Operations Overview - IOI Group

Operations Overview - IOI Group

Operations Overview - IOI Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

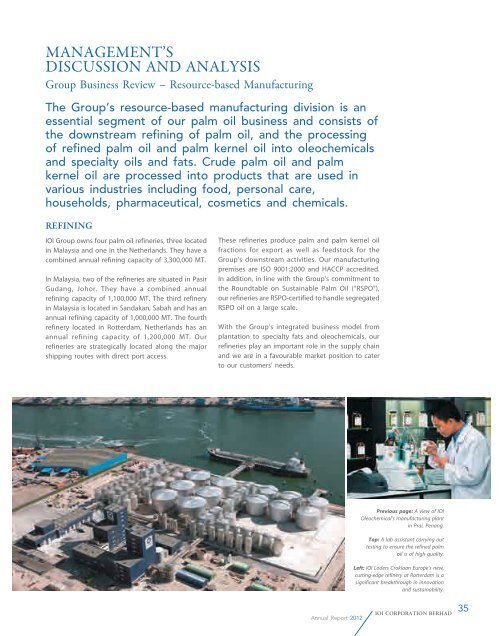

MANAGEMENT’SDISCUSSION AND ANALYSIS<strong>Group</strong> Business Review – Resource-based ManufacturingThe <strong>Group</strong>’s resource-based manufacturing division is anessential segment of our palm oil business and consists ofthe downstream refining of palm oil, and the processingof refined palm oil and palm kernel oil into oleochemicalsand specialty oils and fats. Crude palm oil and palmkernel oil are processed into products that are used invarious industries including food, personal care,households, pharmaceutical, cosmetics and chemicals.REFINING<strong>IOI</strong> <strong>Group</strong> owns four palm oil refineries, three locatedin Malaysia and one in the Netherlands. They have acombined annual refining capacity of 3,300,000 MT.In Malaysia, two of the refineries are situated in PasirGudang, Johor. They have a combined annualrefining capacity of 1,100,000 MT. The third refineryin Malaysia is located in Sandakan, Sabah and has anannual refining capacity of 1,000,000 MT. The fourthrefinery located in Rotterdam, Netherlands has anannual refining capacity of 1,200,000 MT. Ourrefineries are strategically located along the majorshipping routes with direct port access.These refineries produce palm and palm kernel oilfractions for export as well as feedstock for the<strong>Group</strong>’s downstream activities. Our manufacturingpremises are ISO 9001:2000 and HACCP accredited.In addition, in line with the <strong>Group</strong>’s commitment tothe Roundtable on Sustainable Palm Oil (“RSPO”),our refineries are RSPO-certified to handle segregatedRSPO oil on a large scale.With the <strong>Group</strong>’s integrated business model fromplantation to specialty fats and oleochemicals, ourrefineries play an important role in the supply chainand we are in a favourable market position to caterto our customers’ needs.Previous page: A view of <strong>IOI</strong>Oleochemical’s manufacturing plantin Prai, Penang.Top: A lab assistant carrying outtesting to ensure the refined palmoil is of high quality.Left: <strong>IOI</strong> Loders Croklaan Europe’s new,cutting-edge refinery at Rotterdam is asignificant breakthrough in innovationand sustainability.Annual Report 2012<strong>IOI</strong> CORPORATION BERHAD 35

OLEOCHEMICALSMANUFACTURINGThe principal activities of the oleochemical subsegmentare the manufacturing and sales of fattyacids, glycerine, soap noodles and fatty esters. Theseversatile products are used in a wide variety ofapplications, including manufacturing of detergents,surfactants, shampoo, soaps, cosmetics,pharmaceutical products, food additives and plastics.The oleochemical products are exported to morethan 60 countries worldwide mainly to Europe,Japan and China. Its customers include some of theworld’s largest multinational corporations.The oleochemicals manufacturing activities areundertaken in Penang and Johor by various whollyownedsubsidiaries of <strong>IOI</strong> Oleochemical IndustriesBerhad and the Pan-Century group of companies.With a combined total capacity of 710,000 MT, theoleochemical sub-segment is one of the leadingvegetable-based oleochemical producers in theworld. Esterchem (M) Sdn Bhd, a wholly-ownedsubsidiary of <strong>IOI</strong> Oleochemical Industries Berhad, isexpanding its fatty esters production capacity byanother 20,000 MT per annum to come on streamby mid-2013.Top: The robotic automationsystem at <strong>IOI</strong> Oleochemical,Prai, increases productionefficiency.Left: Drumming of refinedglycerine in GoodManufacturing Practice(GMP) environment.Right: Quality Control (QC)personnel taking sampleof raw materials.36<strong>IOI</strong> CORPORATION BERHADAnnual Report 2012

The successful integration of the overall supplychain and the streamlining of its product brandinghas enabled the oleochemical sub-segment to attaingreater economies of scale and to better meet andsatisfy customer needs. This is in line with the<strong>Group</strong>’s business philosophy to develop our existingcustomers into long-term business partners.Our manufacturing facilities are the recipients ofnumerous awards and recognitions at national andinternational levels and are certified and accreditedby globally recognised bodies in various areas ofquality and international standards compliance.These achievements are evidence of our relentlesscommitment to quality, environmental protection,occupational health and safety.SPECIALTY OILS AND FATSThe specialty oils and fats manufacturing business ofthe <strong>Group</strong> is carried out by <strong>IOI</strong> Loders Croklaanwhich has manufacturing operations in theNetherlands, USA, Malaysia, and Canada, and salesoffices in eight other countries with sales to morethan 85 countries worldwide. It has one of the mostdeveloped specialty oils and fats technology base inthe industry with a corporate history tracing back to1891, and is a global market leader in its field.The specialty oils and fats business of <strong>IOI</strong> LodersCroklaan consists of supplying fractionated oils,mainly coating fats (Coberine®, Couva®, CLSP®),filling fats (Creamelt®, Biscuitine®, Prestine®,Freedom®), shortenings (SansTrans®), hard stocks(Crokvitol®), and high stability oils (Durkex®), to theprocessed food industry globally, principally forconfectionery, bakery, frying and margarineapplications.Top: Crokvitol ®enzymatically producedfats enable margarineand bakery producers tomeet consumers’demands for morenatural ingredients.Bottom: <strong>IOI</strong> LodersCroklaan Americas’systematic packing andfilling line ensuresabsolute quality andefficiency.Annual Report 2012<strong>IOI</strong> CORPORATION BERHAD 37

