Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

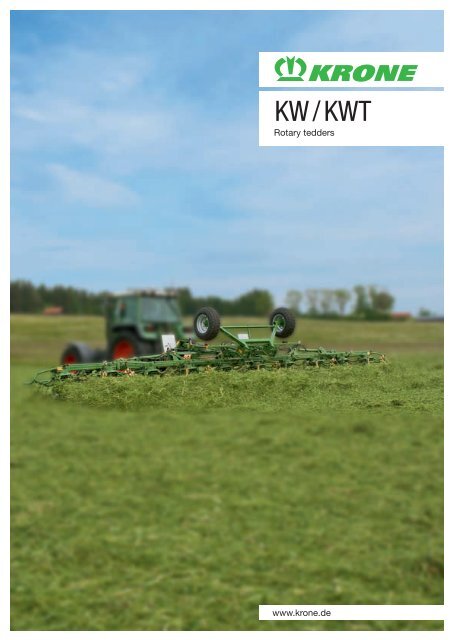

<strong>KW</strong> / <strong>KW</strong>TRotary tedderswww.krone.de

<strong>KW</strong>/<strong>KW</strong>TPowerful rotors turning cropsinto high-quality forageComplete range of mounted and trailed modelsMaintenance-free driveline with 8-finger OctoLink clutchMaintenance-free, liquid-grease lubricated gearboxesHardwearing Super-C tinesCentral border spreading controlMaximum operator comfortRobust box sections2| Rotary tedders 10/11

In-field experience by the thousandsKRONE’s extremely robust and easyto-userotary tedders have proventheir worth tens of thousands of timesaround the worldImpressive features 4Mounted rotary tedders4, 6 and 8 rotors 12Trailed rotary tedderswithout transport running gear4 and 6 rotors 16Trailed rotary tedderswith transport running gear6, 8 and 10 rotors 20Trailed rotary tedderswithout transport running gear12 and 14 rotors 24The right tedder to matchyour mower 30Technical Data 33Rotary tedders 10/11 |3

The drivelinePowerful, dependable and maintenance-freeOctoLink• Maintenance-free 8-finger clutches• Full drive power in any positionRotor gearboxes• Permanently liquid-grease lubricated bevel gears• No service, no maintenance, long service life• Absolutely leak-proofPermanently lubricated rotor gearboxesThe enclosed liquid-grease lubricated gearboxesthat drive the rotors are absolutely maintenancefree.Permanent lubrication gives peace of mind andincreases the machine’s longevity. The chunky boxsectionchassis absorbs all shock loads on the frame.Heavy-dutyMounted beneath the individual sections, the liquidgreasegearboxes drive nothing but the rotors. Thesame sections guide the rotors on the <strong>KW</strong> models,which increases the overall stability and takes the loadoff the gearbox.4| Rotary | VarioPack tedders 10/04 10/11

The dependable systemWhen it comes to preparing wilted silage and hay, KRONE is the manufacturer thatoffers a large and extensive range of high-quality and dependable rotary tedders.These machines not only deliver high-quality work and feature a high level of standardspecification but also boast a host of innovative features including maintenance-freeOctoLink finger clutches and liquid-grease lubricatedgearboxes to drive the rotors.OctoLink:OctoLink is our extremely hardwearing clutch,which forms a frictional connection at all timesand yet requires no attention at all. Some of itseight fingers are always in mesh, even whenthe rotors are folded through 180 degrees.Simple but sophisticatedThe special design of these short fingers and the waythey align ensures a consistent flow of power down thedriveshafts. There is not a single moment the power flowis cut. This type of driveline translates into maximumefficiency and longevity.OctoLink makes it compactOffering unprecedented flexibility, OctoLink allows therotors on the outer ends to fold in through 180 degrees,reducing transport height and storage space requirementon the one hand while increasing road safety onthe other.Rotary tedders 10/11 |5

The rotorsTeaming up for qualityCleanest sweeps from double tines with legs of different lengthsUniform spread as tine arms overlap generouslyHeavy-duty and hardwearing – 9.5 mm (0.4") Super C double tineswith 5 coils and tube-section tines5, 6 or 7 tine armsThe KRONE <strong>KW</strong> and <strong>KW</strong>T rotarytedders are available in various workwidths and dimensions. Yet the rotordiameters and the number of tine armsused on each rotor also vary to suit yourspecial needs and requirements. Pickthe KRONE machine that is tailored toyour conditions – small-diameter rotorswith 5 tine arms per rotor, mediumsizeddiameter rotors with 6 tine armsand large-diameter rotors with up to 7arms.5465476512312312 346| Rotary tedders 10/11

