SUPREME REFRIGERATORS User Manual - Polaris S.p.A.

SUPREME REFRIGERATORS User Manual - Polaris S.p.A.

SUPREME REFRIGERATORS User Manual - Polaris S.p.A.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

22.10.2004 Rev.1. General information ..................................................................................... 11.1 Symbols used in the manual .......................................................................................... 11.2 Symbols used on the appliance ...................................................................................... 11.3 Checking correspondence between the appliance and the manual ............................... 22. Safety .............................................................................................................. 32.1 Using the appliance safely ............................................................................................. 32.2 Recommendations on how to best operate the appliance (2000/40/EC) ....................... 32.2.1 Installation tips ....................................................................................................... 42.3 Disposing of the appliance (environmental protection) ............................................... 43. Functional description .................................................................................. 53.1 Intended use .................................................................................................................. 53.2 Control panel ................................................................................................................. 64. Operating instructions ................................................................................. 74.1 Prior to use ..................................................................................................................... 74.1.1 Preliminary checks ................................................................................................. 74.1.2 Start up and checks ................................................................................................ 84.2 Operation ....................................................................................................................... 84.3 After-use care ............................................................................................................... 84.3.1 Cleaning ................................................................................................................. 84.3.2 Cleaning the neon lamp [TNV, BTV] ................................................................... 84.3.3 Maintenance operations that may be carried out by the user ................................ 94.3.4 Maintenance operations to be performed by authorised technical support personnel94.3.5 Rating plate data .................................................................................................. 104.3.6 Idle periods .......................................................................................................... 105. Installation ................................................................................................... 115.1 General information ..................................................................................................... 115.2 Transport and storage .................................................................................................. 115.3 Unpacking the appliance ............................................................................................. 125.4 Installation ................................................................................................................... 125.4.1 Cleaning ............................................................................................................... 125.5 Electrical connections .................................................................................................. 125.6 First turn-on ................................................................................................................ 125.7 Connections for “Remote cooling” ............................................................................. 135.7.1 Electrical connections .......................................................................................... 13

22.10.2004 Rev.5.7.2 Connecting refrigerant pipes ................................................................................ 135.7.3 Suggestions .......................................................................................................... 136. Adjustment instructions ............................................................................. 146.1 Programming the electronic circuit ............................................................................. 146.1.1 Keyboard .............................................................................................................. 146.1.2 Switching the appliance on and off ...................................................................... 156.1.3 Programming menu .............................................................................................. 156.1.4 Unlocking the circuit ........................................................................................... 156.1.5 Set the card language ........................................................................................... 156.1.6 Setting the date and time ...................................................................................... 156.1.7 Disabling / enabling night buzzers ....................................................................... 156.1.8 Preservation cycle in progress ............................................................................. 156.1.9 Selecting the operation program .......................................................................... 166.1.10 (L1) led .............................................................................................................. 166.1.11 <strong>User</strong> diagnostics ................................................................................................. 166.1.12 HACCP history .................................................................................................. 166.1.13 Changing the relative humidity within a program [TN,TNV] ........................... 166.1.14 Changing the SET POINT within a program ..................................................... 176.1.15 <strong>Manual</strong> defrosting .............................................................................................. 176.1.16 Forcing On for three hours ................................................................................. 176.1.17 Alarm status ....................................................................................................... 176.1.18 Current function type ......................................................................................... 176.1.19 Configuration programs ..................................................................................... 186.2 Changing the light bulb [TN, BT, P] ........................................................................... 186.3 Changing the neon tube [TNV, BTV] ......................................................................... 196.4 Attaching and detaching the grille support guide ........................................................ 197. Troubleshooting .......................................................................................... 208. Spare parts .................................................................................................. 218.1 Voltage codes .............................................................................................................. 238.2 Product codes ............................................................................................................... 239. Technical specifications .............................................................................. 33

General information22.10.2004 Rev. 1.01. General informationThis manual contains information on how to minimise environmental impact in compliancewith ECO-LABEL regulations (2000/40/EC).Read the instructions in this manual carefully, as they contain important information onhow to install, use and service the appliance safely, properly, and effectively.Keep this manual in a safe place for future reference by other users.This appliance should be installed following the instructions provided by the manufacturerand in compliance with all applicable local regulations. This appliance should be connectedto the power and water supply only by qualified personnel.All personnel in charge of using this appliance should be specifically trained in its operation.In the event of failure or malfunction, switch off the appliance. The periodic functionalchecks requested in this manual should be carried out according to the instructions. Havethe appliance serviced by a technically qualified person duly authorized by the manufacturerthat uses genuine spare parts. Never attempt to repair this appliance by yourself. Repairscarried out by unqualified people can cause damage.Failure to comply with the above may jeopardise the appliance’s safety.1.1 Symbols used in the manualThis symbol informs about a situation where a safety risk could be imminent. The instructionsprovided must be followed in order to prevent injury.This symbol informs about the right way to act in order to prevent bad results, damage tothe appliance, or hazardous situations.This symbol informs about tips and tricks that help the user to get the best possible performanceout of the appliance.This symbol informs about a function that needs to be taken into account when doing selfcontrol.1.2 Symbols used on the applianceThis symbol on a part warns the user that there are electrical terminals behind it. Therefore,the concerned part should only be removed by qualified personnel.1

General information22.10.2004 Rev. 1.01.3 Checking correspondence between the appliance and the manualThe rating plate of the appliance shows its serial number. If the manuals are missing, youmay order new ones from the manufacturer or your local representative. When orderingnew manuals it is essential to quote the serial number shown on the rating plate.Keep this manual as well as the wiring diagram with care, and put them at the operator’sdisposal for future reference.2

