SKIT/S-HFO UltraPur-Oily Water Separator The RWO ... - archnav.de

SKIT/S-HFO UltraPur-Oily Water Separator The RWO ... - archnav.de

SKIT/S-HFO UltraPur-Oily Water Separator The RWO ... - archnav.de

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

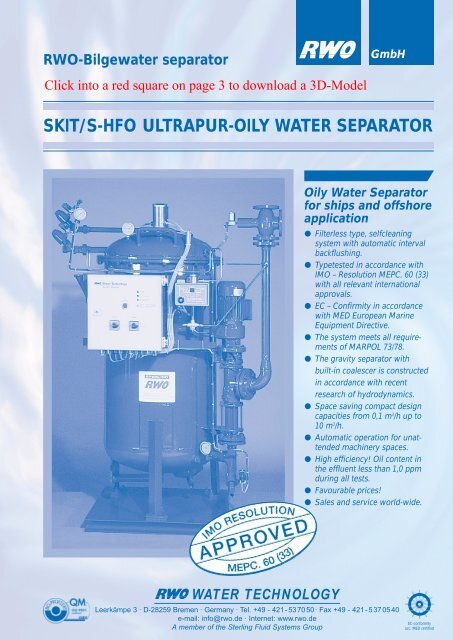

<strong>RWO</strong>-Bilgewater separatorGmbH<strong>SKIT</strong>/S-<strong>HFO</strong> ULTRAPUR-OILY WATER SEPARATOR<strong>Oily</strong> <strong>Water</strong> <strong>Separator</strong>for ships and offshoreapplication Filterless type, selfcleaningsystem with automatic intervalbackflushing. Typetested in accordance withIMO – Resolution MEPC. 60 (33)with all relevant internationalapprovals. EC – Confirmity in accordancewith MED European MarineEquipment Directive. <strong>The</strong> system meets all requirementsof MARPOL 73/78. <strong>The</strong> gravity separator withbuilt-in coalescer is constructedin accordance with recentresearch of hydrodynamics. Space saving compact <strong>de</strong>signcapacities from 0,1 m 3 /h up to10 m 3 /h. Automatic operation for unatten<strong>de</strong>dmachinery spaces. High efficiency! Oil content inthe effluent less than 1,0 ppmduring all tests. Favourable prices! Sales and service world-wi<strong>de</strong>.WATER TECHNOLOGYLeerkämpe 3 · D-28259 Bremen · Germany · Tel. +49 - 421 - 53 70 50 · Fax +49 - 421 - 5 37 05 40e-mail: info@rwo.<strong>de</strong> · Internet: www.rwo.<strong>de</strong>A member of the Sterling Fluid Systems GroupEC-conformityacc. MED certified