Clean forage, uniform spreadQuality requires us to start with the basics.This is how we achieve high standards. Therotors on the KRONE rotary tedders are theideal equipment to produce quality forage foron-farm use. These rotors spin for you – inhay and silage.ProfessionalThe two 9.5 mm (0.4") legs that form one pairof tines vary in length to provide the specialKRONE combing effect for optimum treatmentand cleanest forage. Five coils on each SuperC steel spring tine give flexibility and strength.Special stops on the ends of the tube-sectiontine holders ensure no tines are lost.Adjusting to needsThe hex-head bolt on a separate eccentric plateinstantly locks the double tine in one of three positionsto provide more or less vigorous action and achieveoptimum results in all conditions.Uniform distribution of the materialThe tine arms mesh as they rotate, spreading thematerial uniformly across the working width to ensurethe best possible wilt for quality forage.High performer in arduous conditionsHeavy-duty tine arms (38 mm x 4 mm (1.5" x 0.2") tubesteel) and a special ring attachment system combineto provide dependable performance in tough and permanentoperation. KRONE technology gives you truepeace of mind in the most difficult conditions.Rotary tedders 10/11 |7

All inclusiveThe meaningful systemCentral border spreading control spreads the crop awayfrom the boundary for easier harvestingThe angle of throw is adjusted without tools to adapt tovarying crops and yieldsThe rotors run on large wheels with inner tubes, which give excellentguidance for cleanest sweeps and dependable operationAnti-wrap guards ensure a smooth crop flow and trouble-free workOne movementThe manual border spreading control system is basespecification on all three-point hitch machines and onthe trailed <strong>KW</strong> 5.52/x7 T and <strong>KW</strong> 7.82/6x7 T models.Adjustment is easy and simple. One lever swings allwheels to the left or right.Hydraulic and convenientThe hydraulic border spreading system is an optionalextra on the three-point mounted machines. It is basespecification on the trailed machines with transportrunning gear – <strong>KW</strong>T 7.82/6x7 to <strong>KW</strong>T 11.22/10 models,<strong>KW</strong> 13.02/12 T and <strong>KW</strong> 15.02/14 T. The system isoperated from the cab.8| Rotary tedders 10/11

Fascinating detailsThought-through details and high operator comfort boost theefficiency of your operation. The central border spreadingfacility ensures you are not wasting a single stem along theboundaries. In addition, it allows you to spread uphill withthe machine running at an angle to the tractor. The rotor tiltis adjusted without the need of tools for perfect adaptation tothe current crop and yield. Tedding every stem, the machineprovides uniform conditioning for best quality feed.Tedding at a steep angle, turning at a shallow angleSetting the angle from 13 to 19 degrees is an easy job,which is carried out quickly on a pin-and-hole systemon the brackets that hold the wheel arms. The steepposition is preferred during tedding; the shallow positionis best for turning. Also, the angle setting system adaptsthe rotors accurately to the stubble height and yield,ensuring thorough work across the full work width.Large wheelsEach rotor runs on a large wheel. The16/6.50-8 and 18/8.50-8 balloon tyreswith inner tubes give peace of mind,protect the turf and give excellentcastering.Wrapping – no thanksAnti-wrap guards are base specificationon the KRONE rotary tedders, ensuringthe wheels and arms stay clean andunobstructed.Excellent casteringThe wheels are controlled by theb order spreading control linkage, whiche nsures positive castering. The systemalso provides for optimum performanceon the slope.Rotary tedders 10/11 |9

The headstockCompact and safeThe machine automatically moves into a central positionas it is raised, offering a convenient transport positionDamper braces with compression springs provide forexcellent trackingCompact and safe on the roadStrongThe headstock rests on a separate stand, which foldsdown to support the machine. The driveshaft is storedin a separate holder on the headstock. The stand locksin place automatically when not in use.NimbleThe pivoting headstock provides the maneuverabilityrequired to manage the tightest turns, allowing youto attend every corner, leaving nothing behind andmatching up with the previous pass without time-consumingheadland maneuvers.10| Rotary tedders 10/11