Safety22.10.2004 Rev. 1.02. Safety2.1 Using the appliance safelyRead the following directions and warnings carefully:2.2 Recommendations on how to best operate the appliance (2000/40/EC)Following the suggestions contained in this chapter will result in lower energy consumption.These appliances are designed for indoor use.Choosing a convenient installation location for the appliance is extremely important to ensureproper operation and energy savings; in fact, users who have the possibility of installingthe appliance in a non-heated or less-heated room can achieve significant energysavings.The best performance is obtained when room temperature ranges between +18°C (64°F)and +43°C (109°F) (Climate class T); +18°C (64°F) and +38°C (100°F) (Climate classST); +16°C (61°F) and +32°C (90°F) (Climate class ST); the rating plate found inside theappliance shows the climate class to which it belongs.If room temperature exceeds the values indicated by the climate class of this product,please follow the directions below: when room temperature falls below the minimum value,a proper storage temperature in the freezer compartment may not be ensured; therefore,we recommend that you use up all food contained in it as soon as possible.In order to achieve additional energy savings and ensure proper operation, we recommendthat you avoid opening the door/lid or holding it open more often or longer than necessary.It is important to let foods cool down prior to storing them in the appliance, because otherwisethey will produce steam which, in turn, favours frost build-up on the evaporator;in addition, it is important that the cool-down period is as short as possible (if possible,use blast chillers) for health and hygiene reasons.Avoid heavy frost build-up on the evaporator; if necessary, carry out additional manualdefrost cycles to melt away any frost build-up.Replace the door gasket if it is not working properly.It is useful to keep the condenser found in the appliance’s motor compartment and thespace under the refrigerator clean by removing any dust and cooking vapours.3

Safety22.10.2004 Rev. 1.02.2.1 Installation tipsCheck that the surface on which the appliance will rest is level and suitable to support itsweight.To ensure proper airflow and avoid any damage to the refrigeration circuit, allow a minimumside clearance of 50 mm (2 inches); do not place the appliance close to heat sources(such as ovens, radiators, etc.) or exposed to direct sunlight and provide suitable insulationfrom walls or floor if they transmit heat.If the appliance has been moved, wait for a while before switching it on again.2.3 Disposing of the appliance (environmental protection)Our appliances contain the refrigerant shown on the corresponding rating plate as perRegulation (EC) No. 2037/2000 of 29 June 2000; in addition, the appliance is composedof reusable or recyclable parts and materials. Therefore, at the end of its lifetime, the applianceshould be delivered to a specific disposal centre. The best method to ensure thatno one will remain trapped inside is to take off the door completely.The appliance must not be disposed of together with household waste and metal scrap.Absolutely avoid damaging the refrigeration circuit, particularly near the heat exchanger.Pic. 2.14

Functional description22.10.2004 Rev. 1.03. Functional description3.1 Intended useThis appliance should only be used to store food and beverages. The manufacturer shallnot be held liable for the consequences resulting from unintended uses of this appliance.Do not store food in direct contact with the structure.Both the appliance’s construction features and the condensing unit’s capacity have beendesigned to store only pre-cooled products. Never place carbonated beverages into thelow-temperature compartment as they may explode. Never place liquids or hot food intothe appliance and do not fill lidded containers to the top.In all appliances there are surfaces subject to frosting. Depending on the model, frost maybe melted away either automatically (automatic defrost) or manually. Never attempt to removefrost using a pointed object because in this way you could irreparably damage theappliance.Do not use any mechanical device or other artificial means to accelerate the defrost process.The Manufacturer declines all responsibility, and the warranty shall be null and void, ifelectrical and/or mechanical alterations are made to the product.The warranty shall also be null and void if the product is tampered with or, in general, incase of alterations not expressly authorised and not made in compliance with the instructionsgiven herein.5

Functional description22.10.2004 Rev. 1.03.2 Control panelThe following components can be found on the appliance frontal:Pic. 3.1 - Frontal1. Temperature display2. Electronic control device3. KeyboardUsing instructions are provided in the"Programming the electronic circuit" chapter.6

Operating instructions22.10.2004 Rev. 1.04. Operating instructions4.1 Prior to use4.1.1 Preliminary checksGeneral checksTo ensure a proper operation:• Level the appliance. If necessary, use the mobile part of the adjustable feet to obtaina perfect alignment.• Remove the plastic protection from the external surfaces.• Wash the inside part with tepid water and mild soap.• Place the appliance as far as possible from heat sources.• Do not prevent air from circulating inside the engine compartment.• The closing keys (if available) should not be within reach of children.Checks to the electrical connections• The network voltage and frequency values should be the same of those reported onthe appliance part number plate (point 6 of the "Rating plate data" paragraph).• Connectors should be secured to the electrical switchboard correctly (during handlingand transport, vibrations could have caused loosening).• Fit a 16A fuse upstream from the socket.• Switch the main switch that will be connected to the power lead plug to the OFFposition.• Check that the socket is suitable for the appliance plug. If necessary, the socketshould be replaced with an appropriate one by qualified personnel. This personnelshould also make sure that the socket cable section is appropriate to the power absorbedby the appliance. Check that the plug is plugged into the socket.7

