLEANMENUAD DIELIGHTON1NEWPRESORTREPORTINFOTOI XXXXXX00.000LOW POSTAGEXX/XX/XXXX864131935Y/C17/09/2008ORIG0077-86

SECTION D: MAINTENANCE1. TROUBLE SHOOTING ..................................................... 891.1 Misfeed in the mailing machine 891.2 Machine problems 912. GENERAL MAINTENANCE ............................................... 932.1 Roller cleaning 932.2 Printhead cleaning 942.3 Removing the postage meter 952.4 Touchscreen precautions 96874131935Y/C17/09/2008ORIG0077-87

884131935Y/C17/09/2008ORIG0077-88

1. TROUBLE SHOOTING1.1 Misfeed in the mailing machine- With your fingers, lift and pullthe handle located on the rightside of the machine, indirection (1).- Remove the misfedenvelopes.- Push the handle into themachine to close.(1)When more free space isrequired to facilitate the accessto the machine, you may shiftthe whole machine tablesideways by lifting the tab underthe handle in direction (2).- With handle open, push leverunderneath in an upwards direction and pull thedrawer open.(2)Trouble shooting 894131935Y/C17/09/2008ORIG0077-89

- Then the drawer is fully open- After the misfeed has been cleared, firmly push the wholeassembly into the machine.90Trouble shooting4131935Y/C17/09/2008ORIG0077-90

1.2 Machine problemsPROBLEMThe machine cannot getstarted.The printer does not operateTO CHECKCheck the power cord and theconnection.- Is it switched on? Is it connected?- Is the printer mode selected inthe SETUP menu?The machine displays themessage "COVER OPEN"at start-up.The machine does not printand displays no message.- Make sure that machine coversare closed.- Make sure that the terminator isfitted (see page 16).- Make sure in menu IMPRINT/MODE that the machine is not inthe PASS THR or the MESSAGEmode (with no message selected).Return to PRESORTED orLETTER BOX mode.- Make sure the connection with theinserter is well set.- Did you remove the tape fromthe printhead before inserting itinto the machine?- Clean the printhead (menuCLEAN).The light does not work.Check the connection with themailing system, and the serial portconfiguration. Should be by defaulton port # 1.Trouble shooting 914131935Y/C17/09/2008ORIG0077-91

PROBLEMPoor printing qualityItems are not properlyejected.Communication errorTO CHECK- See paragraph "Cleaning theprinthead".- Make sure that the side drawer isproperly closed.- Make sure that the side drawer isproperly closed.- Clean the rollers.Check the insertion of the meter.92Trouble shooting4131935Y/C17/09/2008ORIG0077-92

2. GENERAL MAINTENANCE2.1 Roller cleaningShift the machine table sideways by releasing handle (seeparagraph 1.1 "Misfeed in the mailing machine" in this section).rollersClean the rollers with a damp cloth.General Maintenance 934131935Y/C17/09/2008ORIG0077-93

2.2 Printhead cleaningIn case of poor printing quality:- Press MENU key then CLEAN , in order to run a cleaning cyclefor the printhead, when the printing quality is getting poor or if themachine has remained unused for several days.- If the problem persists, remove the printhead (see paragraph"Ink reservoir and printhead" in section A) and clean the inkprinthead.94General Maintenance4131935Y/C17/09/2008ORIG0077-94

2.3 Removing the postage meter- Switch off the mailing machine.- Open the cover.- Hold the handle and pull it upwards.General Maintenance 954131935Y/C17/09/2008ORIG0077-95

2.4 Touchscreen precautions- Do not place items on it.- Do not give any shock or vibration to the product.- Do not apply water, organic solvent or chemicals such as acidand alkali to the machine. Do not put the product in such anenvironment.- Upon carrying the machine, be sure to hold the glass edge. Donot touch an operating surface may be stained or damaged.Never pull the cable nor give any considerable force to theperipheral circuit or cable may be damaged.- When any dust or stain is observed on a film surface, clean itusing a commercial for glass cleaner.96General Maintenance4131935Y/C17/09/2008ORIG0077-96

SECTION E: MAINTAINING YOUR TELEMETER SETTING ® ACCOUNT1. ACCOUNT NUMBER ...........................................................992. ACCOUNT BALANCE .......................................................... 993. POST OFFICE REGULATIONS ..........................................994. POSTAGE NOW ................................................................. 1005. STANDARD TMS® BANK ACCOUNTS ............................ 1016. WHERE TO MAIL YOUR DEPOSIT: ................................. 103974131935Y/C17/09/2008ORIG0077-97

984131935Y/C17/09/2008ORIG0077-98

1. ACCOUNT NUMBERAfter you sign a rental agreement for your meter, you will beassigned a TMS ® (Tele Meter Setting) Bank Account Number.An account confirmation Welcome Letter will be mailed to youindicating your TMS ® Bank Account Number and your MailerAgreement Number. These numbers should be kept in a safeplace, yet be readily available, because they are used for allTMS® account maintenance transactions.2. ACCOUNT BALANCEYou can use the <strong>Hasler</strong> Automated TMS ® system to check yourTMS® Bank Account status and other important TMS® information.Simply call 1-800-248-8013 and use your touchtone phoneto enter your TMS® Bank Account Number and your MailerAgreement Number. Then select from the menu options.You can also go online to (1) www.infonowonline.com or (2)www.haslerinc.com and select Postage Accounts (TMS). You willneed to enterTMS ® Bank Account Nnumber and your MailerAgreement Number. Then select from the menu options.With either system, you can then receive details regarding yourAccount Balance (includes the current balance, the availablebalance and any unpaid advances), You can also receive informationon holiday schedules, meter operating guides, liscensingforms, payment addresses, and customized TMS Bank Accountstatements.3. POST OFFICE REGULATIONSUnited States Postal Service regulations require that your metermust be audited at regular intervals (currently set at 90 days). Foryour convenience an audit is automatically performed each timeMaintaining Your Account 994131935Y/C17/09/2008ORIG0077-99