Handling excellenceA KRONE rotary tedder is robust, offeringexcellent road safety, positive castering andconvenient adjustment from the cab. Folded into321transport position, the machine offers a low center ofgravity for compact and safe travelling between fields andcompact storage.121. + 2. Dampers for an enhanced ride qualityThe internal compression spring (1) prevents underrunningwhen working downhill and the adjustable brake(2) prevents bouncing. The large machines of a 7.80 m(25'7") plus work width have additional Eladur springelements (3), which enhance rides on public roads andbumpy dirt roads.3. Automatically locked for transportAs the machine is raised into transport position, thedamper braces maintain the machine in a centralposition behind the three-point headstock.4. Thorough workThe top link pin fits in one of three holes to providethe best possible depth behind various tractors. Anelongated hole is provided for fitting a leading guidewheel.5. Hydraulic and convenientOne single-acting spool is enough to fold the mountedmachine wings. Spring-loaded hydraulic rams ensuresmooth lowering on the slope.3 4 5Rotary tedders 10/11 |11

Three-point mounted modelsWith 4 and 6 rotors<strong>KW</strong> 4.62/4, <strong>KW</strong> 5.52/4x7, <strong>KW</strong> 6.02/6, <strong>KW</strong> 6.72/6 and<strong>KW</strong> 7.82/6x7 – working at 4.60 m to 7.80 m (15'1" to 25'7") widthswith rotors in various diametersCentral border spreading facility manual or hydraulic control (option)Convenient operation via a single-acting spool12An ideal systemThe rotary tedders <strong>KW</strong> 6.02/6, 6.72/6, and 7.82/6x7 havesix rotors and work at widths of 6.00 m (19'8"), 6.70 m(22') and 7.80 m (25'7"), which is excellent specificationto ted three swaths in one operation without the tractorwheels running on the crop. Providing optimum groundadaptation, excellent handling and perfect results, thesix-rotor model has become the best-selling tedder inthe market place. The small rotors on <strong>KW</strong> 6.02/6 areexcellent in hay.| Rotary tedders 10/11

Rugged build and easy handlingFeaturing strong frames, robust gearboxes and rotors, theKRONE rotary tedders perform equally well in hay and heavycrops, having proven themselves best in silage. Pivot jointson the frame and scores of useful setting options makeKRONE rotary tedders the masters of super clean sweepsand quality forage.Compact designThe rotary tedders <strong>KW</strong> 4.62/4 and<strong>KW</strong> 5.52/4x7 benefit from a lowdeadweight, close attachment tothe tractor and standard warningpanels to ensure swift and safe roadtravel.<strong>KW</strong> 4.62/4 and 5.52/4x7Using four rotors and working at widths of4.60 m (15'1") and 5.50 m (18'1"), theselightweight machines are tailored to smallbusinesses and hill farming operations. Themachines feature central border spreadingand rotor tilt adjustment as base specification.The border spreading facilityManual border spreading control comes as seriesspecification with hydraulic control as an optional extra.Requiring only one single-acting tractor spool, thesemachines change from border spreading to folding froma directional control valve.Rotary tedders 10/11 |Built-in road stabilityAs the wings fold up, the machine’s transport widthshrinks to less than 3.00 m (9'10"), making for safeand compact travel on the road. The mounted 6-rotorversions naturally feature an automatic self-centeringsystem, which brings the machine centrally behind thetractor.13

Three-point mounted models8 rotors<strong>KW</strong> 7.92/8, <strong>KW</strong> 8.82/8 – working at widths of 7.90 - 8.80 m(25'11" - 28'11")Small diameter rotors are uniformly spaced for a uniform wiltDamper braces with Eladur spring elements enhance smooth ridesFold-in end rotors reduce transport height14Quality forage from 8 rotorsThe 8-rotor models <strong>KW</strong> 7.92/8 (7.90 m (25'11")) and<strong>KW</strong> 8.82/8 (8.80 m (28'11")) are forage specialists thathave proven themselves well in heavy crops. Each ofthe small-diameter rotors has 6 tine arms and givesextremely effective operation. Operation is very easyfrom only one single-acting spool.| Rotary tedders 10/11