Operating instructions22.10.2004 Rev. 1.04.1.2 Start up and checks4.2 OperationThe appliance can be started up after the above mentioned operations have been carriedout strictly:• Switch the main switch that is connected to the power lead plug to the ON position.• Switch on the appliance using the POWER button (press the button for one second);• To change the SET POINT, see the "Changing the SET POINT within a program"paragraph in the "Programming the electronic circuit" chapter.4.3 After-use careProper storage of foodstuffs is a relevant factor in the safe and sanitary production of food;in addition, it improves the efficiency of foodservice activities and positively affects energyconsumption. Follow the directions below to obtain the highest performance possibleout of your appliance.Products should be placed into the appliance in such a way as to allow unobstructed airflow.Always leave some free space between the products and prevent them from comingin contact with the walls. If needed, adjust the distance between shelves. Products shouldalways be stored on the shelves; do not place any products on the cabinet’s bottom.4.3.1 CleaningHow often you will need to clean the appliance depends largely on how often you use it.Analyze the use and schedule the required cleaning operations.To clean the appliance’s inside and outside, use a neutral or slightly alkaline detergent.We recommend that you clean the inside with a disinfectant every once in a while. Impuritiesmay be removed using a damp cloth. Removing the shelves makes cleaning the insideeasier.Prevent water from coming in contact with the electrical components. Using a pressurisedjet of water to clean the appliance is forbidden. Never use metal objects to clean the appliance,as they could damage it.4.3.2 Cleaning the neon lamp [TNV, BTV]Cleaning operations are limited to the external surface. Do not use detergents, diluents,cleansing agents specific for glass, plastic or other similar materials. Use a soft, slightlydamp cloth only. Before cleaning, remove the plug from the socket or switch the line mainswitch to the “0” position.8

Operating instructions22.10.2004 Rev. 1.04.3.3 Maintenance operations that may be carried out by the userUnder normal conditions of use the appliance only requires a minimum of maintenance.The user can carry out the following operations:• Cleaning the inside and outside every day or as often as needed.• Cleaning the condenser at least twice a year or more often if used in a dusty environment.Before cleaning the condenser, turn the appliance off using the mainswitch and disconnect the power cord from the power socket (outlet). Use a vacuumcleaner or a soft brush. When brushing the condenser, exercise great care so asto avoid damaging the aluminium grid.• Check that the condensate drain hose is not clogged. If needed, clean it. Possiblemalfunctions due to a clogged drain may not be attributed to the manufacturer.• Check that the fan is properly fixed to its frame.• Check for fan unbalancing, evidenced by abnormal vibration or noise, thoroughly.• Check the power cord connecting the appliance to the wall socket (outlet) for cuts,cracks, or alterations which might compromise its insulation. If the power cordneeds servicing, contact your nearest technical support centre.4.3.4 Maintenance operations to be performed by authorised technical support personnelAny maintenance operations not mentioned in the above paragraphs, should be performedby authorised technical support personnel only. The need to perform maintenance operationsdepends largely on the external conditions and how often the appliance is used.For further information, contact your local representative. Identifying the appliance correctlyis useful when ordering spare parts or requesting maintenance or repair operations.The appliance’s model and serial number are shown on the rating plate found inside theappliance.9

Operating instructions22.10.2004 Rev. 1.04.3.5 Rating plate dataRating plate1. Serial Number2. Code3. Model4. Voltage5. Net capacity6. Power7. Defrost heater8. Power input9. Refrigerant10. Lowest and highest pressure11. Lamp12. Climate class13. Gas for expansion14. Year of Manufacture4.3.6 Idle periodsFollow the precautions below if the appliance will be left idle for some time:• Unplug the appliance from the wall socket (outlet);• Remove all foodstuffs from the appliance;• Defrost it and clean the inside;• Leave the door partly open to favour air circulation inside the cabinet and preventunpleasant smells from forming.• Store the appliance in such a way as to avoid that anyone can remain trapped inside.10

Installation22.10.2004 Rev. 1.05. Installation5.1 General information5.2 Transport and storageEnsure that installation is performed according to the instructions given under chapterRecommendations on how to best operate the appliance (2000/40/EC), Installation tips.We remind you that insufficient airflow will certainly result in appliance malfunction ordamage.Once the appliance has been installed, ensure that it is not resting on the power cord.In the event of damage, the power cord should only be replaced by qualified personnelwith a special cable or cable assembly available from the manufacturer.Ensure compliance with all local safety rules in force at the time of installation.Prior to plugging in the appliance, ensure that the power distribution network ratingsmatch the values shown on the appliance’s rating plate.It is absolutely necessary that the appliance be connected to an effective earth (ground)connection. To this end, the power cord plug is equipped with a grounding contact. If thepower socket (outlet) of the system is not grounded (earthed), connect the appliance to aseparate grounding (earthing) system in compliance with applicable regulations in force.Ask for a qualified technician’s advice.The manufacturer declines all responsibility in case of non-compliance with this accidentpreventionrule.You must always be able to disconnect the appliance from power supply; therefore, oncethe appliance has been installed the power socket (outlet) should be easily accessible.If possible, do not unpack the appliance until it is placed near the final installation site. Donot tip it over.If the appliance has been tipped over, wait for a while until oil settles down again.The appliance should always be stored in sheltered areas.If the appliance was stored in a cold place, thus causing the temperature of the refrigerationunit to fall below 0°C (32°F), prior to start using the appliance keep it at room temperaturefor at least one hour so that the refrigeration unit will warm up to +16°C (61°F).Turning on the appliance when temperature is excessively low may result in compressormalfunction.11