Bottom: <strong>IOI</strong> Loders CroklaanAmericas’ 95-acre palm oilprocessing plant inChannahon, USA.Currently, <strong>IOI</strong> Loders Croklaan’s most importantmarket is Europe which is the world’s biggestconsumer of specialty fats where the majority ofsales of specialty fats are to chocolate manufacturersin the form of cocoa butter equivalents and fillingfats. The recently completed expansion of theRotterdam facility has now given the <strong>Group</strong> thecapability to supply enzymatically interesterified fatsto food manufacturers for margarines and bakeryproducts.<strong>IOI</strong> Loders Croklaan’s other markets include EasternEurope, USA, Canada, Central and Latin America, theMiddle East countries, China, Japan, Korea, India andSouth East Asia. <strong>IOI</strong> Loders Croklaan Asia provides themuch needed competitive cost base for entry intothe rapidly expanding Asian specialty fats market.As for the USA operations, the advent of the transfatty acid issue has provided an excellent opportunityfor the <strong>Group</strong>’s palm-based operations to penetratethe USA market and to introduce palm-basedsolutions into the zero trans fatty acid applicationsmarket. The facility in Channahon, Illinois hasrecently been expanded to take advantage of thisopportunity and is now the largest palm oilprocessing plant in the Western Hemisphere.<strong>IOI</strong> Loders Croklaan recently developed the CreativeStudio concept and in March 2011 it opened abranch in Pasir Gudang, Malaysia, the second branchin the <strong>Group</strong> after the Netherlands, which wasopened in June 2010. Through the Creative Studioconcept <strong>IOI</strong> Loders Croklaan establishes newpartnerships on product development with bothglobal and regional confectionery customers. A thirdCreative Studio is planned for the Channahon, USAlocation, which will complete the globalimplementation of the concept.<strong>IOI</strong> Lipid Enzymtec is the latest addition to <strong>IOI</strong> LodersCroklaan’s cutting-edge production facilities with anew plant established within the <strong>Group</strong>’s PasirGudang complex. It uses unique enzyme technology38<strong>IOI</strong> CORPORATION BERHADAnnual Report 2012

for the production of specialty fats, providingbuilding blocks for products within the different <strong>IOI</strong>Loders Croklaan production units. Enzymetechnology enables production of Betapol®, a humanmilk fat replacer for better fat and calcium absorptionin infant nutrition, a key ingredient for high qualityinfant formula. It also enables the <strong>Group</strong> to increaseits competitiveness in the strategically importantmarket for cocoa butter equivalents. The uniqueprocesses and enzymes used by <strong>IOI</strong> Lipid Enzymtecensure competitive advantage in quality and cost ofthe end products.OPERATIONS REVIEWThe resource-based manufacturing division reporteda profit of RM287.1 million for FY2012 which is 36%lower than the reported profit of RM446.0 million forFY2011. The lower profit is mainly due to fair valuedifferences on derivative contracts where a loss ofRM88.2 million was reported for FY2012 comparedto a gain of RM6.4 million for FY2011. After excludingthese fair value differences, the resource-basedmanufacturing division reported a decline of RM64.3million profit to RM375.3 million due to a weakerperformance from the specialty oils and fats subsegmentthat was offset by a better performance inthe oleochemical sub-segment. The refining subsegmentalso managed to register satisfactoryresults despite stiff competition posed by Indonesianrefiners due to their tariff differentiated export dutystructure.OUTLOOK & PROSPECTSWe expect our refinery sub-segment to facecontinued challenges due to Indonesia’s aggressiveexpansion into the downstream activities in linewith the differentiated export duty structurebetween crude palm oil and processed palm oil.Meanwhile our oleochemical sub-segment willcommission an additional fatty ester productioncapacity of 20,000 MT/year by mid-2013. Althoughcontributions from the new plant will only be seenin FY2014, we are optimistic that with the rightstrategies, the performance of the oleochemical subsegmentin FY2013 would remain satisfactory amidsta slowing global economy. As for our specialty oilsand fats sub-segment, the completion of theChannahon facility in the USA as well as thecommissioning of <strong>IOI</strong> Lipid Enzymtec will see outputfrom these two plants increase. Combined with afocus on margin growth and cost reduction in ourEuropean operations, performance by our specialtyoils and fats sub-segment should remain satisfactoryand the <strong>Group</strong> is confident of an improvingperformance in the year ahead.Top: <strong>IOI</strong> Loders CroklaanAsia’s and <strong>IOI</strong> LipidEnzymtec’s tank farm in PasirGudang, Johor have acombined storage capacity of101,561 MT.Bottom: The research anddevelopment (R&D) teamevaluating the end productto determine its quality at <strong>IOI</strong>Loders Croklaan Americas.Annual Report 2012<strong>IOI</strong> CORPORATION BERHAD 39