BYK-315 BYK-320 BYK-322 BYK-323 BYK-325

BYK-315 BYK-320 BYK-322 BYK-323 BYK-325

BYK-315 BYK-320 BYK-322 BYK-323 BYK-325

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

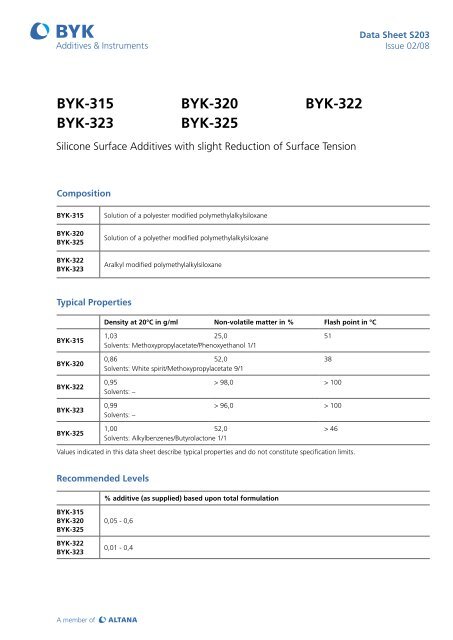

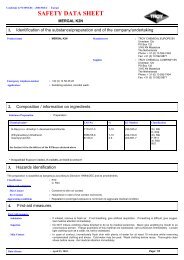

Data Sheet S203Issue 02/08<strong>BYK</strong>-<strong>315</strong> <strong>BYK</strong>-<strong>320</strong> <strong>BYK</strong>-<strong>322</strong><strong>BYK</strong>-<strong>323</strong> <strong>BYK</strong>-<strong>325</strong>Silicone Surface Additives with slight Reduction of Surface TensionComposition<strong>BYK</strong>-<strong>315</strong><strong>BYK</strong>-<strong>320</strong><strong>BYK</strong>-<strong>325</strong><strong>BYK</strong>-<strong>322</strong><strong>BYK</strong>-<strong>323</strong>Solution of a polyester modified polymethylalkylsiloxaneSolution of a polyether modified polymethylalkylsiloxaneAralkyl modified polymethylalkylsiloxaneTypical PropertiesDensity at 20°C in g/ml Non-volatile matter in % Flash point in °C<strong>BYK</strong>-<strong>315</strong><strong>BYK</strong>-<strong>320</strong><strong>BYK</strong>-<strong>322</strong><strong>BYK</strong>-<strong>323</strong><strong>BYK</strong>-<strong>325</strong>1,03 25,0 51Solvents: Methoxypropylacetate/Phenoxyethanol 1/10,86 52,0 38Solvents: White spirit/Methoxypropylacetate 9/10,95 > 98,0 > 100Solvents: –0,99 > 96,0 > 100Solvents: –1,00 52,0 > 46Solvents: Alkylbenzenes/Butyrolactone 1/1Values indicated in this data sheet describe typical properties and do not constitute specification limits.Recommended Levels% additive (as supplied) based upon total formulation<strong>BYK</strong>-<strong>315</strong><strong>BYK</strong>-<strong>320</strong><strong>BYK</strong>-<strong>325</strong><strong>BYK</strong>-<strong>322</strong><strong>BYK</strong>-<strong>323</strong>0,05 - 0,60,01 - 0,4