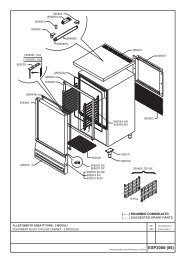

Installation22.10.2004 Rev. 1.05.3 Unpacking the appliance5.4 InstallationUnpack the appliance and check for transport damage. Remove the protective film fromthe appliance’s body.Packing materials (plastic bags, polystyrene foam, nails, etc.) should be kept out of children’sreach as they are potential sources of hazard, and they should be properly recycledin compliance with local regulations in force.Place the appliance in its final installation site.When lifting the appliance with a suitable mechanical device, ensure that the structure atthe base is undamaged.Level the appliance using its adjustable feet. Use a level, if needed. The maximum permissibledeviation from the horizontal plane is +/-0.5 degrees. All four feet should be restingon the floor. This will ensure proper door operation.5.4.1 Cleaning5.5 Electrical connectionsPrior to use, clean the inside, the shelves and the outside with a cloth and wipe dry. Toclean use a neutral or slightly alkaline detergent.5.6 First turn-onThe appliance may be switched on three hours after installation. Plug the appliance into agrounded outlet (earthed socket). To do so, you will need to have a power outlet (socket)with a built-in 16A-fuse fitted upstream of the system. Check that power supply voltagematches the value shown on the appliance’s rating plate.Check that a circuit breaker switch having a contact gap of at least 3 mm is fitted upstreamof the power socket (outlet).Turn on the appliance using the main switch. After 1 minute, the compressor will start cyclinguntil internal temperature reaches the factory-set value. Do not load the applianceuntil the set temperature value has been reached. If you need to change any factory-set parameters,please read the instructions given under chapter "Adjustment instructions".12

Installation22.10.2004 Rev. 1.05.7 Connections for “Remote cooling”5.7.1 Electrical connectionsThis version of the appliance is supplied with an electronic circuit according to what specifiedin the "Control panel" paragraph. In this case, a connection with a condensing unitshould be provided for.Connect the M connector of the electronic circuit to the compressor and to the electric fanby using the parts supplied with the appliance.5.7.2 Connecting refrigerant pipesSuction pipesLay down the suction line according to the established layout making sure that the numberof elbows and vertical sections where the refrigerant flows upward is limited to the veryminimum. Weld the suction line to the appliance exits jutting out of the side, provided forthis purpose. The suction pipe is generally to be distinguished from the liquid line by itsdiameter: it is the larger of them. Repeat the operation on the condensing unit. The verticalsections of the suction pipe shall be equipped with a trap and counter- trap to make oiltrapping easier and prevent it from flowing back to the evaporator when the compressoris off due to the thermostatic control.Please bear in mind that the only method applicable to vertical pipe sections where therefrigerant flows upward to make sure the oil returns to the compressor and prevent iffrom seizing due to insufficient lubrication, consists in “pulling” the oil by exploiting gasspeed.Liquid lineLay the liquid line pipes according to the established layout making sure that the numberof elbows and vertical sections where the refrigerant flows upward is limited to the veryminimum. Braze the liquid line pipe to the appliance outlet pipe located where the especiallyprovided protruding section is. The liquid line pipe can generally be distinguishedfrom the suction pipe by its diameter: it is the smaller one. Repeat the operation for thecondensing unit.5.7.3 Suggestions• SLANT: the horizontal sections of the suction pipes shall have a 0.5% slant towardsthe compressor to ensure oil back flow.• ELBOWS: to reduce pressure drops to a minimum, include as few elbows in yourline as possible and if you do, use large radius elbows only.• THERMAL INSULATION: the liquid line shall be insulated if exposed to the sunor if passing through areas where temperature is higher than condenser outlet temperatur13

Adjustment instructions22.10.2004 Rev. 1.06. Adjustment instructions6.1 Programming the electronic circuit6.1.1 KeyboardPic. 6.1 – Electronic circuitON/OFF key (P1): when the appliance is off (stand-by), by pressing the key for one secondit switches on; when the appliance is on, by pressing the key for one second it switchesto the stand-by status.Light key (P2), enabled in glazed appliances: when pressed, it turns the internal neon lampon or off; if the appliance is not glazed, this button is disabled. [TNV, BTV]TEST key (P3): shows the appliance operating status and silences the current alarm.RH% key (P5): allows to change the default humidity value of the program (not valid forBT).SET key (P6): accesses the SET POINT; unlocks the keyboardUp arrow key (P7): scrolls the menu entries; increases values; starts manual defrosting.Down arrow key (P8): scrolls the menu entries; decreases values; starts the continuous operationmode (3 hours).14

Adjustment instructions22.10.2004 Rev. 1.06.1.2 Switching the appliance on and offWith the appliance connected to the electric network, press the P1 key for one second atleast; the appliance will switch on. By pressing the P1 key for one second with the circuitset to ON, the appliance will go back to the stand by mode.6.1.3 Programming menuWith the keyboard locked, press the P6 key for 5 seconds to enter the programming menu.6.1.4 Unlocking the circuitTo unlock the keyboard, press the P6 key for one second.6.1.5 Set the card languageIn the programming menu, scroll the entries by using the P7 and P8 keys to the “Language”entry.Use the P5 key to change the datum and press the P6 key to exit, or wait for 5 seconds.6.1.6 Setting the date and timeIn the programming menu, scroll the entries by using the P7 and P8 keys to the “Set datetime”entry.P7 and P8 keys allow to change the datum highlighted by using the "_" cursor, while theP5 key allows to confirm and to go to the next datum. Once finished press the P6 key toexit or wait for a few seconds.6.1.7 Disabling / enabling night buzzersIn the programming menu, scroll the entries by using the P7 and P8 keys to the “Nightbuzzers” entry.Use the P5 key to change the datum and press the P6 key to exit, or wait for 5 seconds.6.1.8 Preservation cycle in progressDISPLAY 1 shows the room temperature. DISPLAY 2 shows the settings for the currentprogram.In case of a BT cabinet, the humidity value (RH%) is omitted.15