Work wider and reduce costs<strong>KW</strong> 7.92/8 and <strong>KW</strong> 8.82/8 are mounted to the tractor’s three-point linkage. Dispensingwith the transport running gear, the machine is marketed at a very competitive price andstill offers a high level of base specification including central border spreading control.The tractor requires only one single-acting spool.With all rotors spaced at identical distances, themachine produces a uniform spray pattern.Clean sweeps along boundariesNobody can afford to waste their crop. <strong>KW</strong> 7.92/8 and <strong>KW</strong>8.82/8 offer manual border spreading control as standardspecification and hydraulic control as an option. All wheelsare adjusted centrally, which not only allows tedding alongboundaries but also turning the crop uphill.Safe travel on the road<strong>KW</strong> 8.82/8 folds into a compact transport unit 3.45 m(11'4") high and 2.85 m (9'4") wide, making road travel asafe and relaxed affair.And it’s quiet tooThe damping braces have extraEladur spring elements to absorbthe shock loads from road traveland enhance operator comfort.Rotary tedders 10/11 |Running on big bootsLarge 18/8.50 balloon tires rununder the rotors in the middle toprotect the sward and give stabilitywhen <strong>KW</strong>T 8.82/8 is folded up.Wide wings fold to a narrowtransport widthThe wings are operated hydraulicallyfrom a single-acting spool. Theouter rotors swing in to reduce themachine’s transport height.15

Trailed models4 and 6 rotors<strong>KW</strong> 5.52/4x7T, <strong>KW</strong> 7.82/6x7T5.50 m-7.80 m (18'1" - 25'7") work widthsMinimum input requirementNo load is taken off the tractor’s front axleEasy tractor attachment/removalHydraulic pivoting drawbar moves conveniently into transport positionThe pivoting drawbarThe models <strong>KW</strong> 5.52/4x7T and <strong>KW</strong> 7.82/6x7T featurea height-adjustable pivoting drawbar. Attachment andremoval is quick and easy – either via a swinging or rigiddrawbar.Tractor-based adjustmentsThe hydraulic drawbar provides for plenty of groundclearance under the rotors when the machine is travellingto the next site. When using the swinging drawbaror the rigid linkage drawbar, work depth is set on theturnbuckle on the hydraulic ram.16| Rotary tedders 10/11

Trailed models arelighter in weightThe trailed rotary tedders working at widthsof 5.50 m (18'1") and 7.80 m (25'7") stand outfor their low tractor input requirement. Running on the middle wheels when intransport, the machine does not mount in the tractor‘s three-point linkage – which is idealfor smaller tractors with lower front axle load and lift capacities.Central border spreading facilityThe border spreading facility ensures no crop is lostalong the field boundaries. Move this lever to the leftor right to direct the crop to that specific side. As analternative option, adjust the rotors hydraulically fromthe cab.Nice and compact<strong>KW</strong> 5.52/4x7 T and <strong>KW</strong> 7.82/6x7 T are highly compactmodels, which require little storage space. Parked onlarge balloon tires and a steplessly adjustable stand onthe drawbar, the trailed models offer unsurpassed stability.Adjustable spread angleAdjusting the angle of spread is important to adapt themachine optimally to the desired quality of the forage.The wheel arms are adjusted simply by moving an extensionlever, which is possible because <strong>KW</strong> 5.52/4x7 Tand <strong>KW</strong> 7.82/6x7 T are not lifted out.Rotary tedders 10/11 |17

18| Rotary tedders 10/11

Rotary tedders 10/11 |19

Models with transportrunning gear6 to 10 rotors<strong>KW</strong>T 7.82/6x7 / <strong>KW</strong>T 8.8278 / <strong>KW</strong>T 11.22/107.80 m -11.00 m (25'7"- 36'1")work widthsSequence control for maximum operator comfort40 km/h (25 mph), wide transport running gear, large wheelsSwinging transport running gear, excellent distribution ofweight with no effect on the spread patternBest distribution of loadsOn the headland, the running gear swings up and overthe rotors, distributing the overall machine weight andhence ensuring a perfect and uniform spread across thefull work width. There is nothing in the way.Large wheelsLarge 10.0/75 – 15.3 tires on the transport runninggear give quiet running and stability in rough and bogieterrain as well as when travelling at speed to the nextsite.20| Rotary tedders 10/11