you add postage.If you do not add postage or perform an audit within a 90 dayperiod, a “PO LOCKOUT” message is displayed on the meterand postage printing is disabled. To clear the lockout, simplypress the key and a CLEAR LOCKOUT transaction will beprocessed via the modem connection. When the transaction iscompleted, postage printing is enabled for another 3 months.See Clear Lockout.4. POSTAGE NOWGet the postage you need, when you need it, without having to callahead of time. PostageNow, a service of the United States PostalService, gives you the option to seamlessly fund your postageneeds simply by setting your postage meter!With PostageNow TeleFundsLast-minute mailings are no longer a problem. Now, you can haveimmediate access to additional postage funds simply by settingyour meter! Postage funds will auto-matically be debited fromyour specified corporate bank account, usually the next businessday, but the postage is provided immediately by the USPS. Noprefunding required.Choosing seamless postage funds availability with PostageNowTeleFunds means you won’t have to maintain a minimum balancein your TMS Bank Account. And, with PostageNow TeleFunds,there’s never a transfer processing fee—ever.To begin using PostageNow TeleFunds, simply fill out the ACHCustomer Authorization and Agreement form, check thePostageNow TeleFunds option, and fax the form with avoided check to 1-800-237-0692. There is a one-time, $15 set-100Maintaining Your Account4131935Y/C17/09/2008ORIG0077-100

up fee for new accounts and a $10 pre-note (test of the corporatebank account).With PostageNow OnDemandIf you prefer to have more control over your postage, you maychoose instead to call ahead to debit a specified amount ofpostage funds from your corporate bank account with PostageNowOnDemand. The PostageNow OnDemand option can only beaccessed during the operating hours of the TMS Center. Therewill be a $5 processing fee each time you call to debit funds. Tobegin using PostageNow OnDemand, simply fill out the ACHCustomer Authorization and Agreement form, check thePostageNow OnDemand option, and fax the form with avoided check to 1-800-237-0692. There is a one-time, $15 setupfee for new accounts and a $10 pre-note (test of the corporatebank account).5. STANDARD TMS ® BANK ACCOUNTSStandard TMS® Bank Accounts are prefunded and require thatmoney be in your TMS ® Bank Account to add postage to yourmeter. After using the TMS ® system to add money to your meter,your account decreases by the amount of the postage added.Remember to deposit sufficient funds to cover your plannedsetting withdrawals.Upon receipt of the check, your TMS ® Bank Account will becredited with your deposit (allow 7 to 10 business days for thecheck to be received and posted).Make your check out to United States Postal Service, and writeyour TMS ® Bank Account on the check.Always enclose your Coupon with your check. This will assure theMaintaining Your Account 1014131935Y/C17/09/2008ORIG0077-101

fastest and most accurate bank processing. You will receive apackage of coupons in the mail shortly after setting up your TMS ® .Bank Account. Replacements are re-ordered automatically whenyou submit your 20th coupon with your check.102Maintaining Your Account4131935Y/C17/09/2008ORIG0077-102

6. WHERE TO MAIL YOUR DEPOSIT:From The United States Postal ServiceAnd <strong>Hasler</strong> , <strong>Inc</strong>.1 All checks for postage should be made payable to: UnitedStates Postal Service** Your Five digit AMS-TMS Account # must appear on yourcheck.** Be sure to include your coupon with the green stripe with yourcheck.2 There are three lock box locations to send First Class Mail.Please use the closest lock box for your location.EASTERN UNITED STATESCMRS-TMSP.O. Box 7247-0217Philadelphia, PA 19170-0217MID-WESTERN UNITED STATESCMRS-TMSP.O. Box 0527Carol Stream, IL 60132-0527WESTERN UNITED STATESCMRS-TMSP.O. Box 894757Los Angeles, CA 90189-4757Please allow up to 7-10 days for Citibank to process your check.Maintaining Your Account 1034131935Y/C17/09/2008ORIG0077-103

3 Also, there is one location for overnight service delivery.ENTIRE UNITED STATESATTN: Team One - TMSCitibank Lockbox # 02171615 Brett RdNew Castle, DE 19720Please allow up to 48 hours for Citibank to process your check.4 The Post Office will accept Wire Transfers:Send Wire Transfers to:Citibank , 111 Wall St., New York, NY 10043ABA Routing # 021000089CMRS/AscomAccount # 4067-8617Detail Payment Field:TMS Account #<strong>Inc</strong>lude your TMS Acct # to ensure accurate credit for your transferSend ACH Transfers to:Citibank, 111 Wall St., New York, NY 10043ABA Routing # 021000089CMRS/AscomAccount # 4067-8617Type:CCD/CCD+ TMS Postage Account # in postions in 40 thru 475 If we can be of further assistance, please contact any TMSRepresentative at 1-800-248-8013 or FAX 800-237-0692.104Maintaining Your Account4131935Y/C17/09/2008ORIG0077-104