Adjustment instructions22.10.2004 Rev. 1.06.1.9 Selecting the operation programWith the keyboard locked, press the P7 or P8 keys to select programs. DISPLAY 1 shows“Pr”, while DISPLAY 2 blinks and indicates the selected program.Confirm the selected program, press the scrolling key twice or wait for a few seconds.Once the program has been set, DISPLAY 1 shows the room temperature and DISPLAY2 stops blinking.6.1.10 (L1) led• If on, it signals an alarm in progress.• If blinking, it signals an HACCP alarm that is terminated but has not been displayedyet (the HACCP menu has not been accessed after the alarm has finished).In all other cases the (L1) led is off.6.1.11 <strong>User</strong> diagnosticsDuring standard operation, with the keyboard unlocked, press the P3 key ("Diagnostics")to access the related menu.The display still shows the room temperature. On DISPLAY 2 a summary of the refrigeratoroperation appears. Press the P3 key to exit or wait for a few seconds.6.1.12 HACCP historyIn standard operation mode, press the P4 key ("HACCP") to access the alarm historymenu (the last 10 alarms are in the memory). Note that this menu only stores high/lowtemperature alarms and blackout alarms, if these generate an HACCP alarm.The first alarm being viewed is the most recent one. Press the P7 and P8 (UP and DOWN)keys to view the data related to other alarms (if present).Press the P4 key to exit or wait for a few seconds.If no alarm is present in the history menu, “noA” will blink for 3 seconds on DISPLAY1, while "No alarms" appears on DISPLAY 2, to indicate that the history menu is empty;then the appliance returns to standard operation.6.1.13 Changing the relative humidity within a program [TN,TNV]With the keyboard unlocked, press the P5 key to change the default humidity value for theprogram selected; use the P7 and P8 keys to change the values. DISPLAY 1 shows RH.The last RH% value displayed is stored.16

Adjustment instructions22.10.2004 Rev. 1.06.1.14 Changing the SET POINT within a programWith the keyboard locked, press the P6 key to change the SET for the set program. DIS-PLAY 1 shows SET, while DISPLAY 2 shows "UP and DOWN to change"; use the P7and P8 keys to change setting.6.1.15 <strong>Manual</strong> defrostingWith the keyboard locked, press the P7 key for 5 seconds to carry out manual defrosting.Before enabling the defrosting procedure, DISPLAY 2 shows a count down, followed bythe name of the program set. DISPLAY 1 shows the room temperature.6.1.16 Forcing On for three hoursWith the keyboard locked, press the P8 key for 5 seconds to force the appliance to workcontinuously for three hours; if a low temperature HACCP alarm occurs when this operationmode is enabled, the value is stored.During the continuous forcing mode, with the keyboard locked, press the P8 key for 5 secondsto return to regular operation.6.1.17 Alarm statusDuring an alarm, the buzzer emits a sound continuously for 10 seconds every 5 minutes;the (L1) LED “alarm in progress” is on. The temperature viewed on DISPLAY 1 is thetemperature of the blinking room; when the alarm is generated by a faulty room probe,"Err" appears on the display. DISPLAY 2 shows a message about the kind of alarm occurred.During an alarm, press the P3 key to silence the buzzer. The DISPLAY 1 will stop blinking,while the DISPLAY 2 shows the type of alarm, if still in progress; otherwise it returnsto regular operation. After a parameter-defined time, if the alarm is still in progress it isviewed again on the display and the related buzzer sounds…. (if the alarm is caused by afaulty probe, the alarm condition is viewed on DISPLAY 2 but the buzzer will not sound).From the programming menu, you can set the buzzer so that it does not sound from 10p.m. to 6 a.m. according to the internal clock.If the alarm generates an HACCP alarm, this is stored in the HACCP history. The (L1)LED will blink until the alarm is viewed in the HACCP history.6.1.18 Current function typeDuring regular operation, a symbol indicating the type of function in progress will appearon top right of DISPLAY 2:• Standard operationsnowflake• Defrostingmelting snowflake17

Adjustment instructions22.10.2004 Rev. 1.0• Drippingdroplet• 3 hours ON functiondown arrow6.1.19 Configuration programsThe refrigerator works based on various programs. Each program has default values fortemperature and humidity (if necessary) that are suitable to preserve the different kind offood.Separate programs are available according to the different types of cabinet (low temperature,fish, regular temperature, glazed).The following table reports all the programs and the related settings:Programs Range (°C) R.H. Configuration Kind of food Modifiable1 BT -25 / -20 -Frozen foodKeyboard2 BT -21 / -15 - Low temperature, blind doors Frozen food Keyboard1 BTG -25 / -12 - Ice cream Parameter1P -5 / 0 LOWPacked fishKeyboard1P -3 / -2 HIGH Fish temperature, blind doors Fresh fish Keyboard1P 0 / +5 HIGH Shellfish Keyboard1 TN -2 / +6 HIGHMeatKeyboard2TN +4 / +8 MEDCold pork meats – dairyKeyboardStandard temperature, blind doors products3TN +6 / +10 HIGH Fruit - vegetables Keyboard4TN +8 / +12 LOW Drinks Keyboard1BTV -20 / -15 -Frozen foodKeyboardLow temperature, glass doors2BTV -18 / -12 - Frozen food KeyboardCold pork meats – dairy1TNV +2 / +8 MEDKeyboardproductsStandard temperature, glass doors2TNV +4 / +10 HIGH Fruit - vegetables Keyboard3TNV +8 / +12 LOW Drinks Keyboard6.2 Changing the light bulb [TN, BT, P]To change the light bulb perform the following steps (the voltage of the light bulb isshown on the adhesive label):• Switch off the appliance and disconnect the power cord;• Open the appliance door;• Remove the protective glass shield from the light;• Unscrew the light bulb located in the instrument panel and replace it with an identicalcomponent of the same voltage;• Refit the glass shield.18