Easy moverWorking at wide widths and behind small tractors, themodels <strong>KW</strong>T 7.82/6 x 7, <strong>KW</strong>T 8.82/8 and <strong>KW</strong>T 11.22/10with transport running gear are the ideal machines tooperate behind low-horsepower tractors with smalllift capacities. Working at widths ofup to 11.00 m (36'1"), thesetedders are yet further evidencethat KRONE delivers the goods tomodern farming.Dual powerThe <strong>KW</strong>T 7.82/6x7 and <strong>KW</strong>T 8.82/8 running gear liftsand lowers via single-acting and accumulated rams.The <strong>KW</strong>T 11.22/10 model features a double-acting ram.Gentle on the turfRunning on 18/8.50 tires, the wheels under the centralrotors are larger in size to carry the transport runninggear in the field. The wider tires protect the ground andgive quiet running.Easy rideThe toothed wheels support the hydraulic rams andincrease the transport running gear’s forward swivelrange for enhanced weight distribution during headlandturns.Rotary tedders 10/11 |21

1. Robust, safe and convenientThe headstock suits two-point linkages. The driveshaftis protected from damage if the link arms lift accidentally.The foldable stand locks in place automatically.2. V-frameThe <strong>KW</strong>T with transport running gear is pulled bya sturdy V-frame. The design and the wide-angle12driveshaft on the pivoting headstock make for tightestheadland turns.3. Full adaptationThe pivoting two-point headstock floats in itsmountings to adapt to all ground contours, preventingany torsional force from developing and acting on theframe.4. Easy operationThe reversing valve on the models <strong>KW</strong>T 7.82/6x7 and<strong>KW</strong>T 8.82/8 activates the hydraulic border spreadingsystem, swinging the transport running gear up anddown and the rotors in and out.5. No need to leave the cab<strong>KW</strong>T 11.22/10 is operated via two double-actingspools on the tractor. An electric reversing valve is anoption, which allows the machine to be operated fromonly one single-acting hydraulic spool.43522| Rotary tedders 10/11

11. Leading wheelThe <strong>KW</strong>T models are available with optional wheels thatrun ahead of the unit. Trailing freely in close vicinity tothe tines and giving stepless height-adjustment, thesewheels deliver absolutely clean sweeps.22. Sequence controlConversion from transport to work position and viceversa is very convenient thanks to sequence control,which orchestrates the folding sections and the pivotingrunning gear.3. No crop is lostThe hydraulic border spreading facility adjusts toeither side and is standard specification on the <strong>KW</strong>Tmachines. This system guarantees you won’t waste anycrop along the boundaries and that you will harvest thefull yield.3Rotary tedders 10/11 |23

Trailed models12 to 14 rotors<strong>KW</strong> 13.02/12T / <strong>KW</strong> 15.02/14TWide 13.10 m-15.25 m (43'-50') working widthsUniform spread, small diameter rotorsQuiet castering with damper bracesMaintenance-free OctoLink finger clutchesMaintenance-free, liquid-grease lubricated gearboxes24High workratesWorking at a width of up to 15.25 m (50') andtedding up to 15 ha (37 acres) per hour with only onesingle tractor are indeed impressive stats. The trailed rotarytedders from KRONE are hard workers with small rotors thatdeliver high-quality work. Operation is easy and convenient, andstability is also superb. Many thought-through details were implemented inthis machine to achieve the best possible stability. For example, the locking systemthat locks the leading guard in place also secures the joints between the individualsections.| Rotary tedders 10/11

Higher efficiency from wider widthsIf you are looking to boost your efficiency and tedding operation, you cannot ignore the largeand trailed rotary tedders from KRONE with work widths of 13.10 to 15.25 metres (43' to 50').These rotary tedders are packed with cutting-edge technology and offer an extremely ruggeddesign and outstanding longevity.The two-point headstockThe two-point headstock (cat I/II)is extremely robust. The foldablestand locks in place automatically.The headstock also offers a holderto store the driveshaft.Setting the work depth from the tractorThe work depth is altered by raising/lowering the tractor’slink arms. The design gives the driveshaft plenty of groundclearance so it will not get damaged if the headstock is liftedout accidentally.Absolutely maneuverableIrrespective of the position of the headstock, the machine isable to follow all ground contours. The pivoting suspensionwith front ball sockets and idler wheel in the elongated holeensure best adaptation.Maneuverable V-frame<strong>KW</strong> 13.02/12 T and <strong>KW</strong> 15.02/14 T are pulled by a sturdyV-frame. The frame and the pivoting two-point attachmentmake for tightest headland turns.Rotary tedders 10/11 |Superior and quiet casterThe damping braces use internal compression springs andadjustable brakes to ensure the machines (which can be upto 15.25 m (50') wide) caster without swerving.25

