You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

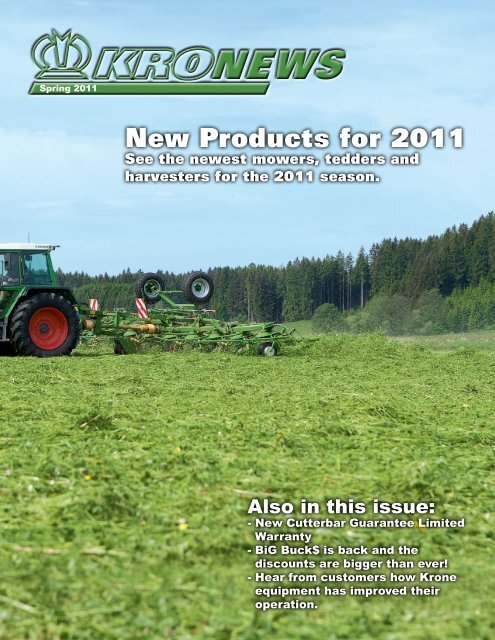

<strong>NEWS</strong>Spring 2011New Products for 2011See the newest mowers, tedders andharvesters for the 2011 season.Also in this issue:- New Cutterbar Guarantee LimitedWarranty- BiG Buck$ is back and thediscounts are bigger than ever!- Hear from customers how <strong>Krone</strong>equipment has improved theiroperation.

<strong>NEWS</strong>Spring 2011CONTENTSNew ProductsSee the new mowers, tedders andharvesters for the 2011 season.Pg. 6 - 7Contact UsMailing Address:P.O. Box 18880Memphis, TN 38181-0880E-mail Address:info@krone-northamerica.comPhone:(901) 842-6011Find us on Twitterwww.twitter.com/KRONE_NAFind us on Facebookwww.facebook.com/<strong>Krone</strong>HayEquipmentJoin us on Facebook and network with other hayproducers from around the world, stay up-to-dateon the latest offers from <strong>Krone</strong> and play HayfieldTrivia for the chance to win <strong>Krone</strong> t-shirts, hats,and other great prizes.Website:www.krone-northamerica.comAre you ready?Tips from <strong>Krone</strong> Service Technicians ongetting your <strong>Krone</strong> equipment ready to makehay this season.- Disc Mowers Pg. 4- Tedders Pg. 10The Life of RoundupReady AlfalfaIs it really here to stay?Pg. 8In their own words...Hear from customers how <strong>Krone</strong> equipmenthas improved their operations.- Danny Forsythe and his AM 283 Pg. 5- Maynard Taylor and his SW 46 T Pg. 9- Todd Thomas and his KW 552 T Pg. 10Get your...Up to $2,000Cash Backor0% FinancingAvailable on:3-Point Mowers, Mower Conditioners,Tedders, Rotary Rakes and Round Balers.2 - KroNews Spring 2011 - 3

Get your <strong>Krone</strong> MowerReady to Mow<strong>Krone</strong> 3-point mowers are easy to maintain andoperate, but there are a few checks that will ensure thatyour <strong>Krone</strong> mower operates as well this year as it didwhen it was shipped from the factory.First check that the cutterbar and all movingcomponents move freely. If the machine will not turn byhand begin investigating the cause, a bearing might be theculprit. The oil levels in all gearboxes should be checkedfor contamination and changed yearly. Condensation isoften the cause of water in the gearboxes and will shortenthe life expectancy of your <strong>Krone</strong> mower. Grease all lubricationpoints as indicated in the operator’s manual, anylubrication points that will not accept grease may needservicing or repair.Clutches must be burnished in order tofree the friction material and ensure thatthe overload clutches are able to protectthe machine and your tractor properly.Failure to prepare the clutch as indicatedin your operator’s manual can result inexpensive repairs. Changes to the overloadclutches will change the operating torque, use only<strong>Krone</strong> parts if repairs are needed before start up. Failureto properly service the clutches before use can result in avoided warranty.Another feature of <strong>Krone</strong> 3-point mowers is thesafety breakaway. On AM series mowers, this safetybreakaway must be serviced yearly to ensure proper operation.Service this mechanism as indicated in the operator’smanual to ensure your mower is protected.Most operators will check the conditionof the blades before beginningthe season, which is important,but just as important is checkingthe condition of the blade retaininghardware and discs. Worn retainingcomponents and discs are a hazard to the operator andothers. Always replace knives and retaining componentsin pairs to prevent unbalanced rotation. Check the weld inleading edges of the cutterbar and the skid shoes for wearor damage. These components protect your cutterbar andprevent costly damage.Lastly, the mower skirt protects the operator andthose around the machine from any accidental projectiles,this skirt may not perform properly if damaged or torn. Inspectthe skirt and repair or replace with <strong>Krone</strong> approvedparts.Danny ForsytheNatchitoches, LAOwner of: AM 283Sold & Serviced