Adjustment instructions22.10.2004 Rev. 1.06.3 Changing the neon tube [TNV, BTV]To replace the neon tube, follow the instructions below:• Switch the lamp off by using the glass ceiling bowl (position 2);• Switch the line main switch off;• Remove the shield by levering one side up;• Remove the neon tube by rotating it by 90° and pulling it downward;• Insert the new tube, identical to the one just removed, by carrying out the reverseprocedure;• Insert the shield back;• Switch the line main switch and the glass ceiling bowl switch both to the “I” position.6.4 Attaching and detaching the grille support guideCarry out the following steps to attach the grille support guides correctly:Push the guide downwards (2) and then inwards (3) in the chosen position of the rack.Pic. 6.2Perform the operation in reverse order to detach the guide.19

Troubleshooting22.10.2004 Rev. 1.07. TroubleshootingIn the event of malfunction, check the list below to see if it is possible to restore the applianceto working condition without needing to call the technical support service. Forfurther information, please contact your nearest technical support centre.TROUBLE POSSIBLE CAUSE REMEDYSENSOR(S) FAILURECOMPRESSOR WILLNOT RESTARTCOMPRESSOR SEL-DOM STOPSFROSTED COMPRES-SOR SHELLNOISY APPLIANCEOVERFLOWING OFSELF-EVAPORATINGCONDENSATE TRAYSensor disconnectedSensor damagedElectrical equipment of the compressor(relay, motor protection and condenser) isfaulty.Compressor has a winding open or shorted,or there is an earth (ground) faultRoom temperature is too highRefrigerated cabinet condenser is dirtyLow refrigerant chargeDoor gaskets do not ensure proper sealFrost build-up on the evaporatorExcess refrigerant chargeFrost build-up on the evaporatorEvaporator motor fan(s) damagedLoose screwsVibrating pipesHot or high-water content foodstuffs arebeing introduced into the appliance too oftenDoors and/or drawers are opened too oftenConnect sensor to the thermostat againCall an authorised technical support centre tohave it replacedCall an authorised technical support centre tohave the concerned component replacedCall an authorised technical support centre tohave the compressor replacedEnsure proper ventilation to the roomCheck it on a regular basis and clean it thoroughlyCall an authorised technical support centre tofind and repair any leaks and to recharge thecompressor with refrigerant.Call an authorised technical support centre toperform the necessary replacementDo not place hot or high water content foodstuffsinto the appliance and, if needed, perform a manualdefrost cycle.Call an authorised technical support centreDo not place hot or high water content foodstuffsinto the appliance and, if needed, perform a manualdefrost cycle.Call an authorised technical support centre toperform the necessary replacementCheck that all screws are tightened and tightenthem if needed.Check that they are well fixed and, if needed,space adjoining pipes out so that they do not collide.Do not introduce hot or high water content foodstuffsinto the appliance.Pay attention to the conditions of use of your appliance.20

Spare parts22.10.2004 Rev. 1.08. Spare partsRefrigeration unit.................................25Evaporator ............................................27Thermostat and Electric components.29General parts ........................................31Door .......................................................3321

Spare parts22.10.2004 Rev. 1.022

Spare parts22.10.2004 Rev. 1.08.1 Voltage codesVoltageABCDFGHIJKLMNOPRSTUVoltage code3/N/PE400/230V 50Hz250V 16A 50Hz3/N/PE380/220V 50Hz3/PE200V 50-60Hz2/PE 220240V 50Hz3/N/PE415/240V 50Hz3/PE230V 50Hz3/PE220V 60Hz3/PE380 50Hz3/PE400V 50Hz3/PE415V 50Hz3/PE440V 60Hz3/PE460V 60Hz3/PE480V 60Hz1/N/PE~220-240V 50Hz2/PE~220-230V 60Hz3/N/PE400/230V 50Hz3/PE230V 60Hz1/N/PE~100V 50-60Hz8.2 Product codesProduct code Full nameModel codesTNTNTNVTNVType codes70 7072 72140 140144 144Accessory codesRCRemote coolingWCasters23

Spare parts22.10.2004 Rev. 1.024

Spare parts22.10.2004 Rev. 1.0TN=TN, TNV=TNV70=70, 72=72, 140=140, 144=144RC=Remote cooling, W=CastersP=1/N/PE~220-240V 50HzID Code Model Type DescriptionModule:Refrigeration unit10 141555100013 TN 70,72 Compressor FR 8.5 G10 141555100017 TN 140,144 Compressor SC 12 G20 141622524093 TN 70,72 Air-cooled condenser20 141622524139 TN 140,144 Air-cooled condenser20 1648020182 TN 70,72 Motor, fan20 1648020182 TN 140,144 Motor, fan30 1495200034 Helical fan25

Spare parts22.10.2004 Rev. 1.026

Spare parts22.10.2004 Rev. 1.0TN=TN, TNV=TNV70=70, 72=72, 140=140, 144=144RC=Remote cooling, W=CastersP=1/N/PE~220-240V 50HzID Code Model Type DescriptionModule:Evaporator50 14330070134 70,72 Evaporator, complete50 14330140134 140,144 Evaporator, complete60 1495230034 Helical fan70 1648001015 Motor, fan27

Spare parts22.10.2004 Rev. 1.028

Spare parts22.10.2004 Rev. 1.0ID Code Model Type DescriptionModule:Thermostat and Electric components80 14261052 Polycarbonate- 16671299 Keyboard for card90 167211 NTC sensor90 167212 NTC sensor100 16811299 Electronic card110 168306 Transformer120 164201 Glass for light130 1610100 Wiring140 1666031 TN 70,140 Heating element, door frame 31W140 1666040 TN 72,144 Heating element, door frame 41W140 1666031 TNV 70,140 Heating element, door frame 31W- 1666321 Evaporator defrost heater 250W- 1666322 140,144 Evaporator defrost heater 300W- 165705 Bulb socket- 164603 Micro-switch- 1640403 TN Lamp 25WTN=TN, TNV=TNV70=70, 72=72, 140=140, 144=144RC=Remote cooling, W=CastersP=1/N/PE~220-240V 50HzModule:General parts190 1405020083 Condensate container200 1412081 Spring220 144530 70,72 Pileup230 144531 140,144 Pileup240 1467515 Round foot260 1412062 Hinge29