<strong>SKIT</strong>/S-<strong>HFO</strong> <strong>UltraPur</strong>-<strong>Oily</strong> <strong>Water</strong> <strong>Separator</strong><strong>The</strong> <strong>RWO</strong>-oily water separatorsare <strong>de</strong>livered as spacesaving compact units ready forinstallation and operation.<strong>The</strong>re are no special requirementsconceming the locationof the <strong>SKIT</strong>/S in the engineroom. It has only to beconsi<strong>de</strong>red that the mohnopump(14) has a maximum suctionof 6mWC. Taking intoaccount the pressure drop inthe separator, the OWS may notbe installed more than 5mabove suction level. <strong>The</strong> recommen<strong>de</strong>ddiameter for the suctionpipe of the separator ismentioned in the technical datasheet.To protect the separator andvalves against dirt, a suitablebasket-filter (21), with a perforationof 1-2 mm has to be installedin the suction pipe.<strong>The</strong> oily water inlet is fitted witha non-retum valve (1), whichprevents the system from emptying.On the <strong>SKIT</strong>/S 0,1 – 2,5the non-return valve is installedinsi<strong>de</strong> the separatorIn case of long suction lines orlarge pipe diameters a nonreturnvalve with strainer (bottomvalve) (18), has to be installed,to prevent the suction linefrom emptying.If fuel oil of a high viscosity isused and low water temperaturesin the bilge have to beexpected, it is necessary toinstall a heating in the bilgetank.At the backwashing inlet (15) awaterpressure of 1 bar is required.Clean sea water as well aswater from the hydrophorsystemare suitable.<strong>The</strong> backwashing water outlet(5) is discharging to the bilge.<strong>The</strong> oil outlet (4) to the oilcollecting tank has to be arrangedin such a way that the oilwill be drained pressureless.<strong>The</strong> oil collecting tank has to beprovi<strong>de</strong>d with an air vent.In accordance with the requirementsof the correspondingclass the effluent outlet (13) hasto be fitted with the requiredInstallation Diagramdischarge valves such asspringloa<strong>de</strong>d discharge valveor/and SDNR-Valve (materialaccording to the particularrules). For the good function ofthe oily water separator SKlT/Saquacilan®no special valvesare required in the dischargepipe.As an option the oily waterseparator will be equipped withan oil monitor (17) and a pneumaticthree-way valve (23),mounted in the effluent outletpipe with an additional recirculation-pipeto the bilge. If thelimit of 15 ppm oil content inthe clear water outlet is excee<strong>de</strong>d,the alarm is activated andthe three-way valve automaticallyswitched over to recirculationto bilge.<strong>The</strong> mohno-pump is a positivedisplacement pump; pumpingagainst a closed valve has to beavoi<strong>de</strong>d.For the supply of the pneumaticpiston valves (4/5/15) and thepneumatic three-way valve (23)one compressed air supply onlyhas to be provi<strong>de</strong>d (6) (airpressure6-8 bar/tube 1/4" – 8 x 1mm dia).<strong>The</strong> voltage existing on boardhas to be specified. <strong>The</strong> automaticcontrolbox is provi<strong>de</strong>dwith a brass cable gland (2) forthe main power supply. All electriccomponents such as pump,el.-heating, pilotvalves and 15ppm alarm monitor are fullywired, ready for operation.According to the el.-rating ofthe pumpmotor and the el.-heatingthe wire gross section hasto be dimensioned. <strong>The</strong> powerconsumption is listed on thetechnical data sheet.After the power supply hasbeen connected the direction ofrotation of the pump has to bechecked ("clockwise" viewedfrom the drive end).During the oilseparation cyclethe system is working un<strong>de</strong>rvacuum conditions. All flangeconnections of the separatorand suction pipe have to bevacuum tight.<strong>The</strong> oily water separator maynot be installed in hazardouslocation and has to be protectedagainst frost.

Dimensioned SketchStandard Voltage:380 V/50 Hz/3 Ph220 V/50 Hz/3 Ph440 V/60 Hz/3 Ph220 V/60 Hz/3 Phother voltage on requestcompressed air supply: 6–8 barclean water supply 1 barTechnical data and dimensions aresubject to further modification.Items 17-25 are not inclu<strong>de</strong>d in thestandard scope of supply andhave to be specified separately.* not with <strong>SKIT</strong> S 0,1123456789101213141516171819202123 B232425262841Non-return valve(at Skit 0,1-2,5 the valve isinstalled insi<strong>de</strong> the vessel)Connection for power supplyAutomatic oildrain controlboxPneumatic piston valve(oil outlet) with pilotvalvePneumatic piston valve(backwashing outlet to thebilge) with pilotvalveAir inlet, size 1/4“ (8 mm dia)Air-pressure gauge (0-10 bar)Vacuum-pressure gauge(-1/+5 bar)Sensorelectro<strong>de</strong>Heating*Safety valveClean water overboarddischargeMohnopumpPneumatic pistonvalve(backwashing inlet), withpilotvalveFoundationOil monitor (15-ppm-Alarm)Suction strainer with bottomvalveSuction pipeSuction valve chestSuction strainerBack flow to bilgePneumatic three-way valve,with pilotvalve(recirculation to bilge)Springloa<strong>de</strong>d discharge valveThree-way ballvalve(Sample water inlet and cleanwater inlet for flushing)Hand hole (Skit/S2.5 ÷ 10.0)Funnel (sample water outletconnection) 1/2 inchZinc ano<strong>de</strong>Technical Data <strong>SKIT</strong>/S-aquaclean ®TypeScapacitiy(m 3 /h)A B C D E F G H I K L M N O P Q R 1(DN)0.1 0.1 770 650 770 650 60 – 100 390 295 170 280 280 – – 0 60 1950.25 0.25 880 765 880 765 70 425 150 350 400 220 300 300 360 235 0 70 3000.5 0.5 1015 905 1015 905 75 560 175 390 600 215 340 340 385 255 0 155 3501.0 1.0 1230 1115 1230 1115 80 570 225 440 700 285 415 415 440 255 0 165 4501.5 1.5 1450 1320 1450 1320 80 605 250 500 650 310 450 450 460 195 0 165 5002.5 2.5 1755 1590 1615 1480 200 770 375 415 750 295 560 560 565 450 30 220 7505.0 5.0 1970 1850 1825 1675 175 875 560 575 1050 560 770 770 760 550 30 240 105010.0 10.0 2415 2195 2230 1970 225 1090 650 675 1300 560 930 930 880 610 30 335 13004 5(R“/DN) (R“/DN)13(DN)15 Power(R“/DN) KWWeightkg15 1/2 1/2 25 1/2 0.5 7015 1/2 1/2 25 1/2 1.5 9525 3/4 1/2 25 1/2 2.5 12025 3/4 1/2 25 1/2 2.5 16532 3/4 1/2 25 1/2 3.0 23032 1 3/4 50 1/2 5.0 26550 1 3/4 50 3/4 5.5 56065 40 32 65 1 6.5 900