A machine customizedto your needsFold/unfold while stationaryEasy operationCompact transport positionBuilt-in road stability40 km/h (25 mph) road travelShifting weight for quiet runningAs some wheels are raised during transport, extraweight is shifted to the four central wheels, the twoleading wheels and the two trailing wheels. The fourcentral wheels are rigid, acting like a tandem axle whenin transport. The two leading wheels and the two wheelsat the rear caster freely. This innovative configurationleads to quiet running at high speeds and provides forgreat maneuverability and very easy steering.26| Rotary tedders 10/11

StraightforwardConversion from transport to work andvice versa: The tractor stops and theoperator carries out all operations fromthe cab.121. - 3. From wide to narrowDouble acting rams fold up the twowings, then the wheels swivel hydraulicallythrough 90 degrees. That’s all.Just accelerate the tractor and travel tothe next field – at 40 km/h (25 mph) anda transport width of as little as 2.88 m(9'5").3In synchThe two wings of the tedder are driven by a centralgearbox and are operated by double-acting rams to foldup and down. The tractor is stationary during folding.Built-in stabilityThe guard frames interlock automatically when in workposition to take the load off the folding rams and therotor arm joints.45Rotary tedders 10/11 |27

Going forward and in reverseThanks to the outstanding axle concept,these rotary tedders are highly nimble andeasy to maneuver. To reverse, the freepivotingwheels simply swivel around. Thenthe rigid wheels in the center take over formachine guidance, giving a ride qualitysimilar to that of a tandem axle trailer.Quietest runningMaintenance-free permanent brakesand large 18/8.50x8 tires on the threecastering wheels – this is the level ofspecification that brings q uietnessto running, even at 40 km/hr(25 mph).The eccentric adjusterSetting the angle of throw from14° to 19° is easy and fast usingan eccentric ring on the wheelassembly.ConvenientThe reversing valve controls theborder spreading facility, theposition of the wheels and the wingsfrom the tractor seat. The tractorrequires only one double-actinghydraulic coupler.28| Rotary tedders 10/11

1. Small rotorsEach rotor has six tine arms to ensure uniform spreading. Drive powerflows smoothly through liquid-grease gearboxes and OctoLink fingerclutches.12. Perfect controlA leading, height-adjustable and castering wheel is an option to optimizeground hugging in any terrain.3. Not need to leave the cabThe models <strong>KW</strong> 13.02/12 T and <strong>KW</strong>15.02/14 T are available with anoptional electric control. Simply toggle a switch to select borderspreading or the machine folding function.24. Hydraulic border spreading systemThis is base specification on <strong>KW</strong> 13.02/12 T and <strong>KW</strong> 15.02/14 T. Thesystem allows the tedder to run at an angle behind the tractor and stillthrow the material consistently across the full work width from the bordertowards the middle of the field.34Rotary tedders 10/11 |29

The right tedder to match your mowerYou get optimum results whenone swath is agitated by tworotors and when the tractor isnot running on the swaths.Mower widths(m)4 rotors 6 rotors<strong>KW</strong> 4.62 / 4 <strong>KW</strong> 5.52 / 4 x 7<strong>KW</strong> 5.52 / 4 x 7 T<strong>KW</strong> 6.02 / 6 <strong>KW</strong> 6.72 / 61.50 1.70(4'11" 5'7")1.80 1.90(5'11" 6'3")2.00 2.25(6'7" 7'5")2.40(7'11")2.80(9'2")3.20(10'6")30| Rotary tedders 10/11

8 rotors 10 rotors 12 rotors 14 rotors<strong>KW</strong> 7.82 / 6 x 7<strong>KW</strong> 7.82 / 6 x 7 T<strong>KW</strong>T 7.82 / 6 x 7<strong>KW</strong> 7.92 / 8 <strong>KW</strong> 8.82 / 8<strong>KW</strong>T 8.82 / 8<strong>KW</strong>T 11.22 / 10 <strong>KW</strong> 13.02 / 12 T <strong>KW</strong> 15.02 / 14 TRotary tedders 10/11 |31