Spare parts22.10.2004 Rev. 1.030

Spare parts22.10.2004 Rev. 1.0ID CodeTN=TN, TNV=TNV70=70, 72=72, 140=140, 144=144RC=Remote cooling, W=CastersP=1/N/PE~220-240V 50HzModel Type DescriptionModule:Door270 1412083 TN280 1412084 TN290 1412086 TN Cabinet hinges housing300 14120470 TN Hinge holding bracket310 14120472 TN Hinge holding bracket320 14120473 TN Hinge holding bracket340 14416191489 TN Door gasket 619x1489330 32630470 TN Door350 32250470 TN Door with gasket350 32250471 TN Door with gasket- 1468002 TN Lock housing360 14830061 Cylinder lockTNVGlass door- 14120475 TNV Hinge holding bracket- 14120477 TNV Hinge holding bracket- 14120476 TNV Hinge holding bracket- 14120478 TNV Hinge holding bracket- 1470025 TNV Glass door, right- 1470026 TNV Glass door, left31

Spare parts22.10.2004 Rev. 1.032

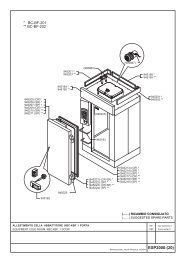

Technical specifications22.10.2004 Rev. 1.09. Technical specificationsMotorised refrigeration circuit diagramRefrigeration circuit diagram of remote-refrigerated appliancesWiring diagram TNWiring diagram TNVInstallation drawing TN, 70Installation drawing TN, 72Installation drawing TNV, 70Installation drawing TN, 140Installation drawing TN, 144Installation drawing TNV, 14033

Technical specifications22.10.2004 Rev. 1.0Motorised refrigeration circuit diagramDescription1 Compressor2 Condenser3 Filter drier dirty4 Capillary tube5 Evaporator34

Technical specifications22.10.2004 Rev. 1.0Refrigeration circuit diagram of remote-refrigerated appliancesDescription1 Compressor2 Condenser3 Filter drier dirty4 Valve5 Evaporator6 Will be borne by the installer35

Wiring diagram TN

Technical specifications22.10.2004 Rev. 1.0HL1M1M2M3RR1R2R3SQF111DescriptionCABINET LIGHTINGMOTOR COMPRESSORCONDENSER MOTOR FANCABINET MOTOR FANDEFROST HEATERCONDENSATE TRAY HEATERDOOR FRAME HEATERDRAIN HEATERDOOR SWITCHFOR 120/140 VERSION ONLYONLY ON REQUEST37

Wiring diagram TNV

Technical specifications22.10.2004 Rev. 1.0HL1M1M2M3RR1R2R3SQF111DescriptionCABINET LIGHTINGMOTOR COMPRESSORCONDENSER MOTOR FANCABINET MOTOR FANDEFROST HEATERCONDENSATE TRAY HEATERDOOR FRAME HEATERDRAIN HEATERDOOR SWITCHFOR 120/140 VERSION ONLYONLY ON REQUEST39

Technical specifications22.10.2004 Rev. 1.0Installation drawing TN, 7040

Technical specifications22.10.2004 Rev. 1.0Installation drawing TN, 7250EVAPORATOR150600706603211470EVAPORATOR1475793208041

Technical specifications22.10.2004 Rev. 1.0Installation drawing TNV, 7042

Technical specifications22.10.2004 Rev. 1.0Installation drawing TN, 14043

Technical specifications22.10.2004 Rev. 1.0Installation drawing TN, 14444

Technical specifications22.10.2004 Rev. 1.0Installation drawing TNV, 14045

Technical specifications22.10.2004 Rev. 1.0Item Model Type SpecificationNominal gross volume 70,72 630 LtNominal gross volume140,144 1405 LtTotal weight TN 70 170 KgTotal weight TN 72 170 KgTotal weight TN 140 250 KgTotal weight TN 144 250 KgTotal weight TNV 70 190 KgTotal weight TNV 140 290 KgPackage dimensions WxDxH 70,72 ~ 800x880x2250 mmPackage dimensions WxDxH140,144 ~ 1550x880x2250 mmVolume with package 70,72 1.6 m3Volume with package140,144 3.1 m3Voltage1/N/PE AC 230 V 50 HzPower of compressor TN 70,72 298 W (Cecomaf -10+55°C)Power of compressor TN 140,144 484 W (Cecomaf -10+55°C)Power of compressor TNV 70 298 W (Cecomaf -10+55°C)Power of compressor TNV 140 484 W (Cecomaf -10+55°C)Working temperature TN -2 / +8 °CWorking temperature TNV +2 / +10 °CRefrigerant feedCapillaryRefrigerant systemVentilatedType of defrost TN ElectricalType of defrost TNV ElectricalDefrosts per day / Defrost duration time (min)2 / 30 minutes + automatic + manualCurrent absorbed during operation TN 70,72 2.0 ACurrent absorbed during operation TN 140,144 3.0 ACurrent absorbed during operation TNV 70 2.3 ACurrent absorbed during operation TNV 140 3.3 ACurrent TN 70,72 2.0 ACurrent TN 140,144 3.0 ACurrent TNV 70 2.3 ACurrent TNV 140 3.3 APower absorbed during operation TN 70,72 340 WPower absorbed during operation TN 140,144 540 WPower absorbed during operation TNV 70 360 WPower absorbed during operation TNV 140 600 WPower absorbed max TN 70,72 340 WPower absorbed max TN 140,144 650 WPower absorbed max TNV 70 360 WPower absorbed max TNV 140 670 WFuse16 ARefrigerant type TN R134aRefrigerant type TNV R134aQuantity of refrigerant TN 70,72 290 grQuantity of refrigerant TN 140,144 510 gr46