Description of ProcessFig. 1 <strong>Oily</strong> water separationOilFig. 2 Oil dischargeBilge<strong>The</strong> <strong>RWO</strong>-oily water separator<strong>SKIT</strong>/S is the combinationof a gravity separatorwith a built-in coalescer.<strong>The</strong> system works with a completelynew principle of hydrodynamics.Latest physicaltrends concerning oil-in-waterdispersion, homogeneousfluid mechanics and coalescenceeffects are incorporatedin the SKlT/S-system.Fig. 1<strong>Oily</strong> <strong>Water</strong> Separation<strong>The</strong> oily water is drawn fromthe bilge through the separatorby an eccentric helicalrotor pump, so that an additionalmixture of oil and water isavoi<strong>de</strong>d.Fig. 3BackwashingImmediately after dischargingthe oil the time-controlledbackwashing is started.Clean water is used for backwashing.<strong>The</strong> coalescer iscleaned from oil and dirt byperiodical backwashing. <strong>The</strong>mixture of oil sludge andwater is drained off to thebilge.<strong>The</strong> fully automatic oil discharge-and backwashingcycleis a special feature ofthe SKlT/S-oily water separator<strong>The</strong> periodic flowreverseenables continuous operationwithout clogging of the coalescerwhich cleans itself whileoperating.OilBilgeAs a result of the excellenthomogeneous fluid mechanicsin the SKlT-oily waterseparator and the differenceof <strong>de</strong>nsity between oil andwater the rough separation ofoil takes place immediately bygravityFig. 3 BackwashingFlowing through the built-inmo<strong>de</strong>m coalescer which is avery open-porous type, smallestoil droplets are separatedby the extremely oleophilicsurface. This system featuresthe outstanding efficiency ofthe SKlT/S-oily water separator.Fig. 2Oil DischargeOilBilge<strong>The</strong> separated oil flowsupwards and is collected onthe surface. A powerful electricheating supports the separation.<strong>The</strong> oil-level is <strong>de</strong>tectedby the <strong>RWO</strong>-sensor unit.<strong>RWO</strong> oil/water-separation –more than 7000 referencesworld-wi<strong>de</strong>.WATER TECHNOLOGYLeerkämpe 3 · D-28259 Bremen · Germany · Tel. +49 - 421 - 53 70 50 · Fax +49 - 421 - 5 37 05 40e-mail: info@rwo.<strong>de</strong> · Internet: www.rwo.<strong>de</strong>A member of the Sterling Fluid Systems GroupEC-conformityacc. MED certifiedDruckStudioFelsch 09/02