By: Goldman EquipmentNatchitoches, LADanny Forsythe is the proud owner of a <strong>Krone</strong>AM 283 3-point disc mower. “I really like the fact that Ido not have to adjust any belts,” says Danny, referring to<strong>Krone</strong>’s beltless, direct drive system. His 9-foot mowerfeatures a drive shaft that powers the mower cutterbar,meaning no belts to adjust or replace. An overrunning, resettingclutch is built-in to slip where others’ belt systemswear. This gives Danny’s mower more power in heavyhay.Danny runs a poultry and cattle operation, wherehe maintains an average of 200 cows. The <strong>Krone</strong> mowerhas improved his operation by helping him mow fasterand put up his hay quicker. When mowing grass in thehot Louisiana summer, he’s noticed that his <strong>Krone</strong> mowerwill out mow the other brand of mower that he also owns.His AM 283 has a better crop flow too. “When cuttingclover, the mower will not wrap up,” explains Danny.This is because the skirt-frame on his mower doesn’t haveany outer end support where crop can wrap. Wrappingissues are also reduced because the gearbox is placedbehind the inner mower drum eliminating the need for aninner shoe.Would Danny purchase another <strong>Krone</strong> mower?“Yes, once I wear out my 283 I want to purchase theEasyCut 320 with quick change blades.”<strong>Krone</strong> <strong>North</strong> <strong>America</strong> now offers a 3-year extended cutterbarlimited warranty. The <strong>Krone</strong> Cutterbar Guarantee offers customersthe option of an additional 2-years of cutterbar protection- including parts and labor - on top of <strong>Krone</strong>’s standard 1-yearlimited warranty.The <strong>Krone</strong> Guarantee is an option for all <strong>Krone</strong> 3-point discmowers, pull-type disc mowers and disc mower conditionerspurchased starting in March 2011.As a special introductory offer, the<strong>Krone</strong> Cutterbar Guarantee isFREE on all eligible disc mowerspurchased in March & April of this year.4 - KroNews Spring 2011 - 3

Previous PageEasy36001122700, 850,1100Products<strong>Krone</strong> has added the new EasyCut 3600 CV to itsline of disc mowers. This new side-pull mower conditionerhas a working width of 11’ 9” and features the EasyCutcutterbar with quick-change blades and SafeCut hubs. Forconditioning it uses a v-tine conditioner with an adjustableconditioner speed and adjustable baffle plate for control ofconditioning intensity. It also features a 2-point hitch forultimate maneuverability in the field and on the road.The new KWT 1122 Rotary Tedder from <strong>Krone</strong>combines a working width of 36 feet and a low tractor requirementof 50 horsepower. It features a transport chassisthat ensures smooth and safe running at transport speedsup to 25 mph with a transport width of only nine feet, nineinches.On the KWT 1122, 10 small-diameter rotors workto spread the crop out flat for improved drying times. Eachrotor has six tubular tine arms with tines wrapped aroundthe arm for added durability and clean forage. Adding tothe machines’ maneuverability is the 2-point hitch, whichallows for better turning in transport and work position.Like all <strong>Krone</strong> Tedders, the KWT 1122 features rotor angleadjustment and a boundary tedding system.<strong>Krone</strong> has released a new line of <strong>Krone</strong> BiG X forageharvesters. The new machines feature a MAN engineand the revolutionary crop flow design, VariStream. Theline-up includes the 775 hp BiG X 700, the 850 hp BiG X850 and the 1,078 hp BiG X 1100.The MAN engine, with its common rail injection,leads to quiet running, low fuel consumption, high efficiencyand low maintenance. With the MAN engine the BiG X850 and 1100 are able to produce more horsepower from asingle engine than their predecessors, the BiG X 800 and1000, were able to with twin-engines.The new VariStream spring-loaded crop flow is arevolutionary design that is unique to the BiG X. It adaptsthe cross section of the crop flow as the crop volume