Technical specifications22.10.2004 Rev. 1.0Item Model Type SpecificationQuantity of refrigerant TNV 70 290 grQuantity of refrigerant TNV 140 400 grHeat emitted TN 70,72 310 WHeat emitted TN 140,144 570 WHeat emitted TNV 70 310 WHeat emitted TNV 140 470 WAir capacity TN 70,72 390 m3/hAir capacity TN 140,144 290 m3/hAir capacity TNV 70 390 m3/hAir capacity TNV 140 280 m3/hTN=TN, TNV=TNV70=70, 72=72, 140=140, 144=144RC=Remote cooling, W=CastersP=1/N/PE~220-240V 50Hz47

DICHIARAZIONE DI CONFORMITA’DECLARATION OF CONFORMITYKONFORMITÄTSERKLÄRUNGDECLARACIÓN DE CONFORMIDADDECLARATION CE DE CONFORMITECostruttore / Manufacturer / Hersteller / Producteur /FabricanteMacchinario / Machine / Bezeichnung der Machine / Machine /MáquinaTipo, Modello / Type, Model / Maschinentyp / Type, Modèle /Tipo, Modeloinizio produzione / production start / debut production /producto a partir de / Produktions-Beginn<strong>Polaris</strong> SpAVia Cavalieri di Vittorio Veneto 2532030 Bribano di Sedico (BL)ARMADI FRIGORIFERI / <strong>REFRIGERATORS</strong> /KÜHLSCHRÄNKE / ARMOIRES FRIGORIFIQUES /ARMARIOS FRIGORIFICOSKSA TN 70; KSA TN 72; KSA TNV 70; KSA BT 70; KSA BT72; KSA BTV 70KSA TN 140; KSA TN 144; KSA TNV 140; KSA BT 140;KSA BT 144; KSA BTV 140KSA P 70 ; KSA P 140KSA BT 70G04Si dichiara che l’apparecchiatura di nostra produzione, specificata sopra, è progettata e costruita in conformità ai requisiti essenziali di sicurezzadettati dalla Direttiva Europea sulla Sicurezza. Vi rammentiamo che la presente dichiarazione perde validità in caso di modifichedell’apparecchiatura eseguite senza il nostro consenso.It is hereby declared that the mentioned machine manufactured by us is designed and manufactured in compliance with the essential safetyrequirements as provided under the European Directive on Safety. May we remind you that the present declaration shall be null and void shouldany modifications be carried out on the machine without our approval.Hiermit erklären wir, daß die bezeichnete Maschine bei uns hergestellt aufgrund ihren Konzipierung und Bauart sowie in der von uns in VerkehrAusfuhrung den einschlagigen grundlegenden Sicherheitsanforderungen der EG-Maschinenrichtline entspricht. Bei einer mit uns nichtabgestimmten Änderung der Maschine verliert diese Erklärung ihre Gültigkeit.Nous déclarons que la machine de notre production spécifiée a été conçue et construite de façon à répondre aux conditions essentiellesrequises en matière de sécurité dictées par la Directive Européenne sur la Sécurité. Nous vous rappelons que la présente déclaration perdra savalidité en cas de modifications apportées à la machine sans notre autorisation.El fabricante declara que la máquina de su producción especificada fue proyectada y fabricada de conformidad con los requisitos esenciales deseguridad prescritos en la Directiva europea sobre las seguridad. Se deja constancia de que la presente declaración perderá su validez en casode que se realicen modificaciones en los productos sin previa autorización del fabricante.Direttive di riferimento:Direttiva Bassa Tensione 73/23/EECDirettiva Compatibilità Elettromagnetica 89/336/EECDirettiva 93/68/EECNorme applicate in particolare: EN 60335-1:94 A16:01 EN 55014-2: 97 A1:01EN 60335-2-24: 00 EN 61000-3-2: 00 A1:01EN 55014-1: 00 A2:02 EN 61000-3-3: 95 A1:00Relevant Directives:Low Voltage Directive 73/23/EECElectromagnetic Compatibility Directive 89/336/EECDirettiva 93/68/EECSpecifically applied standards: EN 60335-1:94 A16:01 EN 55014-2: 97 A1:01EN 60335-2-24: 00 EN 61000-3-2: 00 A1:01EN 55014-1: 00 A2:02 EN 61000-3-3: 95 A1:00Einschlägige EG-Richtlinien:EG-Niederspannungsrichtline 73/23/EWGEG -Richtline Elektromagnetische Verträglickeit 89/336/EECEG Richtlinie 93/68 CEEAngewandte Normen, insbesondere: EN 60335-1:94 A16:01 EN 55014-2: 97 A1:01EN 60335-2-24: 00 EN 61000-3-2: 00 A1:01EN 55014-1: 00 A2:02 EN 61000-3-3: 95 A1:00Directives de référence:Directive Basse Tension 73/23/CEEDirective Compatibilité Èlectromagnétique 89/336/EECDirective 93/68 CEENormes appliquées en particulier: EN 60335-1:94 A16:01 EN 55014-2: 97 A1:01EN 60335-2-24: 00 EN 61000-3-2: 00 A1:01EN 55014-1: 00 A2:02 EN 61000-3-3: 95 A1:00Identificazione del firmatario / Identification of signer / Angaben zum Unterzeichner / Identification du signataire / Identificación del firmanteL’Amministratore DelegatoPaolo CandiagoSupreme KSA.pdf