32| Rotary tedders 10/11

Technical DataThree-point mounted rotary tedders<strong>KW</strong> 4.62 / 4 <strong>KW</strong> 5.52 / 4 x 7 <strong>KW</strong> 6.02 / 6 <strong>KW</strong> 6.72 / 6 <strong>KW</strong> 7.82 / 6 x 7 <strong>KW</strong> 7.92 / 8 <strong>KW</strong> 8.82 / 8Work width to DIN 11220 mm 4,600 (15'1") 5,500 (18'1") 6,000 (19'8) 6,700 (22') 7,800 (25'7") 7,900 (25'11") 8,800 (28'11")AcreageApprox. ha/h(acres/hr)4.6(11.4)5.5(13.6)6(14.8)6.7(16.5)7.8(19.3)7.9(19.5)8.8(21.7)Transport width mm 2,690 (8'10") 2,980 (9'9") 2,690 (8'10") 2,850 (9'4") 2,980 (9'9") 2,980 (9'9") 2,850 (9'4")Storage height mm 2,400 (7'11") 2,680 (8'9.5") 3,120 (10'3") 3,400 (11'2") 3,580 (11'9") 3,150 (10'4") 3,450 (11'4")Min. power requirement Min. kW/hp 25/34 37/50 37/50 44/60 48/65 48/65 55/75Weight Approx. kg 570(1,256.6 lbs)680(1,499.1 lbs)750(1,653.5 lbs)860(1,896 lbs)980(2,160.5 lbs)1,090(2,403 lbs)1,180(2,601.4 lbs)No. of rotors 4 4 6 6 6 8 8No. of tine arms per rotor 6 7 5 6 7 5 6Tire size16/6.50x8–16/6.50x8–16/6.50x8–16/6.50x8–16/6.50x8–16/6.50x8–16/6.50x818/8.50x8(middle)Border spreading systemmech.(hydr. option)mech.(hydr. option)mech.(hydr. option)mech.(hydr. option)mech.(hydr. option)mech.(hydr. option)mech.(hydr. option)Attachment category Cat I/II Cat II Cat II Cat II Cat II Cat II Cat IIHydraulic couplers 1 sa 1 sa 1 sa 1 sa 1 sa 1 sa 1 saAngle of throw 13° - 19° 13° - 19° 13° - 19° 13° - 19° 13° - 19° 13° - 19° 13° - 19°Absolutely safeThe optional free-running clutch on themain driveshaft is useful on machinesup to 6.70 m (22') in width. It is operatedby a tractor with pto brake, where itoffers maximum safety when shuttingoff the machine.Rotary tedders 10/11 |A perfect systemLonger link arms are available as anoption to lift mounted equipment higher.Also, longer link arms increase thedistance between tractor and machine,so the machine runs more easily behinda tractor with large rear wheels.Lighting is saferThe three-point linkage machines areavailable with a lighting system for saferoad travel at night.33

Technical DataTrailed rotary tedders<strong>KW</strong> 5.52 / 4 x 7 T <strong>KW</strong> 7.82 / 6 x 7 T <strong>KW</strong>T 7.82 / 6 x 7Work width to DIN 11220 mm 5,500 (18'1") 7,800 (25'7") 7,800 (25'7")AcreageApprox. ha/h(acres/hr)5.5(13.6)Transport width mm 2,980 (9'9") 2,980 (9'9) 2,980 (9'9")Storage height mm 2,680 (8'9.5") 3,130 (10'3") 3,640 (11'11")Min. power requirement Min. kW/hp 18/25 37/50 37/50Weight Approx. kg 680 (1,499.1 lbs) 1.030 (2,270.7 lbs) 1.280 (2,821.9 lbs)7.8(19.3)No. of rotors 4 6 6No. of tine arms per rotor 7 7 7Tire size 18/8.50 x 8–18/8.50 x 8–7.8(19.3)16/6.50 x 818/8.50 x 8 (middle)Tire size on running gear – – 10.0/75-15.3Trailed Swinging drawbar Swinging drawbar Tractor link armsBorder spreading system mechanical mechanical hydraulicAttachment category – Cat II Cat IIHydraulic couplers 1 sa 1 sa 1 saAngle of throw 13° - 19° 13° - 19° 13° - 19°That’s possible tooSome farmers prefer making narrow swaths so that the crop absorbs less moistureduring the night and dries out faster.Narrow swathing gearboxThis optional gearbox is simply pushedon the shaft and reduces the rotorspeed to produce narrow night swaths.34| Kreiselzettwender 10/11