variesusing spring-loaded plates in the cutting cylinder and thecrop blower. The benefits are more efficient fuel consumption,higher throughput and less wear.Easy2801Don’t Compromise on Quality -Use <strong>Krone</strong> Excellent PartsYour investment in a <strong>Krone</strong> machine showsthat you are convinced of its high quality and reliability.Using parts from the original manufacturer isthe only way to ensure your machine will maintain itspeak performance well into the future.All <strong>Krone</strong> Excellent Parts are engineering approvedto the highest standards and top-quality OEMstandards, assuring longevity and value. Remember:Operational reliability is the single top priority in theheat of harvest. Only parts made to the correct tolerancesfor <strong>Krone</strong> machines provide optimum performance.Excellent Twine is auniversal twine from <strong>Krone</strong>, whichensures bales are tied effectivelyand tightly on every baler - knot byknot.The new EasyCut 2801 CV is a heavy-built mowerconditioner with a cutting width of 8’11”. This new mowerhas several features that make it a strong, reliable machine.It has a new parallel linkage with redesigned center of gravityflotation for the best ground following. The gearbox hasa new oil flow design for the optimum lubrication of bearings.Also, covers have been added to the side of the cutterbarto prevent the crop from being thrown out, so all ofyour crop ends up in your windrow.The innovative SafeCut disc protection systemoffers effective protection and peace of mind. Rather thantransferring the shock load of an impact to the cutterbar,the system transfers the load to a roll pin, which breaks as aresult of the impact. Then the disc moves up on its threadeddrive pin and clears out of the way of neighboring discs.SafeCut is now available on all <strong>Krone</strong> EasyCut DiscMowers and EasyCut Disc Mower Conditioners.Time is money. For this reason farmers needto rely on fast and dependable parts supply service inthe heat of harvest. To ensure our customers are suppliedwith the required parts in the shortest possibletime, <strong>Krone</strong> continues to invest in its logistics systemto streamline procedures. <strong>Krone</strong> has four parts warehousesin <strong>North</strong> <strong>America</strong>, with locations in Memphis,Tenn., Reno, Nev., Ontario and Quebec. The Memphiswarehouse is over 60,000 square feet with stockof over 20,000 items. An integrated logistics systemallows for picking and shipping more than 200 ordersper day.Excellent RoundEdgeNet-Wrap ensures highest quality netwrapson every baler and in any crop.6 - KroNews Spring 2011 - 7

Previous PageThe Life ofRoundup Ready AlfalfaBy Kristine WalkerRoundup Ready crops werenothing new when Monsanto firstbegan working on the technologyfor Roundup Ready Alfalfa in 1998.Farmers already enjoyed the benefitsof having crops resistant to glyphosate,called Roundup Ready, such ascorn and soybeans, so why not addAlfalfa to that list? Crops resistant toglyphosate are able to withstand beingsprayed with the common herbicideRoundup to kill weeds in the field,without affecting the crop. Monsantolicensed the Roundup Ready Alfalfatechnology to Forage Genetics, whichthen worked with several other majorseed companies to further develop thetechnology. The process of developingRoundup Ready Alfalfa to thepoint where it would be sold to farmerswould not be a quick or easy one.It took time to develop the glyphosateresistant plant, and then it tookseveral years for the United StatesDepartment of Agriculture to approveRoundup Ready Alfalfa to be soldwithout regulations or conditions.The development process ofthe glyphosate resistant plants beganby planting the alfalfa with theRoundup Ready gene in a greenhouse.Once the plants were established, theywere sprayed with Roundup and themost tolerant plants were then transplantedto the field. Once in the field,the alfalfa was given a final tolerancetest. It was sprayed with Roundupthat was twice as concentrated as theusual