Data Sheet S203Issue 02/08Incorporation and Processing InstructionsThese additives can be incorporated during any stage of the production process, including post-addition.ApplicationsSolvent-borne coatingsAqueous coatings<strong>BYK</strong>-<strong>315</strong> –<strong>BYK</strong>-<strong>320</strong><strong>BYK</strong>-<strong>322</strong> –<strong>BYK</strong>-<strong>323</strong> –<strong>BYK</strong>-<strong>325</strong>recommendedsuitableFunctionThese additives provide a slight reduction of surface tension of paint systems. Therefore, they improve flow and leveling as wellas display partial defoaming properties. Additionally, they prevent Bénard cell formation.Special Features and Benefits<strong>BYK</strong>-<strong>315</strong><strong>BYK</strong>-<strong>320</strong><strong>BYK</strong>-<strong>322</strong><strong>BYK</strong>-<strong>323</strong><strong>BYK</strong>-<strong>325</strong><strong>BYK</strong>-<strong>315</strong> is especially designed for usage in automotive coatings. It improves flow and leveling as well as increasesgloss. <strong>BYK</strong>-<strong>315</strong> does not show blushing in clear coats after water immersion tests.<strong>BYK</strong>-<strong>320</strong> is a silicone leveling additive with defoaming properties. It is particularly suitable for non-polar tomedium-polar paint systems. Its defoaming activity rises with increasing coating polarity. In automotive andindustrial coatings, <strong>BYK</strong>-<strong>320</strong> will not exhibit problems with ghosting or telegraphing. To avoid these effects<strong>BYK</strong>-<strong>320</strong> should be added to the paint which has to be recoated.<strong>BYK</strong>-<strong>322</strong> is a silicone additive which is thermally stable at baking temperatures up to 250°C. Causing only aslight surface tension reduction, it does not normally stabilize foam and can even impart a defoaming action.Coatings containing <strong>BYK</strong>-<strong>322</strong> can normally be recoated without any loss of adhesion.<strong>BYK</strong>-<strong>323</strong> acts in a defoaming fashion (i.e., no or only slight foam stabilization), depending on the polarity ofthe paint system. It is heat resistant up to 250°C and does not decrease intercoat adhesion when overcoated.In wood and furniture coatings, <strong>BYK</strong>-<strong>323</strong> is used to orient the flatting agent in flat topcoats and in multi-coatsystems. Even in difficult to flat high-solids polyurethane, acid curing and unsaturated polyester coatings, theuse of <strong>BYK</strong>-<strong>323</strong> does not lead to shining up. In addition, optimal orientation of the flatting agent is achieved.In flow coat systems, <strong>BYK</strong>-<strong>323</strong> provides a stable curtain. In industrial coatings, <strong>BYK</strong>-<strong>323</strong> supports the orientationof flatting agents and aluminium flakes in metallics.<strong>BYK</strong>-<strong>325</strong> prevents ghosting (wipe-marks) if recoated with the same paint. It typically does not cause rewettingproblems and does not influence recoatability.Page 2

Data Sheet S203Issue 02/08Special Note<strong>BYK</strong>-<strong>322</strong>Please evaluate the compatibility of <strong>BYK</strong>-<strong>322</strong> before incorporation into clear coatings.In comparison to silicone oils these additives are „user friendly“. Through a series of tests, however, it shouldbe ascertained as to whether foam is being stabilized by these additives before large-scale application starts.Also, the recoatability and cratering should be evaluated.Storage and Transportation<strong>BYK</strong>-<strong>315</strong><strong>BYK</strong>-<strong>325</strong>Separation or turbidity may occur at temperatures below -5°C.Warm to 20°C and mix well.At temperatures below 15°C the product may become solid.Warm to < 50°C and mix well.Page 3

Data Sheet S203Issue 02/08<strong>BYK</strong>-Chemie GmbHP.O. Box 10 024546462 WeselGermanyTel +49 281 670-0Fax +49 281 65735info@byk.comwww.byk.com/additivesANTI-TERRA ® , <strong>BYK</strong> ® , <strong>BYK</strong> ® -DYNWET ® , <strong>BYK</strong> ® -SILCLEAN ® , <strong>BYK</strong>ANOL ® , <strong>BYK</strong>ETOL ® , <strong>BYK</strong>OPLAST ® , <strong>BYK</strong>UMEN ® , DISPER<strong>BYK</strong> ® , DISPERPLAST ® , LACTIMON ® ,NANO<strong>BYK</strong> ® , SIL<strong>BYK</strong> ® and VISCO<strong>BYK</strong> ® are registered trademarks of <strong>BYK</strong>-Chemie.AQUACER ® , AQUAFLOUR ® , AQUAMAT ® , CERACOL ® , CERAFAK ® , CERAFLOUR ® , CERAMAT ® , CERATIX ® and MINERPOL ® are registered trademarks of<strong>BYK</strong>-Cera.This information is given to the best of our knowledge. Because of the multitude of formulations, production and application conditions, all the abovementioned statements have to be adjusted to the circumstances of the processor. No liabilities, including those for patent rights, can be derived fromthis fact for individual cases.This data sheet replaces all previous issues - Printed in Germany