<strong>KW</strong>T 8.82 / 8 <strong>KW</strong>T 11.22 / 10 <strong>KW</strong> 13.02 / 12 T <strong>KW</strong> 15.02 / 14 T8,800 (28'11") 11,000 (36'1") 13,100 (43') 15,250 (50')8.8(21.7)11(27.2)2,980 (9'9") 2,980 (9'9") 2,880 (9'5") 2,880 (9'5")3,530 (11'7") 3,700 (12'2") 1,350 (4'5") 1,350 (4'5")37/50 40/55 44/60 51/701,480 (3,262.8 lbs) 1,770 (3,902.1 lbs) 1,870 (4,122.6 lbs) 2,110 (4,651.7 lbs)8 10 12 146 6 6 616/6.50 x 818/8.50 x 8 (middle)16/6.50 x 818/8.50 x 8 (middle)13(32)15(37)18/8.50 x 8 18/8.50 x 810.0/75-15.3 10.0/75-15.3 – –Tractor link arms Tractor link arms Tractor link arms Tractor link armshydraulic hydraulic hydraulic hydraulicCat I / II Cat I / II Cat I / II Cat I / II1 sa 2 da 1 da 1 da13° - 19° 13° - 19° 14° - 19° 14° - 19°Spare wheelStored on a holder supplied with thewheel, the spare is easy to remove withouttools.Anti-wrap guardsOptional plates are available for attachmentto the wheel holders that protectthe wheels from wrapping sticky forage.Genuine spare parts pay dividendsUser experience and tests conductedby agricultural magazines have shownthat manufacturer-tested quality partslast longer. Do not compromise onquality; trust in Original KRONE parts.Kreiselzettwender 10/11 |35

InternetDiscover the world at KRONE and browse through our website pagesto find facts and figures and also new developments plus a wide rangeof services. Explore our website and find out how versatile the KRONEworld is.NewsClick here to find uptothe minute information about KRONE –from new product presentations to show reviews. Here you areat the pulse of KRONE life.ServiceHere you find all the service information you require – froma point of contact at the factory to finance schemes for yourKRONE machine as well as training schemes for staff and users.ProductsFind extensive information on our full product range. This sectionholds everything you need – from video clips to manuals.Sales organisationHere you find a distributor in Japan as well as your local KRONEdealer who will be pleased to support you. This is where you findyour KRONE partner who will be pleased to assist you.JobsWould you like to join our company? KRONE is often lookingfor diligent and motivated staff to work at our farm machineryfactory as well as at our commercial trailer production plant. So,this section is always worth a visit.Media centerThe KRONE ‘database’ holds thousands of documents, pictures,test reports and much more. Here you find very detailedinformation on KRONE products that are of special interest toyou.EventsAre you in for a KRONE live experience? Check out for KRONEevents and look at a machine on show or watch it during ademonstration. After all, there is little that is more effective thana handson experience.Your KRONE dealerDownload CenterAre you looking for a KRONE calendar for your desktop or asmart picture for your presentation? Here, at the KRONEdownload center, you will find plenty of useful material for a widerange of projects.Used MachineryKRONE often has a wide range of demonstration or exhibitmachinery on offer. This is a good site to find your KRONEmachine. Then contact your local KRONE dealer to arrange thedetails of a potential purchase.Parts24 / 7... This service gives you the opportunity to find yourKRONE part at any time and without waiting. The KRONEAgroparts Portal has an article number and exact description forevery part. You can order the part instantly at your local KRONEdealer by sending an email to Agroparts.KRONE shopAre you looking for a gift or are you a collector of farm models?Then you should definitely shop around at our KRONE shop. Wetake your orders at any time of the day.Maschinenfabrik Bernard KRONE GmbHKreiselzettwender-10.11-EN-209007990Heinrich-Krone-Straße 10D-48480 SpelleTelefon: +49 (0) 5977.935-0Telefax: +49 (0) 5977.935-339info.ldm@krone.dewww.krone.de