application. The success of thefinal test concluded the first step ofthe development process; the RoundupReady gene had been established.The next step of development wasto begin establishing varieties of theplant so that it would be a high qualityforage with increased pest resistance,boast high yields, and be winter hardy.During this development stage iswhen Roundup Ready Alfalfa wouldbegin the process of clearing governmentregulations.On June 27, 2005, the Animaland Plant Health Inspection Services(APHIS) granted non-regulated statusto Roundup Ready Alfalfa. However,soon after the approval, a lawsuitwas filed that resulted in requiringAPHIS to develop an EnvironmentalImpact Statement (EIS) to determineif there were any significant environmentimpacts caused by RoundupReady Alfalfa. Until the EIS wascompleted, the court prohibited thesale of Roundup Ready Alfalfa seedon March 12, 2007. Farmers whoalready had their stands planted didnot have to remove them and theycould also harvest and sell the RoundupReady Alfalfa, however no moreRoundup Ready Alfalfa could beplanted. Once the EIS was completed,APHIS published a notice on February2, 2011 announcing that basedon the finding in the EIS, RoundupReady Alfalfa would be granted nonregulatedstatus. Just when farmersthought the Roundup Ready Alfalfadebate was over, a new lawsuit hasbeen filed. March 18, 2011, the Centerfor Food Safety and Earthjustice fileda lawsuit claiming the non-regulatedstatus given to the crop was unlawfuland APHIS failed to do their job onassessing the environmental impact.This spring many farmers willbe able to reap the benefits of plantingRoundup Ready Alfalfa. Farmerswho choose to plant RoundupReady Alfalfa seed will see that it ismore productive when compared toconventional alfalfa. They can alsoexpect to see higher profits per acre,with some farmers self-reporting upto $110 advantage per acre. Furthermore,the quality of the baled foragewill be superior due to the eliminationof weeds. It was a long journeyfor Roundup Ready Alfalfa to getwhere it is today, and now with a newlawsuit filed only time will tell whatimpact it will have on the non-regulatedstatus of Roundup Ready Alfalfa.Maynard TaylorConnelly Springs, NCOwner of: Swadro 46 TSold & Serviced By: Tractor and EquipmentNewton, NCMaynard Taylor is a busy man. He runs a successfulAg dealership and does all of the hay for his beef cowoperation. Being a dealer, Maynard knows about the manyoptions a customer has for hay equipment. He wants to beable to sell his customers the best product he can, that’swhy he sells and owns <strong>Krone</strong> equipment.When Maynard was looking to upgrade from hisroller bar rake, he wanted a more efficient way to rake anddry his hay. So, he chose the 15’ Swadro 46 T. Accordingto him, the purchase of the <strong>Krone</strong> rake has cut his rakingtime in half and makes a better windrow. Because of thenice windrow his rake makes, the hay in the windrow hasa faster dry time.When it comes to features on his Swadro rake,Maynard really likes the transport features. He explains,“the transport height of the machine ensures that I don’thave to rake myself out of the field. The foldable tine armsmake transporting the rake down the road simplistic. Also,the tandem axle give a smooth transport even in roughfield conditions.”Would he purchase <strong>Krone</strong> again? “Yes, <strong>Krone</strong> isfirst in class in new technology.”8 - KroNews Spring 2011 - 9

Get your <strong>Krone</strong> TedderReady to TedA <strong>Krone</strong> tedder is a well-built and low-maintenanceimplement, but there are a few things that shouldbe inspected before your machine goes to the field for thefirst time this year. Let’s start at the front of the machine,the PTO shaft needs to be greased, the cross assembliesshould be checked for wear, the clutches must be maintainedas suggested in the operator’s manual, and all safetyguards should be in place. Many <strong>Krone</strong> tedders utilizeflange bearings that should be inspected and greased. Allgrease fittings should be greased before first use.The main gearbox should be checked for leaks andthe oil should be at the proper level. If oil is needed, checkyour operators manual for what type to use. All hydraulicconnections should be inspected for leaks and repaired ifnecessary.Todd Thomas – Hunter Bottom FarmsTriune, TNOwner of: KW 552 TSold & Serviced By: Rutherford Farmers CoopMurfreesboro, TNThe rotor gearboxes on <strong>Krone</strong> tedders arevery low maintenance and should onlyneed lubricant (GFO 35) added if there isan indication of a leak. The leak should benoted and repaired as soon as possible toprevent further damage.Check the condition of the tires on your tedder, ifthere is excessive wear consider replacing the tire beforethe season begins rather than risk expensive downtimewith hay on the ground.<strong>Krone</strong> Tedders are equipped with guards andshields for your safety, check that they are in place andthat they are in good condition and the retaining hardwareis tight. Tines and tine arm hardware should also bechecked for proper torque and any hardware that causesdoubt should be replaced. Losing a tine in the field can bea costly accident if it is found by your tractor tire or baler.Lastly, tines are a wear item and if your machinehas a few seasons of wear it might betime to consider replacing them. There isalways risk in farming, but hopefully thesereminders will help those with a <strong>Krone</strong> tedderhave a trouble free and profitable year.Todd Thomas will readily admit that he pushes hisequipment to the limit. “I don’t abuse my equipment, but Ido use it.” Todd owns Hunter Bottom Farms in the WilliamsonCounty community of Triune, just a long windrowsouth of Nashville, Tennessee. Todd has a beef cattleoperation and a grain operation, and in his free time balesstraw.“I like the hydraulic fold and tilt feature on my<strong>Krone</strong> tedder. I farm in three different counties so wetravel quite a bit. I don’t have to worry about makingadjustments when we change fields, I just hit the remoteand go on to the next field.” Todd does a large amountof wheatlage in the spring. “I needed a heavy tedder tohandle the high volume of material. The <strong>Krone</strong> tedder wasthe only tedder that looked like it was heavy enough tohandle a heavy crop.”With his busy schedule, downtime is a critical factorand Todd reports that after two seasons of extreme usagehe has not experienced any failures, not even a brokentine! He is confident that if a problem ever surfaces hecan depend on his local dealer, Rutherford Farmers Coopin Murfreesboro, where he purchased his <strong>Krone</strong> tedder.“They are a good dealer to work with,” Todd explains,“and that was another of the reasons I went with the <strong>Krone</strong>tedder.”“I expect a lot from my equipment and my<strong>Krone</strong> tedder has exceeded those expectations.”10 - KroNewsSpring 2011 - 3

Looking for machinery to improve the performanceand productivity levels in your operation?We invite you to see how <strong>Krone</strong> machines can make a difference for you. That difference can be a higher chop quality,a tighter bale, a uniform windrow, a precision cut, increased capacity and many other advantages depending on the typeof machine you require. <strong>Krone</strong>’s development and growth in the <strong>North</strong> <strong>America</strong>n market has evolved as a result of innovationand technology designed to cut your cost per unit of production; cost per acre, cost per ton, cost per gallon orany measure you use to determine productivity levels.<strong>Krone</strong> equipment is manufactured in Spelle, Germanywhere the company is still run by the <strong>Krone</strong> family.The <strong>Krone</strong> <strong>North</strong> <strong>America</strong>n headquarters is locatedin Memphis, Tennessee.New Products for 2011 * New Cutterbar Guarantee WarrantyPO Box 18880Memphis, TN 38181BiG Buck$ Cash Discounts * Hear from <strong>Krone</strong> Customers<strong>NEWS</strong>